Automatic feeding device of high-speed precision punching machine and method of using same

An automatic feeding and precision punching technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve problems such as difficulty in improving production efficiency, too little or too much feeding, product stamping failure, etc., to reduce labor intensity, High degree of automation, the effect of meeting production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

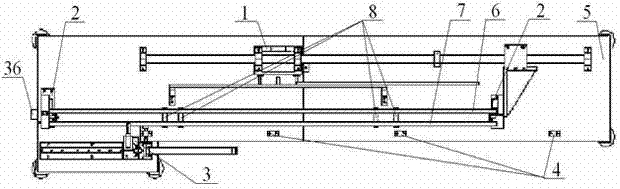

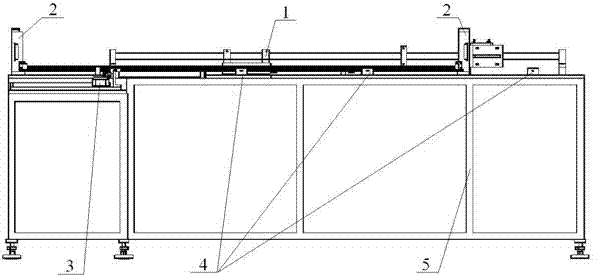

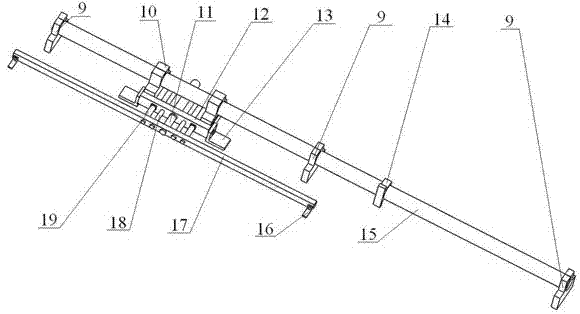

[0021] The automatic feeding device of the high-speed precision punching machine includes a pushing mechanism 1, two storage mechanisms 2, a feeding mechanism 3, a strip limit block 4, an underframe platform 5, a strip to be fed 6, a transmission strip 7, and a magnetic backing plate 8 And infrared probe 36, wherein pusher mechanism 1 comprises optical axis positioning plate 9, support plate positioning block 10, pusher cylinder rod 11, pusher support plate 12, fixed baffle plate 13, storage mechanism positioning plate 14, optical axis 15 , push block 16, push plate 17, push material limit rod 18, support rod 19; Material storage mechanism 2 comprises material storage base block 20, height adjustment support block 21, height adjustment block 22, material storage tank 23, base plate 24, Width adjustment block 25, scale 26; feeding mechanism 3 includes guide rail bottom plate 27, motion guide rail 28, first support plate 29, feeding cylinder positioning plate 30, feeding cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com