Jewellery bead making machine

A beading machine and jewelry technology, which is applied in the direction of operating devices, metal processing equipment, manufacturing tools, etc., can solve the problems of difficult to maintain uniform specifications and difficult to guarantee quality, and achieve the effects of quality assurance, production efficiency improvement, and elimination of safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

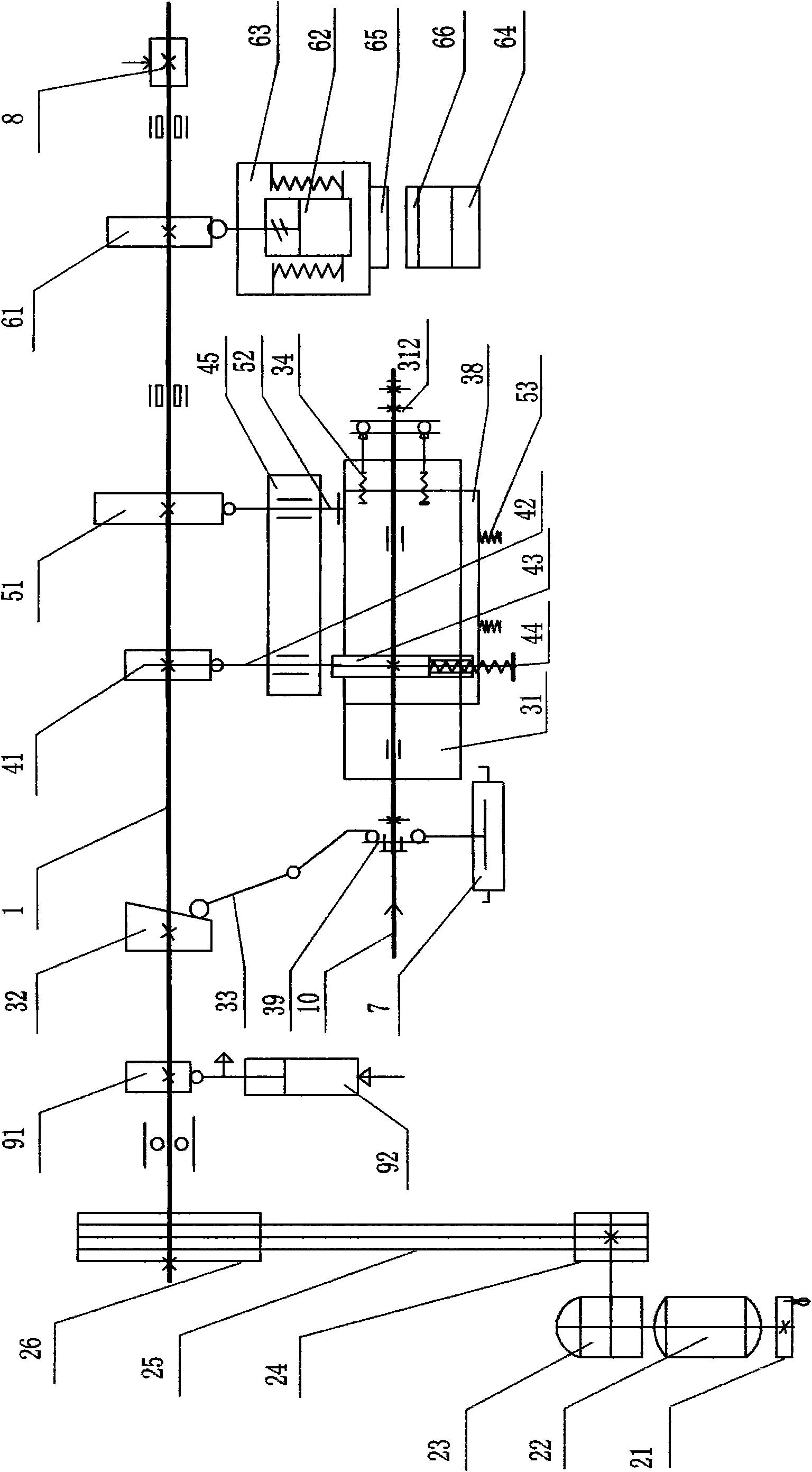

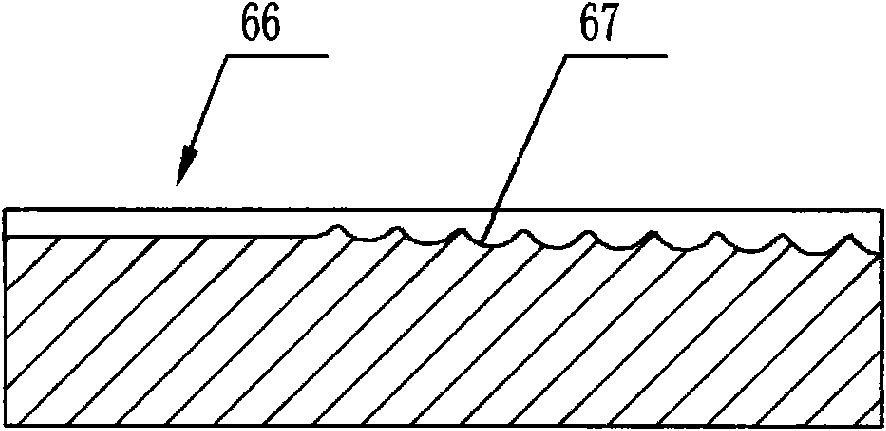

[0023] Such as figure 1 As shown, the jewelry beading machine includes a frame (not shown in the figure); a die forging device (detailed later) installed on the frame, and the die forging device is provided with a metal tube blank 10 A plurality of forging stations arranged in sequence in the direction of travel, the die forging forming device is used to gradually forge the metal tube blank 10 into a bead string or a single bead; the feeding device installed on the frame (detailed later ), the feeding device includes an auxiliary lifting device for lifting the metal tube blank 10, and an axial feeding device for transporting the lifted metal tube blank 10 down a step to the next forging station , an overturning feeding device used to make the metal tube blank 10 rotate intermittently in a forging station and form multiple forging phases.

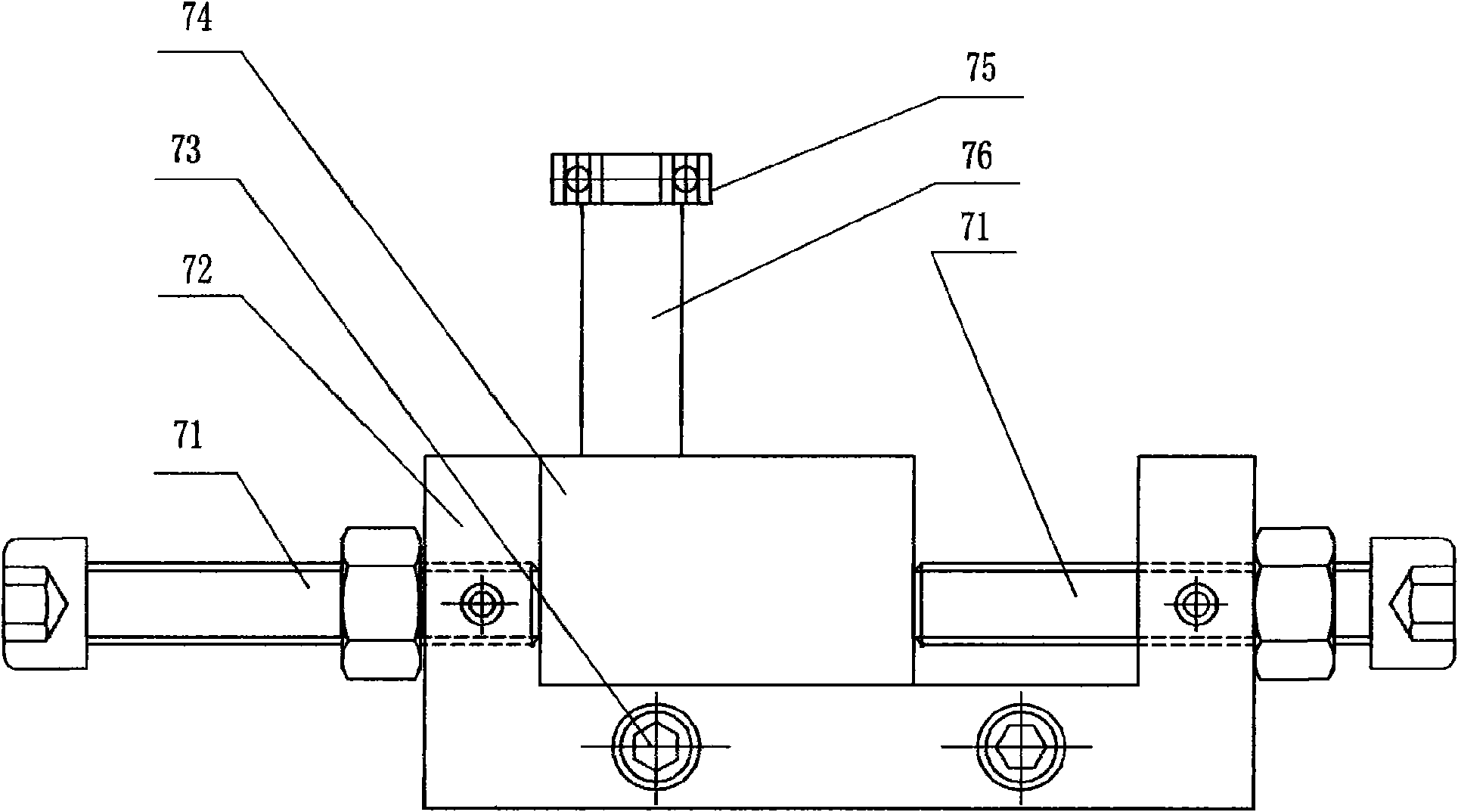

[0024] Such as figure 1 and Figure 4 Commonly shown, the axial feeding device includes a feeding body 31, the feeding body 31 is slidab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com