Limiting arm feeding device of assembly machine for main body parts of automobile door limiters

A technology of a main body and a limit arm, which is applied in the field of limit arm feeding devices, can solve the problems of inaccurate feeding position, increased production cost, and impact on product quality, etc., and achieves accurate feeding position, high work efficiency, and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

[0010] see Figure 1 to Figure 3 , the embodiment of the present invention includes:

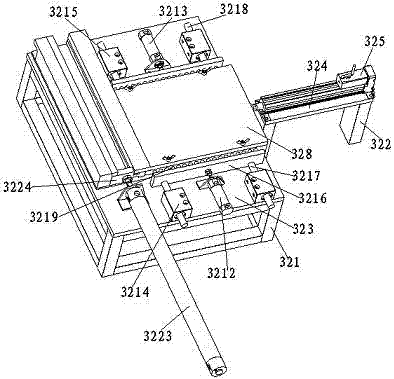

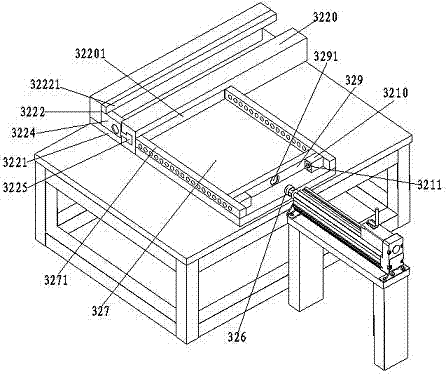

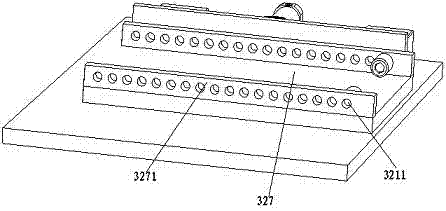

[0011] A limit arm feeding device of an assembly machine for the main part of an automobile door limiter, the limit arm feeding device of the main part assembly machine for an automobile door limiter includes an assembly frame 321 and an electric cylinder sequentially installed on the ground Bracket 322, assembly mounting plate 323 is installed on the assembly frame 321, electric cylinder mounting plate 324 is fixed on the electric cylinder support 322, electric cylinder 325 is installed on the upper end surface of electric cylinder mounting plate 324, the output end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com