Automatic feeding device of power lithium battery pole pieces

An automatic feeding and lithium battery technology, applied in the direction of transportation and packaging, conveyor objects, etc., can solve the problems that restrict the automatic production of power lithium batteries, affect the quality of lithium batteries, and have no good solutions, so as to achieve compact structure and deviation The effect of small amount and accurate feeding position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

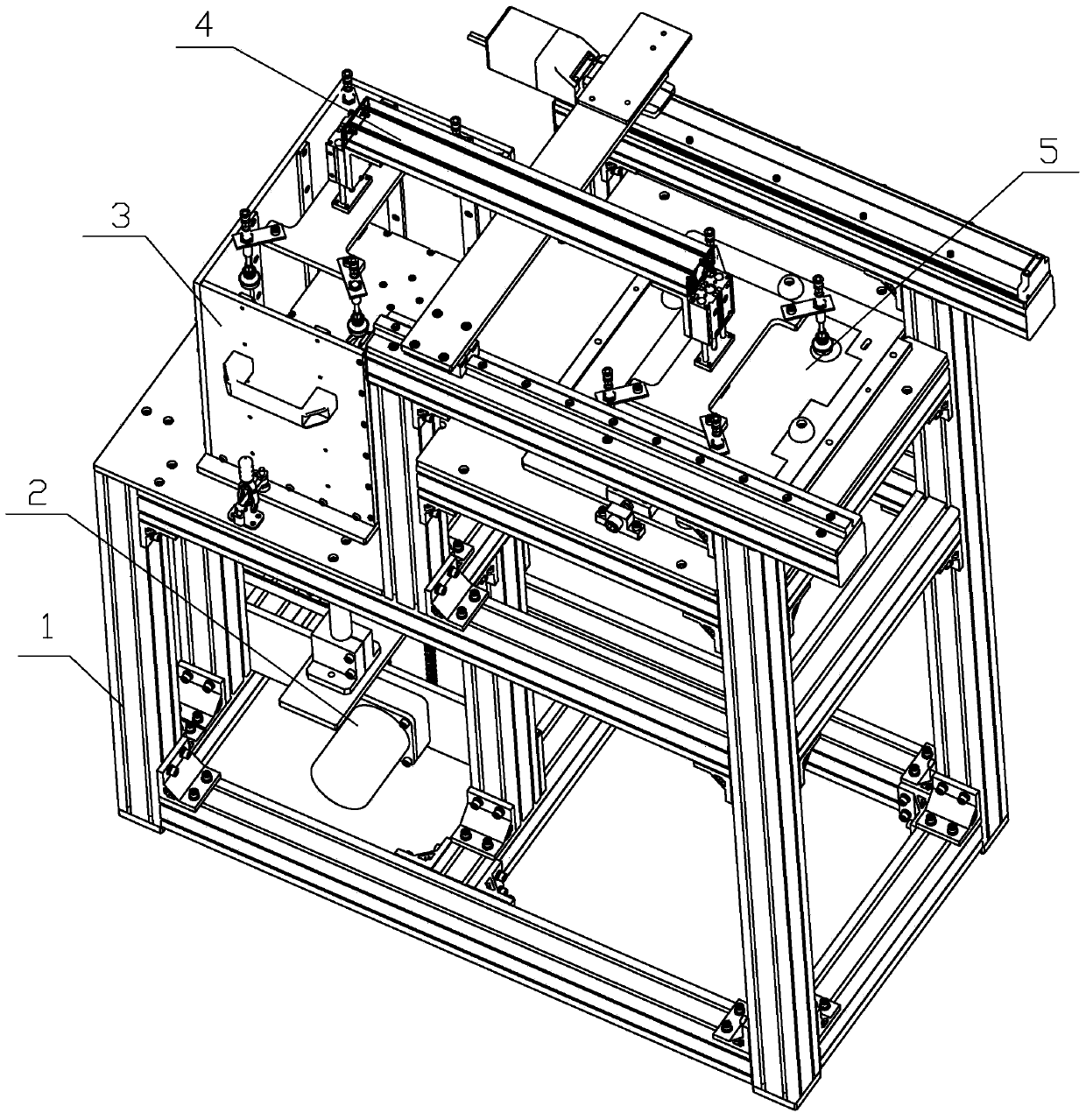

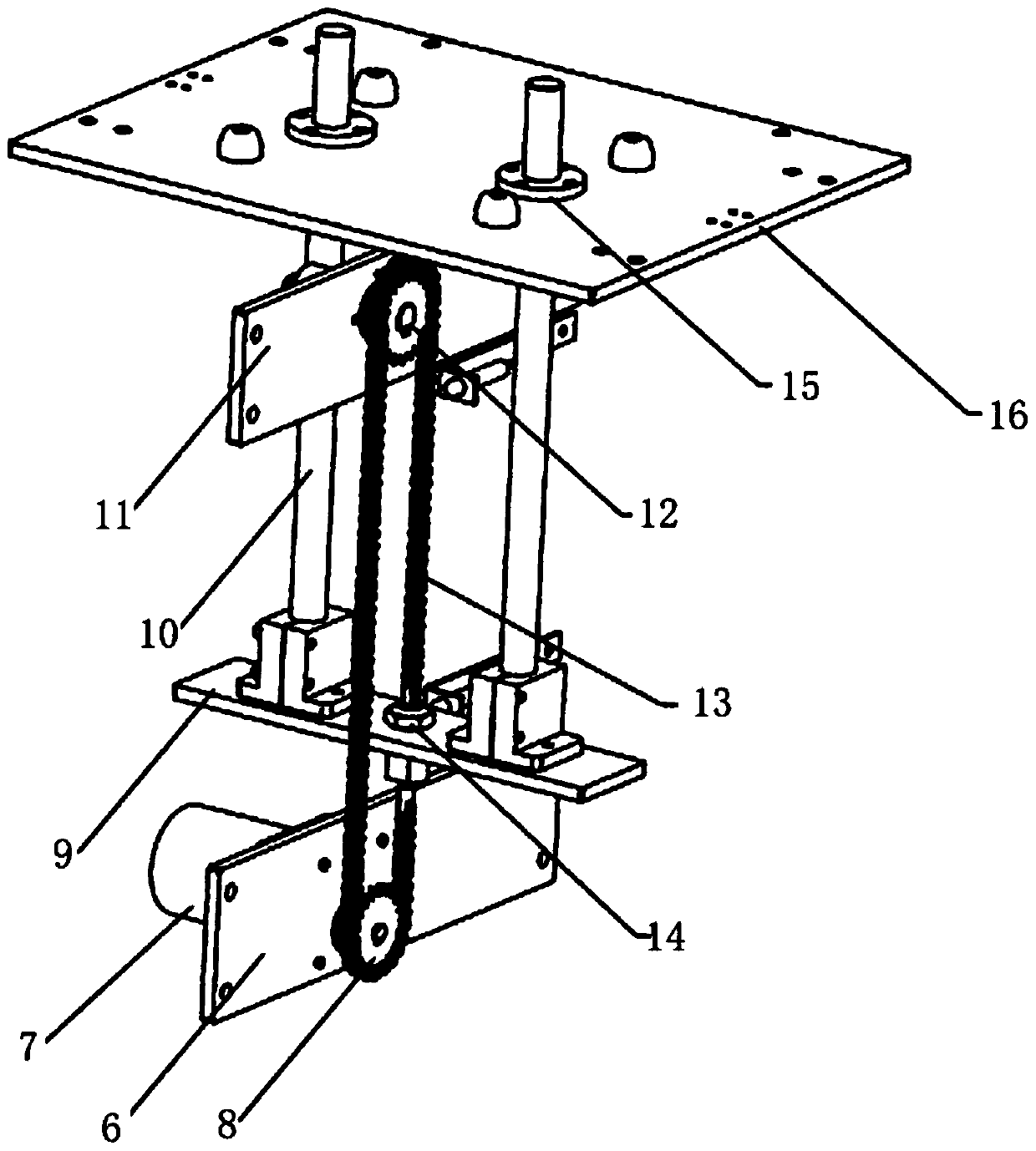

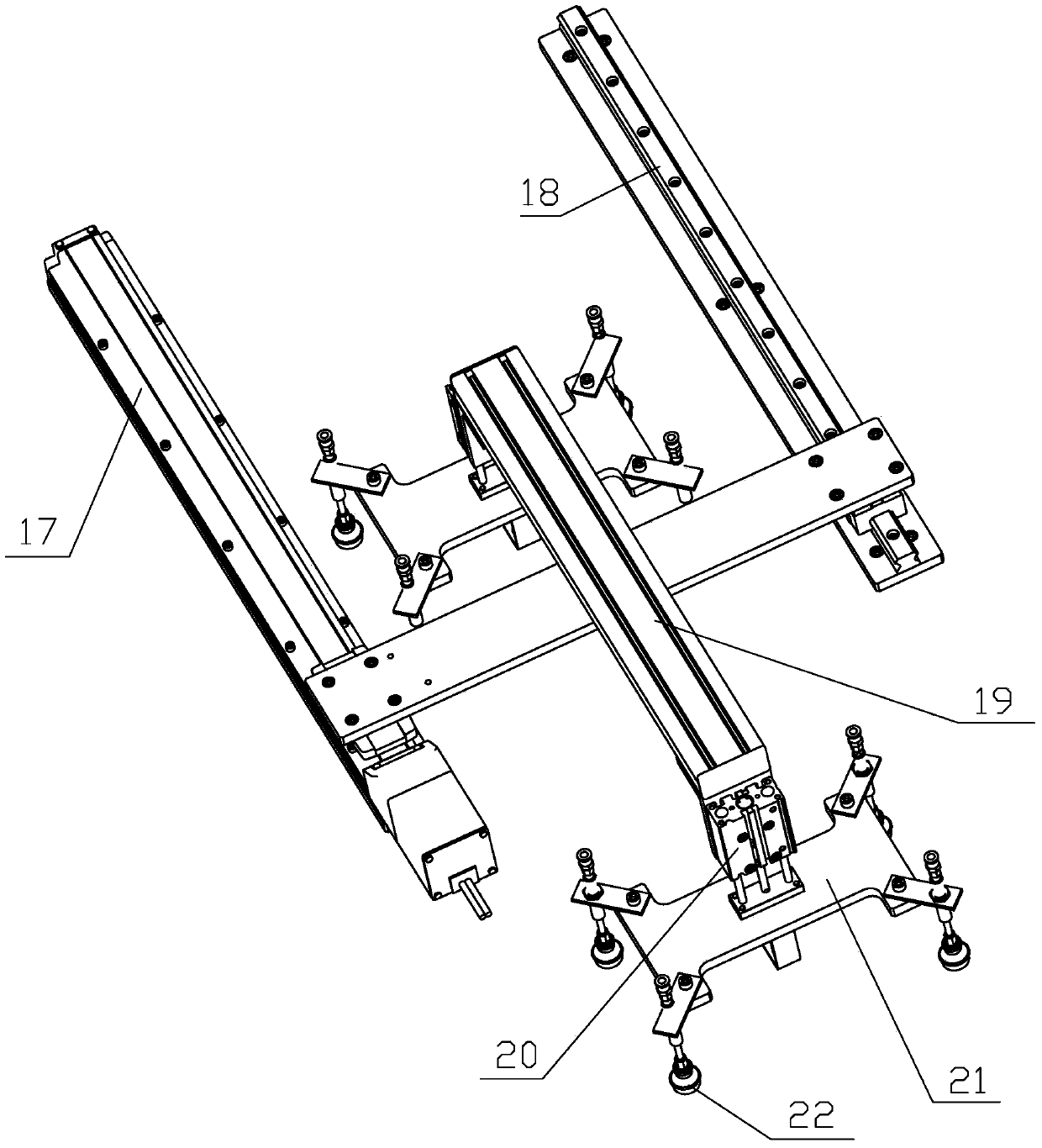

[0015] Refer to the attached figure 1 to attach Figure 4 A power lithium battery pole piece automatic feeding device of the present invention will be described in detail below.

[0016] A power lithium battery pole piece automatic feeding device of the present invention, its structure includes a profile bracket 1, a jacking mechanism 2, a pole piece material box 3, a handling manipulator 4 and a secondary positioning system 5, the jacking mechanism 2 , the pole piece material box 3, the handling manipulator 4 and the secondary positioning system 5 are respectively arranged on the profile support 1, the described jacking mechanism 2 is arranged on the bottom of the pole piece material box 3, and the described secondary positioning system 5 is set At the rear of the pole piece material box 3 , the transfer manipulator 4 is arranged on the upper part of the profile support 1 between the pole piece material box 3 and the secondary positioning system 5 .

[0017] Described jacki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com