Automatic material loading, feeding and unloading equipment for bar stock blanking and method thereof

A technology of automatic feeding and strip material, which is applied in the fields of automatic feeding, unloading equipment and feeding of strip blanking. , to improve product quality, the effect of convenient switching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. While the invention will be described in conjunction with the preferred embodiments, it will be understood that it is not intended to limit the invention to the described embodiments. On the contrary, the invention is to cover alternatives, modifications and equivalents, which may be included within the scope of the invention as defined by the appended claims.

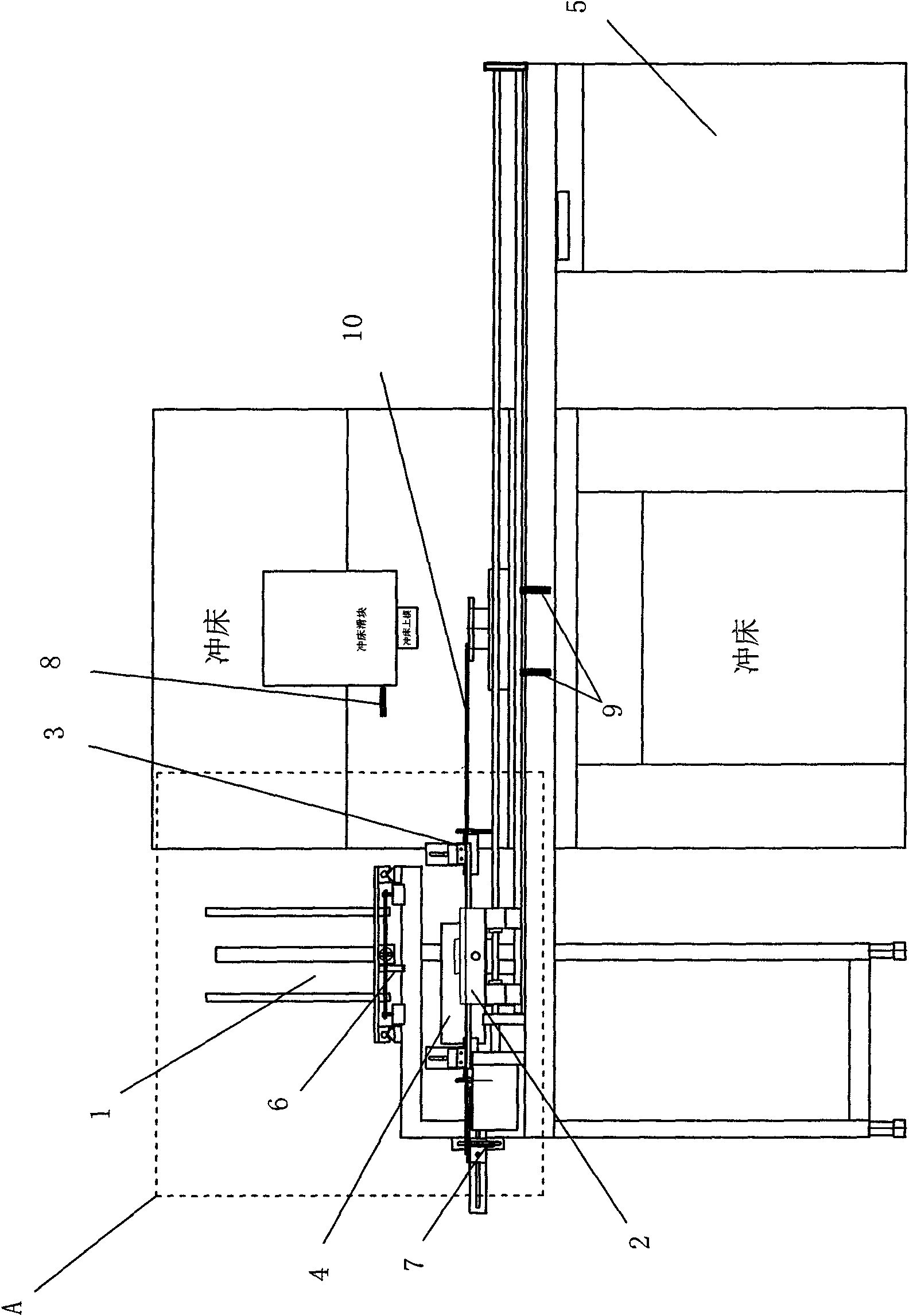

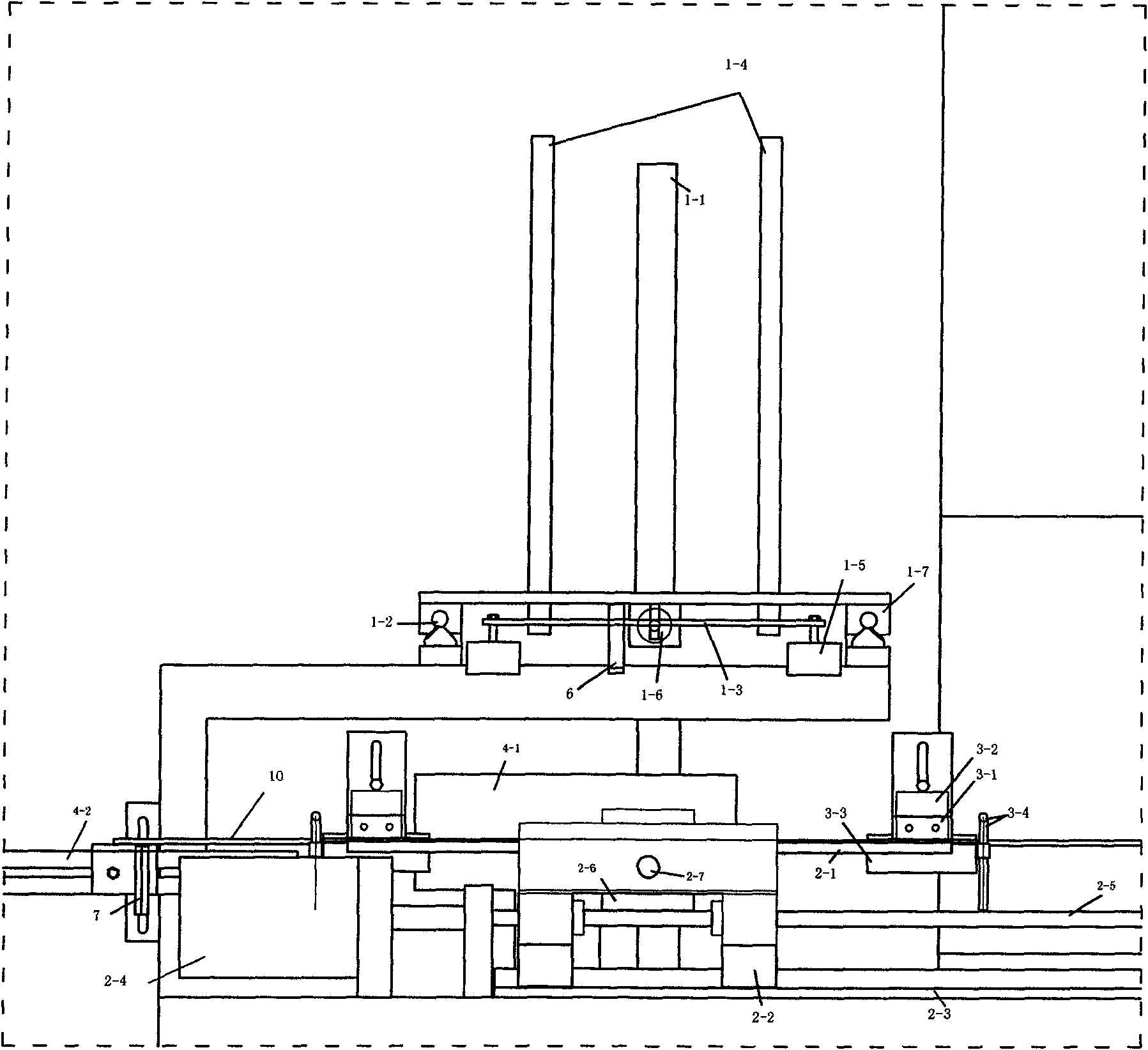

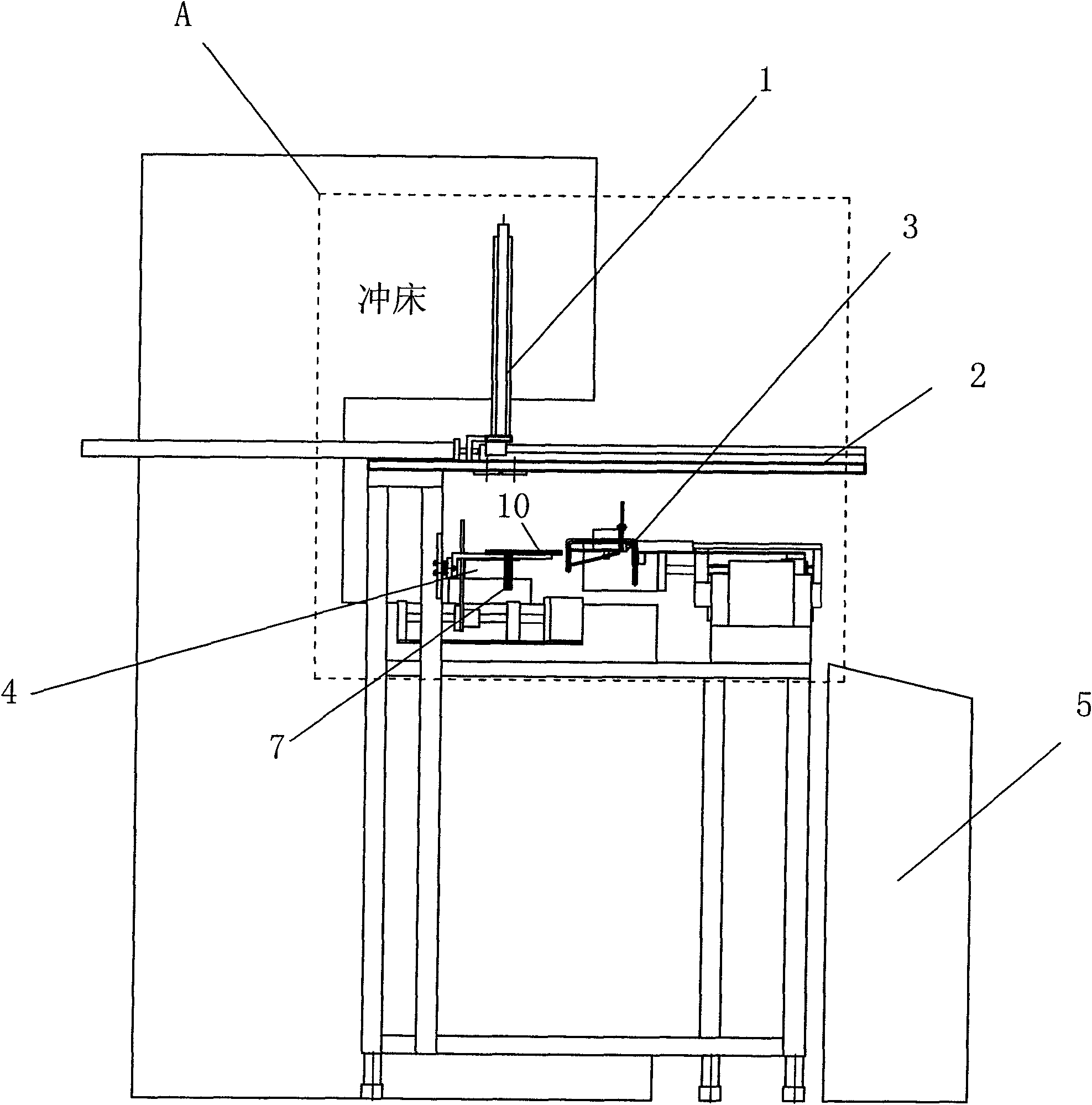

[0033] see Figure 1 to Figure 9As shown, the automatic loading, feeding and unloading equipment for strip blanking introduced here generally uses the type of punch: open punch. Feeding object, the basic range of punch strip 10 is: about 1 meter to 2 meters long, about 50cm to 400cm wide, strip sheet material in thick 20cmm. However, it should be understood that the present invention can also be used for automatic loading, feeding and unloading of other equipment.

[0034] 1. Feeding mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com