Patents

Literature

63results about How to "Avoid manual work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

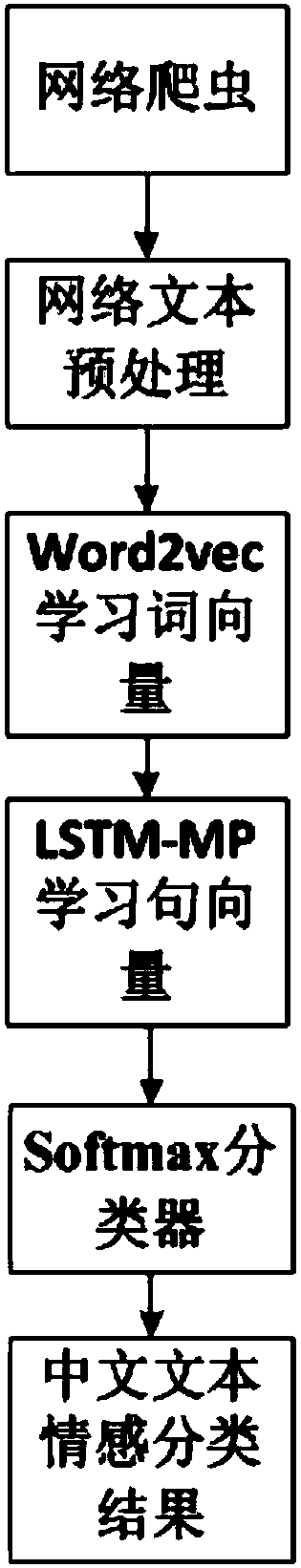

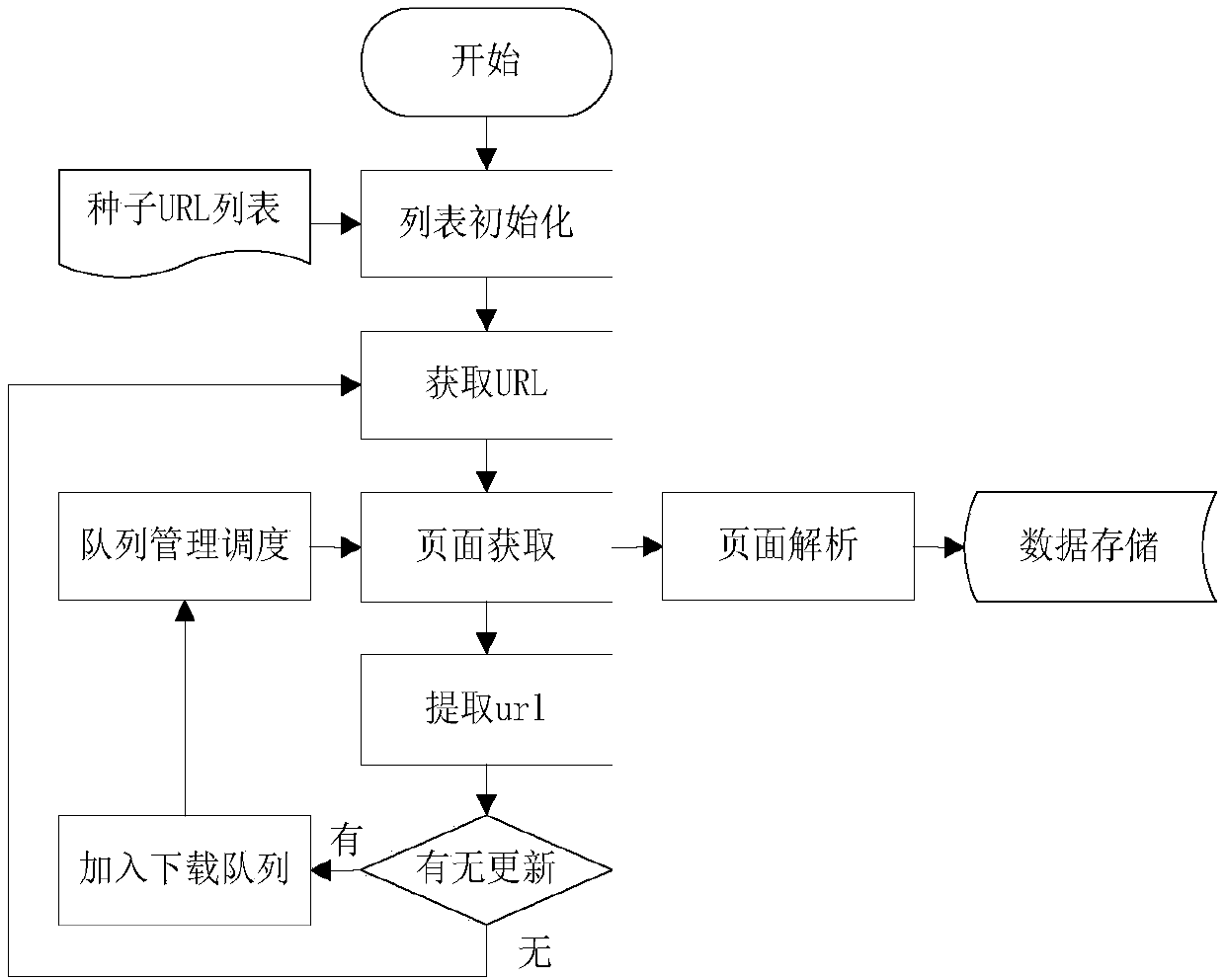

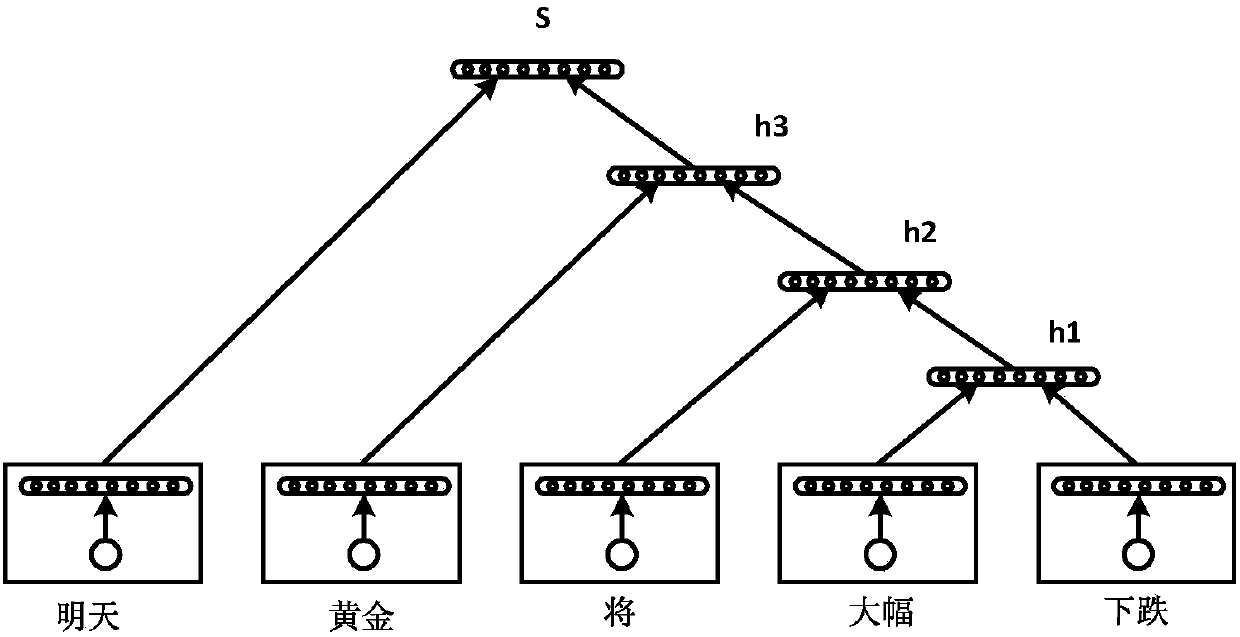

Deep-learning-based Chinese sentiment analysis method

InactiveCN107944014AImprove classification accuracyImprove efficiencyNatural language data processingSpecial data processing applicationsAlgorithmChinese word

The invention discloses a deep-learning-based Chinese sentiment analysis method, comprising: acquiring online text, reasonably designing a conversion logic of Chinese sentences to mathematical vectors, constructing a word vector dictionary via a Chinese word segmentation technique in conjunction with a word vector learning tool, using an LSTM-MP (long short-term memory) model to perform sentence vector conversion, and using a softmax classifier to perform positive and negative sentiment classification on representative sentence vectors so as to arrive at sentiment analysis. The deep-learning-based Chinese sentiment analysis method has the advantages that classification accuracy is high, classification efficiency is high, flexibility is high, mass manual operations in supervised learning methods are avoided, text sentiment orientation classification efficiency and accuracy are effectively improved, automation integrity is high, and manpower sources are greatly saved.

Owner:HOHAI UNIV

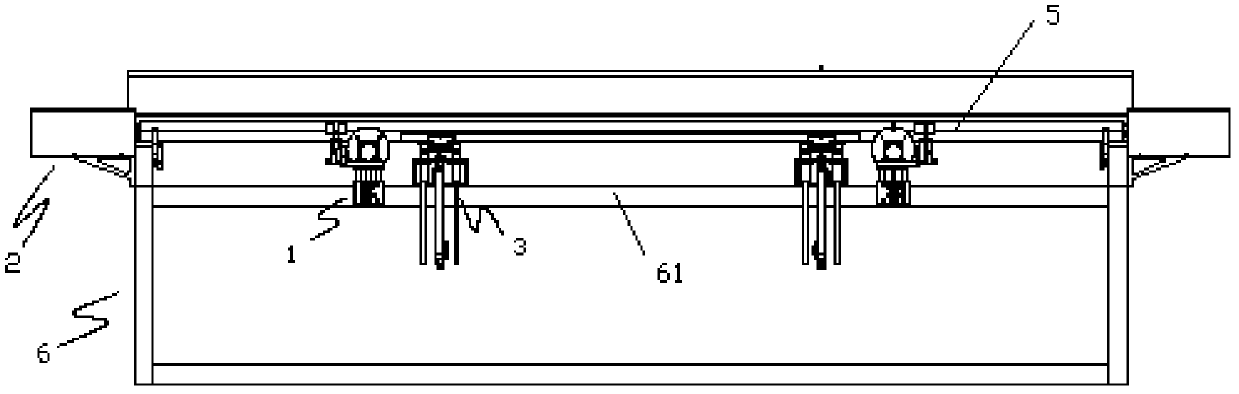

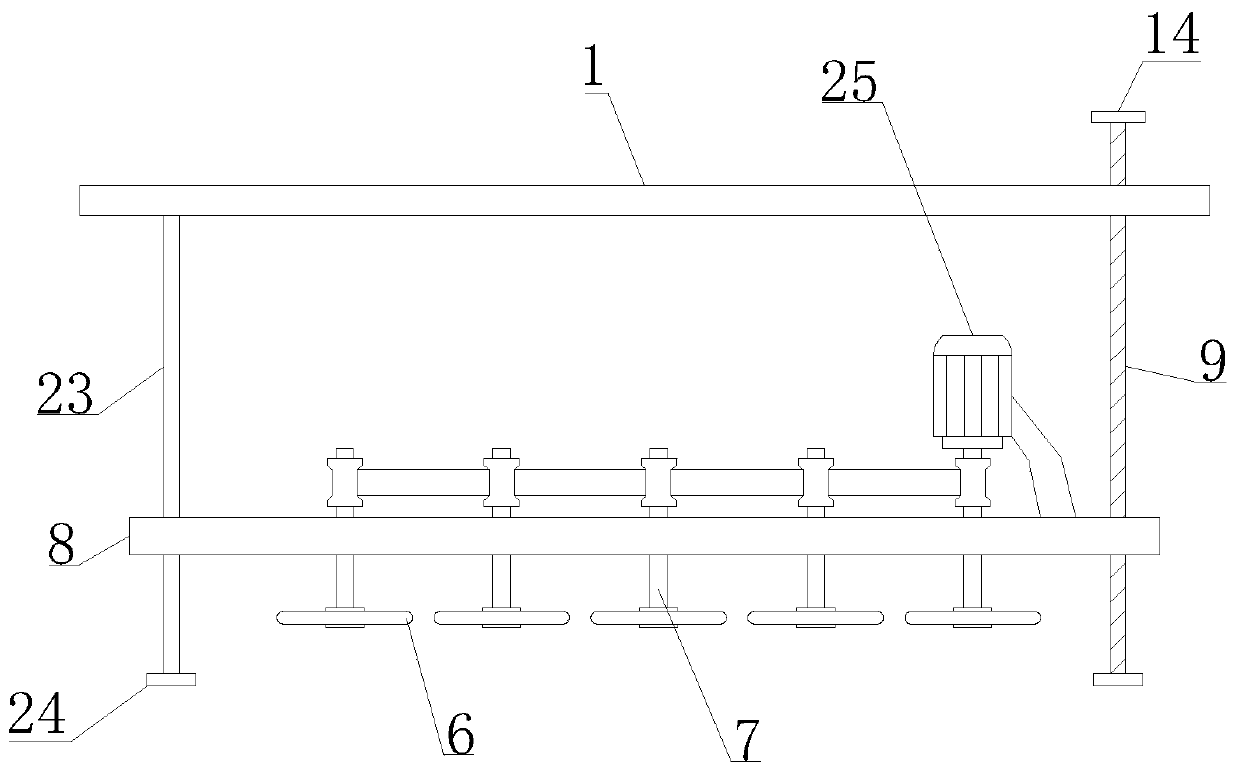

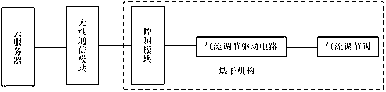

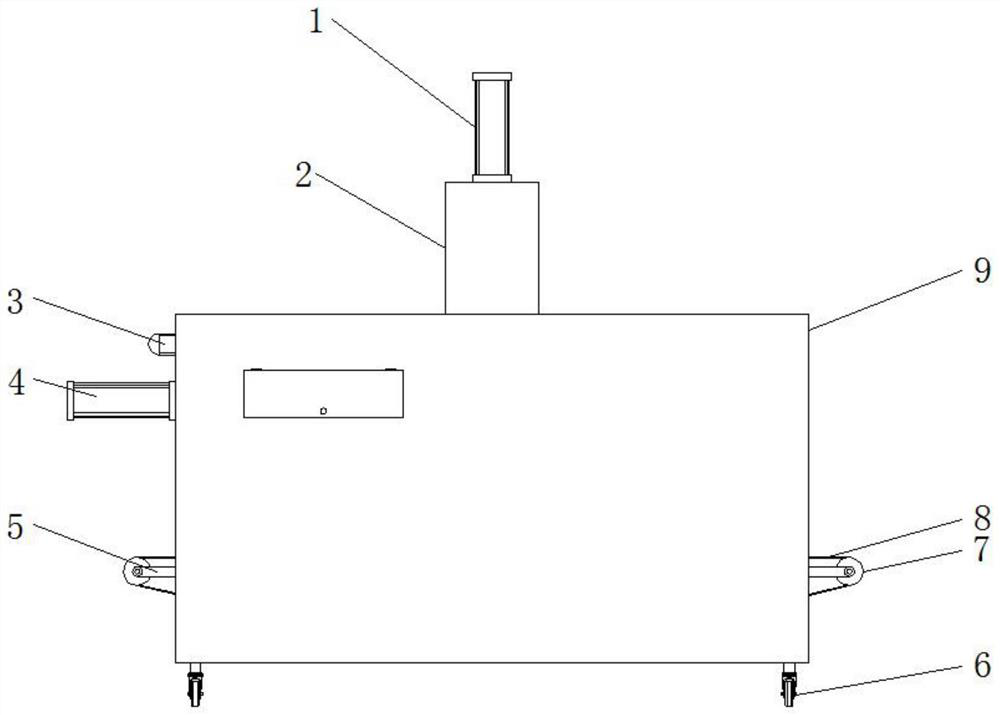

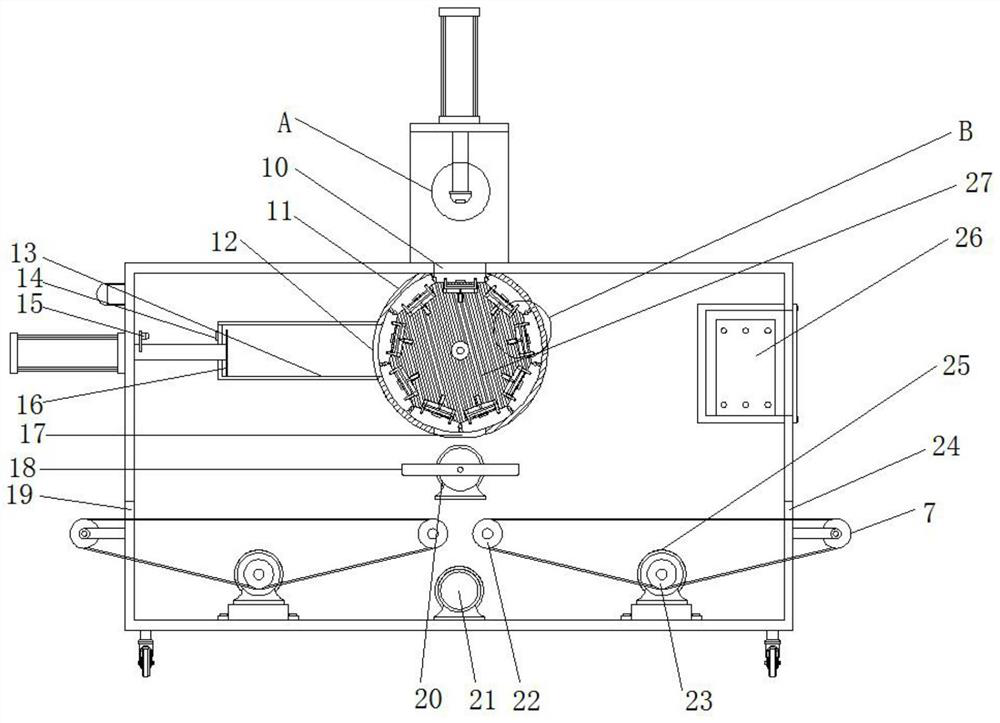

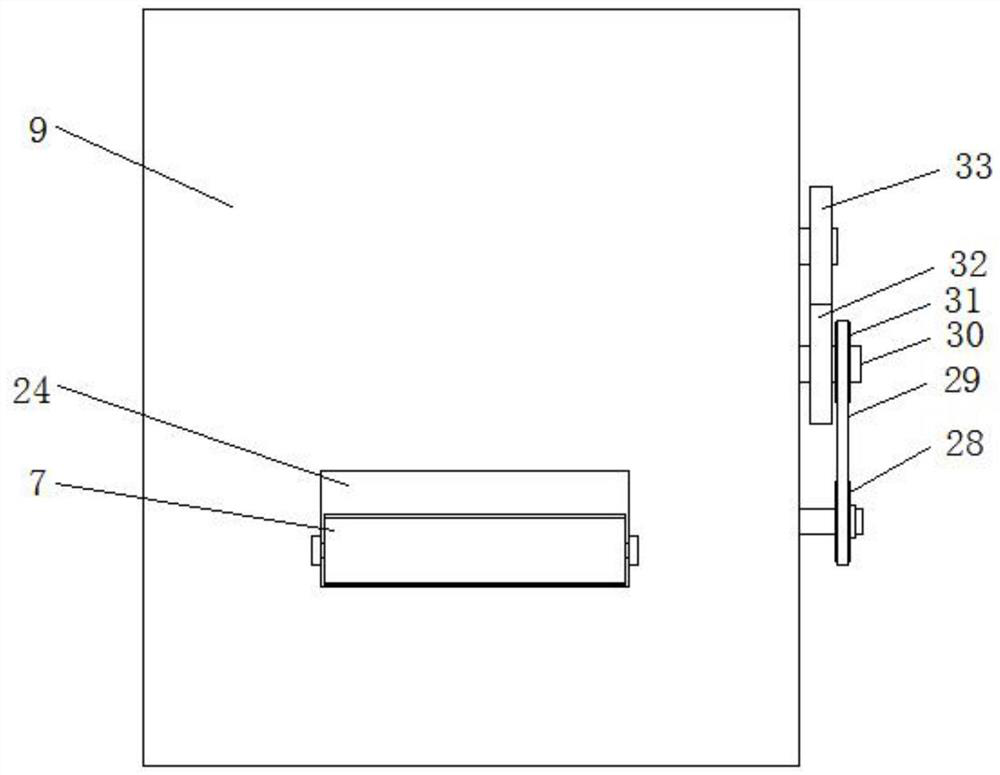

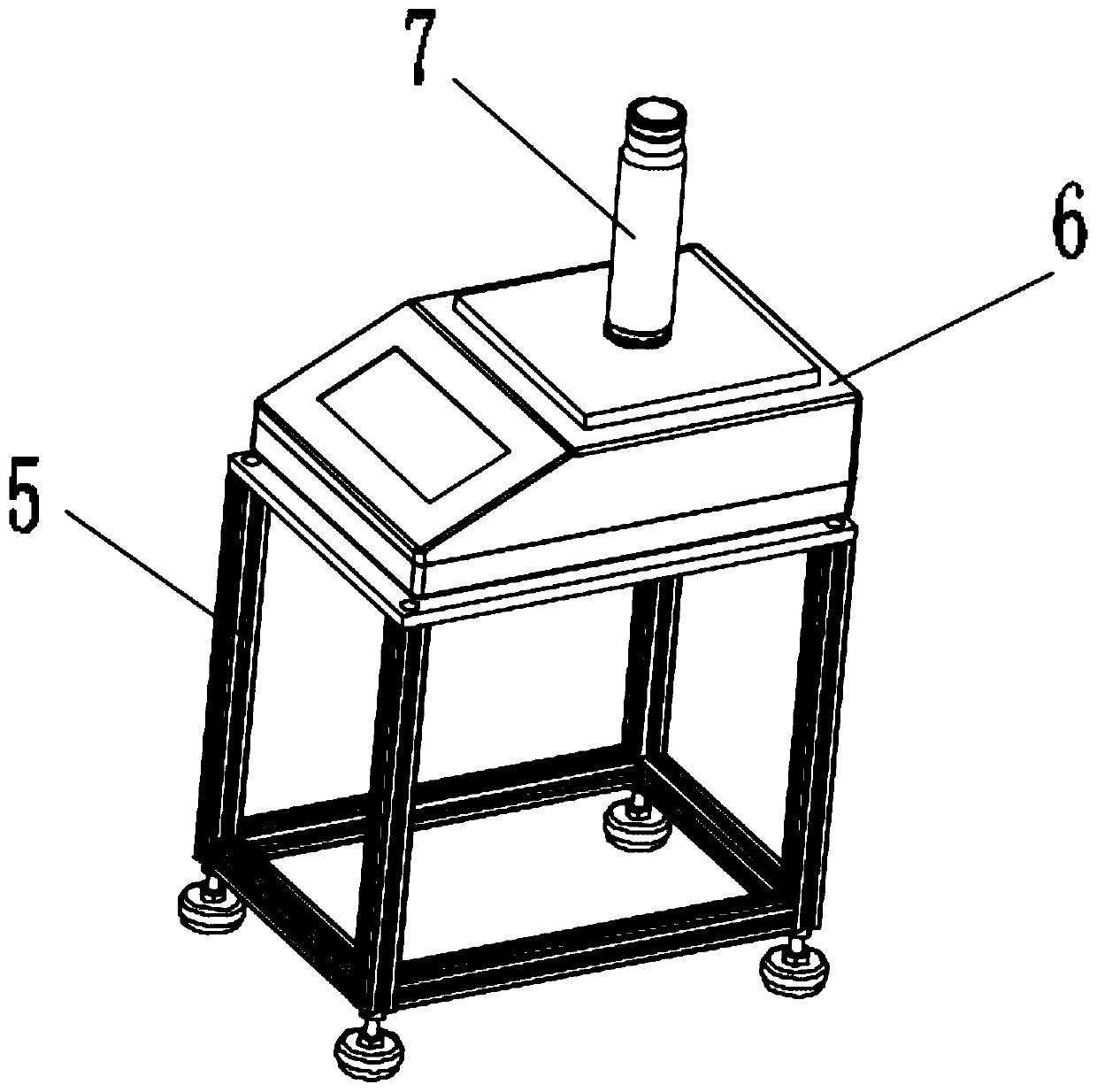

Painted-face automatic drying system

ActiveCN108405286AHigh degree of automationGuaranteed smoothAntenna supports/mountingsPretreated surfacesInformation transmissionComputer science

The invention belongs to the technical field of automation, and particularly relates to a painted-face automatic drying system. The painted-face automatic drying system comprises a cloud server, a drying mechanism and a wireless communication module used for information transmission between the cloud server and the drying mechanism. The cloud server is suitable for storing painted-face informationof a workpiece and drying parameters corresponding to the painted-face information, and sending drying instruction information to the drying mechanism through the wireless communication module so asto control the drying mechanism to dry the paint-sprayed face of the workpiece. The automatic degree of the painted-face automatic drying system is increased, and manual work is effectively avoided.

Owner:江苏睿中轨道交通装备有限公司

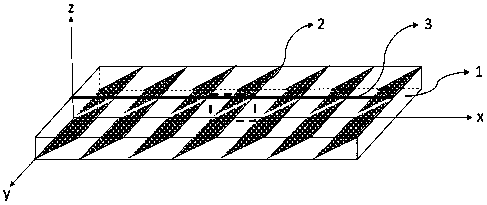

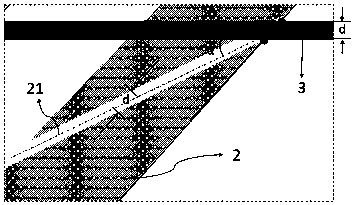

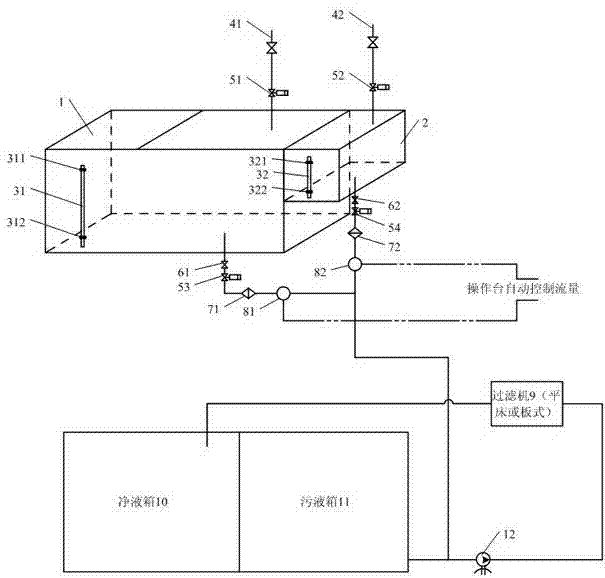

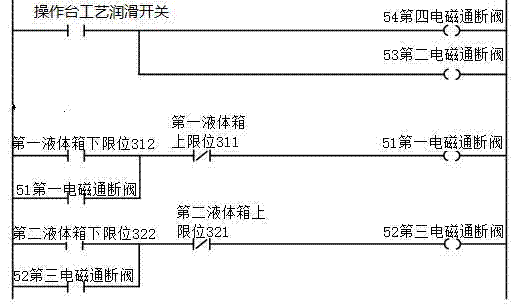

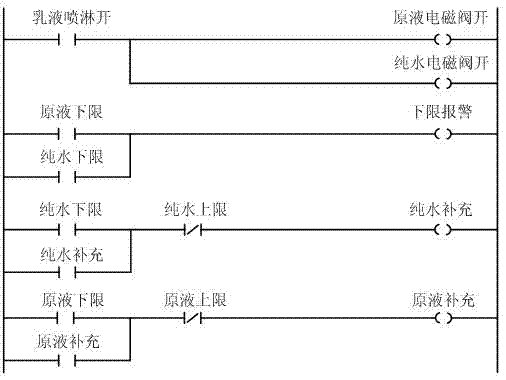

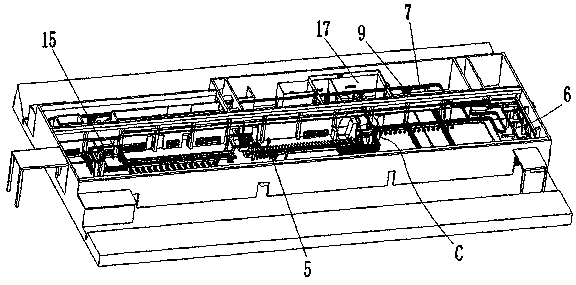

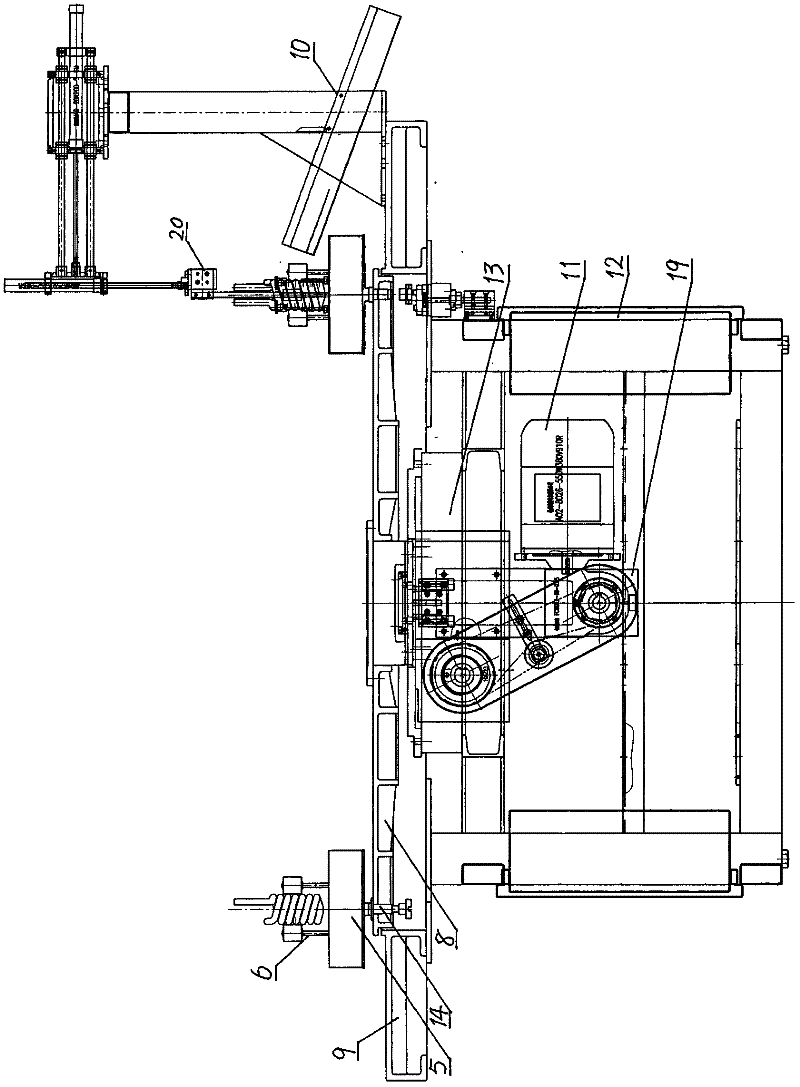

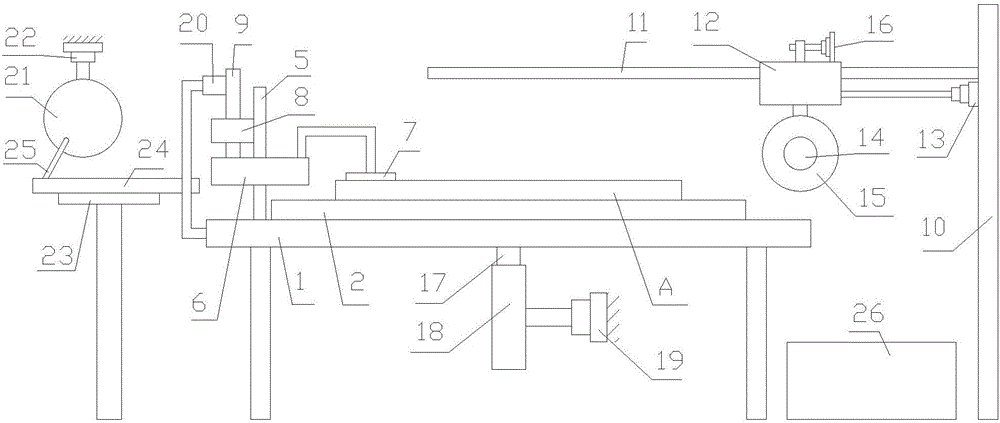

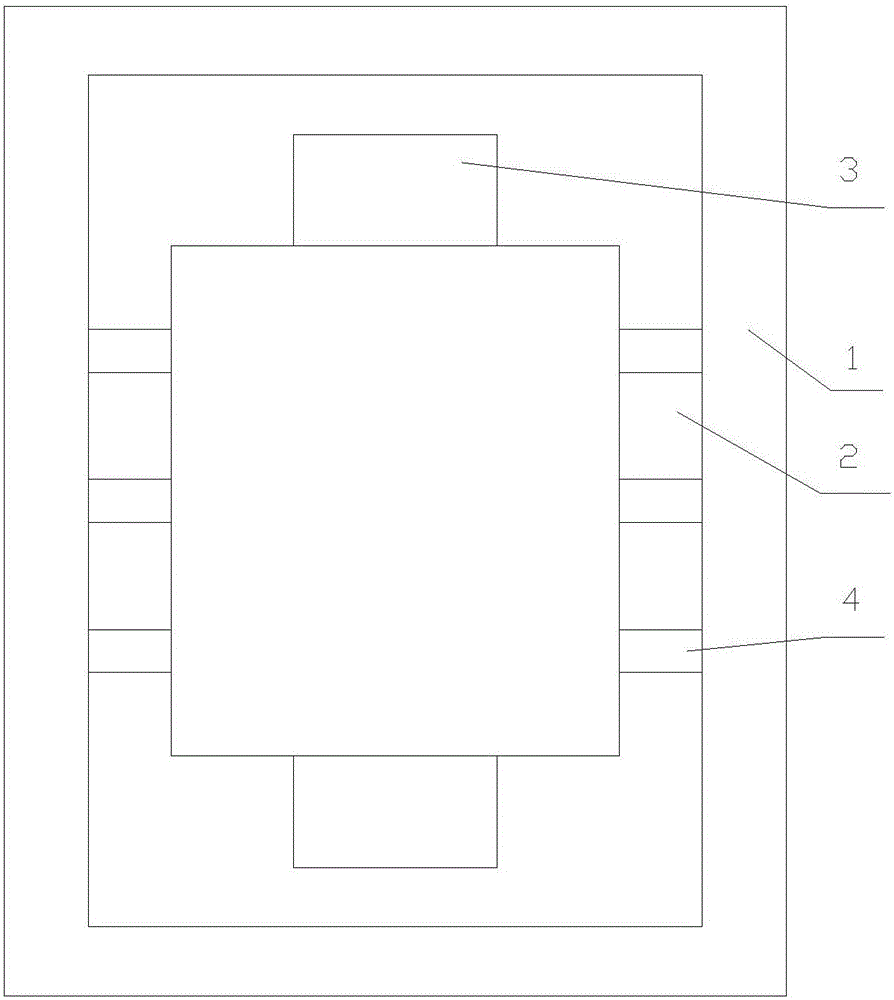

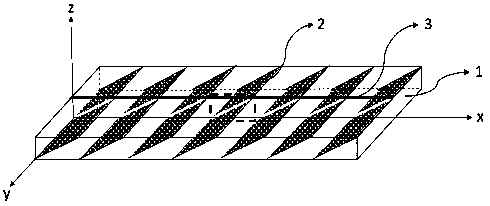

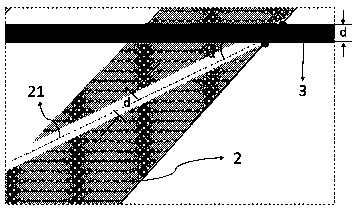

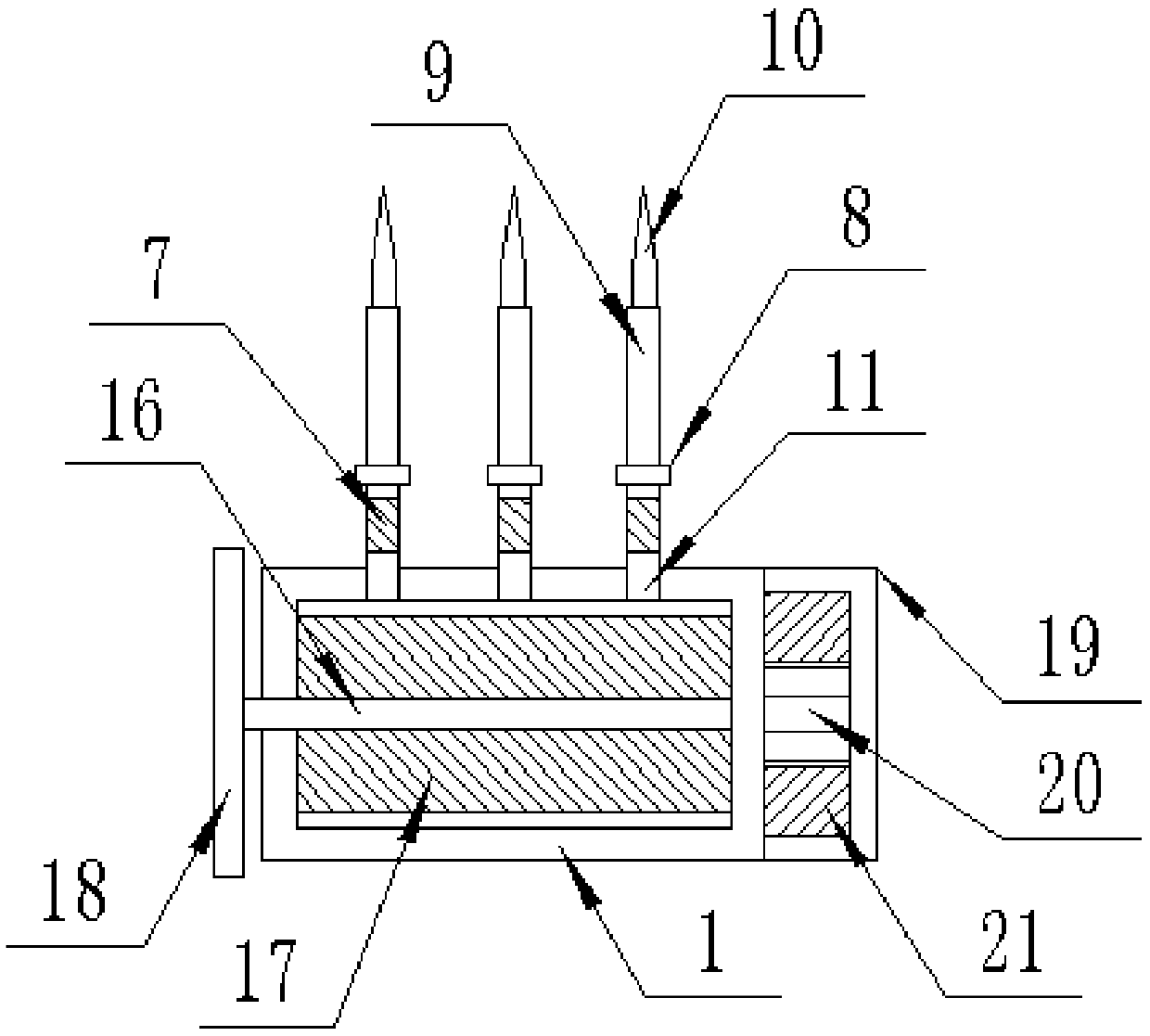

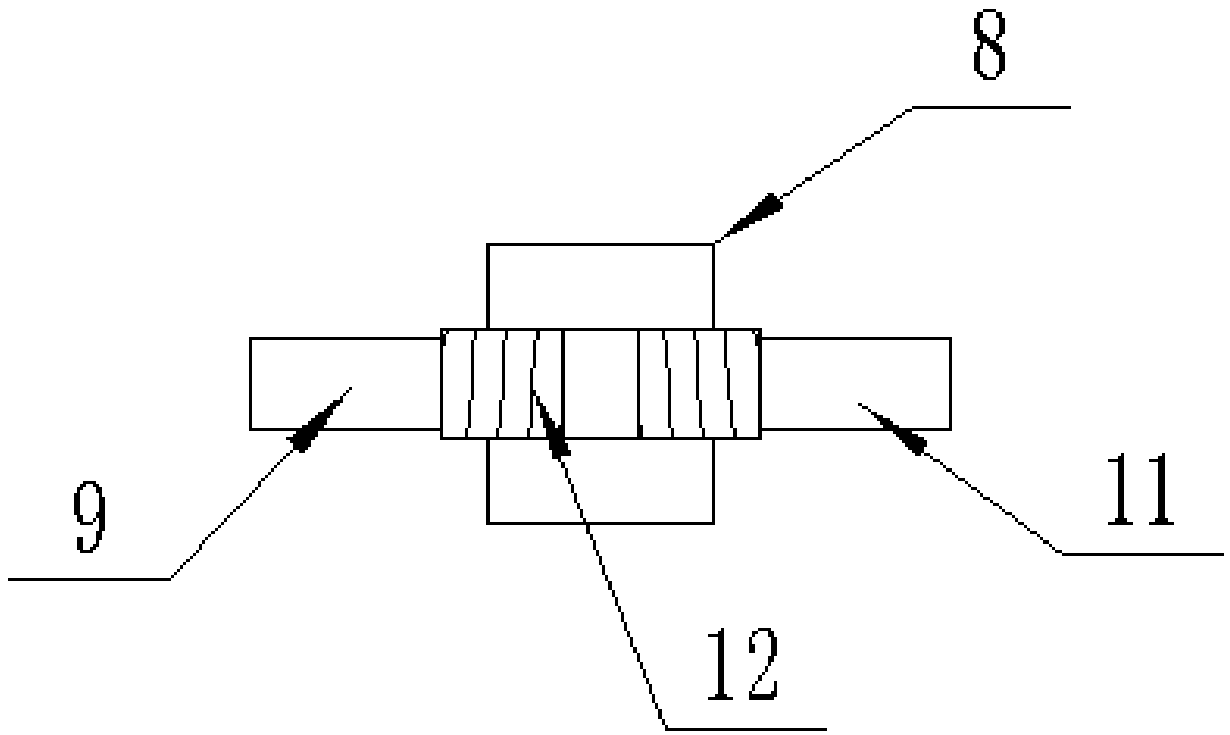

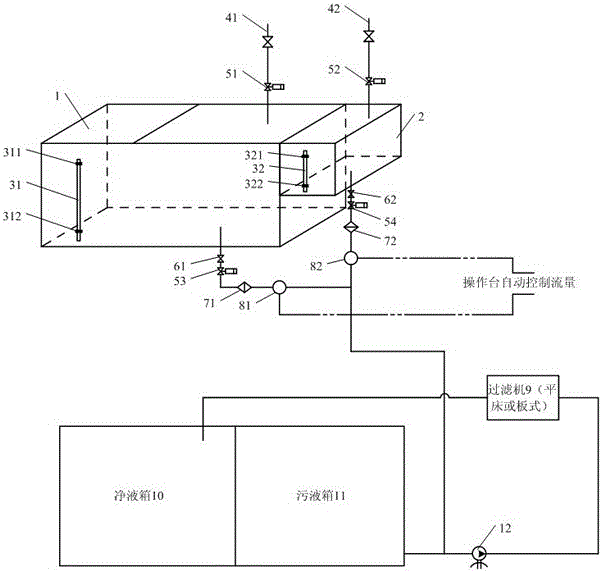

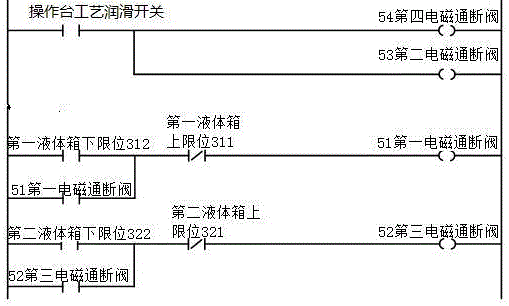

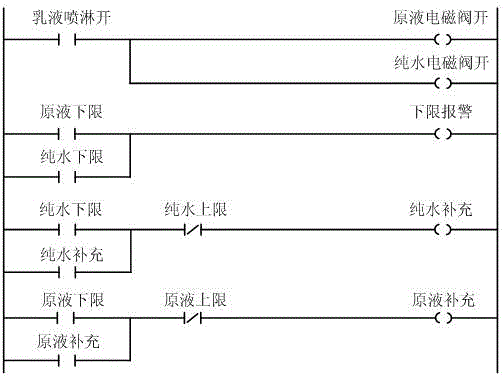

Automatic liquid preparing device and method of technological lubrication liquid in plate and strip foil calendering

ActiveCN103042052AIncrease productivityAvoid manual workWork treatment devicesMetal rolling arrangementsEmulsionEngineering

The invention discloses an automatic liquid preparing device and method of a technological lubrication liquid in plate and strip foil calendering. The device comprises a mechanical portion and a control portion, the mechanical portion is used for performing liquid preparing to a corresponding technological lubrication liquid during plate and strip foil calendaring, the control portion is used for real-timely controlling the liquid preparing process of the mechanical portion on the corresponding technological lubrication liquid on the basis of monitored liquid level and flow quantity of the corresponding technological lubrication liquid, and the mechanical portion and the control portion are in a signal connection. By means of the automatic liquid preparing device and method of the technological lubrication liquid in plate and strip foil calendaring, defects that production efficiencies are low, manual labor intensity is large, product surface qualities are poor and energy consumption is high in prior art can be overcome so that production efficiencies are improved, manual labor intensity is reduced, product surface qualities are improved, energy consumption is reduced, simultaneously, personnel is prevented from directly contacting petrochemical materials of emulsion, rolling oil, additives and the like, and harm of petrochemical products to the personnel is prevented.

Owner:XINJIANG JOINWORLD CO LTD

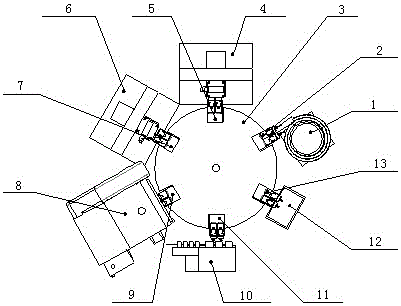

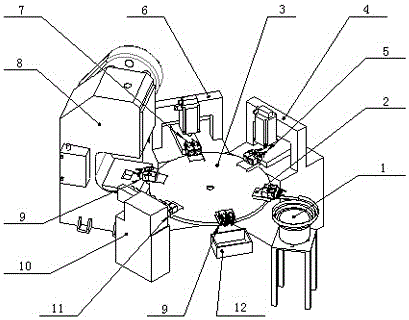

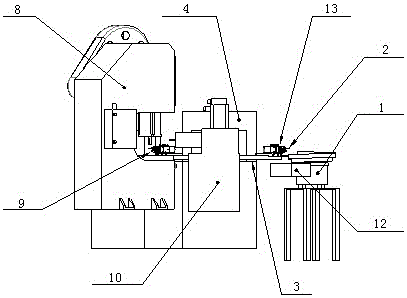

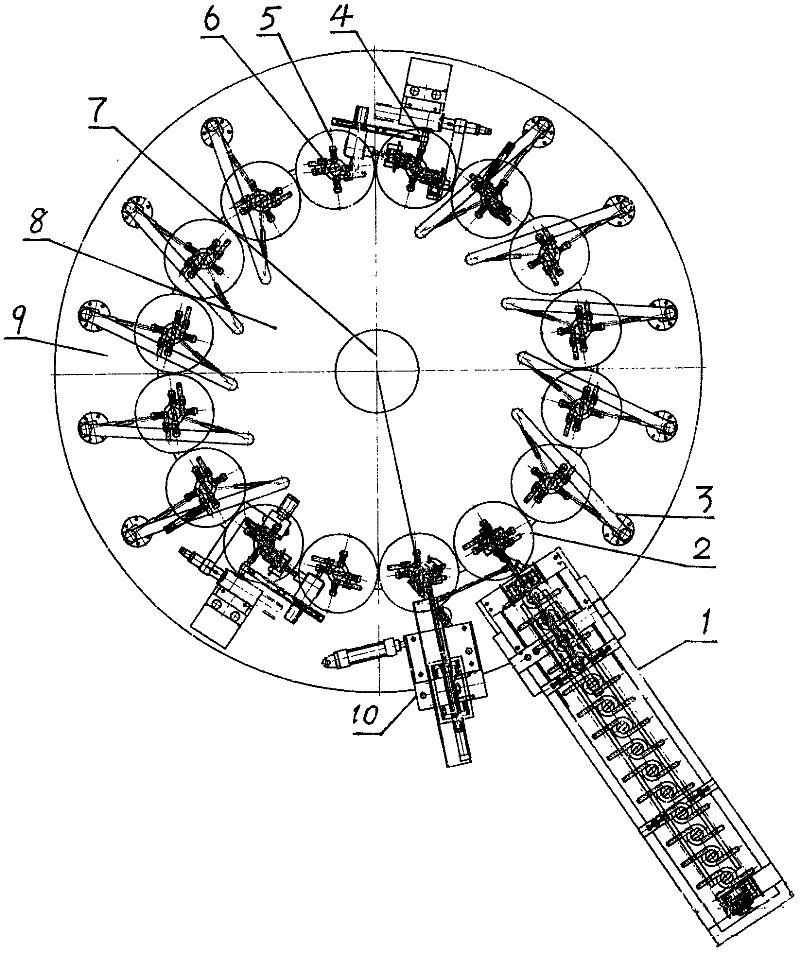

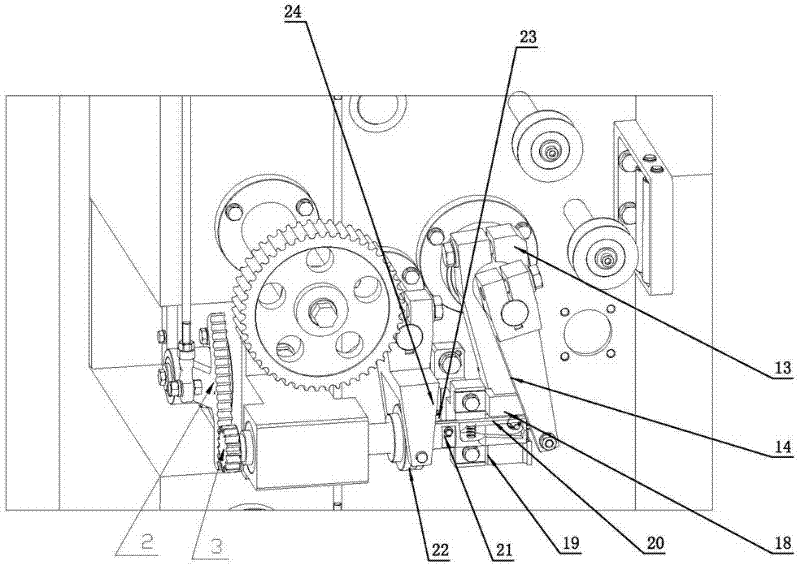

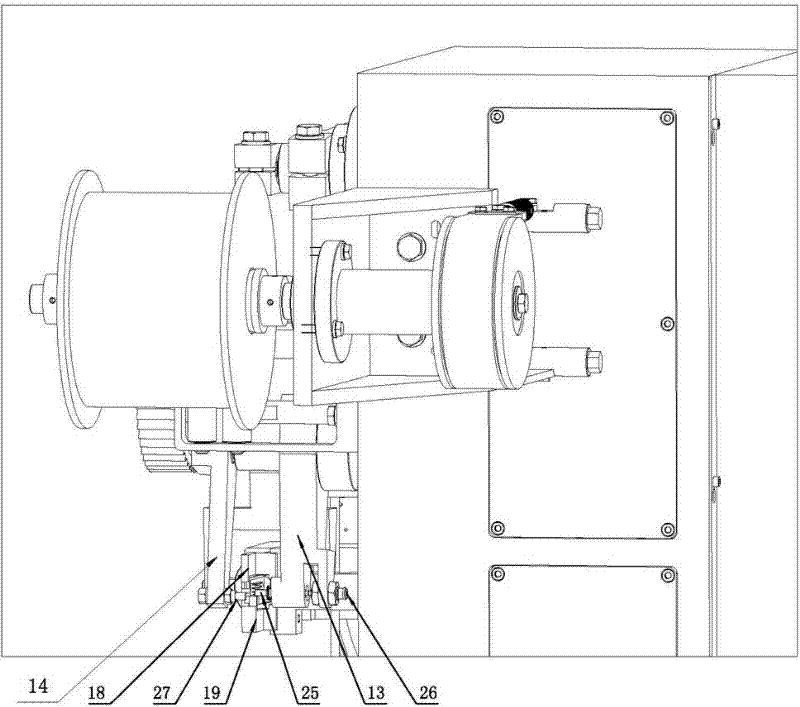

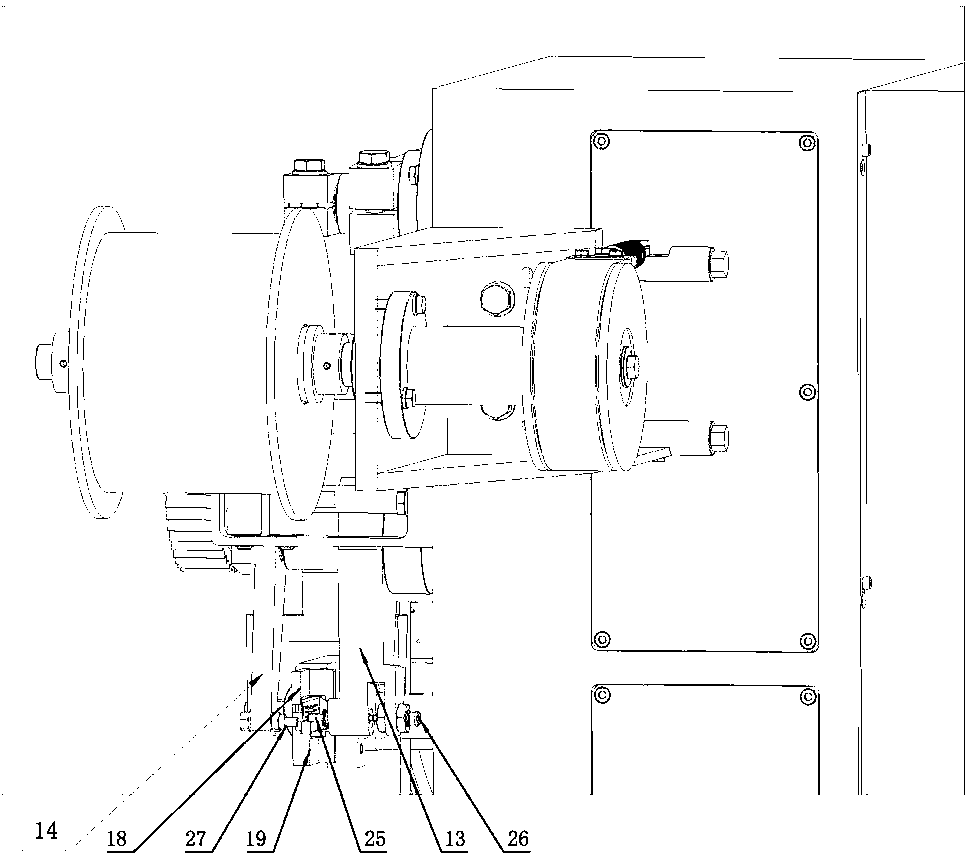

Novel key machine

The invention provides a novel key machine. The novel key machine comprises a rotary disc, a vibrating disc, two perforating machines and six clamps, wherein the rotary disc is in transmission connection with a driving device, the vibrating disc is arranged around the rotary disc in a surrounding mode, and the six clamps are in transmission connection with a cylinder. The first clamp is in transmission connection with the vibrating disc. The second clamp is in transmission connection with the first perforating machine. The third clamp is in transmission connection with the second perforating machine. The fourth clamp is in transmission connection with a punch press. The fifth clamp is in transmission connection with a rolling machine. The sixth clamp is in transmission connection with a discharging box. The first clamp is fixedly arranged on the rotary disc and is opposite to the vibrating disc. The second clamp is fixedly arranged on the rotary disc and is opposite to the first perforating machine. The third clamp is fixedly arranged on the rotary disc and is opposite to the second perforating machine. The fourth clamp is fixedly arranged on the rotary disc and is opposite to the punch press. The fifth clamp is fixedly arranged on the rotary disc and is opposite to the rolling machine. The sixth clamp is fixedly arranged on the rotary shaft and is opposite to the discharging box. The novel key machine achieves full-automatic machining of keys, improves labor productivity, saves energy, is environmentally friendly, high in energy efficiency and low in cost, and has broad market economic benefits.

Owner:方新国 +2

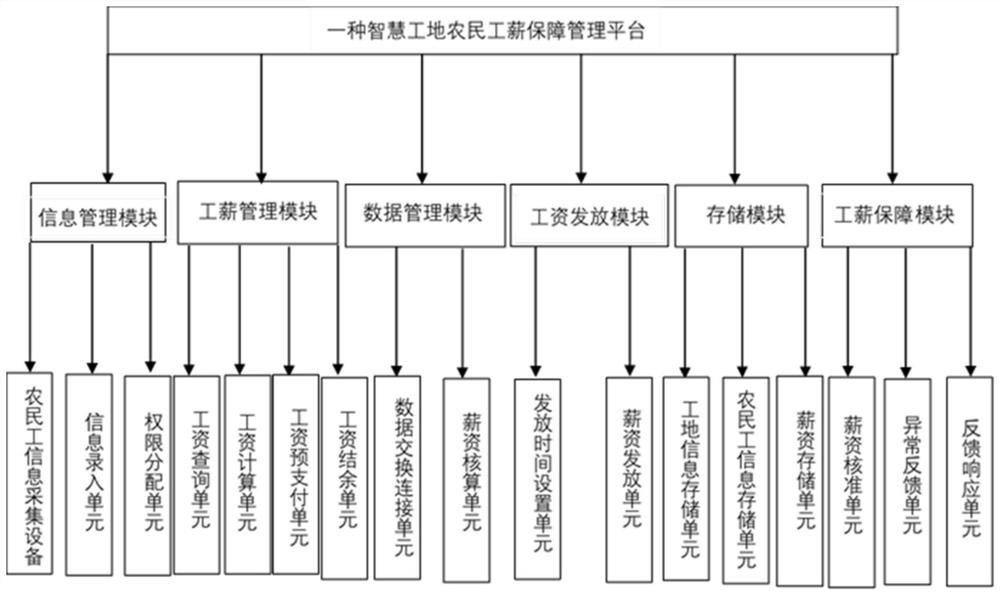

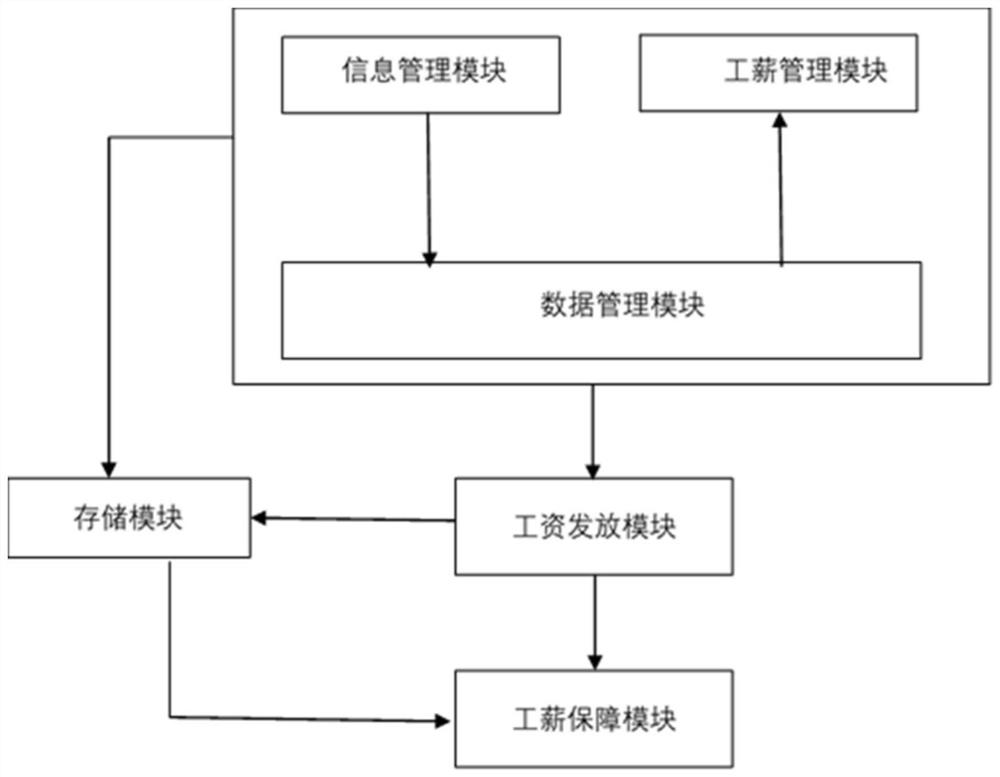

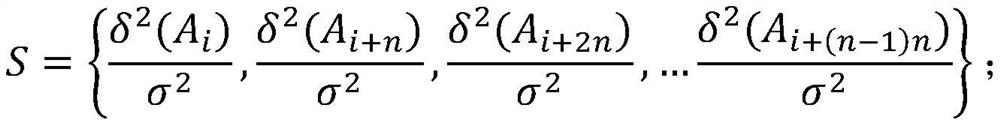

Intelligent construction site migrant worker salary guarantee management platform

PendingCN111898971AImprove computing efficiencyImprove distribution efficiencyOffice automationResourcesFarm LaborersComputer science

The invention discloses an intelligent construction site migrant worker salary guarantee management platform. The invention comprises an information management module, a salary management module, a data management module, a salary payment module, a storage module and a salary guarantee module. The modules are matched with each other, so construction site and worker information is collected, storedand inquired; meanwhile, salaries of migrant workers are calculated in proportion. In a fixed setting time, salaries are paid for migrant workers and a salary table is sent to the workers; when the migrant workers have doubts, the salaries can be approved, abnormal problems existing in salary payment are fed back and complained, and after receiving the feedback and the complaint, system personnelrespond to specific problems in time. According to the invention, a new mode is provided for the salary guarantee of the migrant workers, the personal interests of the migrant workers are guaranteedthrough the salary pre-payment unit and the salary guarantee module, and the management of the migrant workers is more programmed.

Owner:ZHEJIANG HUAWEI INTELLIGENT BUILDING TECH

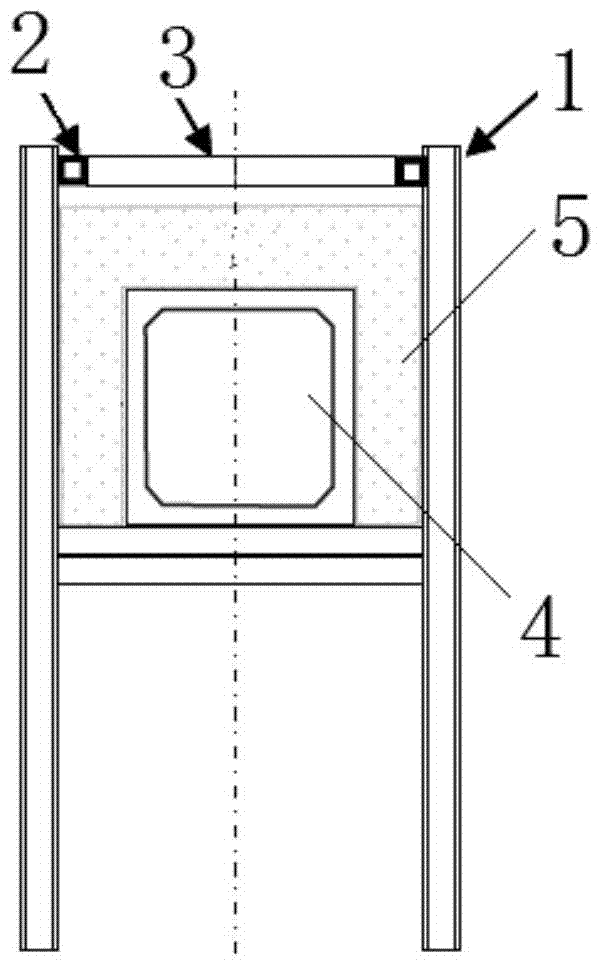

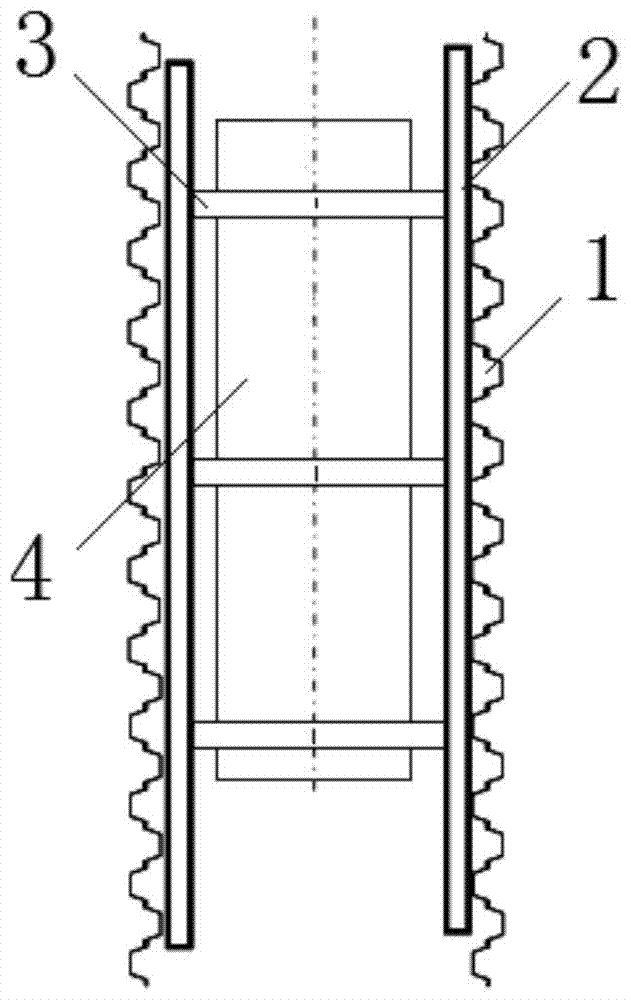

Pipe sorting device

ActiveCN103302038AEnsure consistencySolve the problem of high detection error rateSortingIndustrial engineeringSupport plane

The invention provides a pipe sorting device. The device comprises a support frame, a locating mechanism, detection mechanisms and defective product removing mechanisms, wherein the locating mechanism is arranged on the support frame and is used for locating a workpiece to be detected; the detection mechanisms are fixedly arranged on the support frame and are used for detecting the workpiece to be detected, which is located by the locating mechanism; and the defective product removing mechanisms are arranged on one side of the workpiece to be detected along the axial direction of the workpiece to be detected and are used for sorting out unqualified workpieces detected by the detection mechanisms. By applying the pipe sorting device, the work efficiency of pipe detection and sorting operations can be improved, the manpower consumption can be reduced, and unification of the pipe quality can be ensured.

Owner:GREE ELECTRIC APPLIANCES INC

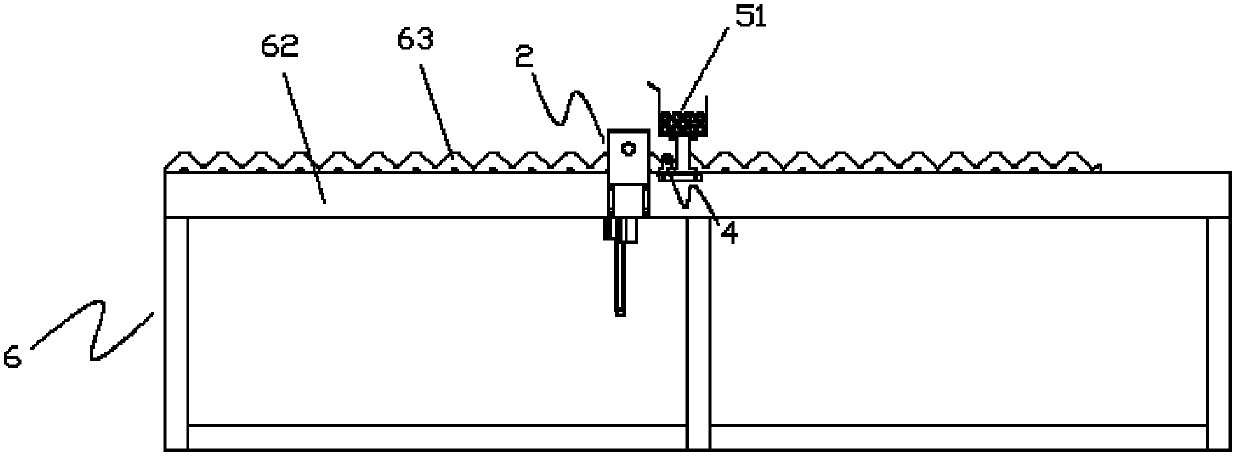

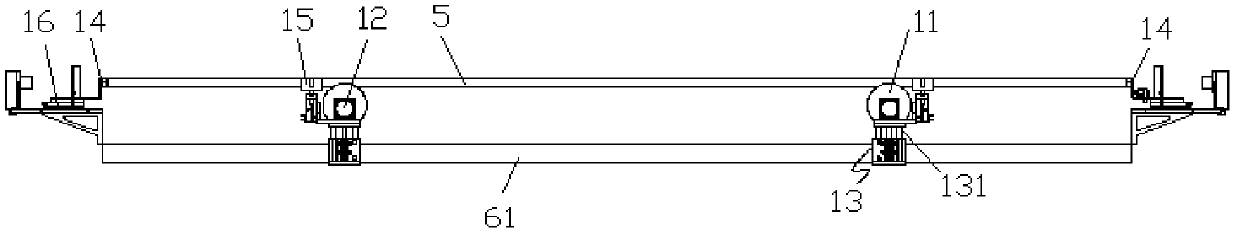

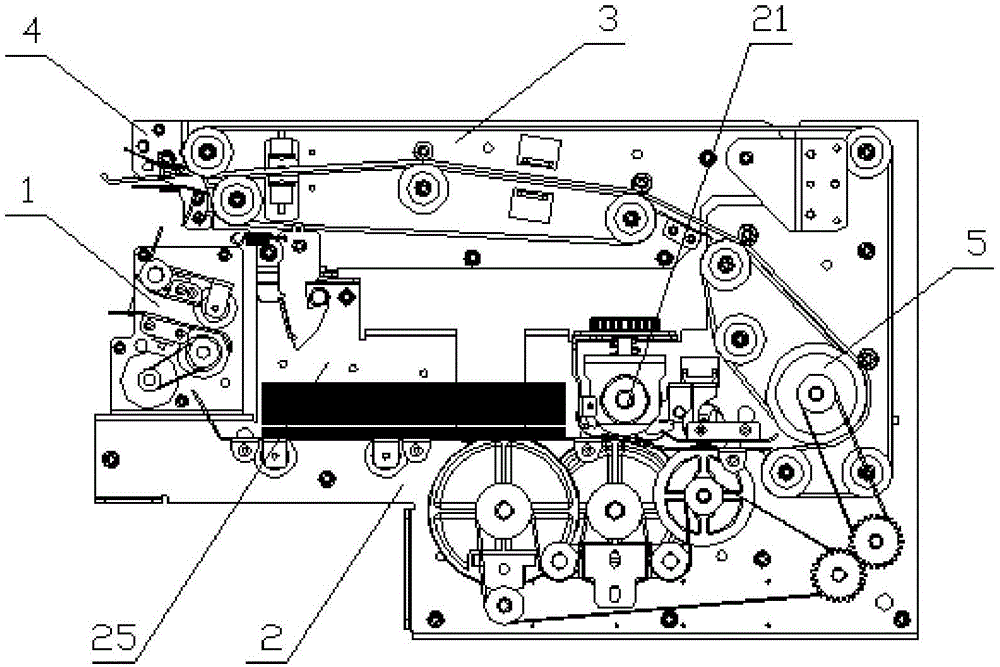

Single paper currency continuous transmission device

ActiveCN105374112AAvoid manual workImprove work efficiencyCoin/currency accepting devicesPulp and paper industry

Owner:浙江众合科技股份有限公司

Workpiece stamping machining production line

InactiveCN108817251ARealize automatic feedingAvoid manual workMetal-working feeding devicesPositioning devicesProduction lineEngineering

The invention discloses a workpiece stamping machining production line. The production line comprises a machining table, a machining plate, a power unit, a limiting plate, a punch and a driving mechanism, wherein a plurality of containing grooves are formed in the machining plate, the plurality of containing grooves are sequentially distributed in the length direction of the machining plate, the depth of each containing groove is smaller than H, wherein H is the height of a workpiece, the machining plate is arranged on the machining table, the power unit is used for driving the machining plateto move in the length direction of the machining plate, the limiting plate is located above the machining plate, the plane where the limiting plate is located is perpendicular to or obliquely intersected with the length direction of the machining plate, the distance between the limiting plate and the bottom walls of the containing grooves is larger than H and is smaller than 2H, the punch is located on the downstream side of the limiting plate and located above the machining plate, and the driving mechanism is used for driving the punch to move close to or away from the containing grooves.

Owner:芜湖华铸汽车部件有限公司

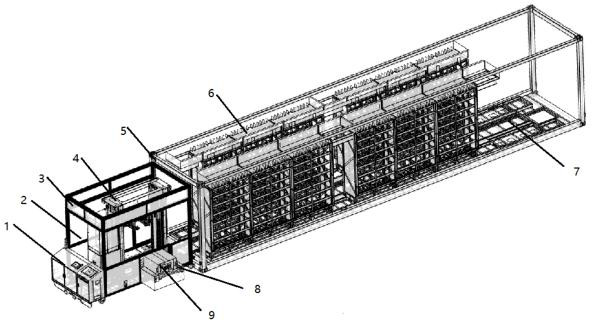

Large bomb production line

PendingCN110715581AReduce labor intensityImprove production pass rateAmmunitionCleaning using toolsBody cleaning brushThermodynamics

The invention discloses a large bomb production line. The large bomb production line comprises a vertical empty body feeding device, a bomb body cleaning brushing device, a paint spraying device, a vertical discharging device, a booster grain assembling system, an explosive injection hanging chain, a paint spraying hanging chain and a transmission plate chain machine. The explosive injection hanging chain and the paint spraying hanging chain are each provided with multiple cranes used for hanging connection of vertical type bombs, the bomb body cleaning brushing device, the paint spraying device and the vertical discharging device are sequentially arranged below the paint spraying hanging chain in the moving direction of the cranes, one end of the paint spraying hanging chain is connectedwith the paint spraying hanging chain, the paint spraying changing chain transmits vertical type bombs fed by the vertical empty body feeding device, and explosive injecting is carried out through anexplosive injecting workshop. The transmission plate chain machine is used for receiving the bombs output by the vertical discharging device, and the booster grain assembling system is arranged in thetransmission direction of the transmission plate chain machine. Vertical bomb automatic production transmission is achieved, labor intensity is reduced, the production yield can be improved, production efficiency is improved, and the manual work of the dangerous procedure is avoided.

Owner:HUNAN JUNCHENG TECH

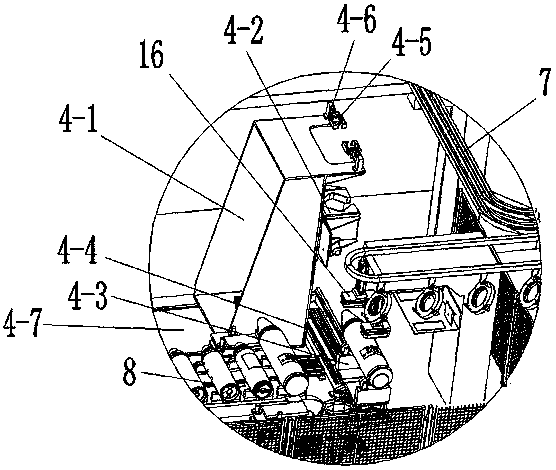

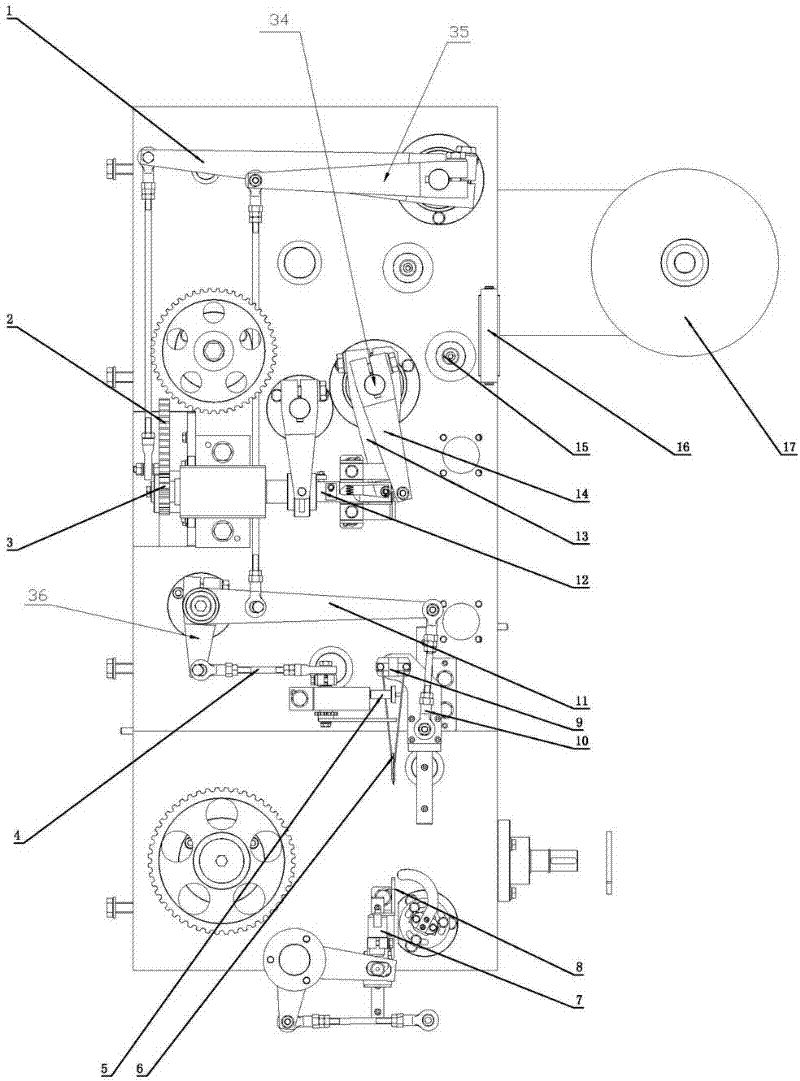

Spiral luminous tube pin bending machine

InactiveCN102408189AMake sure it's fullLabor savingGlass reforming apparatusAutomatic controlPrimary station

The invention relates to a spiral luminous tube pin bending machine which comprises a distribution box, an automatic control system, a motor, a reduction gear box and a workbench, wherein a central rotating shaft (8) is provided with a rotary table (8) which is provided with 16-24 equally spaced stations (2); in the case of 16 stations, the station close to the inner side of a tube conveying and placing device (1) is called the primary station (2), and other stations in counterclockwise sequence comprise the 2-6th and 9-13th stations provided with a fire head heating device (3), the 7th and 14th stations provided with a pin bending device (4), the 8th station the lower part of which is provided with a station steering device (14), the 15th station which is a natural cooling station, and the 16th station provided with a tube unloading device (10) nearby; and a spiral luminous tube with V-shaped pins is subjected to each of the process steps on the 16 stations, so that the V-shaped pins are bent into straight pins. The pin bending machine has the advantages of automate line production, low energy consumption, high work efficiency, labor saving and capability of improving high-temperature working environment. In addition, the machine is capable of collecting afterheat for preheating and thermal insulation of the luminous tube to be processed, and has the advantages of reasonable inflation time and pressure control, stable product quality and high qualification rate.

Owner:杭州森浦设备制造有限公司

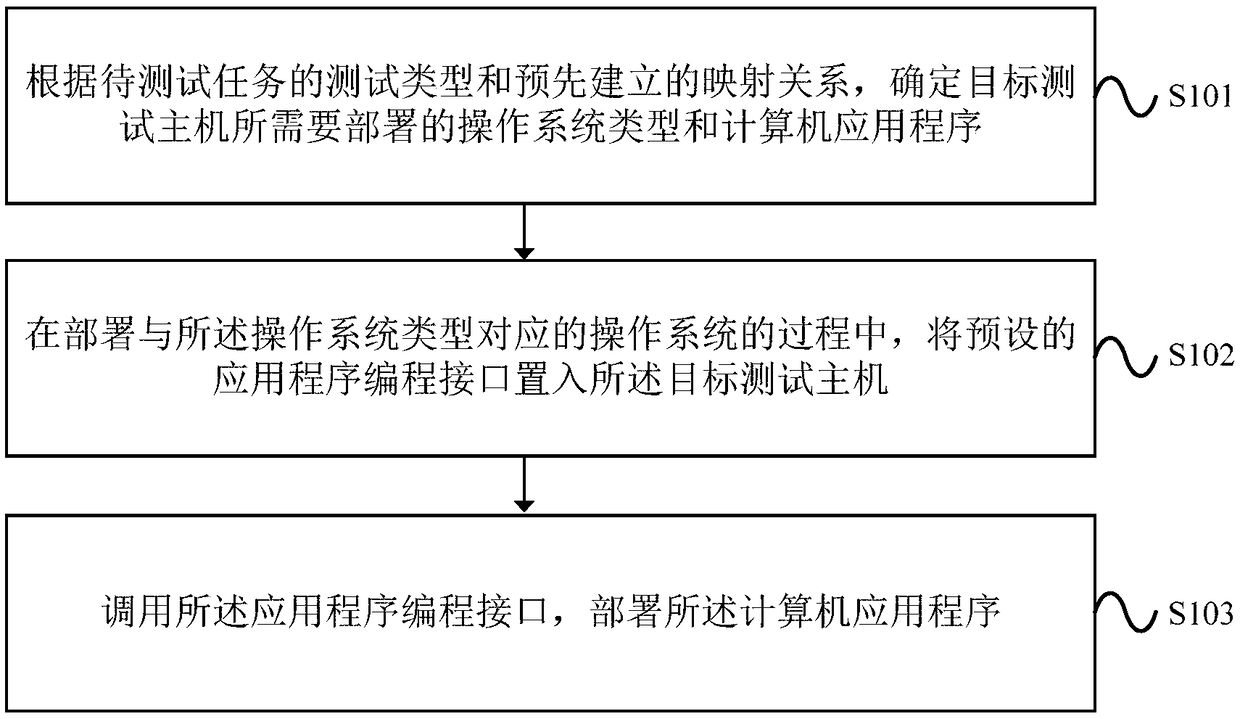

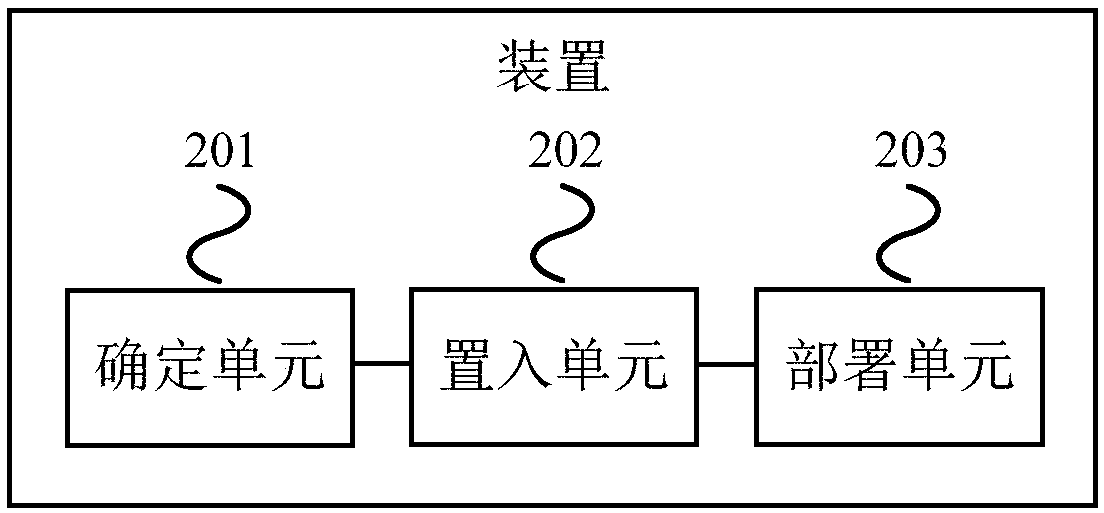

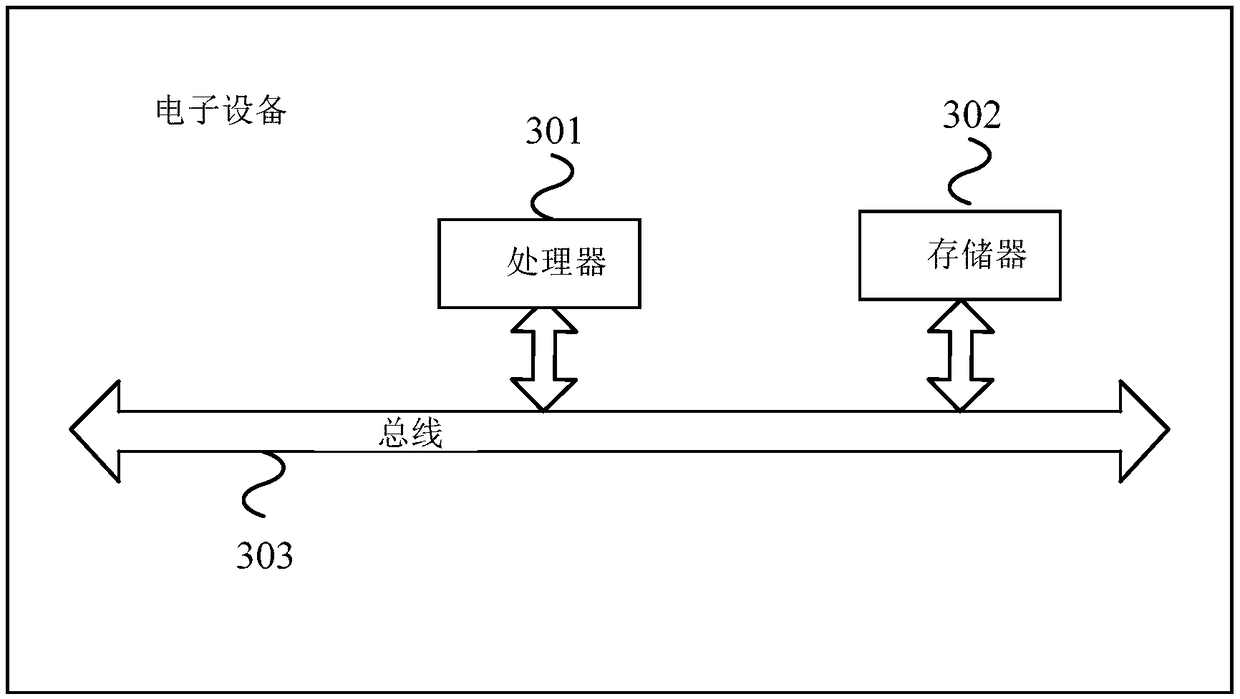

A processing method and a device for automatically deploying a cluster test host

InactiveCN109213494ASave system resourcesAvoid manual workSoftware deploymentOperational systemApplication programming interface

The embodiment of the invention provides a processing method and a device for automatically deploying a cluster test host. The method comprises the following steps: according to a test type of a taskto be tested and a mapping relationship established in advance, determining an operating system type and a computer application program required to be deployed by a target test host; wherein the mapping relationship comprises a correspondence relationship between test host information in the cluster and a preset test type; in the process of deploying an operating system corresponding to the operating system type, a preset application programming interface is placed into the target test host; the application programming interface is invoked to deploy the computer application program. The apparatus performs the method described above. The processing method and the device for automatically deploying the cluster test host provided by the embodiment of the invention can avoid repetitive human work, improve the deployment efficiency and save the system resources of the test host.

Owner:BEIJING QIANXIN TECH

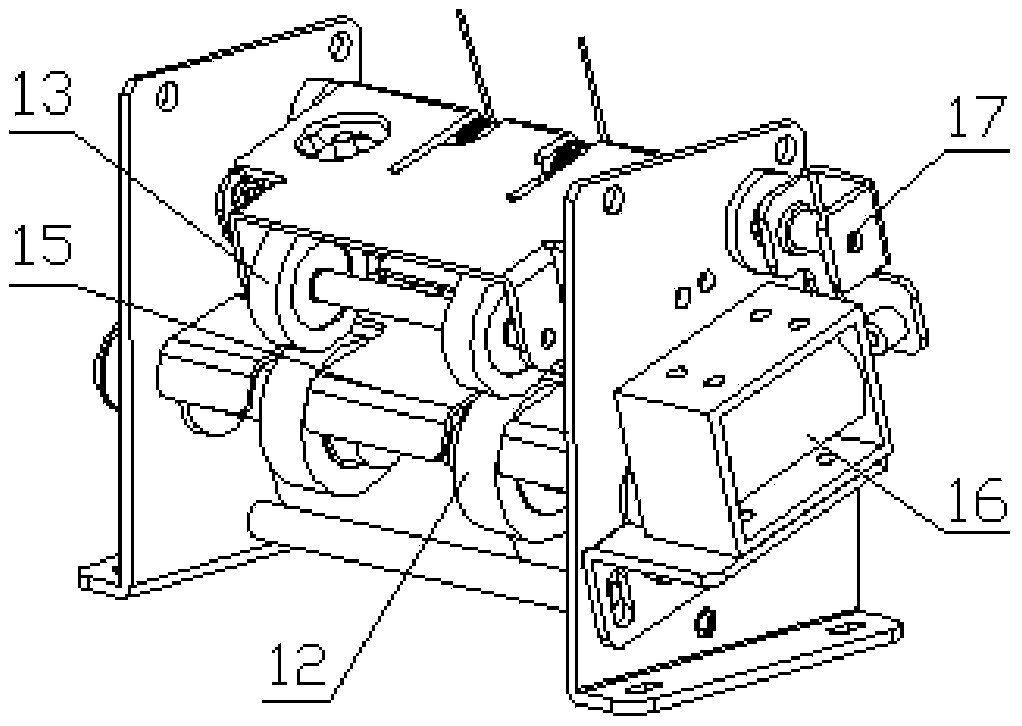

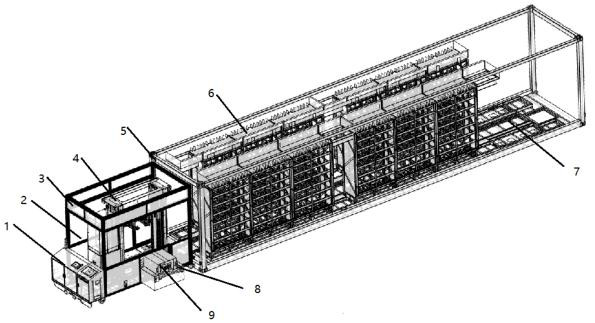

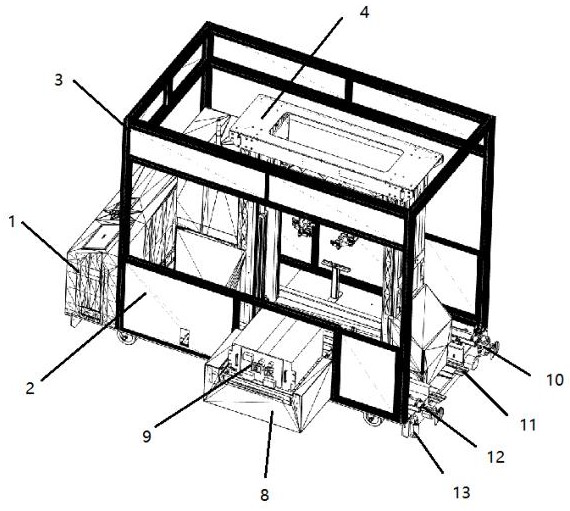

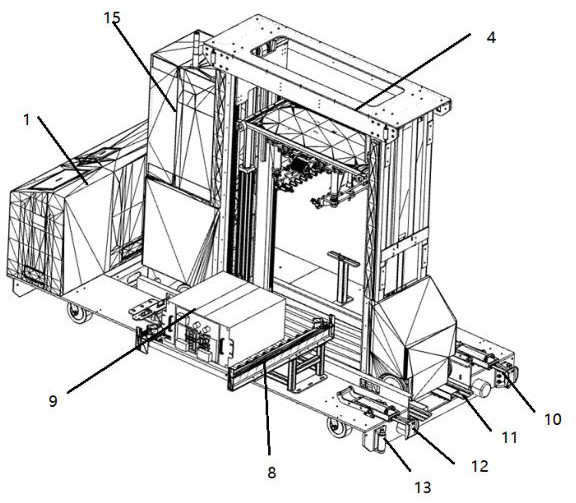

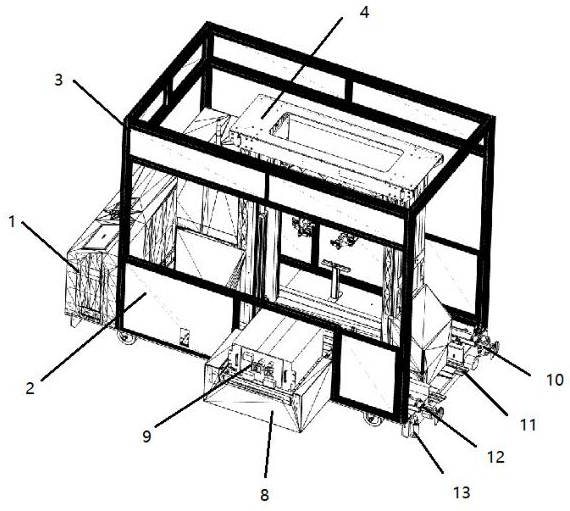

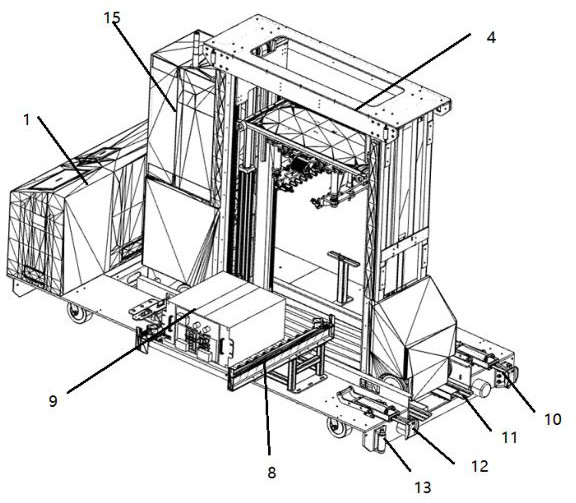

Assembly combination structure

ActiveCN112693912ARealize automatic loading and unloadingAvoid damageLoading/unloadingConveyor partsVehicle frameElectric control

The invention is applicable to the technical field of mobile assembly, and provides an assembly combination structure which comprises a placement room, a placement rack mounted in the placement room, a movable plug-in box vehicle used for grabbing, transporting and transferring parts, a fixed platform vehicle is in detachable butt joint with the placement room to form a walking channel, a material receiving conveying line connected to the fixed platform vehicle, an electric control box connected with the fixed platform vehicle, the material receiving conveying line and the movable plug-in box vehicle and used for controlling input, grabbing, transportation and transfer of the parts. The mobile plug-in box vehicle comprises a vehicle frame used for supporting and mounting, a roller clamping and injecting claw arranged on the vehicle frame in a liftable manner and is used for grabbing and outputting the parts, a walking structure mounted at the bottom of the vehicle frame and used for driving the vehicle frame to move, and a lifting mechanism arranged on the vehicle frame, connected with the roller clamping and injecting claw and used for driving the roller clamping and injecting claw to ascend and descend. The assembly combination structure has the advantages of being accurate in loading, high in loading and unloading efficiency, good in safety and capable of effectively preventing wrong loading.

Owner:大捷智能科技(广东)有限公司

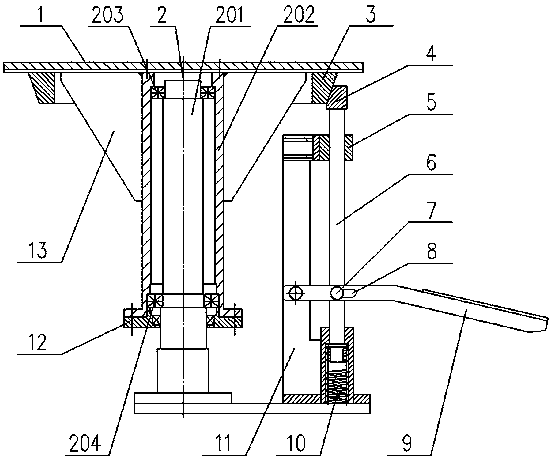

Rotary worktable with self-locking function

The invention discloses a rotary worktable with a self-locking function. The rotary worktable with the self-locking function comprises a rotary table plate arranged on a rotary mechanism. A conical guide ring is arranged at the bottom of the rotary table plate. The rotary table with the self-locking function further comprises a plug-pin with a conical guide block at the end of the plug-pin. A plug-pin seat is connected to the other end of the plug-pin through a spring. The spring is used for jacking the plug-pin to enable the conical surfaces of the conical guide block and the conical guide ring to be attached tightly to achieve the self locking of the rotary worktable. A footplate is hinged to the plug-pin seat. A sliding groove is formed in the footplate. A positioning block is installedon the plug-pin. The one end away from the plug-pin, of the positioning block is arranged in the sliding groove in a penetrating mode. The footplate is driven to move in the direction of a base to enable the positioning block to slide in the sliding groove and to drive the plug-pin to move in the direction of the plug-pin seat, so that the conical surfaces of the conical guide block and the conical guide ring are separated to facilitate the free rotation of the rotary table plate, the structure is simple, the cost is low, the problems that a worker walks around the worktable and stands on theworktable for manual operation are avoided, the use is convenient, convenience is brought for the manual operation, the production efficiency is improved while the economic benefit is achieved.

Owner:HENAN UNIV OF SCI & TECH

Automatic sensing mechanical hand device

InactiveCN103465265ATroubleshoot technical issues with a single jobAvoid manual workProgramme-controlled manipulatorManipulatorProgrammable logic controller

The invention discloses an automatic sensing mechanical hand device. The automatic sensing mechanical hand device comprises a motor, a mechanical arm, a mechanical hand, a storage cabinet and a PLC (Programmable Logic Controller) control room, wherein the mechanical hand is connected with the mechanical arm, the motor is connected with the mechanical arm, the PLC control room is communicated with the motor, the mechanical arm is internally provided with a temperature sensing system, and the temperature sensing system is communicated with the PLC control room. According to the automatic sensing mechanical hand device disclosed by the invention, the problem of traditional hand operation is solved, product performance can be detected, products can be classified to store, and the technical problem of single operation of existing machinery is solved.

Owner:JIANGSU XINGMALI TECH

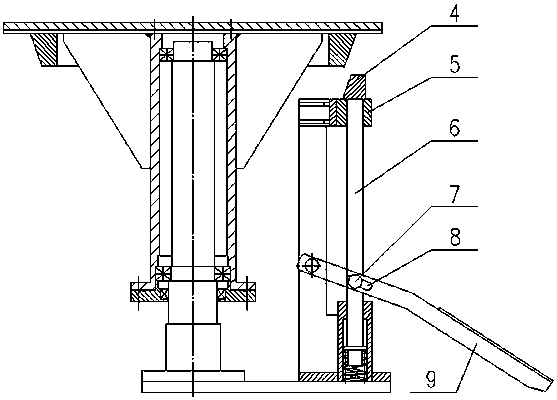

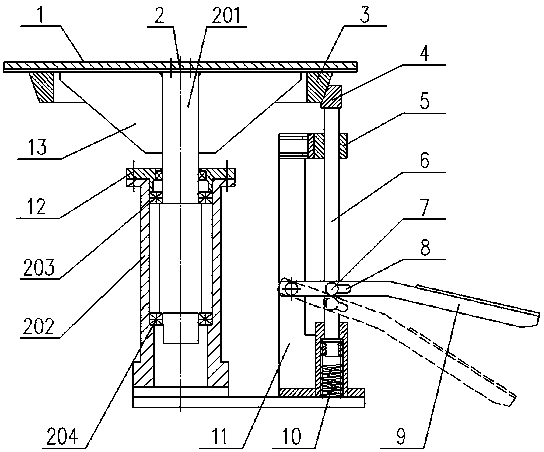

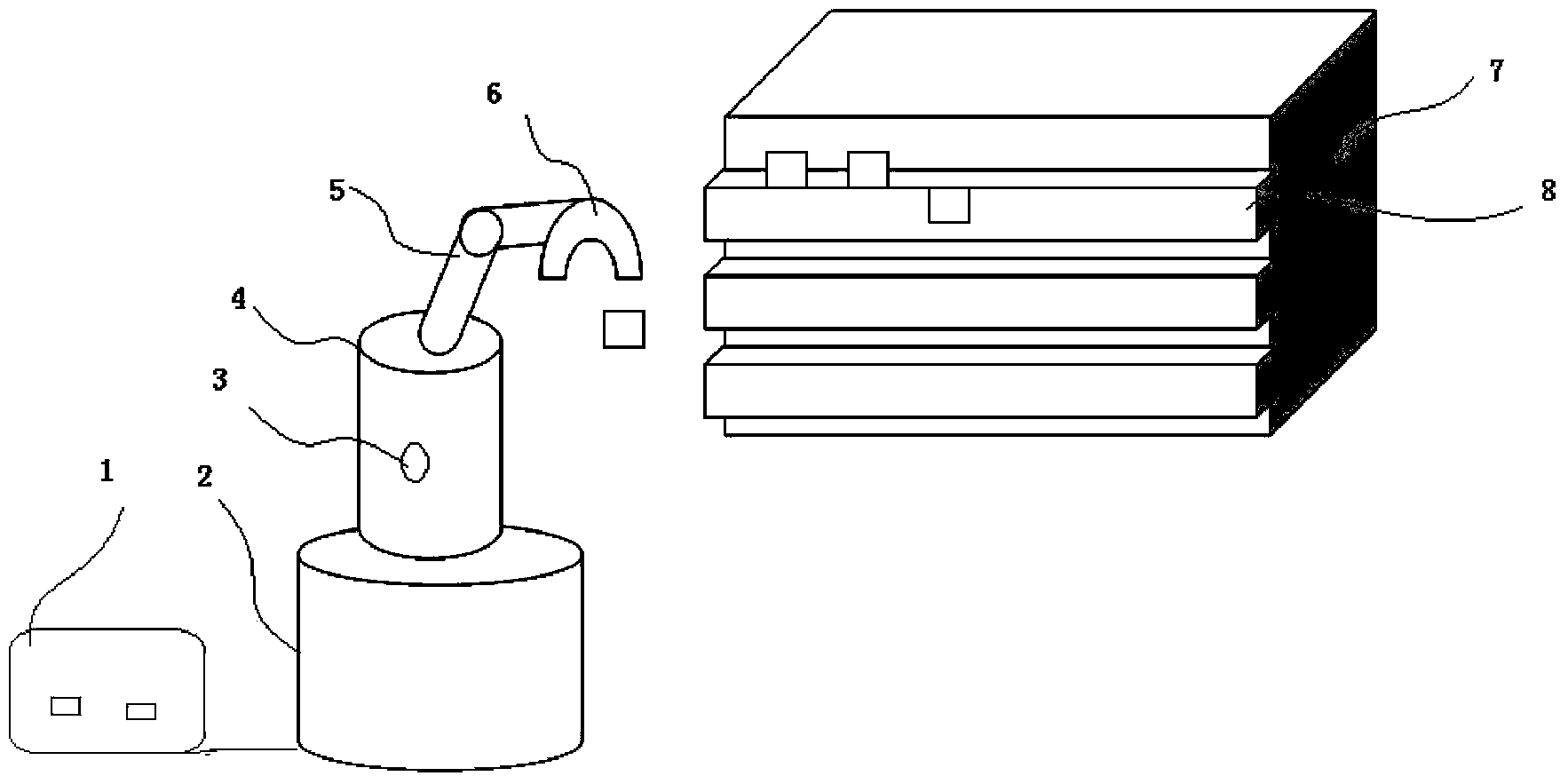

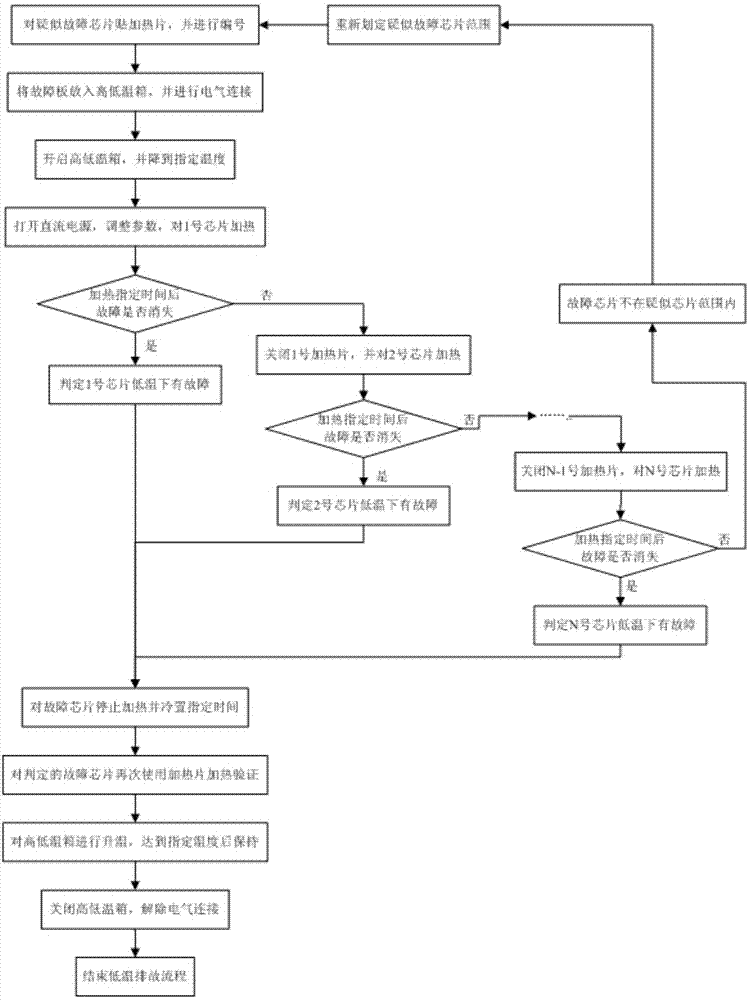

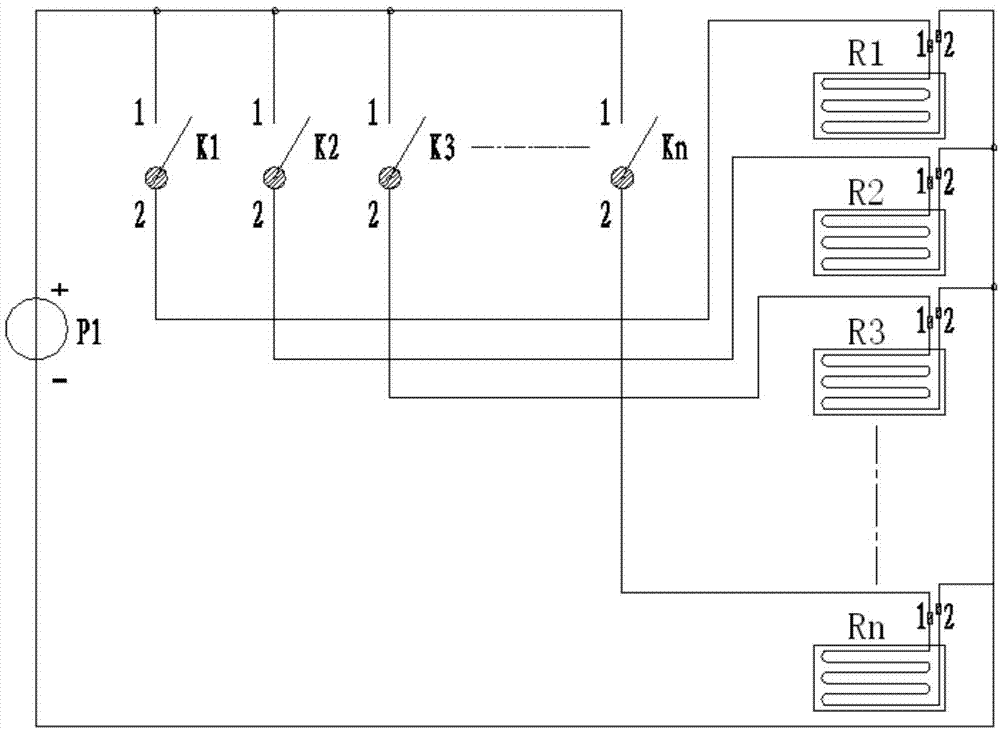

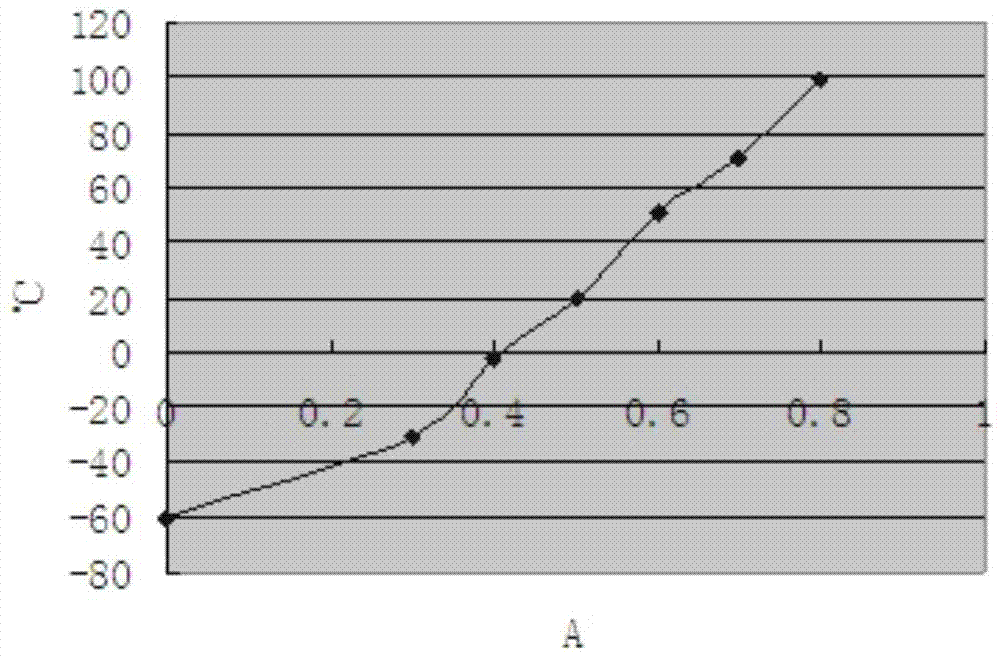

Circuit board low-temperature fault locating method and heating device thereof

InactiveCN104297655APrecise positioningPrecise temperature controlIndividual semiconductor device testingTemperature controlCircuit Failure

The invention relates to a circuit board low-temperature fault locating method and a heating device thereof. The method comprises the following steps: a heating sheet of the heating device is arranged on a suspected faulty chip of a faulty board; the faulty board is placed in a cooling device, and the temperature is decreased to a set temperature; the suspected faulty chip is heated by the heating device; after the suspected faulty chip is heated for a specified period of time, whether the fault of the faulty board disappears is detected, and the suspected faulty chip is a faulty chip if the fault disappears; and if the fault does not disappear, no fault occurs to the suspected faulty chip. Low-temperature fault removal is carried out through local heating by the electric heating sheet. A faulty chip of a circuit board can be accurately located in a low-temperature environment. A circuit fault is enabled to reappear and disappear by making a faulty chip work in different temperature states. Temperature control is accurate. Blind chip replacement and manual operation in a low-temperature environment are avoided. Time and manpower and material costs are saved. A low-temperature faulty chip can be accurately located.

Owner:LUOYANG INST OF ELECTRO OPTICAL EQUIP OF AVIC

Automated high-precision PVC wallboard processing equipment

ActiveCN106695941AAvoid accidental movementImprove cutting accuracyPlastic recyclingMetal working apparatusEngineeringMechanical engineering

The invention discloses automated high-precision PVC wallboard processing equipment. The automated high-precision PVC wallboard processing equipment comprises a processing table, a processing board, a power mechanism, a hold-down mechanism and a cutting mechanism. A guide rail is arranged on the processing table in the length direction of the processing table. The processing board is movably mounted on the guide rail. A containing groove for containing PVC wallboards is formed in the upper surface of the processing board and formed in the length direction of the processing table. N cutting passageways are arranged on the upper surface of the processing board and are uniformly distributed in the length direction of the processing table. The length direction of the cutting passageways and the length direction of the processing table are perpendicular to each other or set in an oblique crossing manner. The power mechanism is used for driving the processing board to move in the length direction of the processing table. The hold-down mechanism comprises N hold-down sets. The N hold-down sets correspond to the N cutting passageways in a one-to-one manner. Each hold-down set comprises a hold-down unit. Each hold-down unit comprises a support rod, a sliding block, a pressing plate, a supporting block and a supporting rod. The support rods are mounted on the processing board in the vertical direction. The sliding blocks are movably mounted on the corresponding support rods.

Owner:安徽优丽普科技有限公司

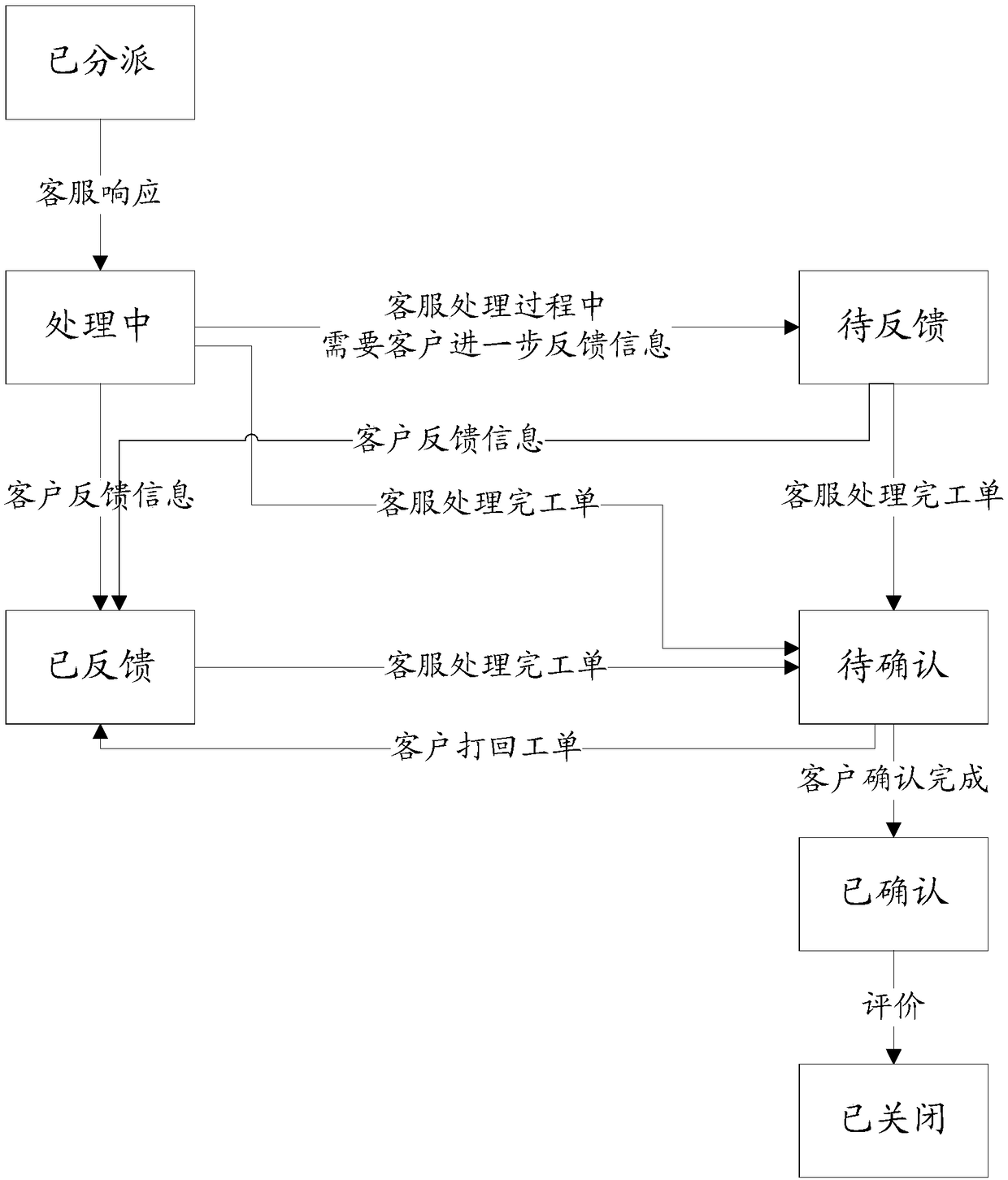

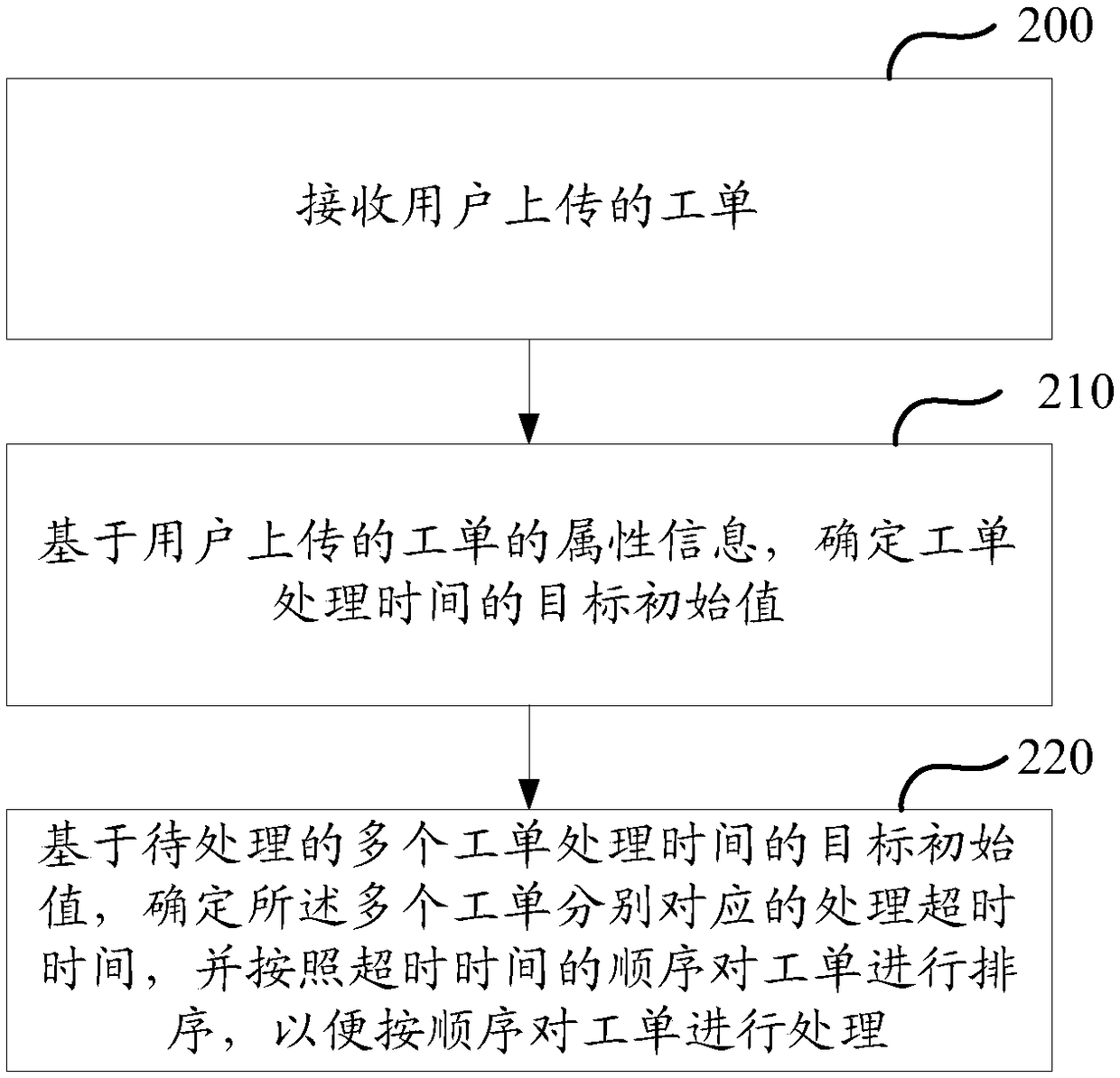

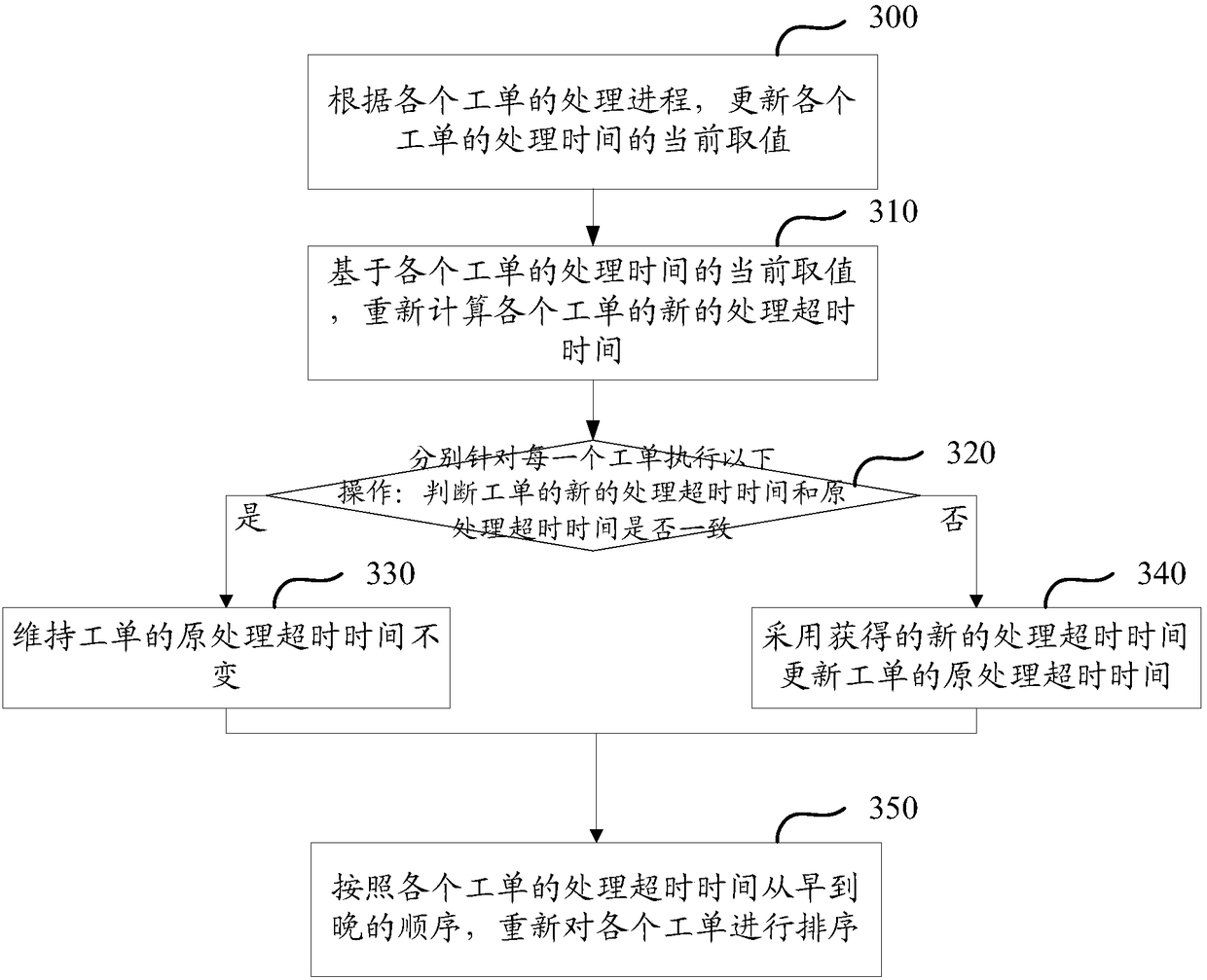

A method and apparatus for implement intelligent service

ActiveCN109508843AImprove experienceAvoid manual workResourcesManufacturing computing systemsService implementationComputers technology

this application relates to that field of computer technology, in particular to an intelligent service implementation method and apparatus, In order to solve the existing problem of unreasonable job processing, the method comprises the following steps: Determine correspondence by attribute information of orders uploaded by users based on a target initial value of a plurality of job processing times to be processed, Determining the processing timeout times corresponding to multiple jobs, and sorting the jobs in order of timeout time, so that work orders can be processed based on the order of the work orders, In this way, instead of manually determining the job order sorting, the different attribute information of each job order is comprehensively considered, and each job order is automatically sorted, so that the work order to be processed urgently can be processed first, not only the accuracy of job order sorting is improved, but also the processing efficiency is improved, and furtherthe user experience is improved.

Owner:ALIBABA GRP HLDG LTD

Tower tea bag threading method and device

ActiveCN102343995ACompact structureMeeting Speed and Accuracy RequirementsPackagingCotton threadRocker arm

The invention relates to a tower tea bag threading method and device. The tower tea bag threading device mainly comprises a cotton thread roll and a threading device connected with the cotton thread roll, wherein the cotton thread roll provides rolled cotton threads; the cotton thread is downwardly connected with a pneumatic chuck via a limiter and a roller; an internal rocker arm and an externalrocker arm are arranged in a knot molding machine connected with the cotton thread; the internal rocker arm and the external rocker arm are connected with each other by a shaft; the inner rocker arm is positioned on the internal side of the external rocker arm; a cutting knife is arranged at the upper end of the pneumatic chuck; a lower chuck is arranged at the lower end of the pneumatic chuck; and the lower chuck is mounted on a first cylinder. The tower tea bag threading method and device, provided by the invention, have the following advantages that: (1) compact structure is obtained; and all functions of cotton thread connection and fixation are finished through limited actions; (2) requirements on the speed and accuracy matched with the machine are satisfied; and (3) high automation degree is obtained so that the problem of a lot of manual operations is effectively solved and consistency and standard rate of the product quality are assured.

Owner:中华全国供销合作总社杭州茶叶研究院 +1

Efficient and energy-saving forestry mechanical weeding device

InactiveCN111183790AAvoid damageEasy to control the lengthBatteries circuit arrangementsMowersRotational axisAgricultural engineering

The invention discloses an efficient and energy-saving forestry mechanical weeding device. The weeding device includes a rack, a liquid spraying pipe, an installation plate, a separating rack, a liquid sucking device, a medicine holding box and a control box; the rack is provided with two sets of push rods, multiple sets of front supporting columns and multiple sets of rear supporting columns; therear supporting columns are provided with reversing wheels; the front supporting columns are provided with walking wheels; the lower end surface in the forward direction of the rack is successively provided with the separating rack and an elevating assembly for driving the installation plate to move up and down side by side; the installation plate is rotatably provided with multiple rotating shafts; the rotating shafts are in transmission connection with each other and are in transmission connection with a driving device; the rotating shafts are provided with cutting knives; the liquid holding box communicates with the liquid spraying pipe on the rack through the liquid sucking device; the liquid spraying pipe is provided with nozzles; a battery pack and a controller are arranged in the control box; the controller respectively controls the driving device and the liquid sucking device and is electrically connected to the battery pack and a main switch; and the main switch is arranged on any set of the push rods. The weeding device is simple in operation and convenient in using, and can efficiently and rapidly cut weeds.

Owner:刘深

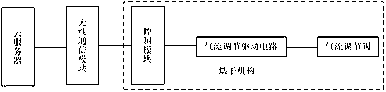

An automatic paint drying system

ActiveCN108405286BHigh degree of automationGuaranteed smoothAntenna supports/mountingsPretreated surfacesInformation transmissionComputer module

The invention belongs to the technical field of automation, and particularly relates to a painted-face automatic drying system. The painted-face automatic drying system comprises a cloud server, a drying mechanism and a wireless communication module used for information transmission between the cloud server and the drying mechanism. The cloud server is suitable for storing painted-face informationof a workpiece and drying parameters corresponding to the painted-face information, and sending drying instruction information to the drying mechanism through the wireless communication module so asto control the drying mechanism to dry the paint-sprayed face of the workpiece. The automatic degree of the painted-face automatic drying system is increased, and manual work is effectively avoided.

Owner:江苏睿中轨道交通装备有限公司

Safe tempered glass film hardness detection equipment

PendingCN113909131AEasy to addEasy to storeSortingInvestigating material hardnessFixed frameToughened glass

The invention relates to safe tempered glass film hardness detection equipment. The safe tempered glass film hardness detection equipment comprises a detection box, wherein a fixing frame is fixed to the middle of the upper end of the detection box, a first air cylinder is fixed to the upper end of the fixing frame, a telescopic part of the lower side of the first air cylinder penetrates through the fixing frame and is fixedly provided with a detection head, and a pressure sensor is fixedly embedded in the lower portion of the detection head; and a limiting groove is fixedly welded to the upper portion in the detection box. According to the safe tempered glass film hardness detection equipment, through cooperation of the limiting groove, a detection seat and detection grooves, workpieces are conveniently stored, and the situation that the workpieces slip from the limiting groove when not detected is avoided; through the first air cylinder, the detection head and the pressure sensor, pressure is conveniently applied to the workpieces, the hardness testing is conveniently conducted on the workpieces, and the pressure applied to the workpieces can be accurately controlled through the pressure sensor; and through contact sensors in the detection grooves, unqualified products can make contact with the contact sensors conveniently when damaged by the specified pressure, so that the unqualified products can be detected.

Owner:瑞容光电科技(江苏)有限公司

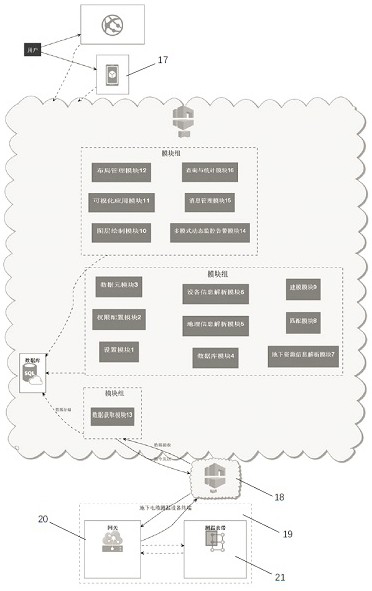

Power cable visual monitoring and maintenance management system based on GIS

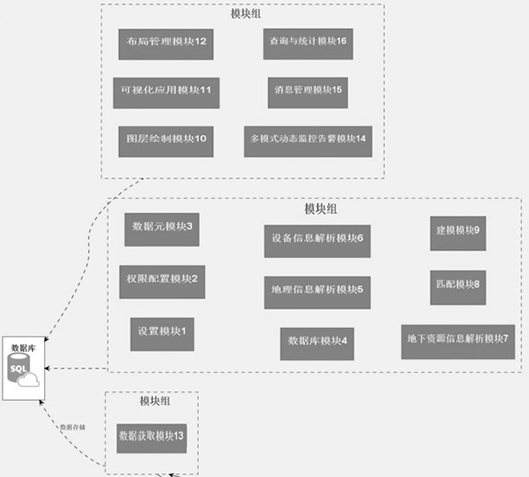

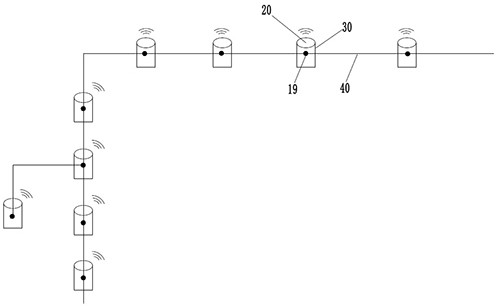

PendingCN114065955AConducive to follow-up planningEasy constructionThermometer detailsData processing applicationsInformation analysisDynamic monitoring

The invention relates to a power cable visual monitoring and maintenance management system based on a GIS, and the system comprises a cloud system, an Internet of Things platform, a database, an underground cable temperature measurement terminal, a setting module, an authority configuration module, a data element module, a database module, a geographic information analysis module, a device information analysis module, an underground resource information analysis module, a matching module, a modeling module, a layer drawing module, a visual application module, a layout management module, a data acquisition module, a multi-mode dynamic monitoring alarm module, a message management module. and a query and statistics module. According to the invention, the information of all underground power cable devices in the current environment can be visually and accurately restored, so that the maintenance work is more efficient and orderly, the low-efficiency and high-error manual operation in the process of matching the geographic information and the device information is avoided, and the subsequent planning and construction of overall power cable wiring are facilitated.

Owner:浙江徕米物联网科技有限公司

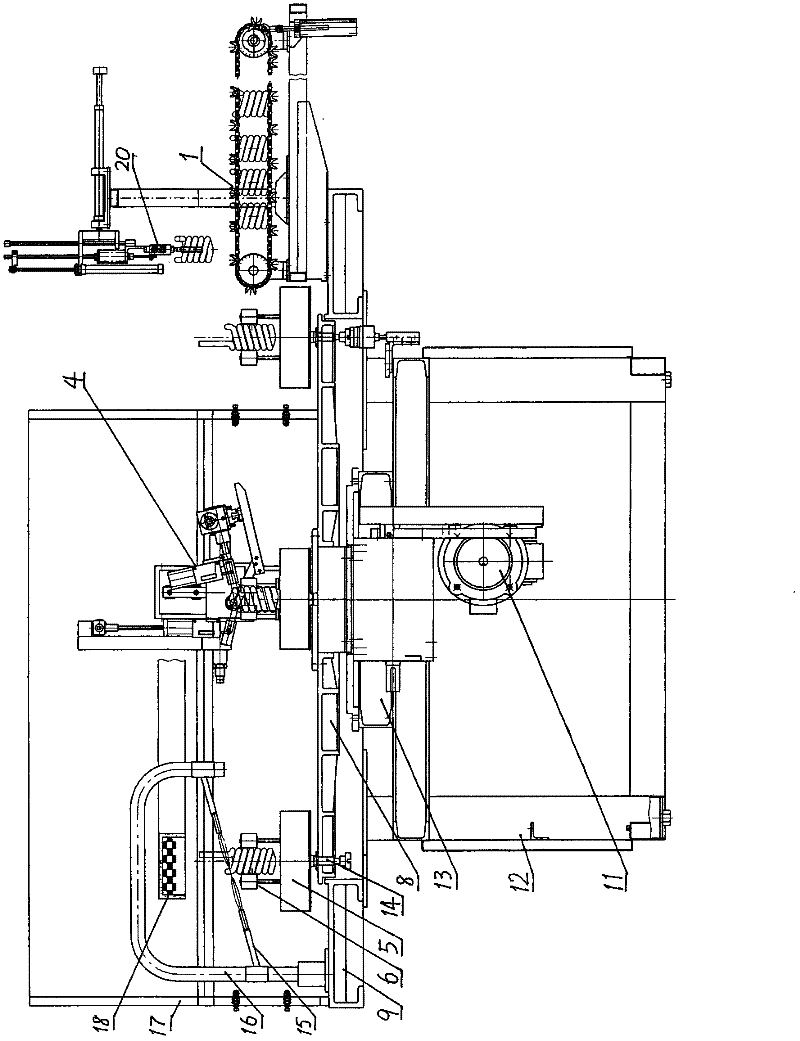

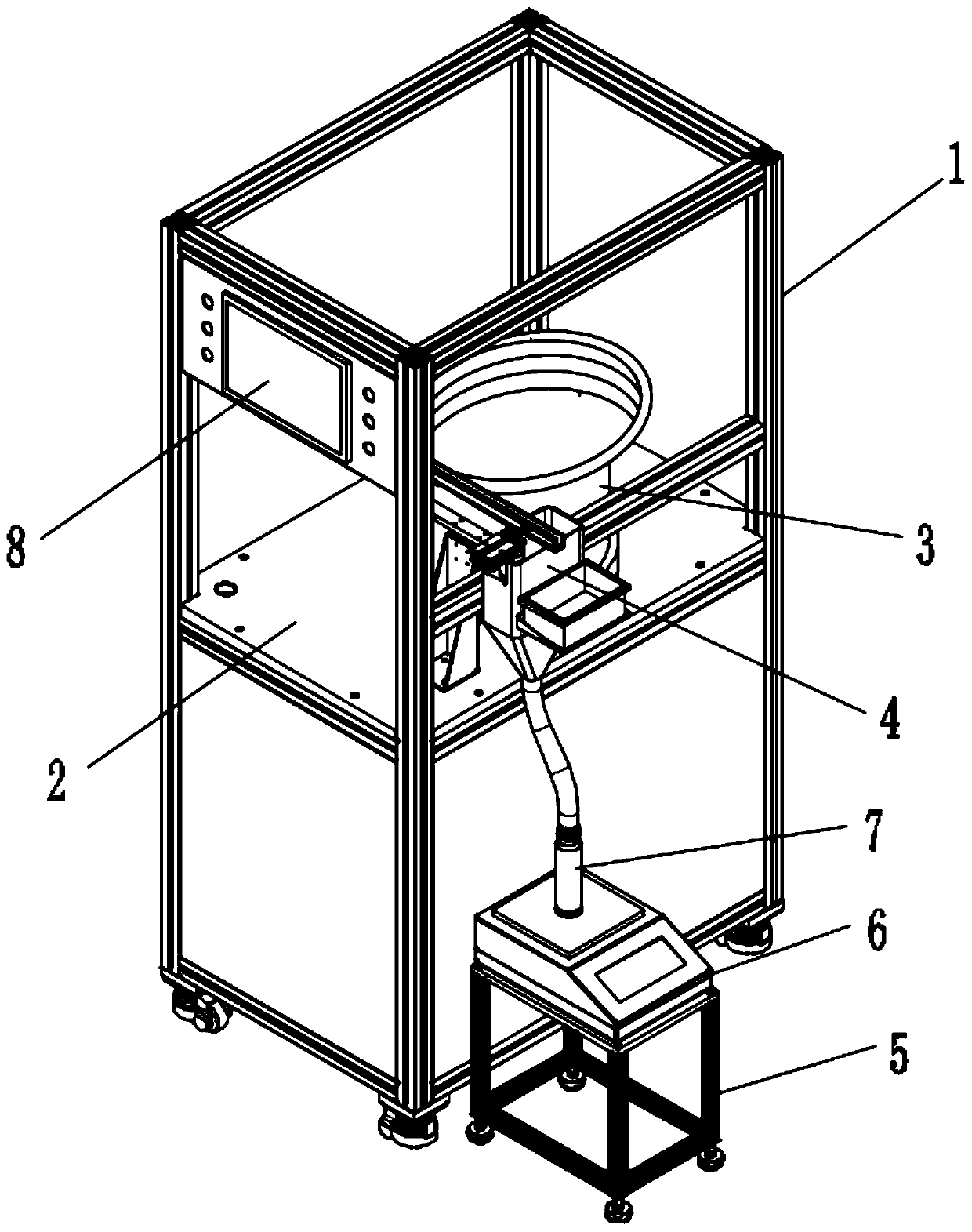

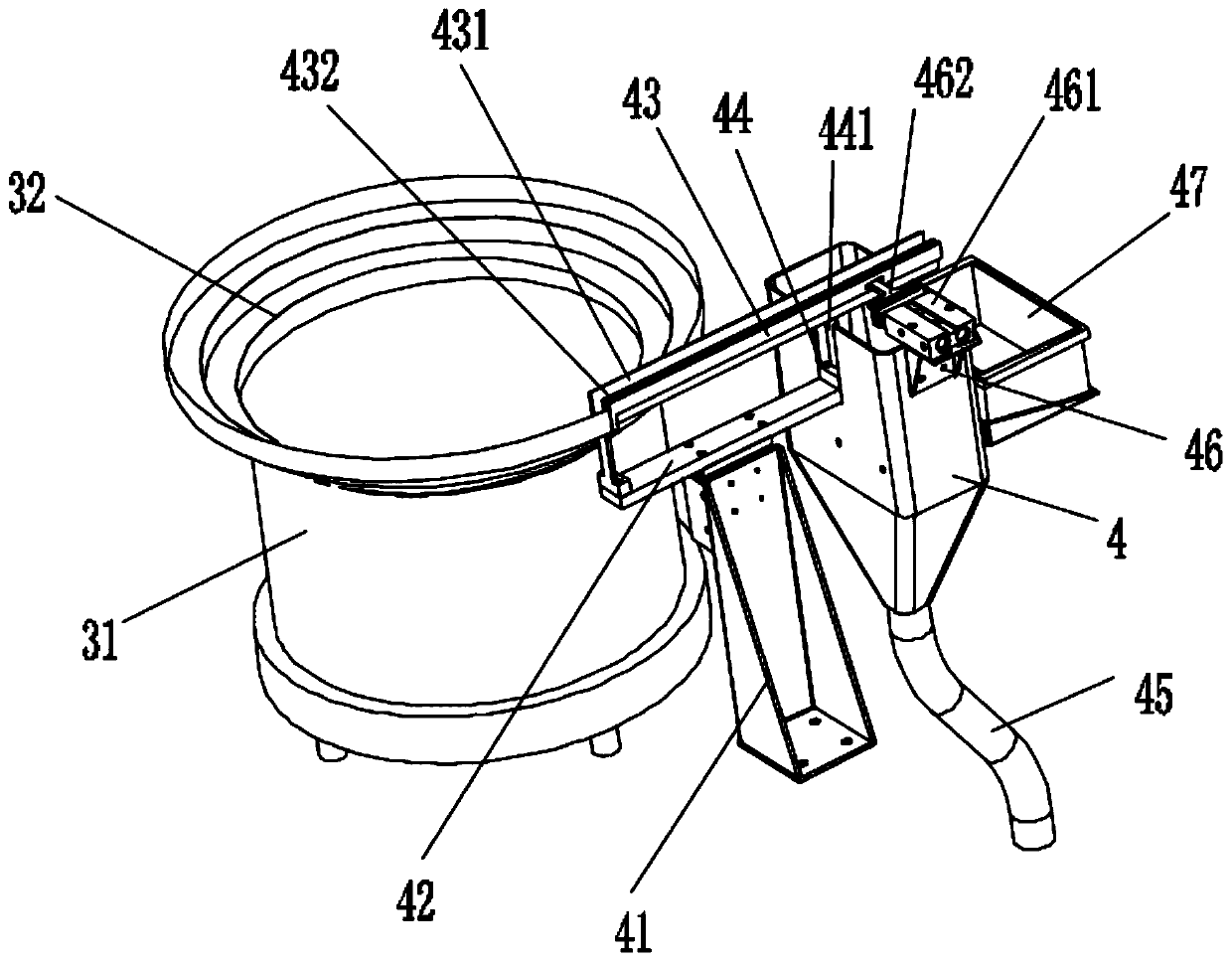

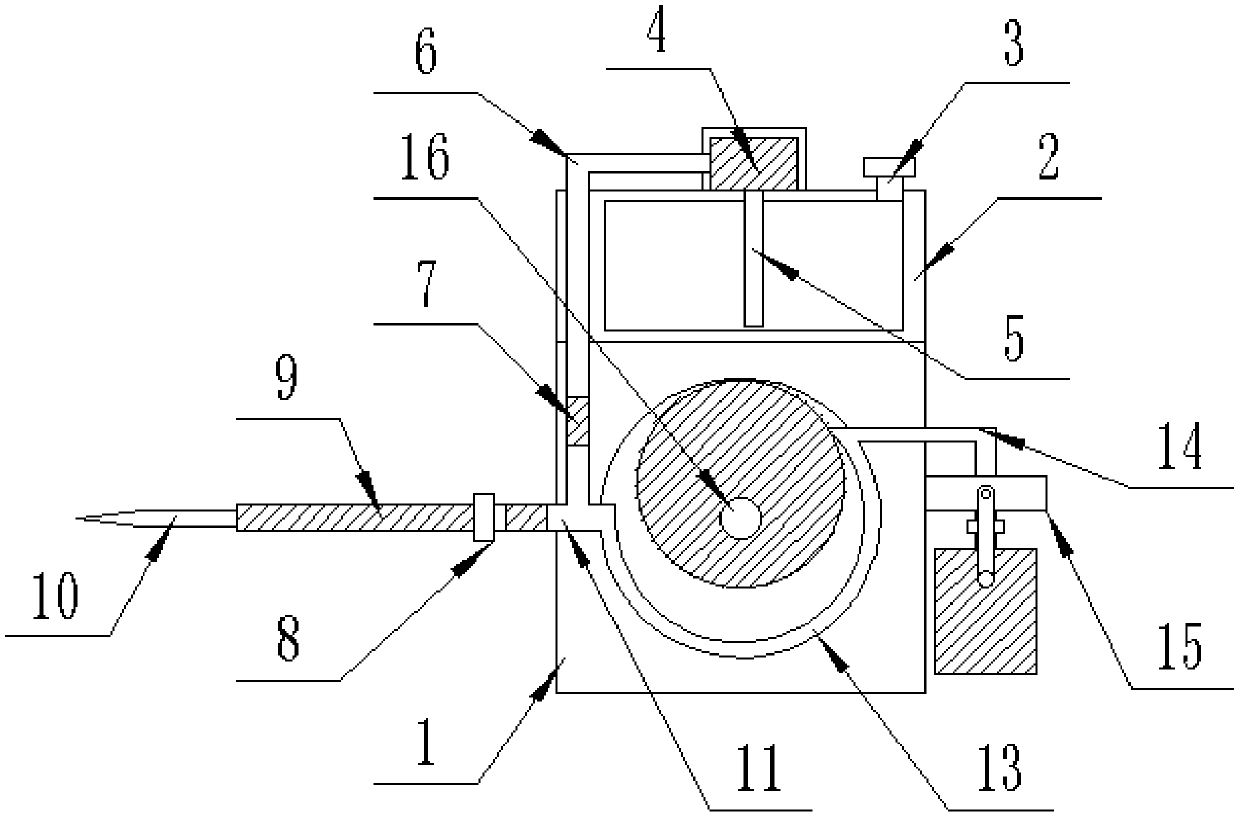

Propellant gamma weighing and loading machine

PendingCN110736386AGuaranteed charging accuracyAchieve precision assemblyAmmunition loadingWeighing apparatus with automatic feed/dischargeEngineeringCartridge

The invention discloses a propellant gamma weighing and loading machine. The propellant gamma weighing and loading machine comprises a rack, a supporting frame and a cartridge case, and further comprises a vibrating distributing mechanism and a charging barrel which are arranged in the rack, wherein the charging barrel is provided with a pouring mechanism, a collecting box and a barrier assembly,the charging barrel is connected with the vibrating distributing mechanism through the pouring mechanism, the collecting box is fixedly installed on the surface of one side of the charging barrel, thecollecting box is communicated with the charging barrel, and the charging barrel is located on the outer side of the vibrating distributing mechanism. The lower end of the charging barrel is communicated with a material pipe, and the supporting frame is provided with a weighing device. According to the propellant gamma weighing and loading machine, materials are arranged through a vibrating material plate, granular propellants are vibrated into a coarse feeding channel and a fine feeding channel through a spiral sliding way, the propellant loading precision is ensured, when the propellant loading precision reaches a set value, the fine feeding channel is closed, weighing and loading of the propellants are completed, and therefore, precise assembly of the cartridge case and the propellantsis achieved. In the machine, coarse feeding and fine feeding are achieved, manual operation is replaced, the labor intensity is reduced, the production efficiency is improved, and manual operation ina hazardous process is avoided.

Owner:HUNAN JUNCHENG TECH

A vibration compaction method for foundation pit backfilling sand

ActiveCN105064372BAvoid manual workImprove working environmentEmbankmentsExcavationsPurlinPull force

The invention discloses a vibration-compacting method for foundation pit backfill sand, which comprises the following steps: 1) driving steel sheet piles; 2) supporting a pair of steel sheet piles through purlins and support rods; 3) excavating the foundation pit; 4 ) The pipe gallery structure construction is placed in the foundation pit; 5) The sides and top of the pipe gallery are backfilled with sand; 6) The backfilled sand in the foundation pit is filled with water for preliminary compaction; 7) The purlins and support rods are removed; 8) Vibration hammer is used Clamp the steel sheet pile, pull out the steel sheet pile by vibration, and use the vibration force of the pile to compact the backfill sand; 9) Check the density of the backfill sand at one time; 10) Backfill the surface soil and complete the project. The use of mechanical compaction instead of manual compaction avoids manual work in poor environments and improves the working environment; one-time backfilling of sand reduces multiple conversions of processes, speeds up the construction progress, saves layered inspections, and reduces costs.

Owner:CCCC SHEC FOURTH ENG +1

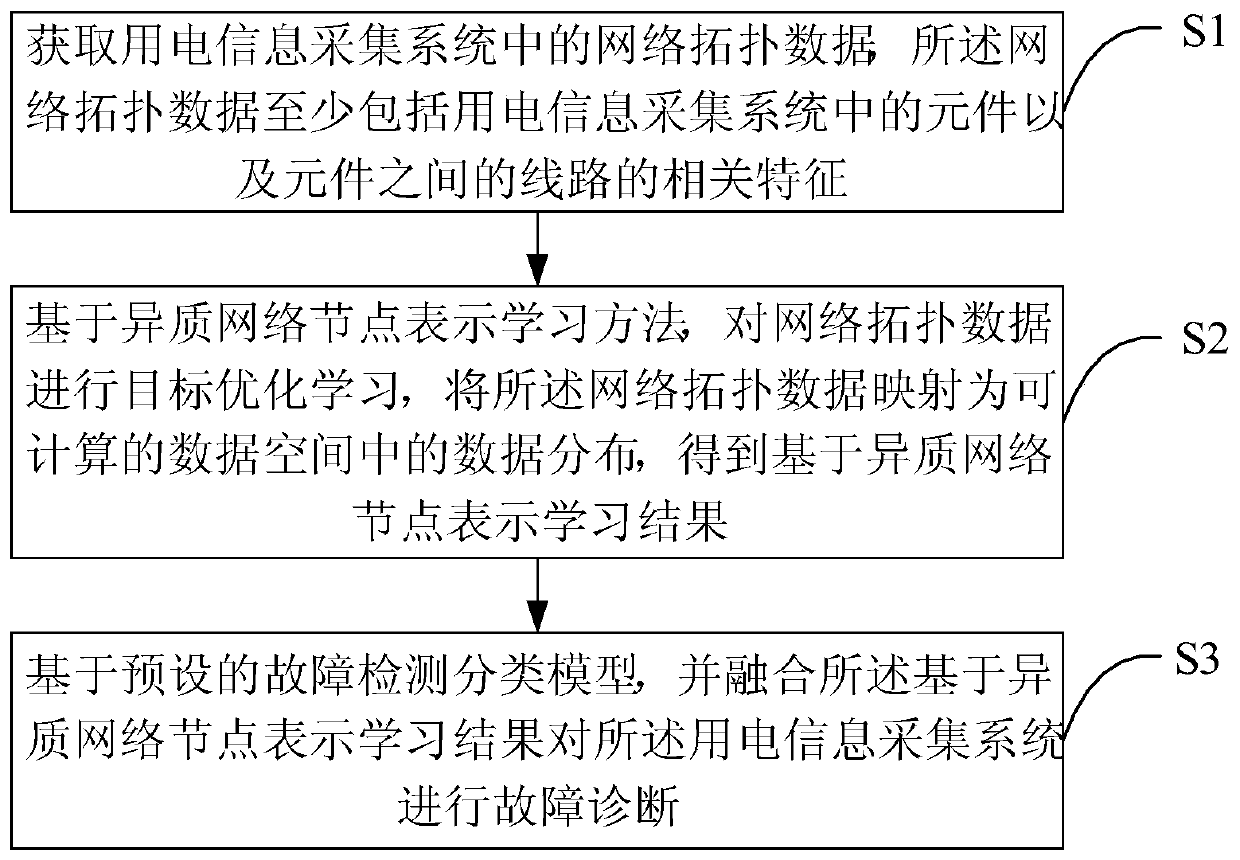

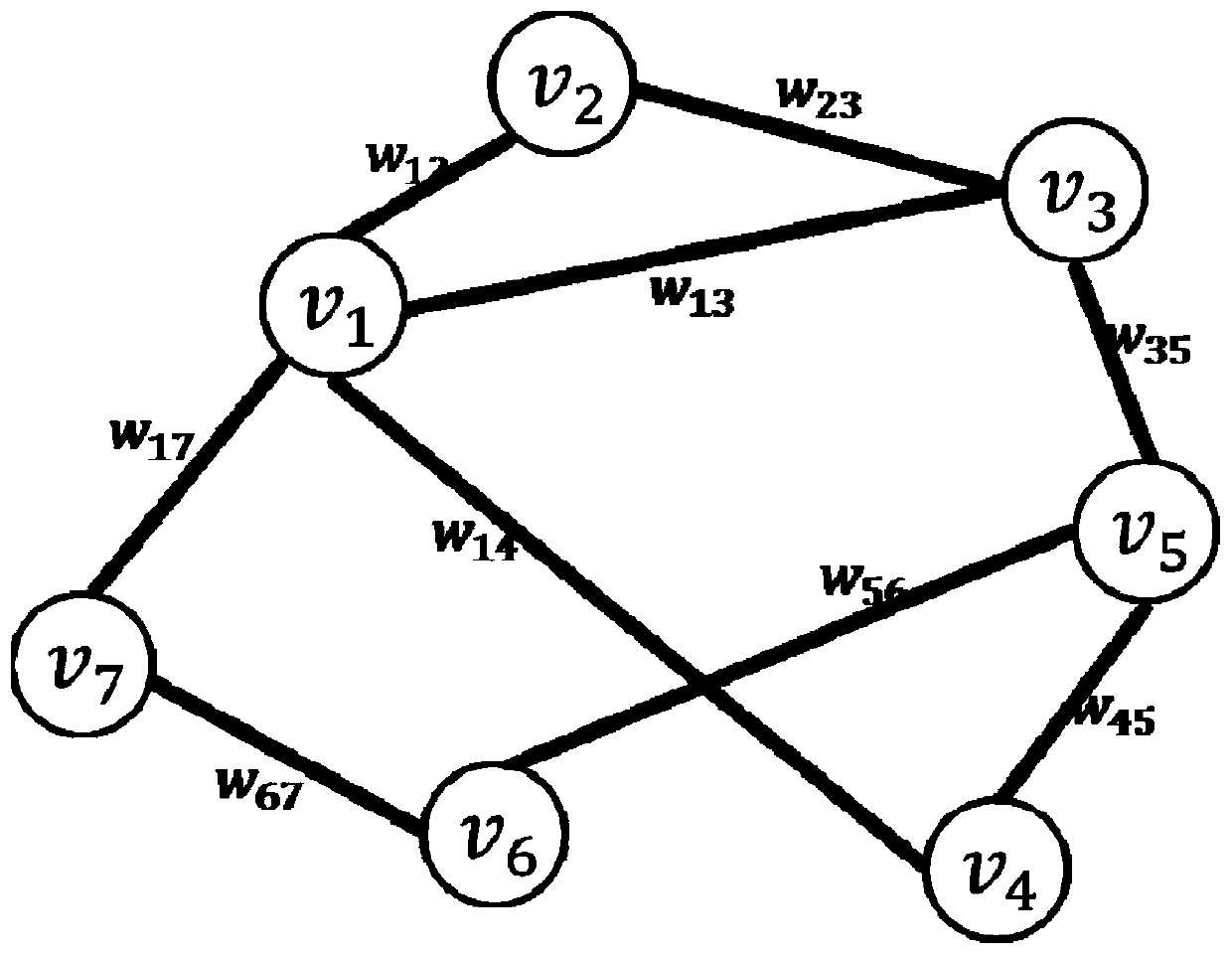

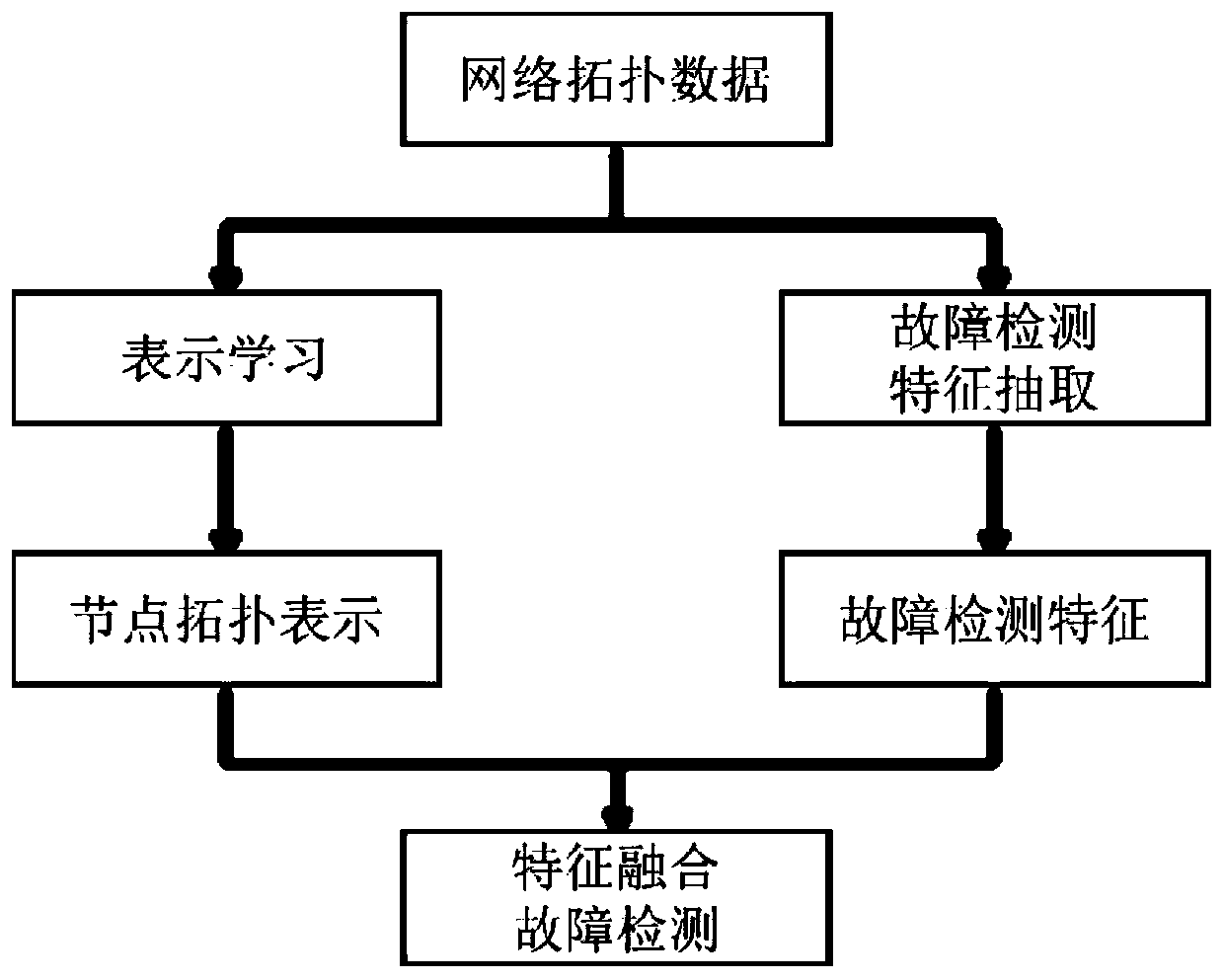

Fault diagnosis method and fault diagnosis device for power consumption information collection system

ActiveCN107016410BLow costImprove adaptabilityCharacter and pattern recognitionDiagnosis methodsData space

The invention discloses a fault diagnosis method and device for an electricity consumption information collection system. The method includes the following steps: acquiring network topology data in the electricity consumption information collection system, the network topology data at least including components and components in the electricity consumption information collection system The relevant characteristics of the lines between them; based on the heterogeneous network node representation learning method, the target optimization learning is performed on the network topology data, and the network topology data is mapped to the data distribution in the computable data space, and the learning based on the heterogeneous network node representation is obtained. Results: Based on the preset fault detection and classification model, and integrating the learning results based on heterogeneous network node representation, the fault diagnosis of the power consumption information collection system is carried out. The present invention avoids a large amount of manual work, reduces the cost of system implementation, and improves the adaptability of the system to new data; and in terms of computing system, the related methods designed in this scheme are compatible with the feature modules in the traditional method, which greatly improves the performance of the system. performance.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO ELECTRIC POWER RES INST +3

Tower tea bag threading method and device

The invention relates to a tower tea bag threading method and device. The tower tea bag threading device mainly comprises a cotton thread roll and a threading device connected with the cotton thread roll, wherein the cotton thread roll provides rolled cotton threads; the cotton thread is downwardly connected with a pneumatic chuck via a limiter and a roller; an internal rocker arm and an external rocker arm are arranged in a knot molding machine connected with the cotton thread; the internal rocker arm and the external rocker arm are connected with each other by a shaft; the inner rocker arm is positioned on the internal side of the external rocker arm; a cutting knife is arranged at the upper end of the pneumatic chuck; a lower chuck is arranged at the lower end of the pneumatic chuck; and the lower chuck is mounted on a first cylinder. The tower tea bag threading method and device, provided by the invention, have the following advantages that: (1) compact structure is obtained; and all functions of cotton thread connection and fixation are finished through limited actions; (2) requirements on the speed and accuracy matched with the machine are satisfied; and (3) high automation degree is obtained so that the problem of a lot of manual operations is effectively solved and consistency and standard rate of the product quality are assured.

Owner:中华全国供销合作总社杭州茶叶研究院 +1

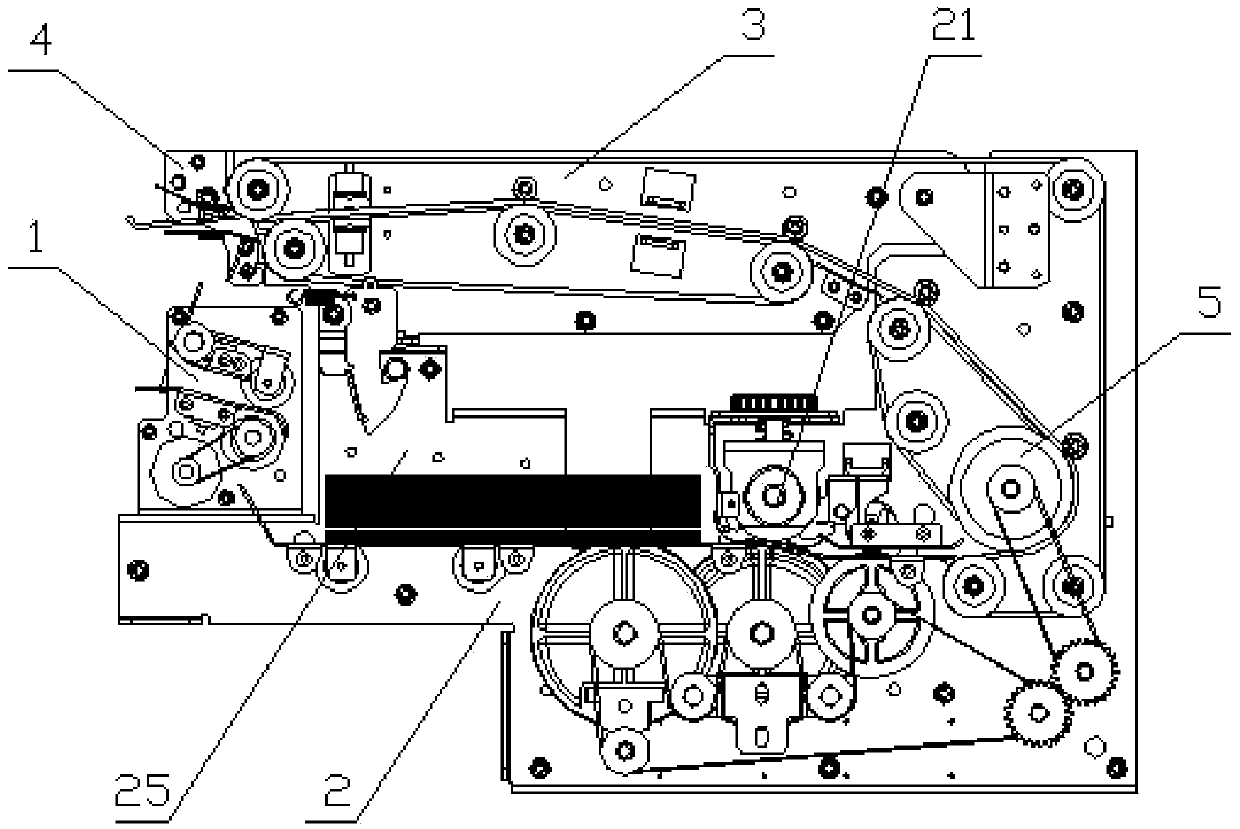

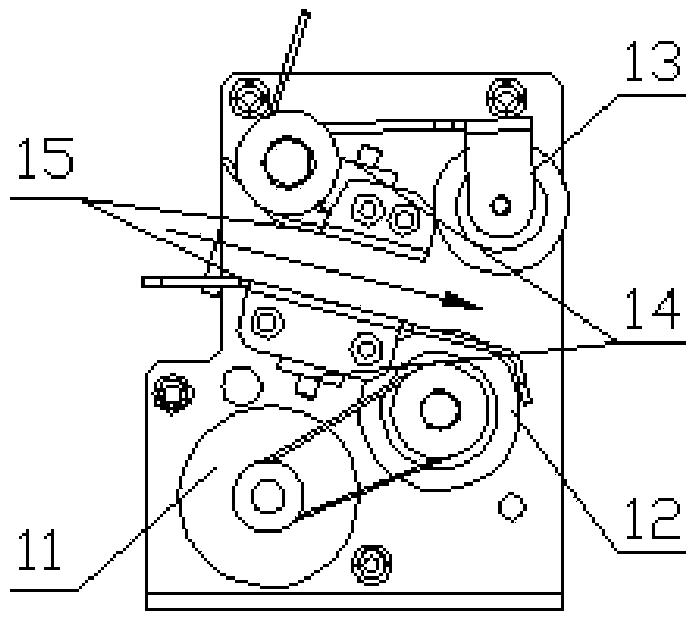

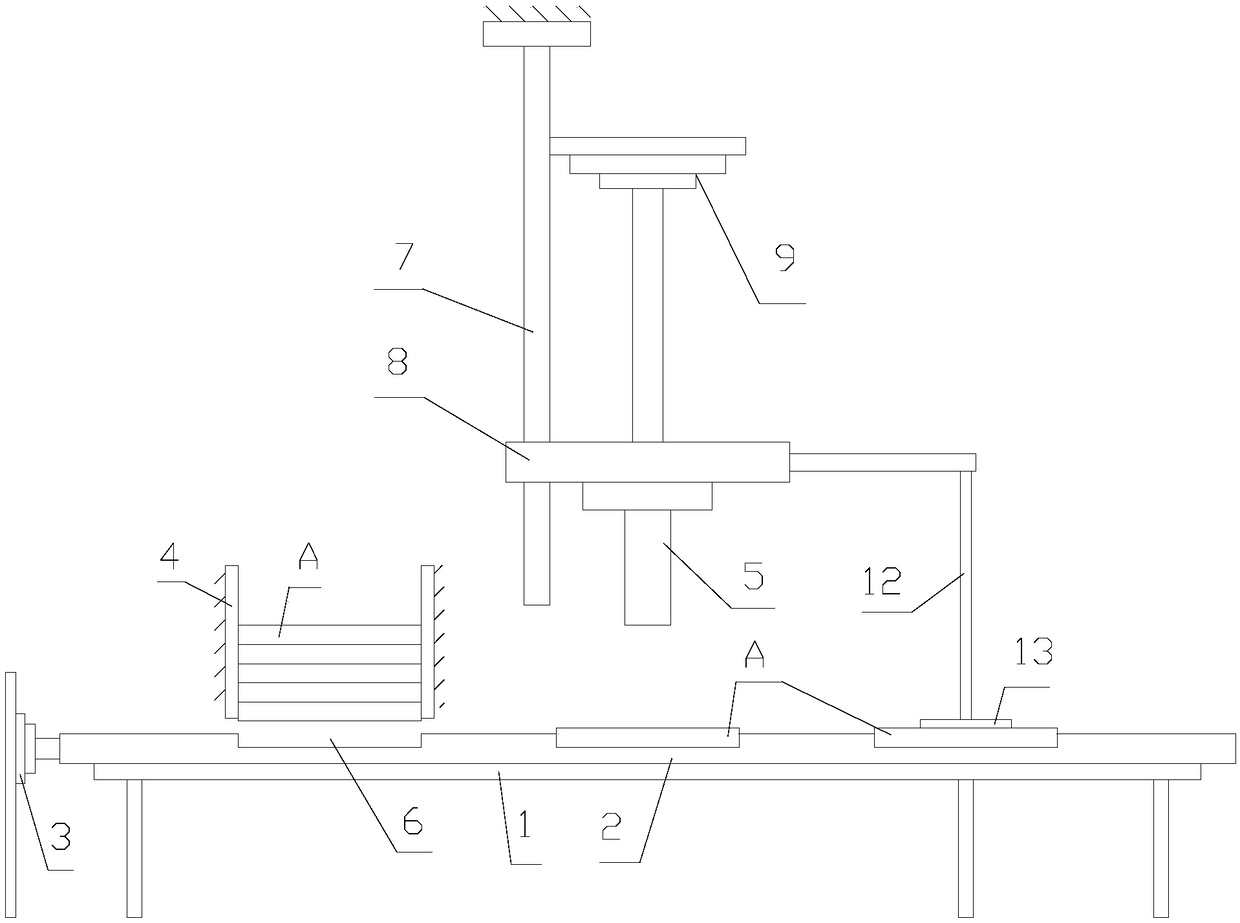

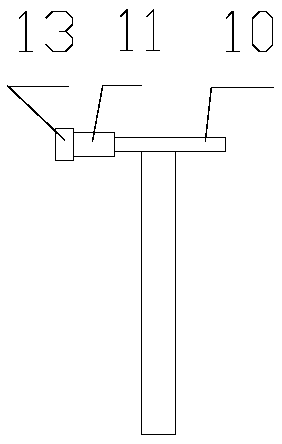

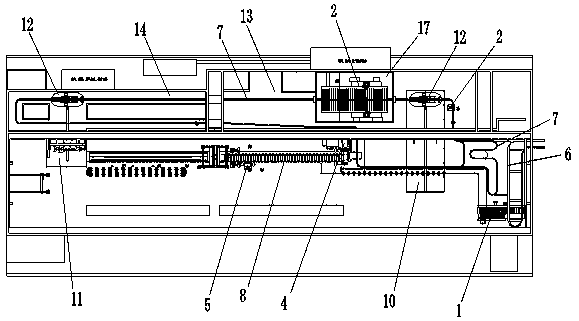

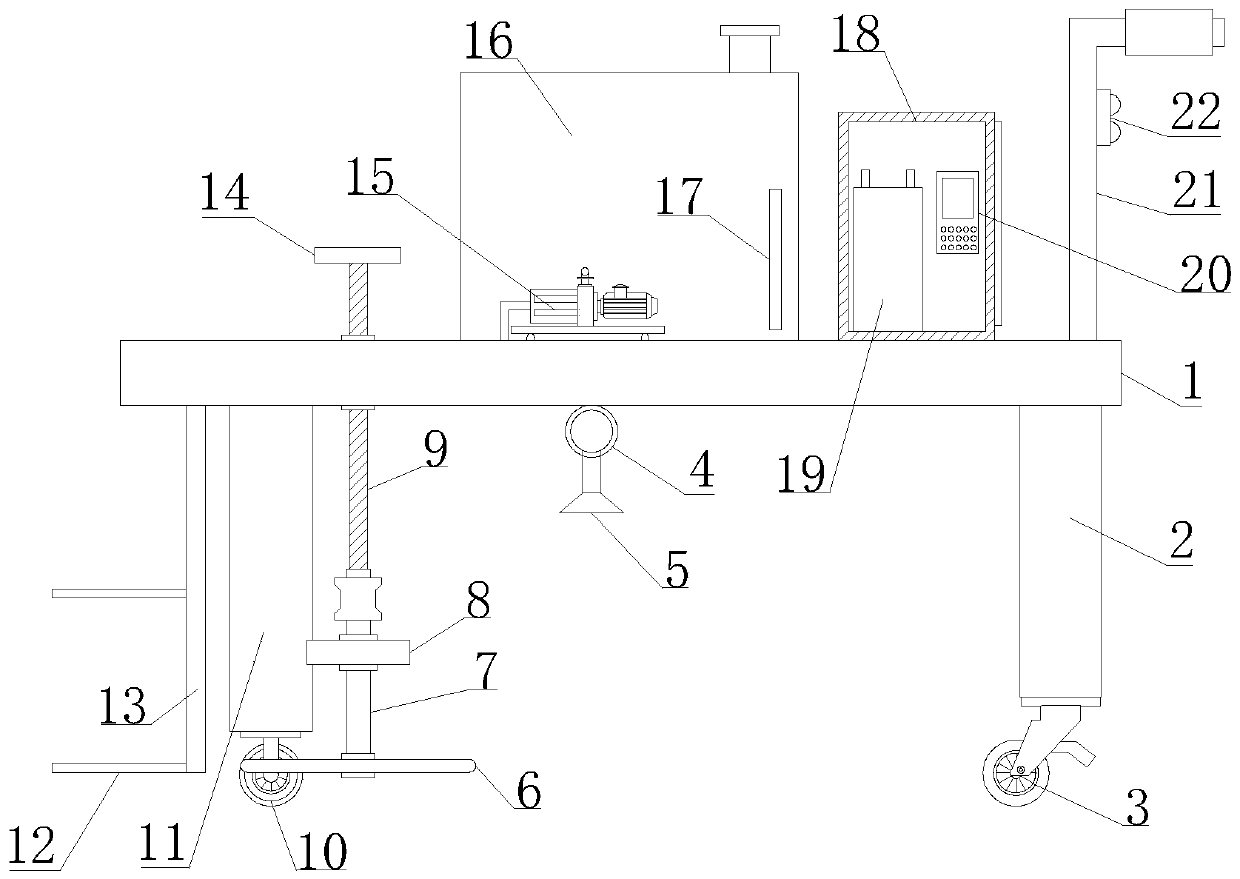

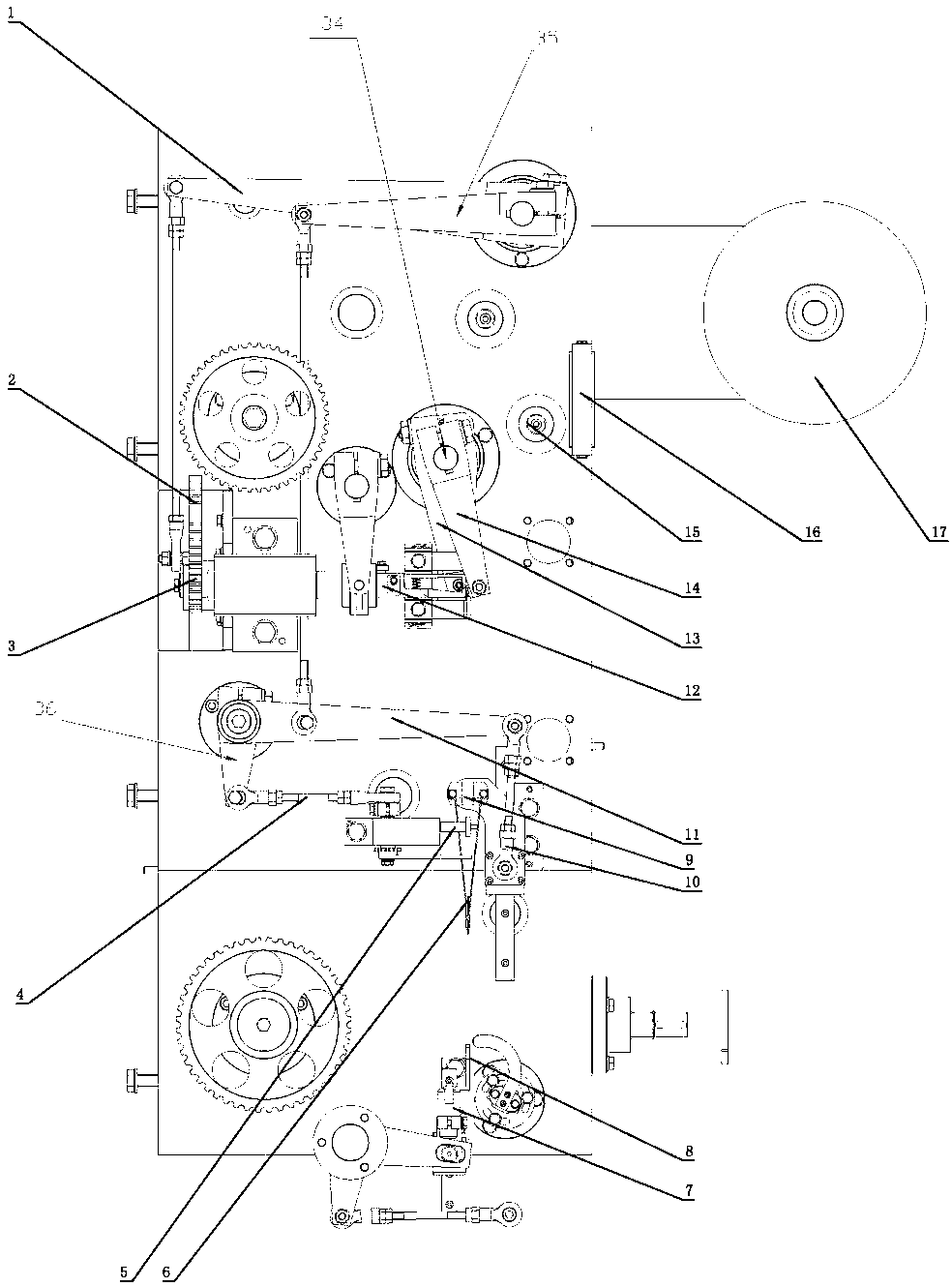

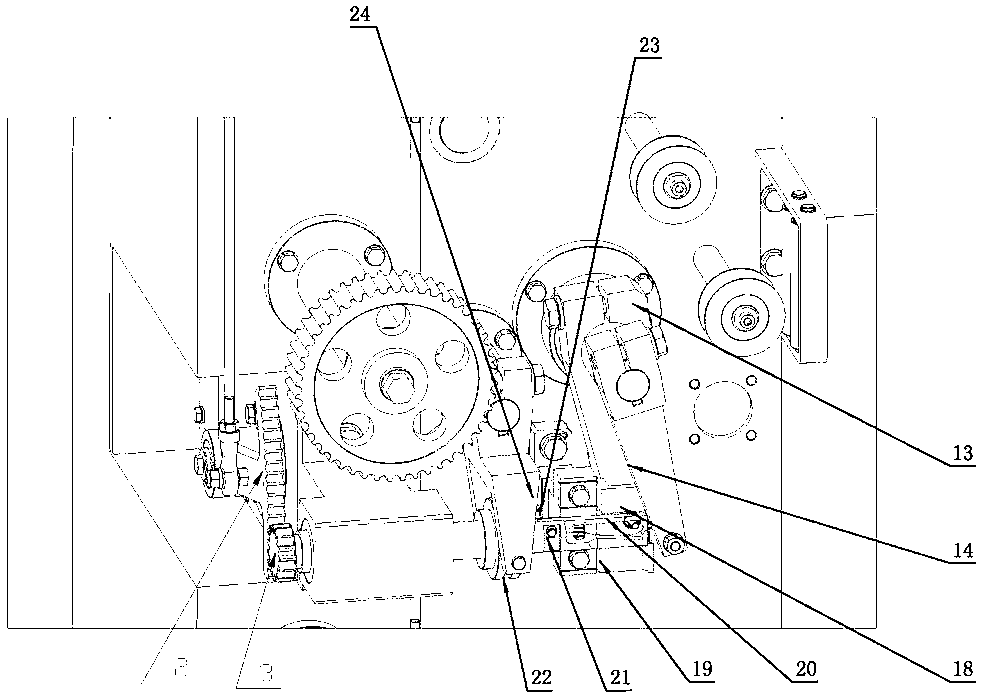

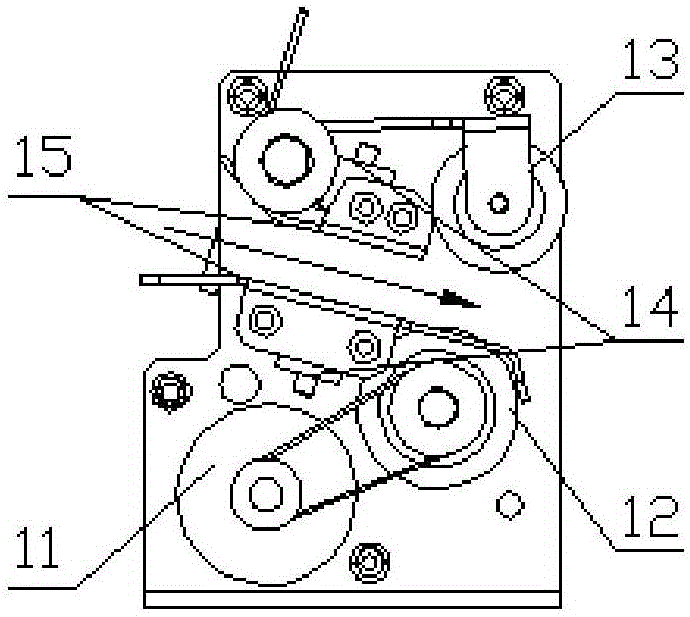

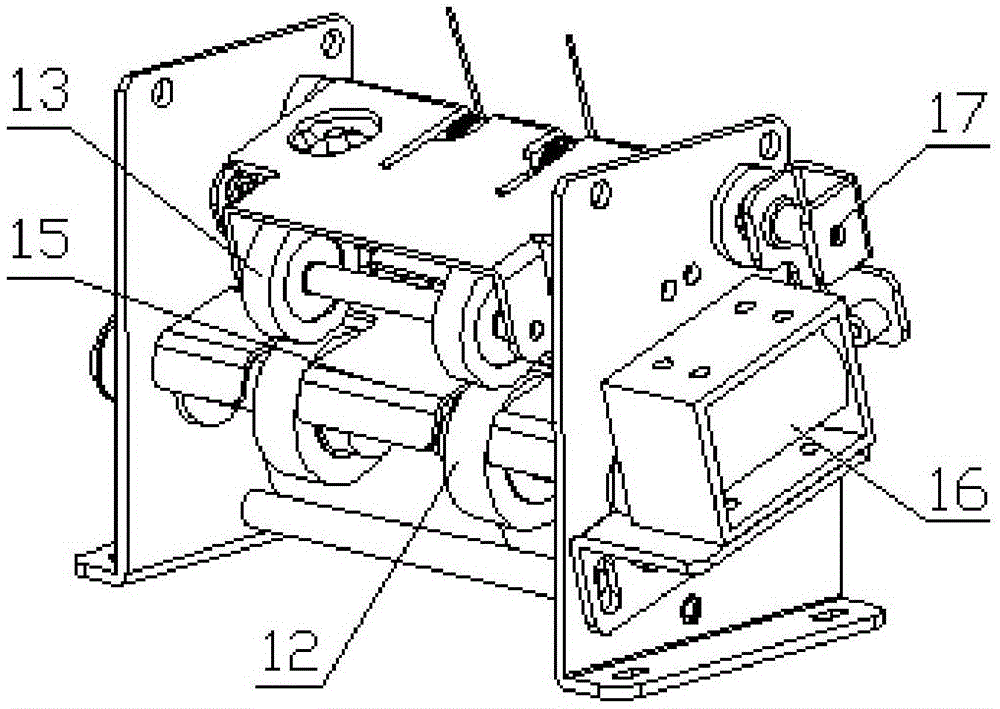

An automatic cycle test machine for banknote acceptors

ActiveCN103745524BAvoid manual workImprove work efficiencyCoin/currency accepting devicesCyclic testPulp and paper industry

The invention discloses an automatic circular testing machine tool for a paper currency receiving machine. The automatic circular testing machine tool comprises a machine body, wherein the machine body is provided with a paper currency receiving hole, a paper currency storing cabin, a single paper currency twisting device, a paper current conveying mechanism and a paper currency conveying hole, wherein the paper currency receiving hole is used for receiving a paper currency rejected from a paper currency rejecting hole of the paper currency receiving machine and conveying the paper currency to the top of piled paper currencies in the paper currency storing cabin; the single paper currency twisting device is used for twisting a single paper currency away from the bottom of the piled paper currencies in the paper currency storing cabin and conveying the paper currency into the paper currency conveying mechanism; the paper currency conveying mechanism is used for conveying the paper currencies to the paper currency conveying hole; the paper currency conveying hole is used for conveying the paper currency into the paper currency receiving hole of the paper currency receiving machine. By adopting the automatic circular testing machine tool, paper currency receiving, authentication, rejection and the like can be finished automatically, manual work is replaced, a large amount of simple and repeated manual work is avoided, and the working efficiency is increased.

Owner:浙江众合科技股份有限公司

an assembled structure

ActiveCN112693912BRealize automatic loading and unloadingAvoid damageLoading/unloadingConveyor partsVehicle frameElectric control

The present invention is applicable to the field of mobile assembly technology, and provides an assembly combination structure, including: a placement room; a placement rack, installed inside the placement room; a mobile box insertion vehicle, used for grabbing, transporting and transferring components ; The fixed platform truck is detachably docked with the placement room to form a walking channel; the material receiving conveyor line is connected to the fixed platform truck; the electric control box is connected to the fixed platform truck, the material receiving conveyor line and the mobile box insertion vehicle , used to control the input, grabbing, transportation and transfer of components; among them, the mobile box insertion vehicle includes: a frame for support and installation; roller clamping claws, which can be lifted and lowered on the frame for Grabbing and output of components; walking structure, installed on the bottom of the frame, used to drive the frame to move; lifting mechanism, installed on the frame, and connected with the roller clamping claw, used to drive the roller clamping claw to lift. The invention has the advantages of precise loading, high loading and unloading efficiency, good safety and effective prevention of wrong loading.

Owner:大捷智能科技(广东)有限公司

Hydrops processing device for oncology department

InactiveCN108671283AAvoid manual workReduce the use of laborHollow article cleaningIntravenous devicesWater storage tankWastewater

The invention discloses a hydrops processing device for the oncology department. The hydrops processing device comprises an extraction pump and a water storage tank and is characterized in that a first pipeline is horizontally arranged at the right end inside the extraction pump, a connecting block is arranged at the left end of the first pipeline, a plurality of soft tubes are horizontally evenlyarranged at the left end of the connecting block, a probe is arranged at the left end of each soft tube, the water storage tank is fixedly connected to the upper end of the extraction pump, a water inlet is vertically fixedly connected to the upper end of the right side of the water storage tank, a water pump is fixedly connected to the center of the upper end of the water storage tank, and the right end of the fourth pipeline penetrates the extraction pump. The hydrops processing device has the advantages that after the device is used, an indicating arrow is rotated to point at a right aboveposition to allow a grinding wheel to be located at a right above position so as to guarantee the smoothness of an arc-shaped rubber pipe, liquid storage bags and the soft tubes are taken down by utilizing hollow screws, then the water pump is started, the water pump sucks out cleaning liquid through a second pipeline and injects the cleaning liquid into the arc-shaped rubber pipe through a thirdpipeline to perform cleaning, wastewater is discharged through the fourth pipeline, and new liquid storage bags and soft tubes can be conveniently replaced to prevent infection.

Owner:THE FIRST AFFILIATED HOSPITAL OF HENAN UNIV OF SCI & TECH

A method for automatically dispensing process lubricating liquid in the rolling of sheet, strip and foil materials

ActiveCN103042052BIncrease productivityAvoid manual workWork treatment devicesMetal rolling arrangementsEmulsionProcess engineering

The invention discloses an automatic liquid preparing device and method of a technological lubrication liquid in plate and strip foil calendering. The device comprises a mechanical portion and a control portion, the mechanical portion is used for performing liquid preparing to a corresponding technological lubrication liquid during plate and strip foil calendaring, the control portion is used for real-timely controlling the liquid preparing process of the mechanical portion on the corresponding technological lubrication liquid on the basis of monitored liquid level and flow quantity of the corresponding technological lubrication liquid, and the mechanical portion and the control portion are in a signal connection. By means of the automatic liquid preparing device and method of the technological lubrication liquid in plate and strip foil calendaring, defects that production efficiencies are low, manual labor intensity is large, product surface qualities are poor and energy consumption is high in prior art can be overcome so that production efficiencies are improved, manual labor intensity is reduced, product surface qualities are improved, energy consumption is reduced, simultaneously, personnel is prevented from directly contacting petrochemical materials of emulsion, rolling oil, additives and the like, and harm of petrochemical products to the personnel is prevented.

Owner:XINJIANG JOINWORLD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com