A vibration compaction method for foundation pit backfilling sand

A sand filling and compaction technology, which is applied in filling, excavation, infrastructure engineering, etc., can solve the problems of difficult control of manual work quality, low manual compaction energy, and narrow work space, and achieves uniform and reliable compaction quality. Layered detection, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Through the description of the embodiments, the specific implementation of the present invention will be further described in detail, so as to help those skilled in the art to have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

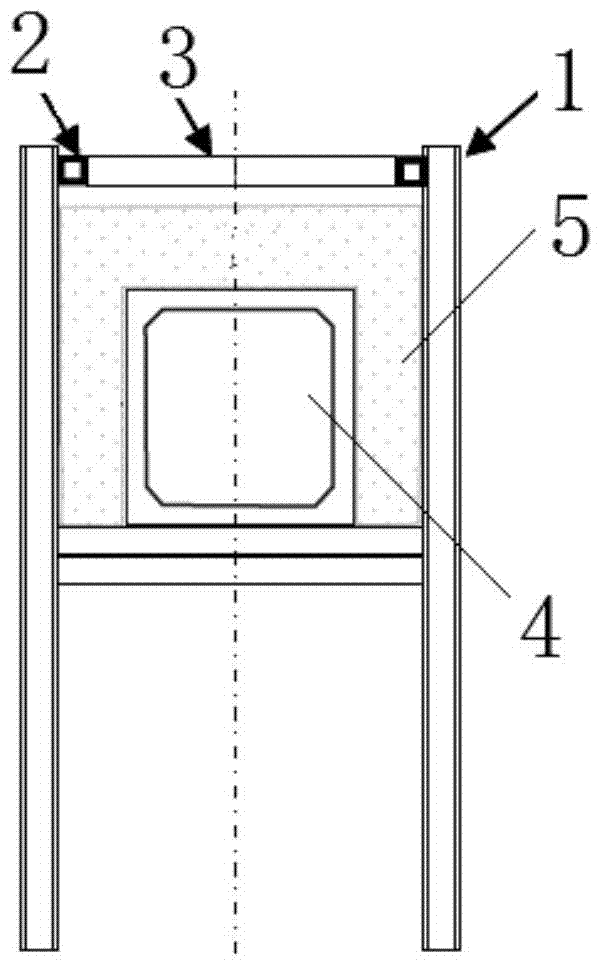

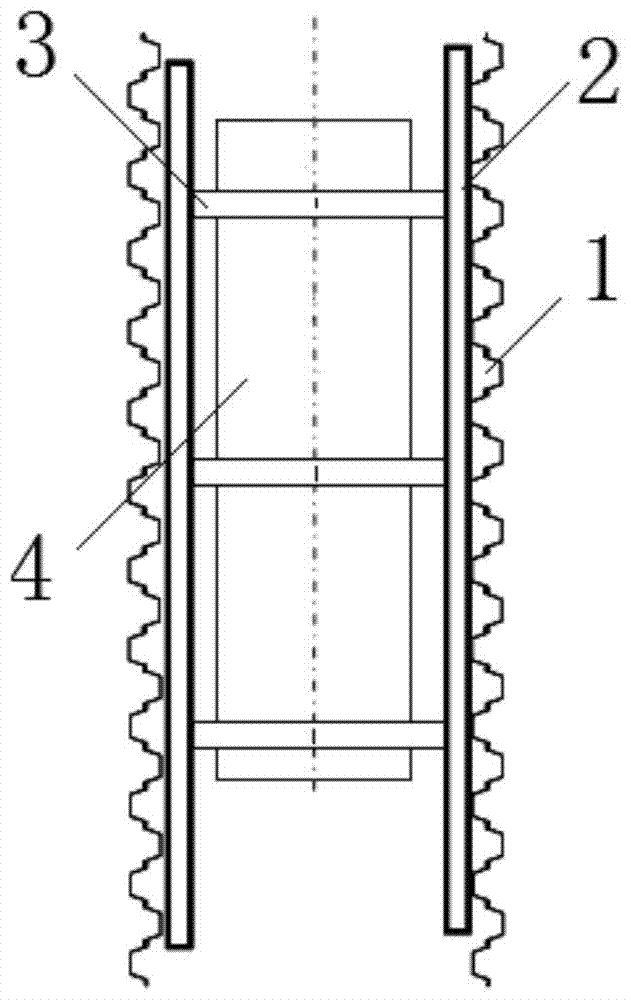

[0031] Such as figure 1 and 2 As shown, the foundation pit backfilling sand vibration compaction method includes the following steps: driving a pair of steel sheet piles 1 → supporting the pair of steel sheet piles through purlins 2 and support rods 3 → excavating the foundation pit → pipe gallery 4 structure The construction is placed in the foundation pit → waterproof the pipe gallery structure → backfill sand on both sides and the top of the pipe gallery 5 → pour water into the backfill sand in the foundation pit for preliminary compaction → remove the purlins and support rods → clamp the steel plate with a vibrating hammer Pile, pull out the steel sheet pile ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com