Tower tea bag threading method and device

The technology of threading device and tea bag is applied in the field of threading and device of tower type tea bag, which can solve the problems of high processing cost, low qualified rate of product quality, low degree of automation, etc., and achieves compact structure, high degree of automation, guaranteed consistency and qualified rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

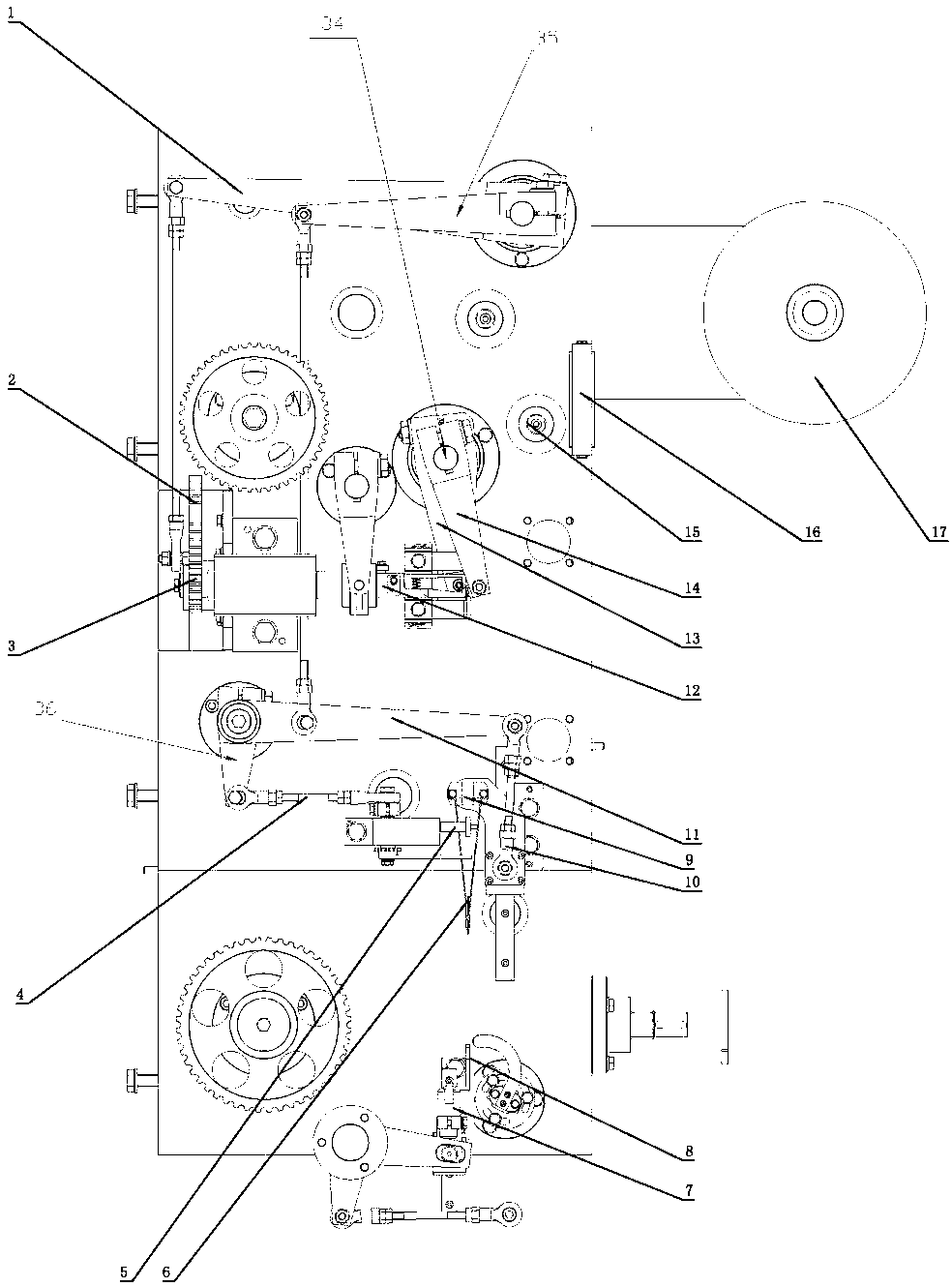

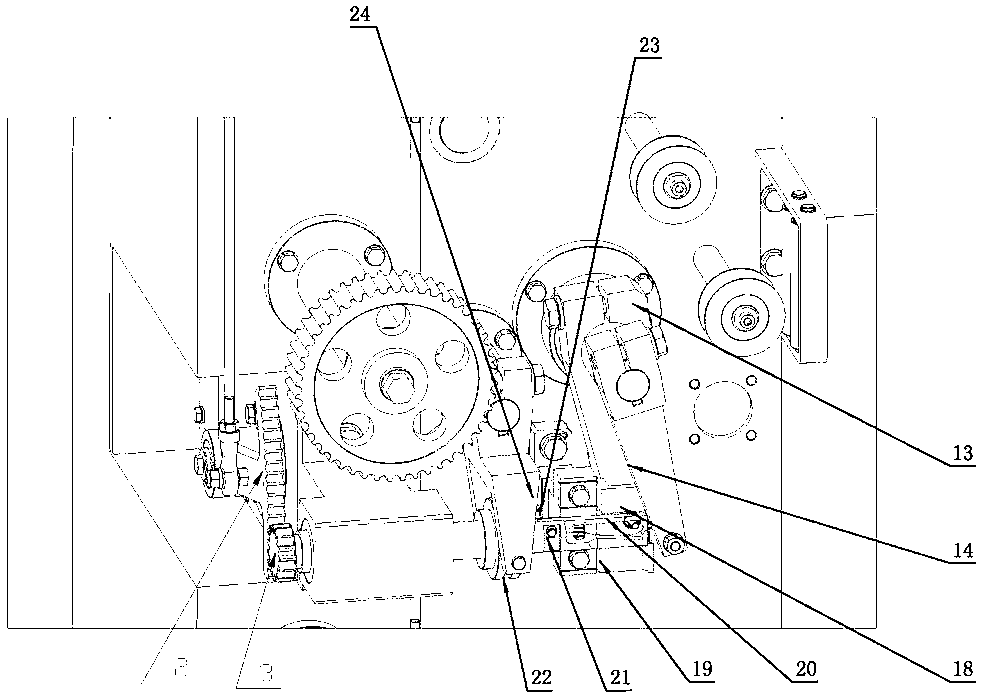

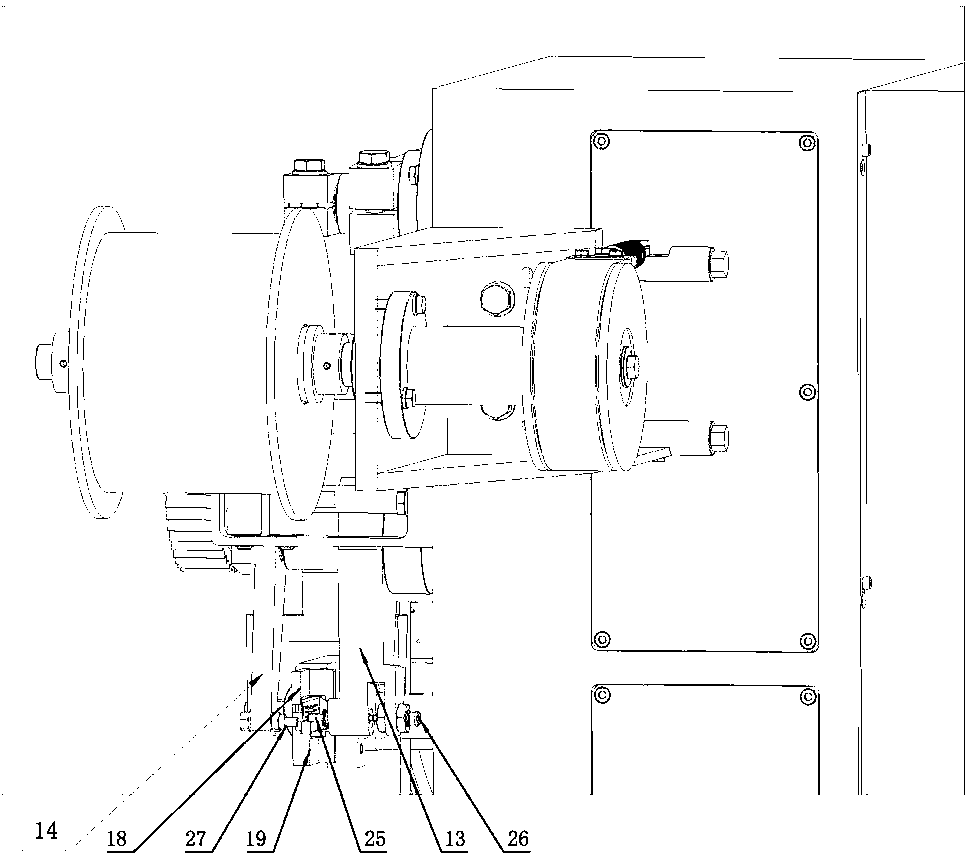

[0018] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention mainly consists of a cotton thread reel and a threading device connected to the cotton thread reel. The cotton thread reel 17 provides rolled cotton thread. Move down under traction. First, the cotton thread of fixed length enters the kink former 12. The kink is formed under the combined action of the inner rocker arm 13 , the outer rocker arm 14 and the shaft 34 . Because the lower end of pneumatic chuck 6 is the taper point of wrapping cotton thread, he will finish passing tea bag action. After the cotton thread is pulled by the fixed length of the pneumatic chuck 6, the cutting knife 9 moves to cut the cotton thread. After the pneumatic chuck 6 continues to pass through the tea bag downwards, it intersects with the lower chuck 8 installed on the first cylinder 7 waiting here. The lower chuck 8 clamps the lower end of the cotton...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com