Rotary worktable with self-locking function

A rotary table, self-locking technology, applied in the direction of the table, manufacturing tools, etc., can solve the problems of the table can not be rotated, reduce production efficiency, large area, etc., to facilitate workers to manually rotate the table, easy transportation and installation, Taking into account the effect of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

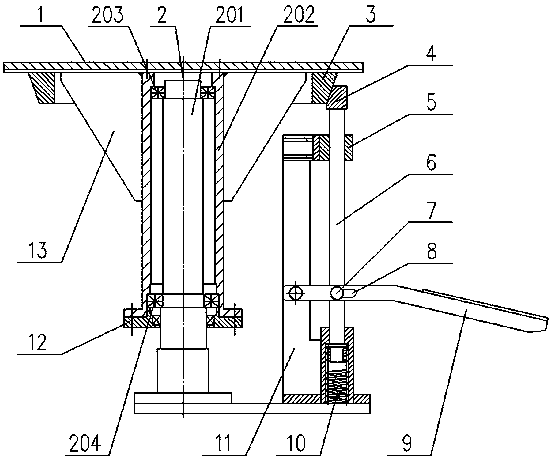

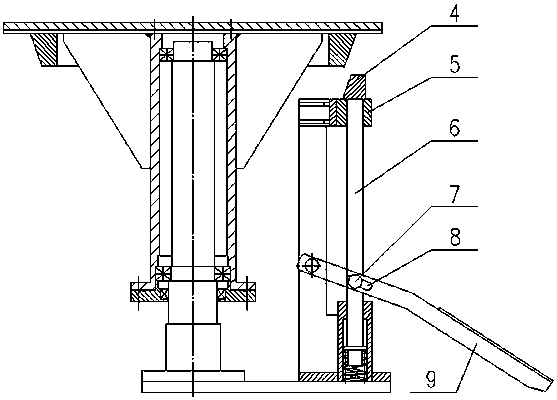

[0020] see figure 1 , 2 , 4. A rotary table with self-locking function, including a shaft 201 vertically installed on the base, a sleeve 202 is sleeved on the outer circumference of the shaft 201, and the axis centers of the sleeve 202 and the shaft 201 coincide and pass through The upper bearing 203 and the lower bearing 204 are supported and positioned, and the end of the sleeve 202 away from the base is equipped with a turntable plate 1 for placing parts, and the other end of the sleeve 202 is equipped with a sleeve end cover 12 to facilitate sealing and positioning; the turntable plate 1 It is a circular plate and the axis of the circular plate coincides with the axis of the sleeve 202 and the shaft 201. There are several lifting holes 14 on the upper end surface of the turntable plate 1, and several spaced holes are arranged on the outer circumference of the turntable plate 1. The handrail 15 is in order to manually rotate the turntable plate 1, and several reinforcing r...

Embodiment 2

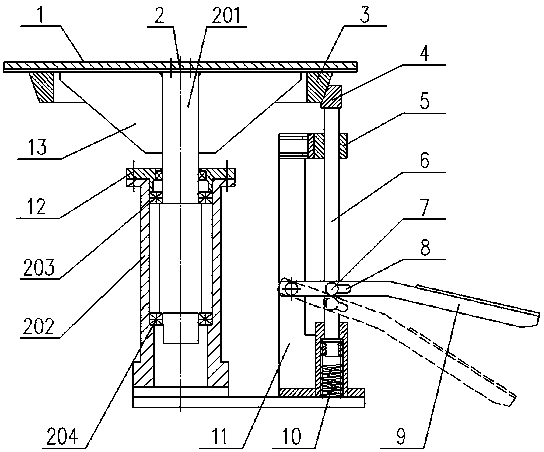

[0022] see image 3 , a rotary table with self-locking function, the difference from Embodiment 1 is that the sleeve 202 is installed vertically on the base, the shaft 201 is passed through the sleeve 202 and passes through the upper bearing 203 and the lower bearing 204 Supporting positioning, the turntable plate 1 is installed on the end of the shaft 201 away from the base, several reinforcing ribs 13 are installed between the bottom of the turntable plate 1 and the shaft 201, and the rest are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com