Circuit board low-temperature fault locating method and heating device thereof

A fault location and heating device technology, applied in the direction of single semiconductor device testing, etc., can solve the problems of high cost and difficult troubleshooting, achieve accurate positioning, avoid manual work, and achieve accurate temperature control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

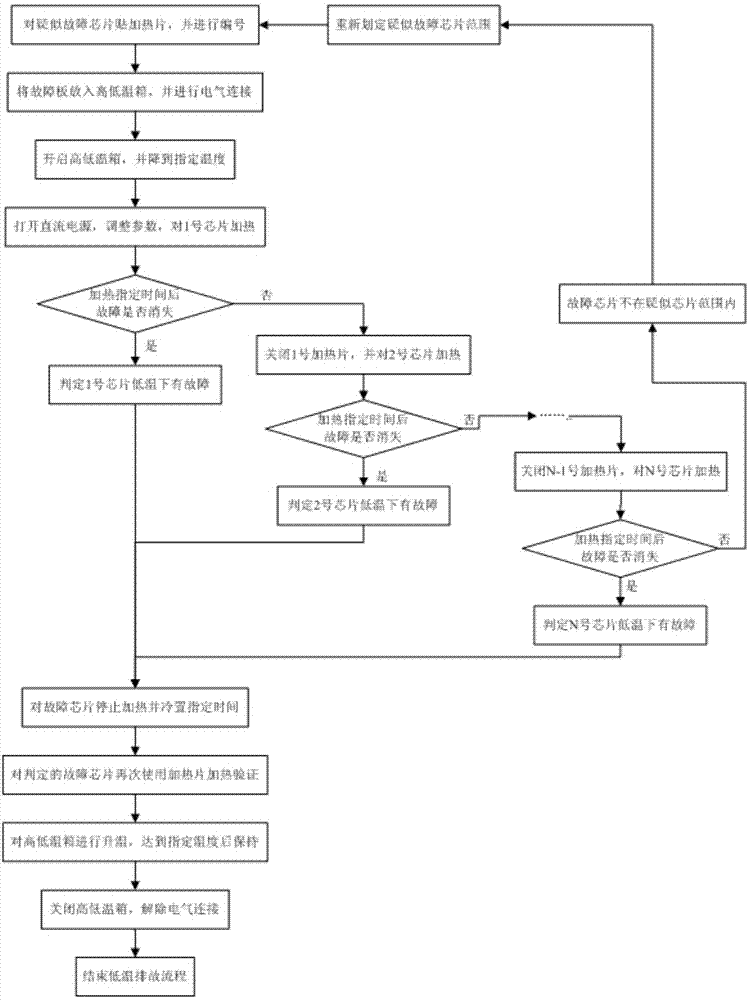

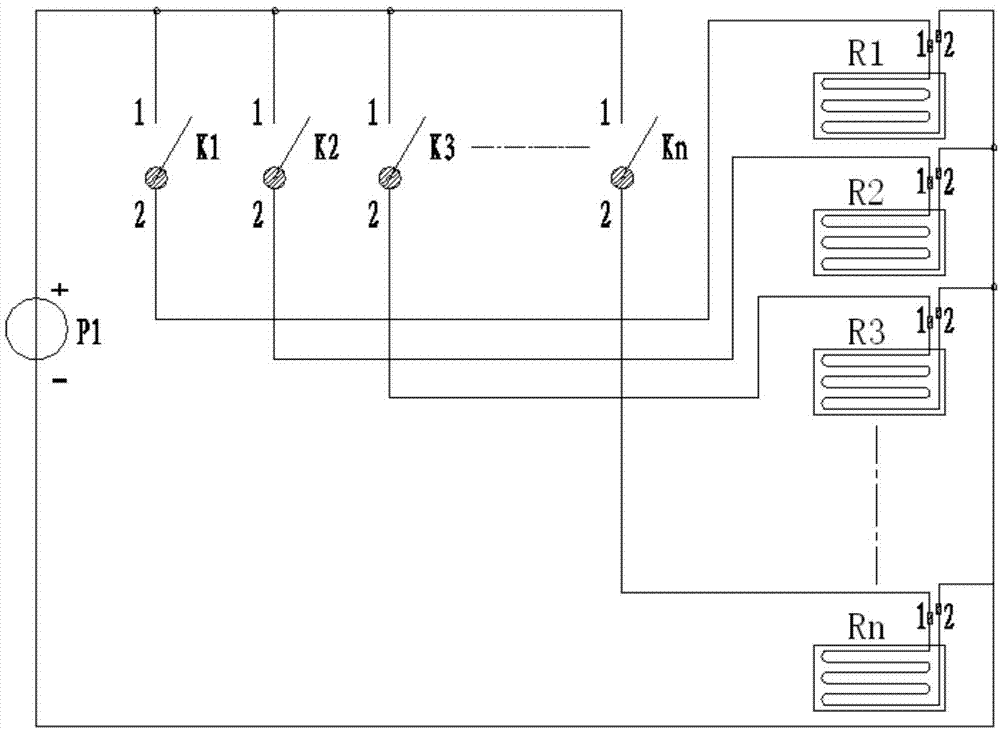

[0020] The low-temperature fault location method of the circuit board is to use the electric heating sheet to heat locally for low-temperature troubleshooting, so the heating device needs to be selected first. Such as figure 2 As shown, the heating device includes a power supply, n button switches and n heating chips, and there are n heating chip branches on the power supply, and each heating chip branch is controlled by a button switch and connected to a heating chip. n button switches (numbered K1, K2, K3...Kn, n is a natural number, it is recommended that n is not greater than 8), n heating chips (numbered R1, R2, R3...Rn), the positive pole of the power supply is connected to the The switches K1, K2, K3...1 pin of Kn, 2 pins of K1 connect to 1 pin of R1, 2 pins of K2 connect to 1 pin of R2, 2 pins of K3 connect to 1 pin of R3,...Kn 2 pins The pin is connected to the 1st pin of Rn, and the 2nd pin of R1, R2, R3... Rn is connected to the negative pole of the power supply. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com