Spiral luminous tube pin bending machine

A technology of bending machine and lamp tube, which is used in glass re-molding, glass manufacturing equipment, glass molding and other directions, can solve the problems of incapable of streamlined production, inability to compare, difficult to explain, etc., and achieves inflation time and pressure. Accurate control, high pass rate and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

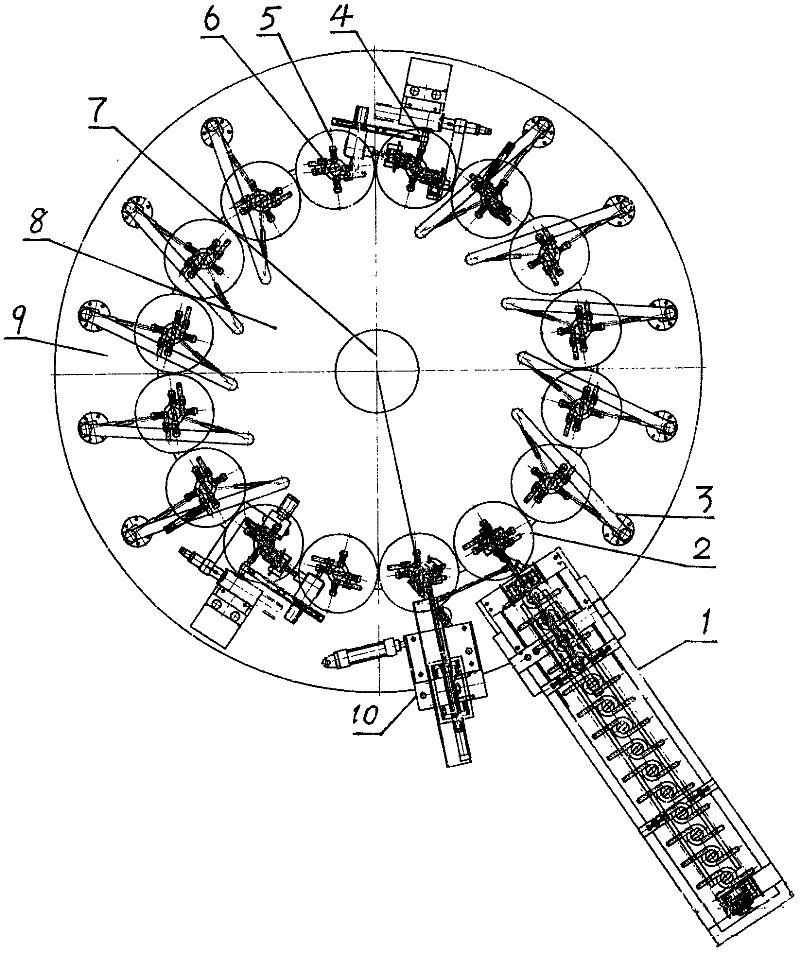

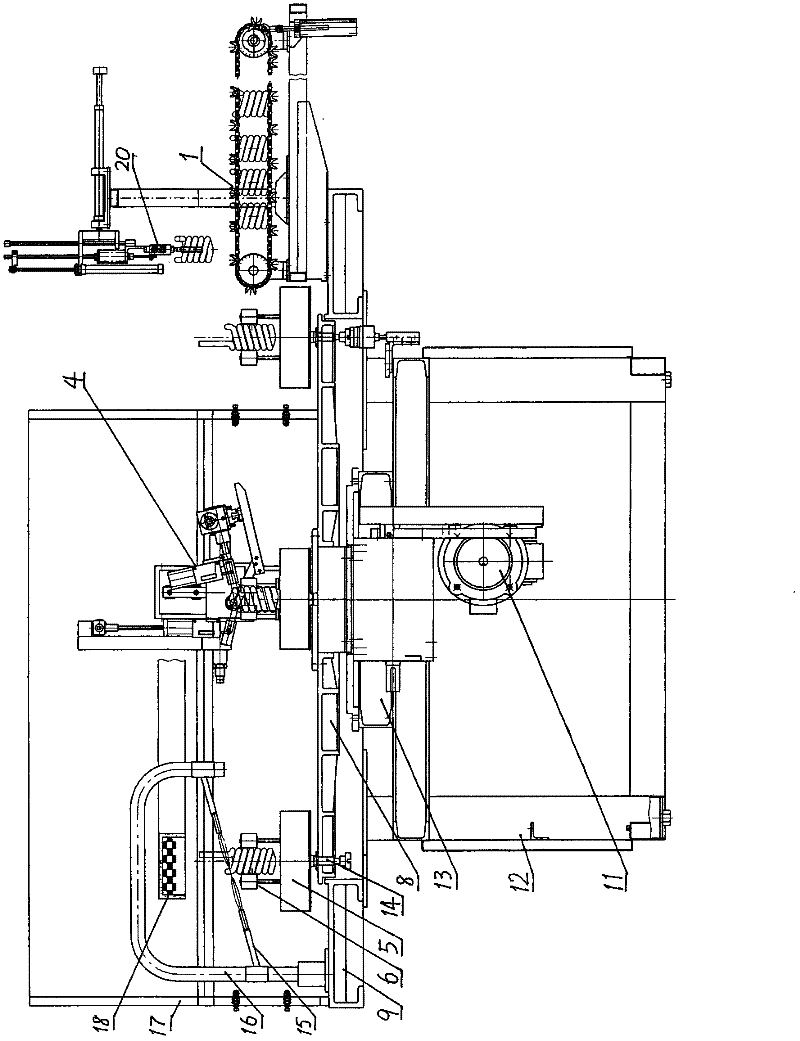

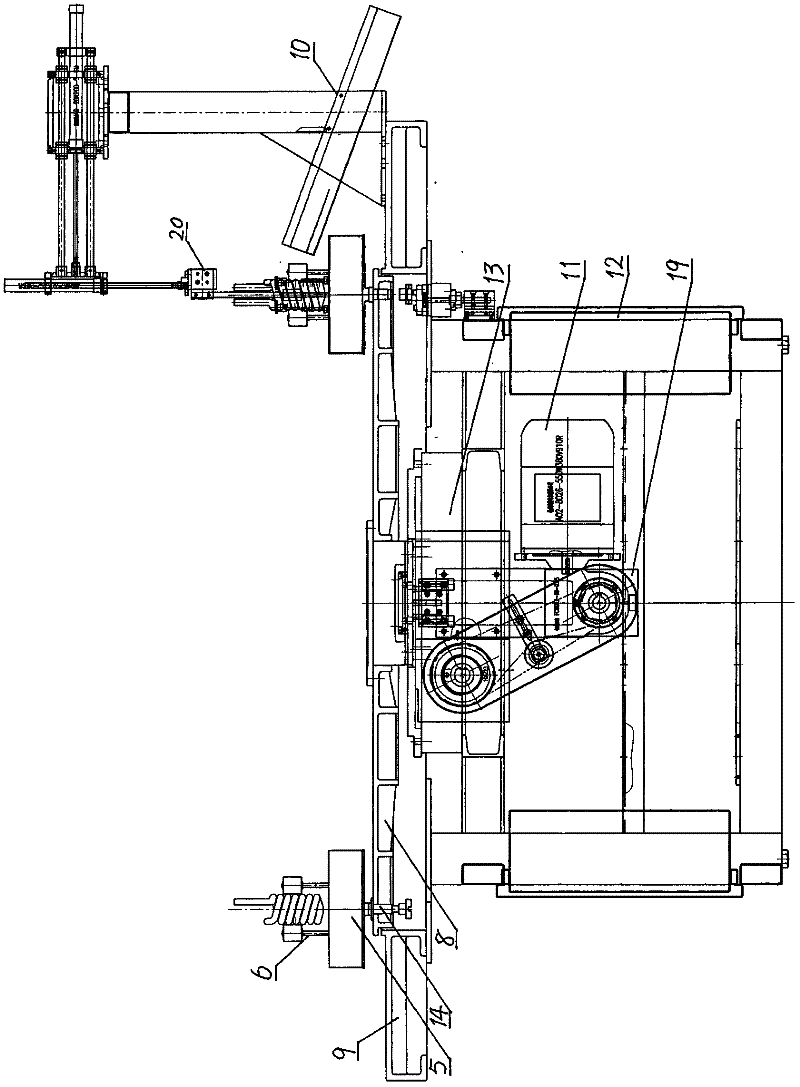

[0028] The present invention is described in detail below in conjunction with embodiment and with reference to accompanying drawing: see Figure 1-3 , is a structural schematic diagram of sixteen stations as an example. Spiral lamp tube bending machine, including distribution box, automatic control system, motor 11, gear reducer, cylinder, workbench and frame 12, motor 11, gear reducer 19, divider 13 and ring workbench 9 are installed on On the frame 12, a turntable 8 is installed on the central rotating shaft 7, and an annular workbench 9 is arranged around the turntable 8, and the surface of the turntable 8 near the outer circumference is equidistantly installed with sixteen to twenty-four stations 2, now press There are 16 stations and the station 2 adjacent to the inner side of the delivery tube setting device 1 is used as the first station, that is, the starting station, and the counterclockwise order is as follows: the second to sixth stations all have fire head heating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com