A hybrid loose-tube layer-stranded optical cable and its manufacturing method

A production method and a hybrid technology, which are applied in the field of optical cable manufacturing, can solve the problems of the influence of the optical cable core structure stability, the reduction of optical fiber density, and the difficulty in meeting design requirements, etc., to achieve improved optical fiber density, satisfactory water permeability, and stable structure. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

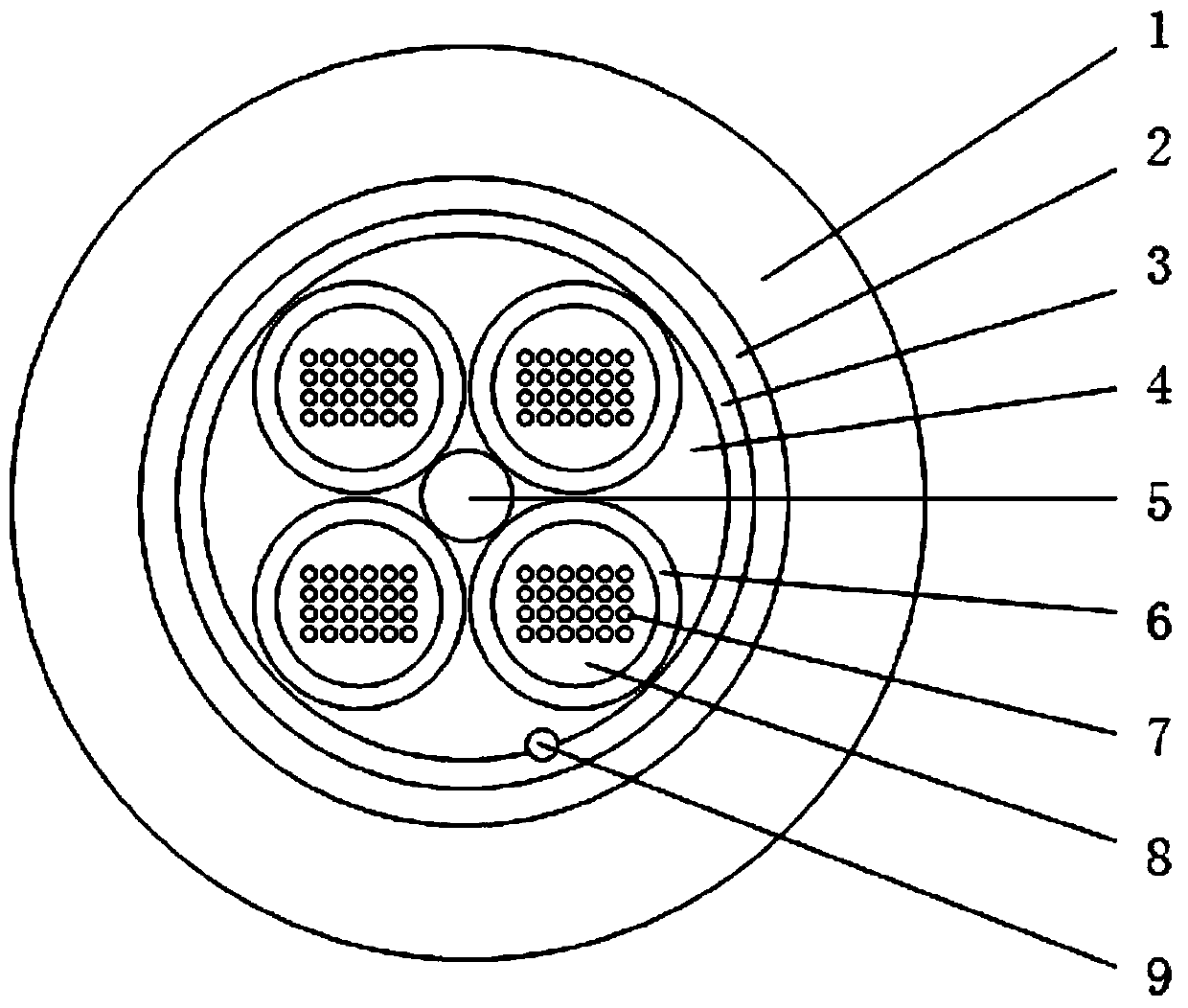

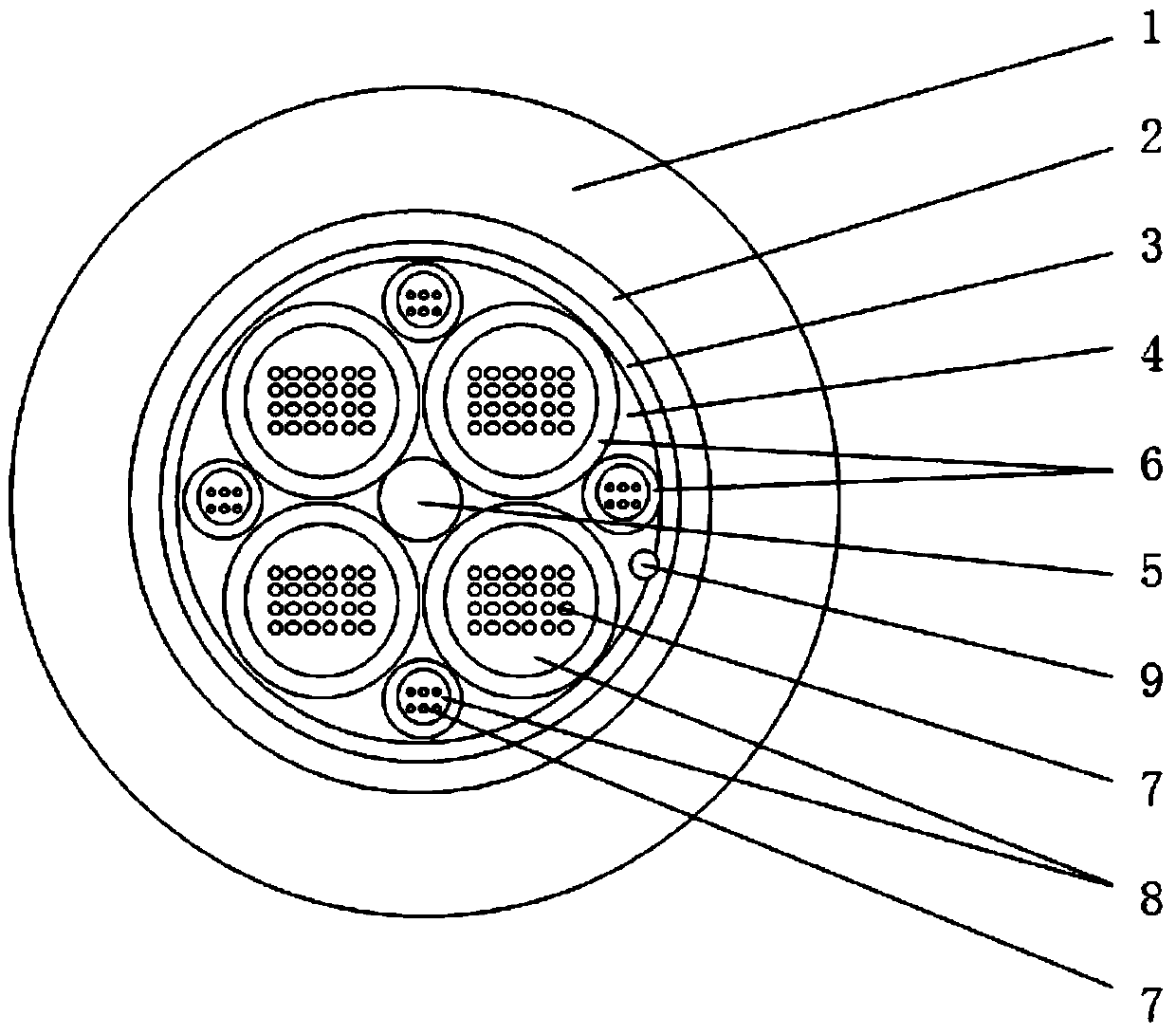

[0061] like image 3 As shown, it is a schematic diagram of the structure of an eight-unit hybrid loose-tube layer-stranded optical cable. The cable core consists of a loose tube 6 of a built-in fiber bundle or fiber ribbon containing an optical fiber bundle or fiber ribbon matrix 7 and fiber paste 8, a loose tube 6 of an optical fiber bundle with a small number of cores, and is longitudinally twisted in an "SZ" manner. Wrapped around the central reinforcement 5, and then bidirectionally wound the binding yarn 3 outside the stranding unit to form a stable optical cable core; the optical cable core is filled with water-blocking cable paste 4 and tear rope 9, and then sequentially wrapped outside the cable core The metal moisture barrier layer 2 is vertically wrapped, and the extrusion sheath 1 forms the present invention.

[0062] Wherein, the sheath 1 is made of polyethylene material, low-smoke halogen-free flame-retardant polyolefin material, polyamide material or thermoplas...

Embodiment 2

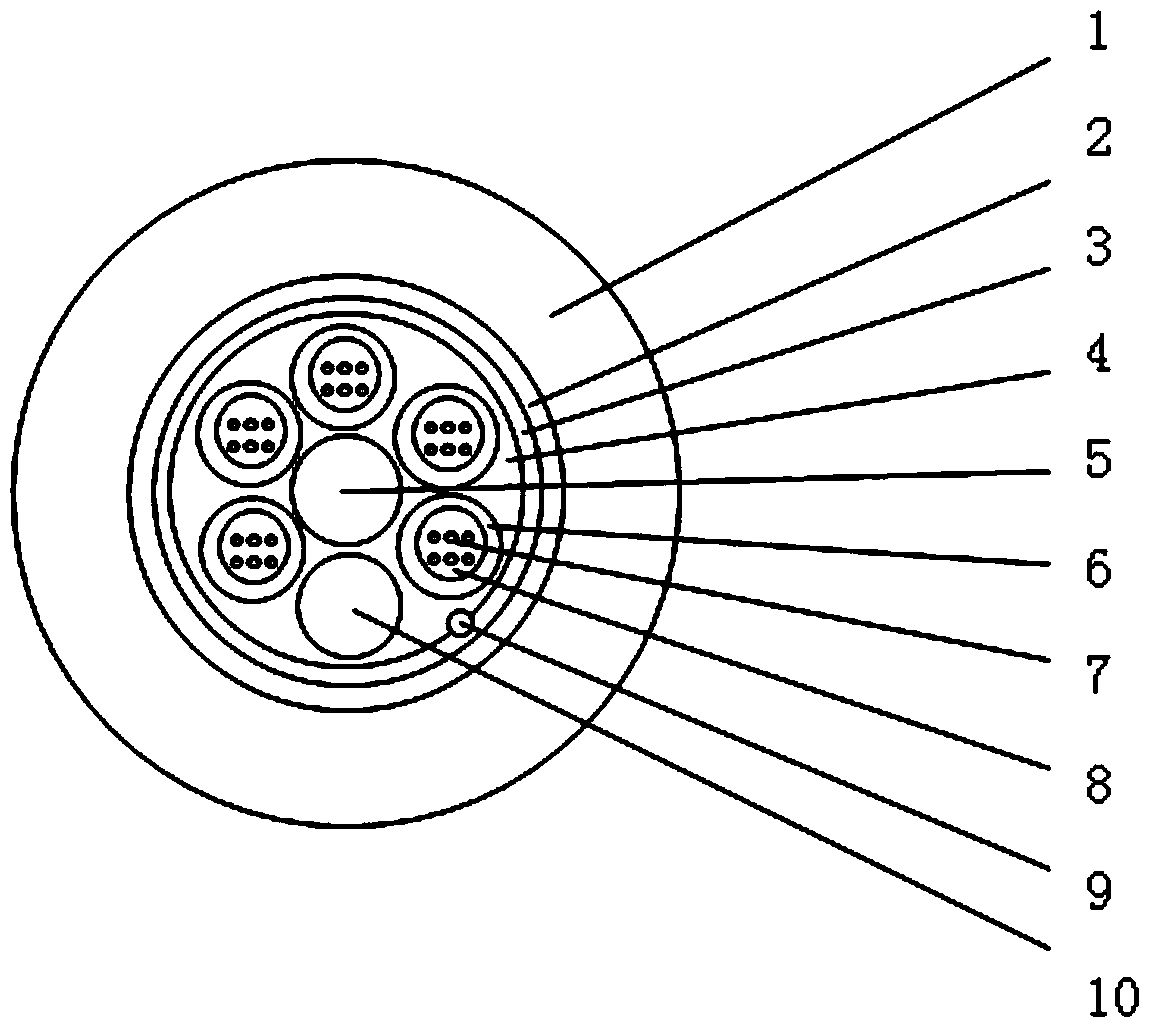

[0076] like Figure 4 As shown, it is a schematic diagram of the structure of a twelve-unit hybrid loose-tube layer-stranded armored optical cable. It differs from Embodiment 1 in that: the number of stranding units of the optical cable core is increased to twelve, the stranding units of the cable core include filling ropes 10, the central strengthening member 5 is extruded with a central strengthening member cushion 11, and the sheathing The sleeve 1 is longitudinally wrapped with an armor layer 12 in turn, and an outer sheath 13 is extruded.

[0077] Wherein, the filling rope 10 can be a polyethylene material, a polypropylene material or a filling rope that contains a PBT outer coating made by foaming technology, and the outer diameter of the filling rope 10 is the same as the outer diameter of the optical fiber bundle or the loose tube of the optical fiber ribbon. same diameter.

[0078] Wherein, the cushion layer 11 of the central strength member can be polyethylene mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com