A reinforced concrete prefabricated component

A technology of reinforced concrete and prefabricated components, applied in building construction, processing of building materials, construction, etc., can solve problems such as high energy consumption, complicated operation, and difficult quality control, and achieve simple operation, improved connection strength, and assembly efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

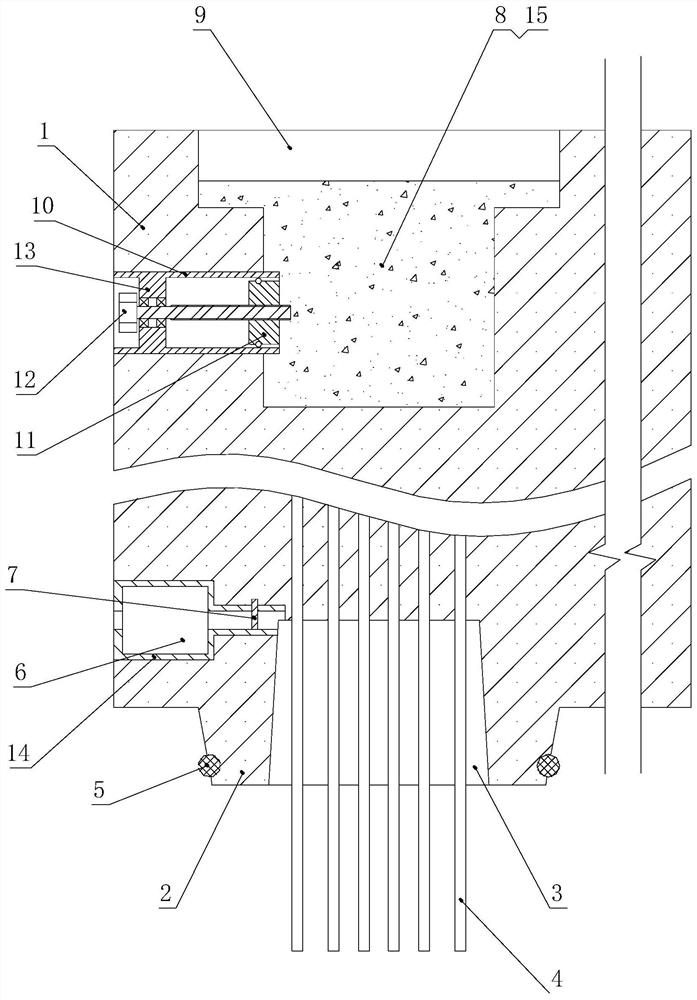

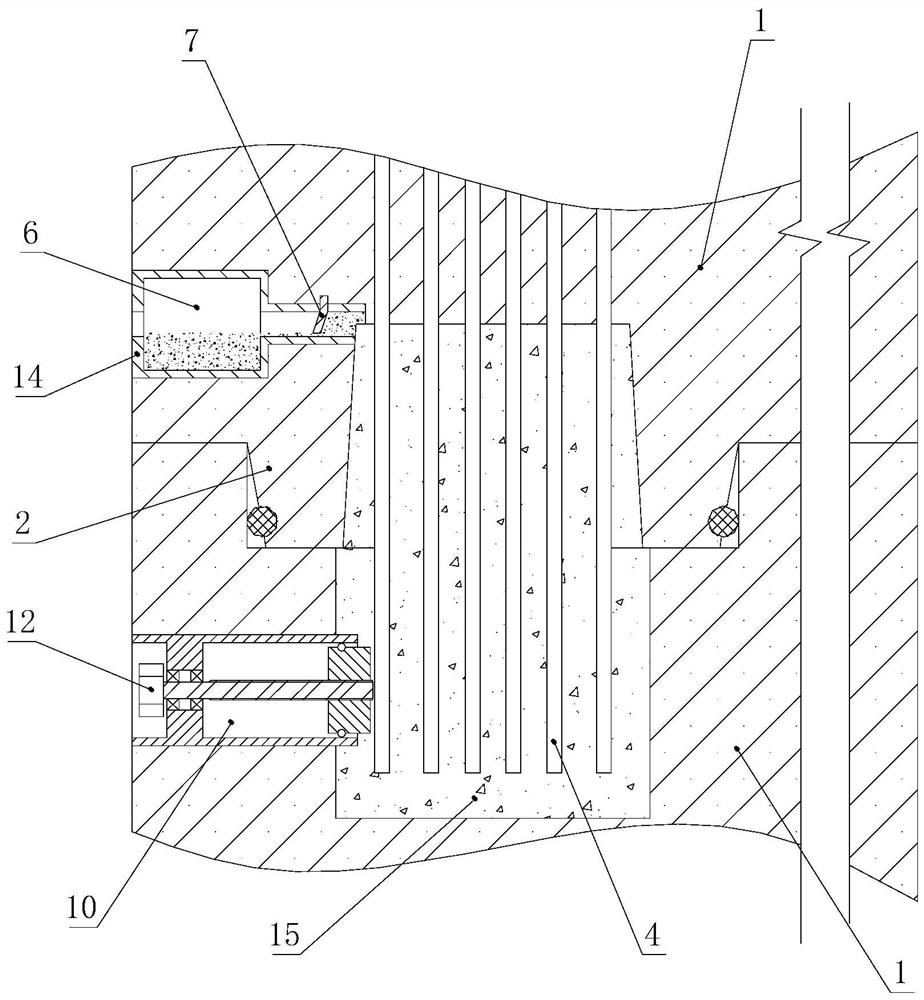

[0030] A reinforced concrete prefabricated component, comprising a prefabricated component body 1, the lower end of the prefabricated component body 1 is provided with a connecting protrusion 2, and the middle part of the connecting protrusion 2 is vertically provided with a grouting cavity 3; inside the grouting cavity 3 There are several connecting ribs 4 vertically, one end of the connecting ribs 4 extends into the prefabricated component body 1, and the other end of the connecting ribs 4 extends outside the prefabricated component body 1; the connecting protrusion 2 is covered with a connecting sealing ring 5. The connection sealing ring 5 is used to seal the gap between the connection protrusion 2 and another prefabricated component or building structure; the prefabricated component body 1 is also provided with a slurry overflow cavity 6, and the slurry overflow cavity 6 At the same time, it communicates with the outside of the prefabricated component body 1 and the grouti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com