Indexable universal joint grease injection device

A technology of oil injection device and universal joint, which is applied in the direction of valve device, distribution device, engine lubrication, etc., can solve problems such as bearing failure, grease not being renewed, increased cost, etc., to achieve increased radius of gyration, less number of parts, receptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

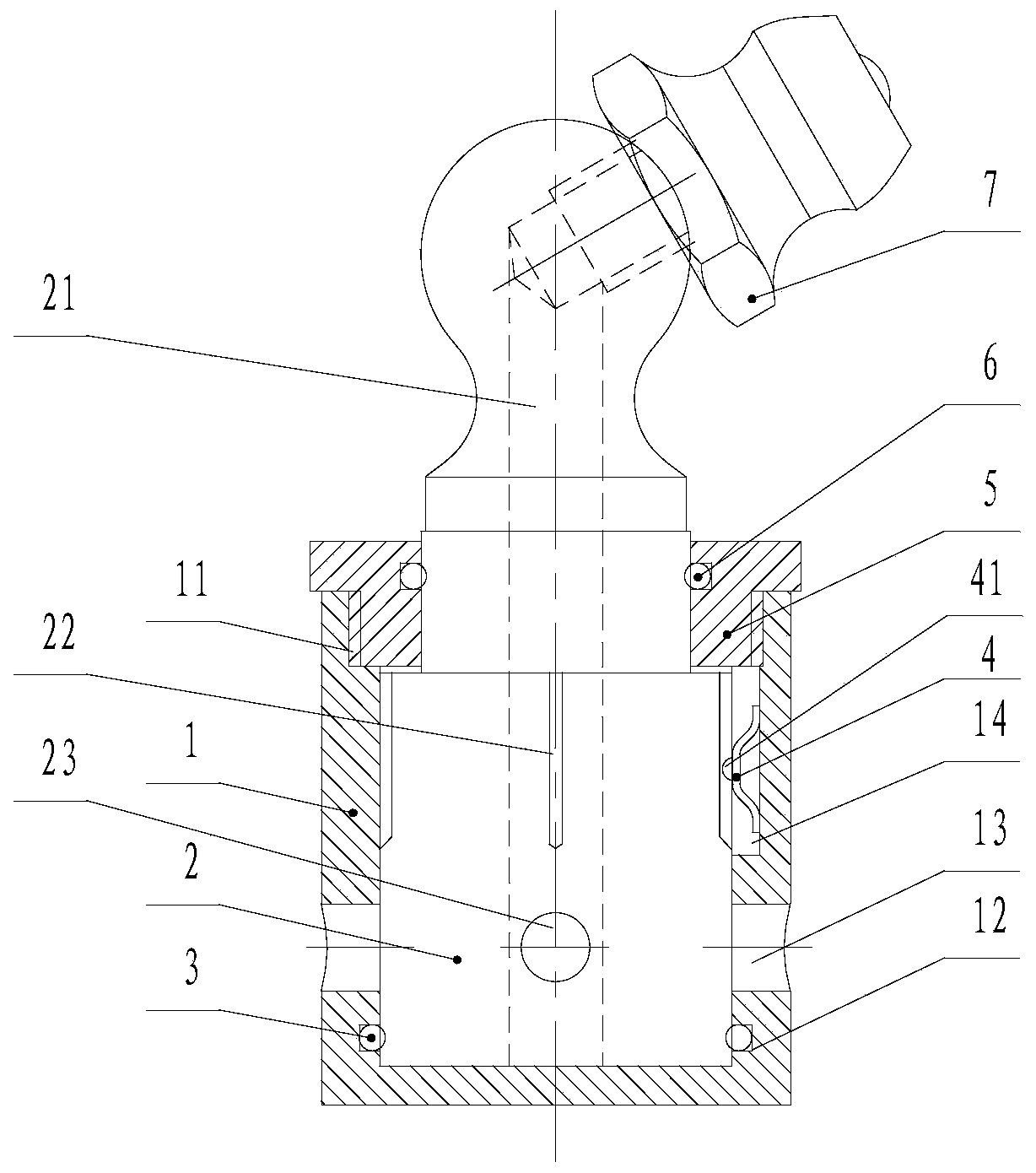

[0021] Embodiment 1: as attached figure 1 As shown, this indexable universal joint oil filling device mainly includes an oil cup sleeve 1, an oil cup core 2 and a straight-through pressure oil injection cup 7. The upper inner wall of the oil cup sleeve 1 is provided with an internal thread 11 for Screw in the lock nut 5 to axially fix the oil cup core 2 installed in the oil cup sleeve 1. A sealing ring B6 is provided at the joint between the oil cup core 2 and the lock nut 5. The oil cup core 2 can Rotate relative to the oil cup sleeve 1; the center of the oil cup core 2 is provided with an oil passage 21, and the straight-through pressure oil injection cup 7 is threadedly connected with the ball head on the top of the oil cup core 2 and communicated with the oil passage 21; The lower part of the oil cup sleeve 1 is evenly opened with four oil outlet holes 13 at intervals of 90° along the circumferential direction, which are respectively connected to the four "ten" through-hol...

Embodiment 2

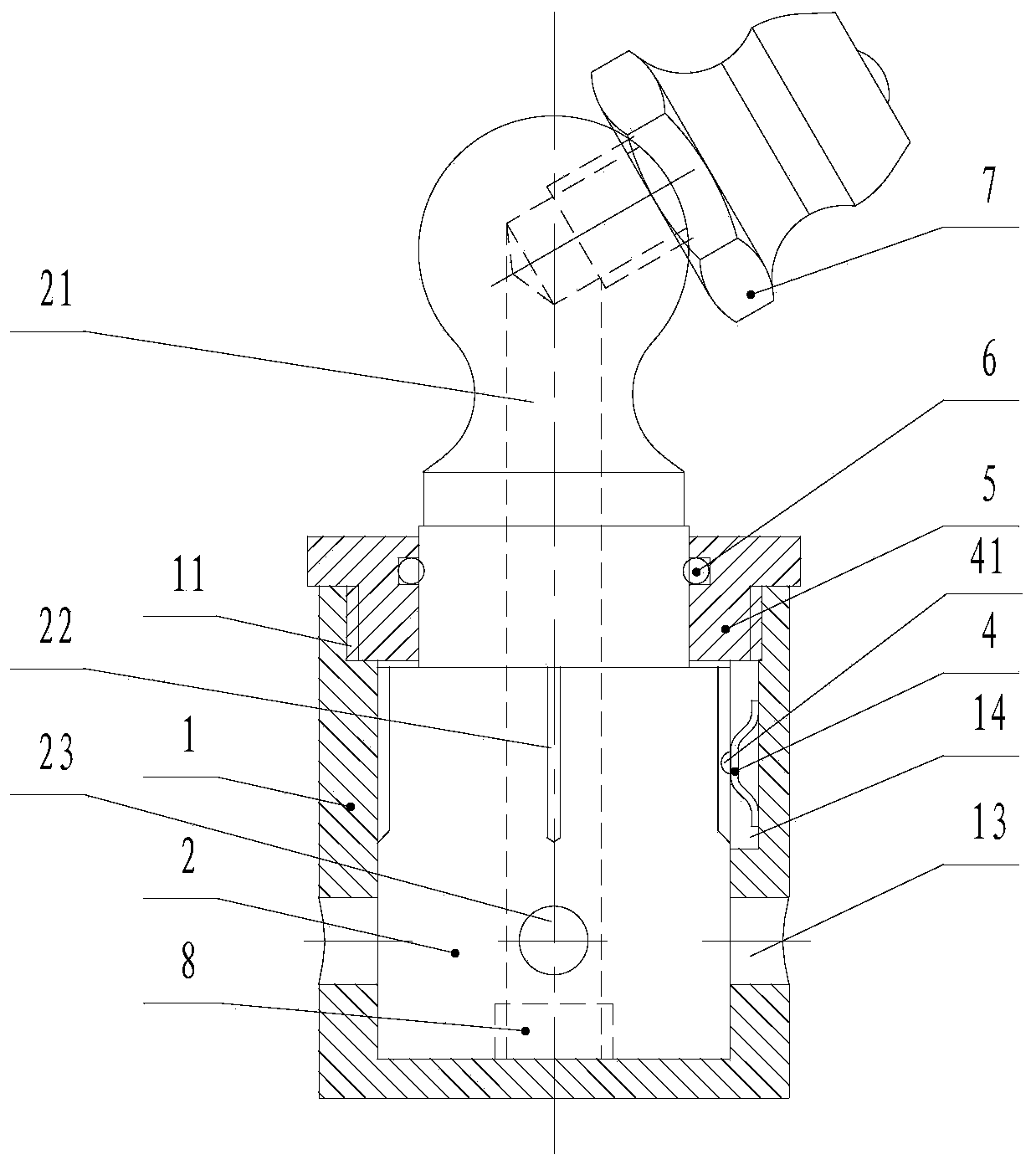

[0024] Embodiment 2: as attached figure 2 As shown, the difference from Example 1 is that the sealing ring A3 and the ring groove 12 on the oil cup sleeve 1 are cancelled, threads are added at the bottom of the oil passage 21 of the oil cup core 2, and the oil plug 8 is screwed in. Other parts are the same as Example 1 is the same.

Embodiment 3

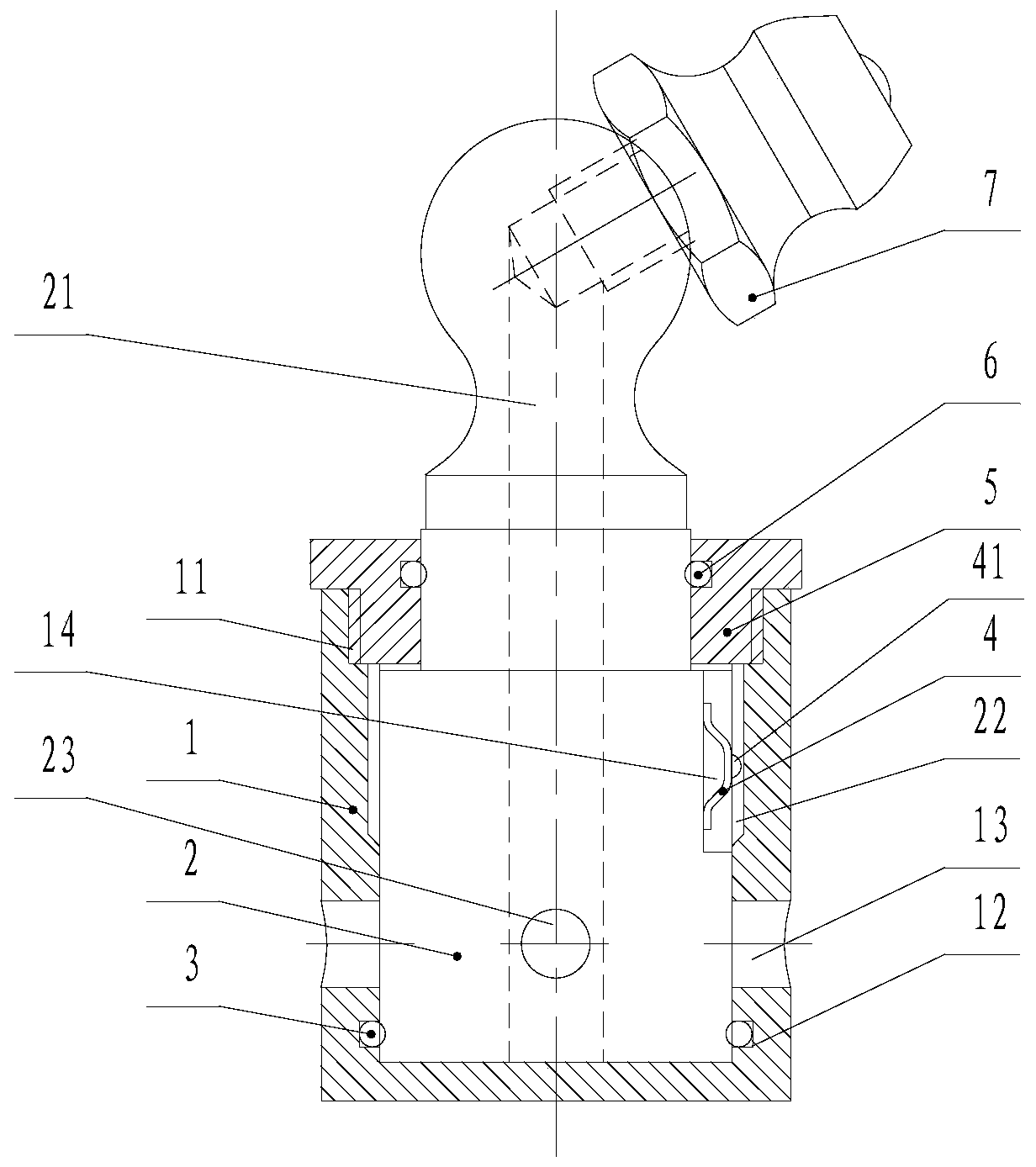

[0025] Embodiment 3: as attached image 3 As shown, the difference from Example 1 is that the rectangular groove 14 on the oil cup sleeve 1 is interchangeable with the four V-shaped grooves 22 on the oil cup core 2, that is, the middle part of the inner wall of the oil cup sleeve 1 is spaced along the circumferential direction. Four V-shaped grooves 22 are evenly opened at 90°, and a rectangular groove 14 is set at the same height position as the V-shaped grooves 22 on the oil cup core 2, and other parts are the same as in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com