Joint connecting structure for connecting steel tower and concrete tower base and construction method thereof

A joint connection and concrete technology, which is applied in the bridge field, can solve the problems of affecting the safety and durability of steel-concrete hybrid bridge tower joints, increasing construction difficulty, and poor fluidity, so as to improve the effect of internal force transmission and improve anchorage and adhesion. excellent bonding performance and bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

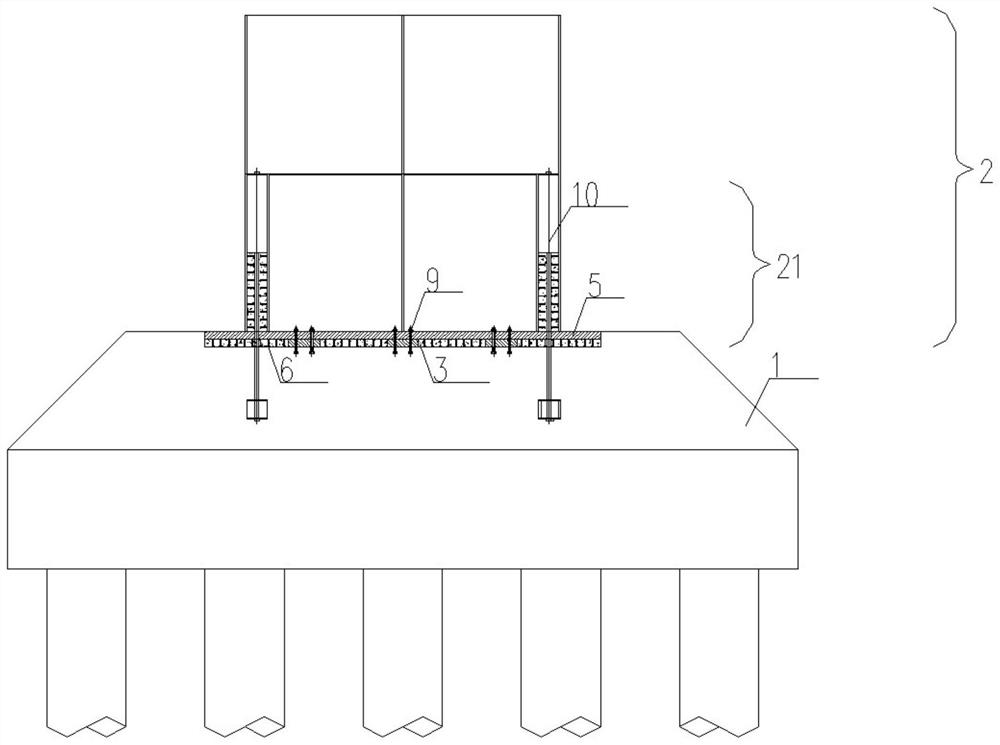

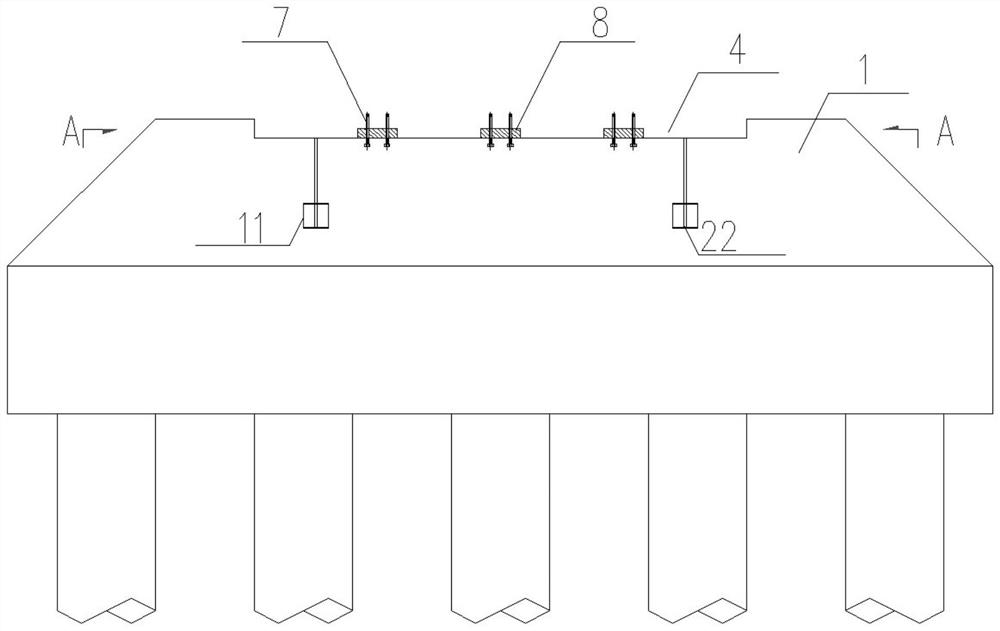

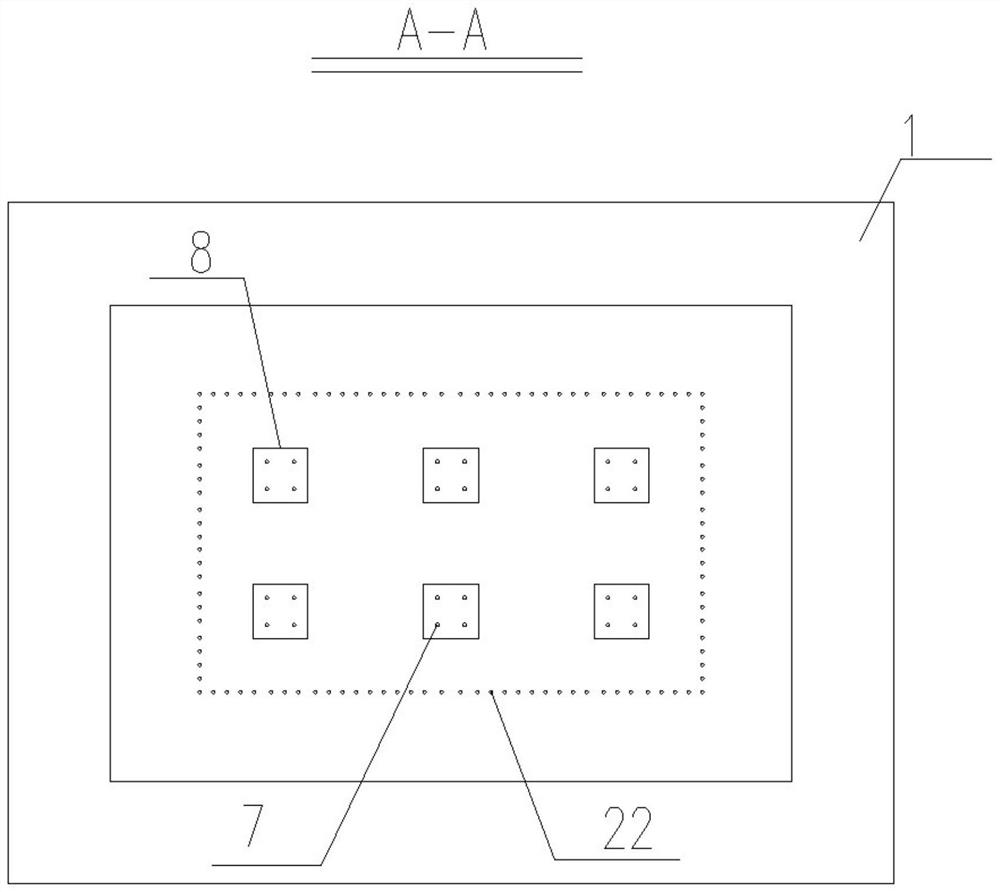

[0041] Such as figure 1 As shown, the joint connection structure for the connection between the steel tower and the concrete tower base of this embodiment includes a concrete tower base 1, a steel tower 2, a UHPC grouting layer 3 and a prestressed tension structure. The top of the concrete tower base 1 is provided with The grouting notch 4, the UHPC grouting layer 3 is fixed in the grouting notch 4; the bottom of the steel tower 2 is provided with a steel bottom plate 5, and the bottom of the steel bottom plate 5 is provided with a shear connector 6 (such as a stud), and the steel bottom plate 5 is fixedly connected to the UHPC grouting layer 3 through the shear connector 6; the prestressed tension structure is stretched between the concrete tower base 1 and the steel tower 2.

[0042] In this example, UHPC refers to concrete that contains steel fibers and no coarse aggregate in its components, and has a compressive strength of not less than 100 MPa and an axial tensile streng...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com