Self-priming pump with sealing mechanism

A technology of sealing mechanism and self-priming pump, which is applied to pumps, components of pumping devices for elastic fluids, driving pumps, etc., can solve problems affecting sealing effect, loss, affecting pump efficiency and self-priming performance, etc., to achieve Guarantees the effect of sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

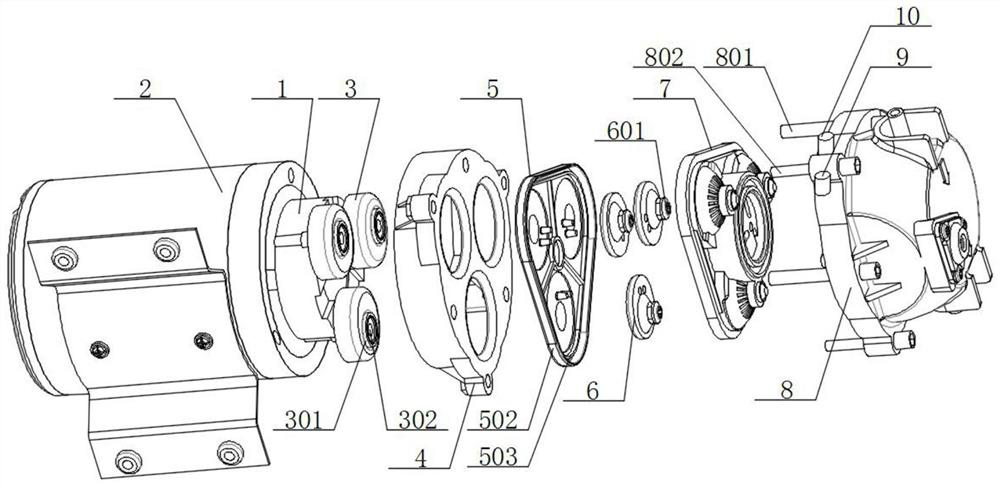

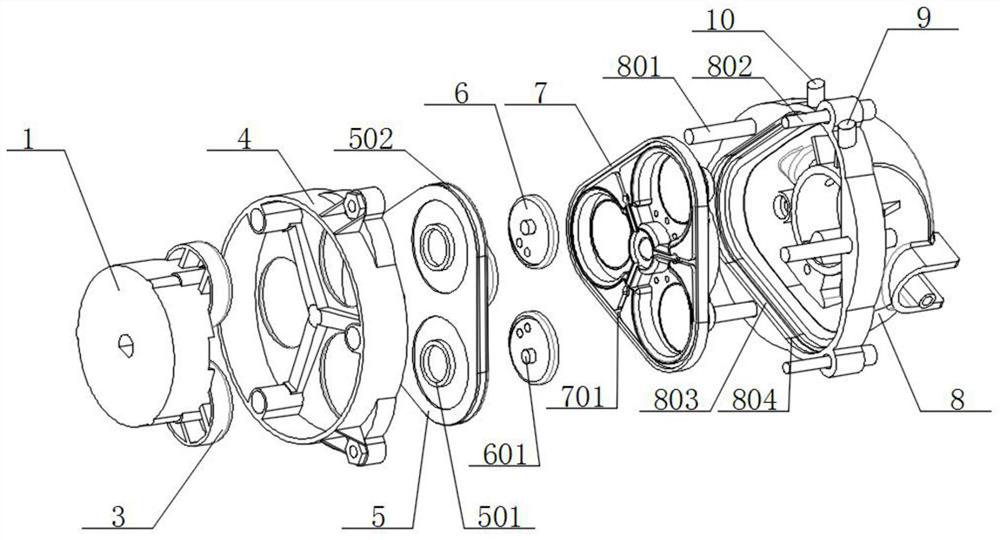

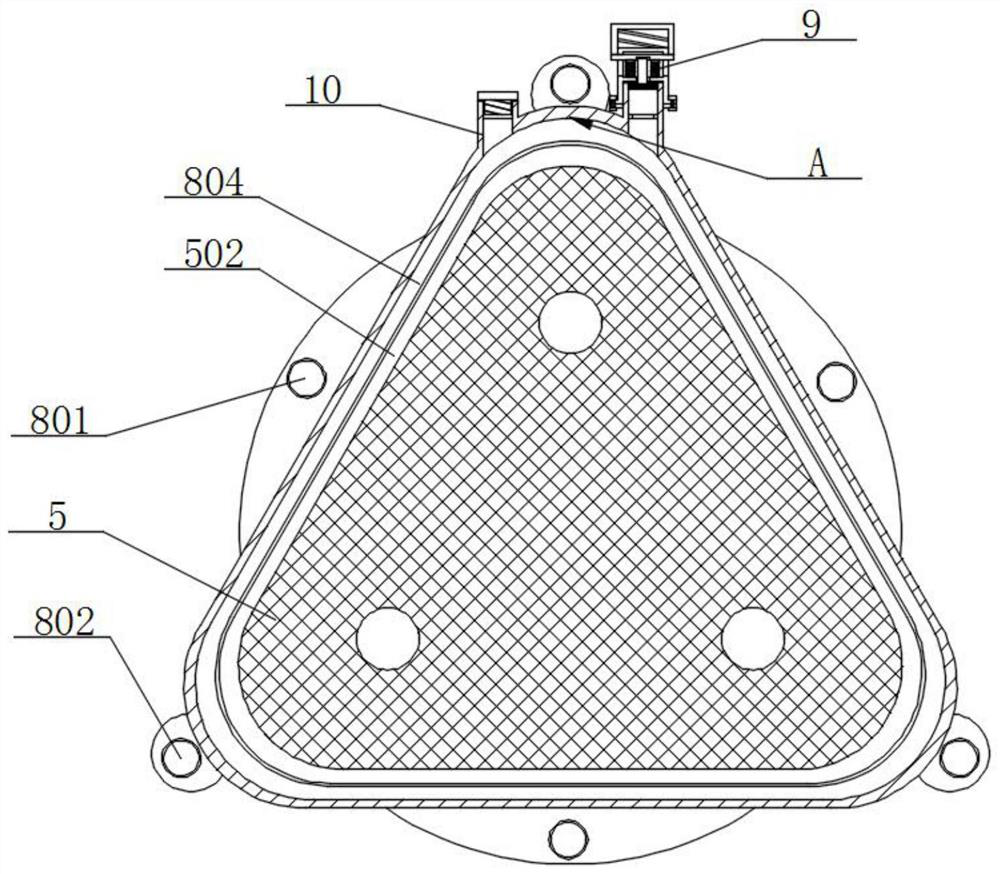

[0031] Such as figure 1 , figure 2 , image 3 As shown, the self-priming pump with a sealing mechanism includes an eccentric wheel 1, a first screw 801 and a second screw 802. One end of the eccentric wheel 1 is connected to a motor 2, and the other end of the eccentric wheel 1 is connected to a transmission wheel 3. The wheel 3 moves through the support seat 4 and is inserted into the valve seat 7. The valve seat 7 is sleeved with the pump casing 8, the first screw 801 connects the pump casing 8, the support seat 4 and the motor 2, and the second screw 802 connects the pump casing 8 and the motor 2. Support seat 4;

[0032] The drive wheel 3 is provided with a first annular groove 301 and a threaded hole 302, the pump casing 8 is provided with a second annular groove 803, and the second annular groove 803 is provided with a second sealing groove 804;

[0033] The valve seat 7 is sleeved with a rubber diaphragm 5, and a sealing ring 501 is connected to the rubber diaphragm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com