Patents

Literature

92results about How to "High degree of automation integration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

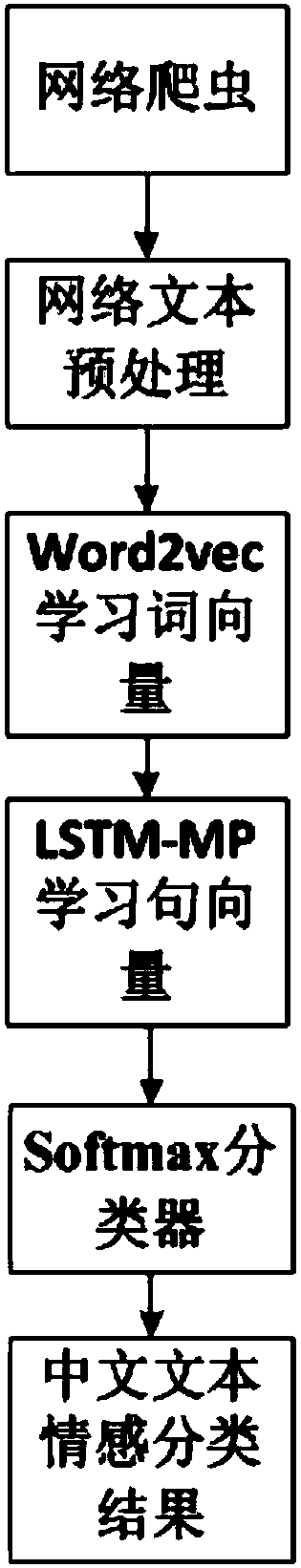

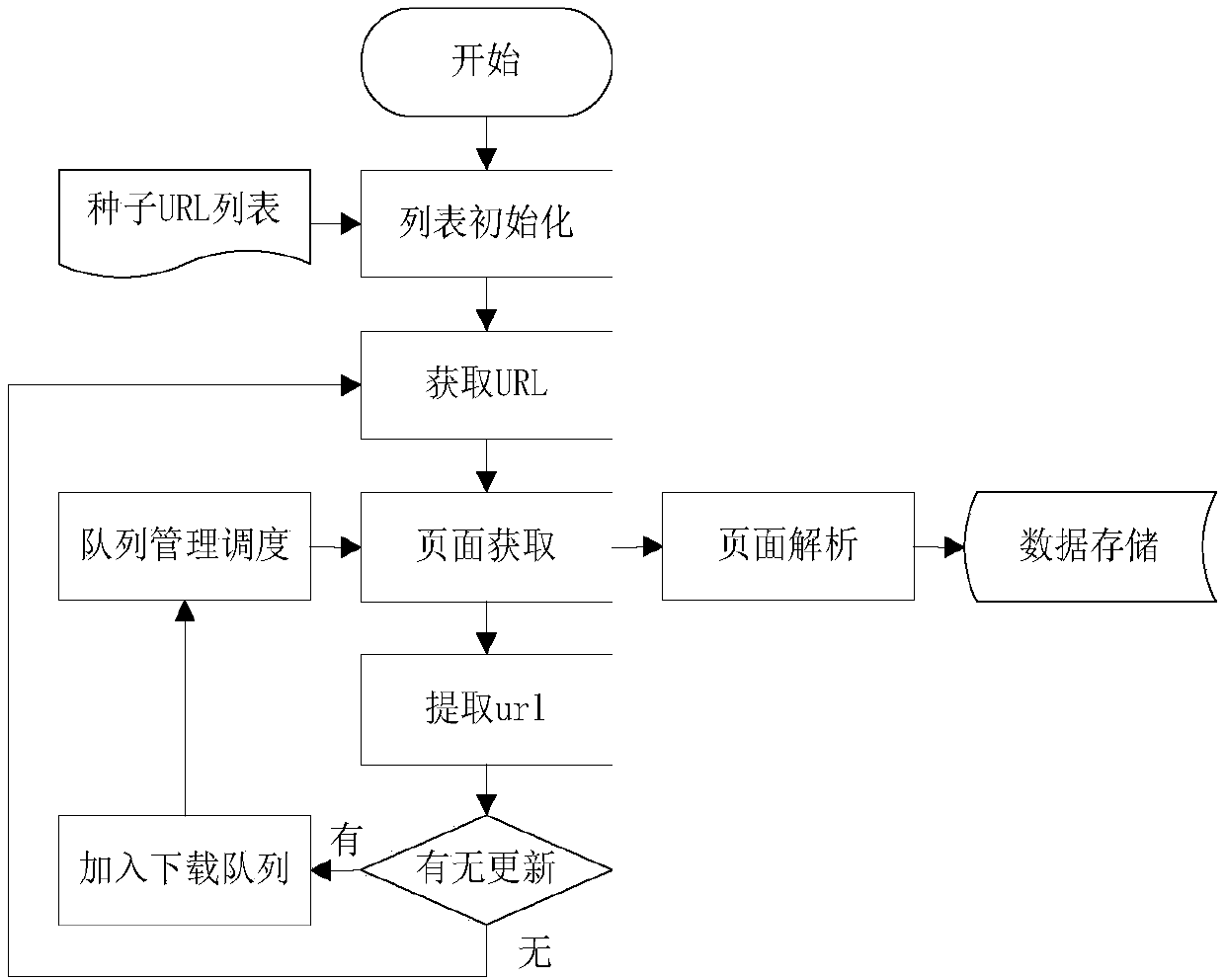

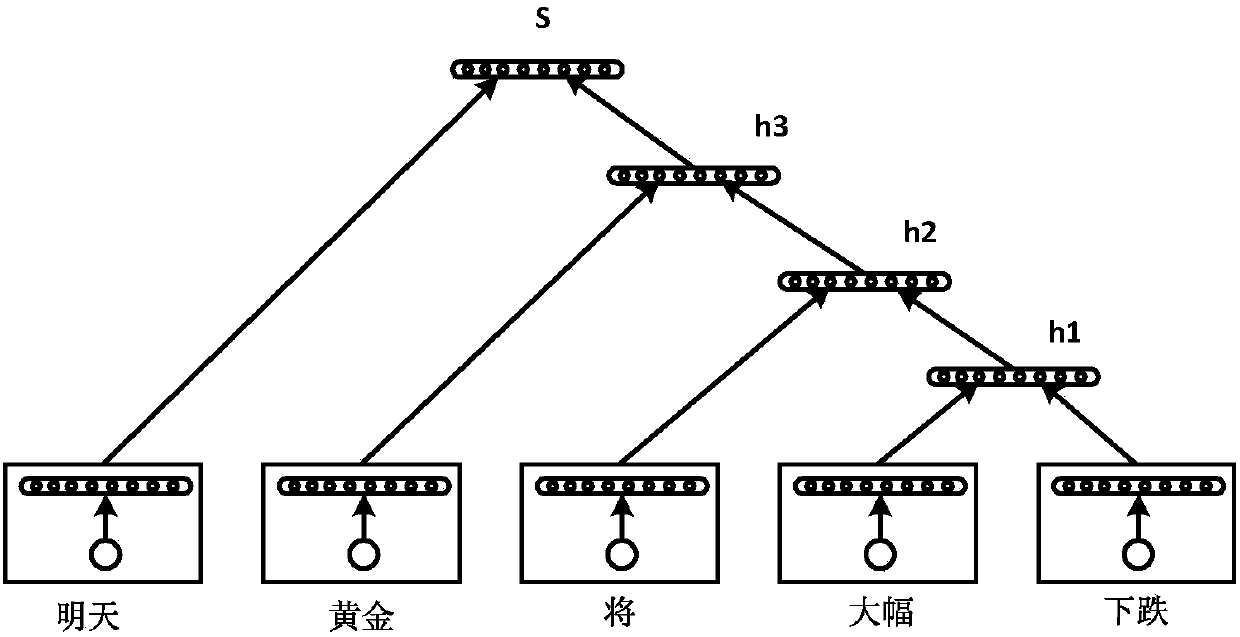

Deep-learning-based Chinese sentiment analysis method

InactiveCN107944014AImprove classification accuracyImprove efficiencyNatural language data processingSpecial data processing applicationsAlgorithmChinese word

The invention discloses a deep-learning-based Chinese sentiment analysis method, comprising: acquiring online text, reasonably designing a conversion logic of Chinese sentences to mathematical vectors, constructing a word vector dictionary via a Chinese word segmentation technique in conjunction with a word vector learning tool, using an LSTM-MP (long short-term memory) model to perform sentence vector conversion, and using a softmax classifier to perform positive and negative sentiment classification on representative sentence vectors so as to arrive at sentiment analysis. The deep-learning-based Chinese sentiment analysis method has the advantages that classification accuracy is high, classification efficiency is high, flexibility is high, mass manual operations in supervised learning methods are avoided, text sentiment orientation classification efficiency and accuracy are effectively improved, automation integrity is high, and manpower sources are greatly saved.

Owner:HOHAI UNIV

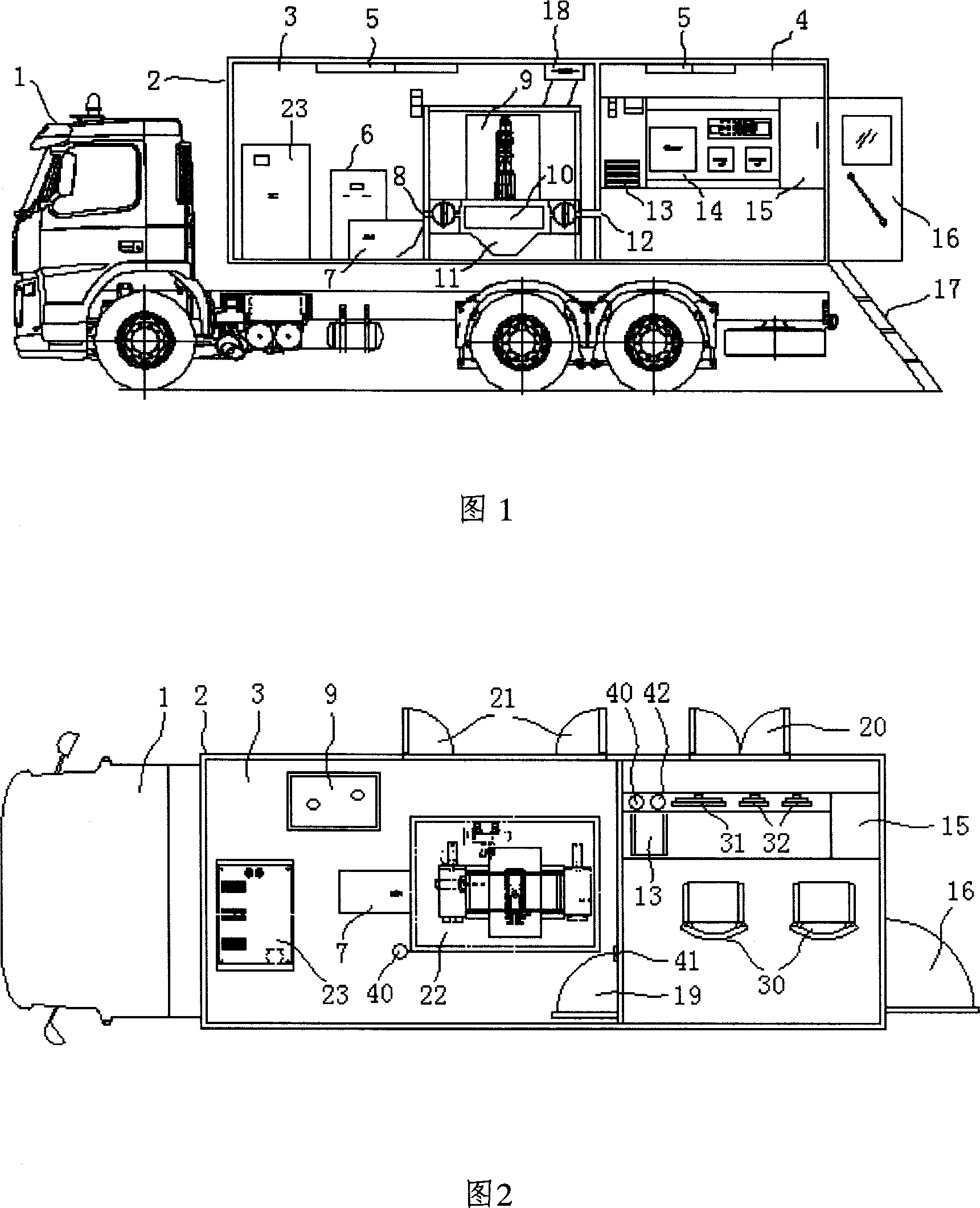

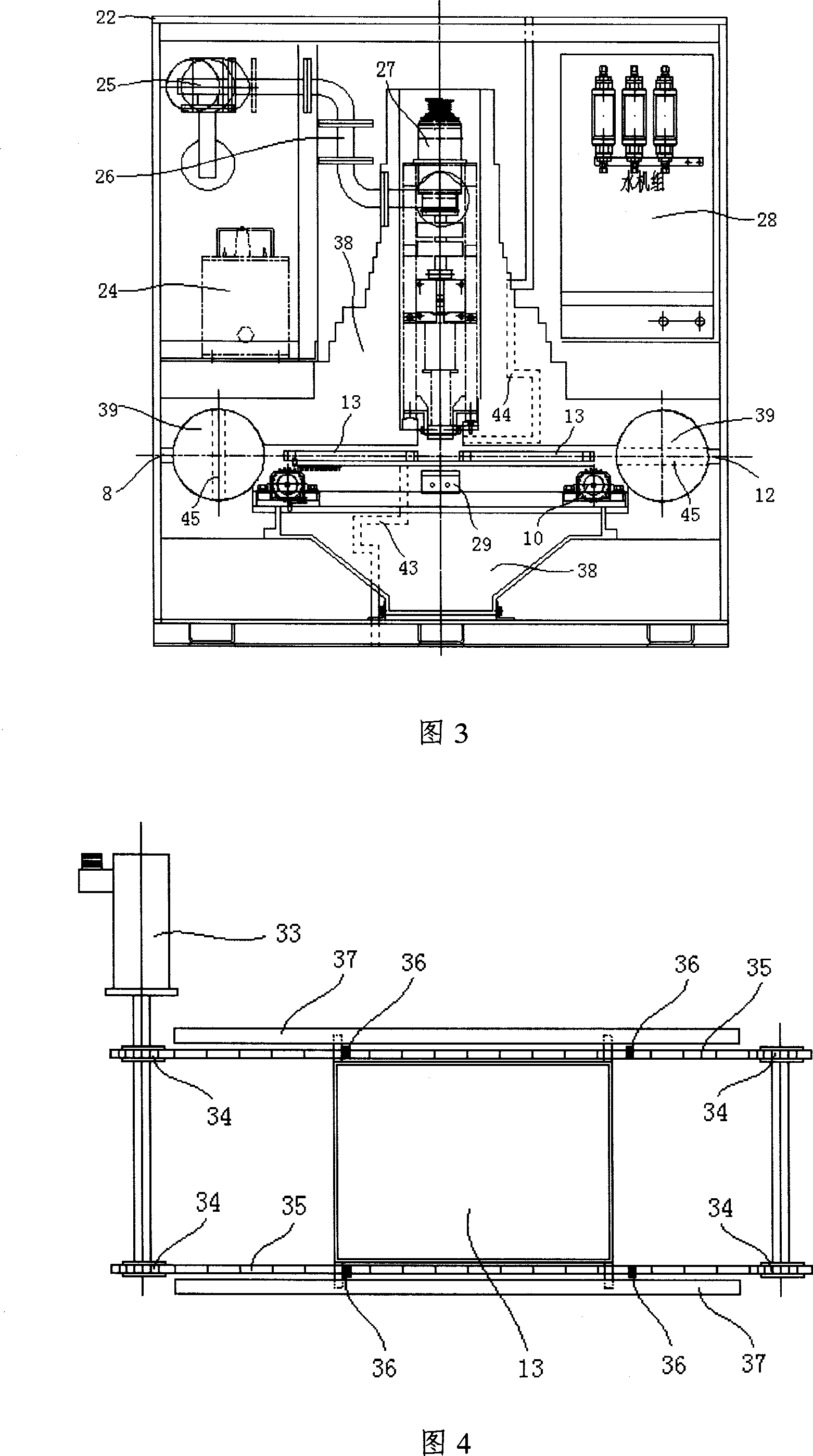

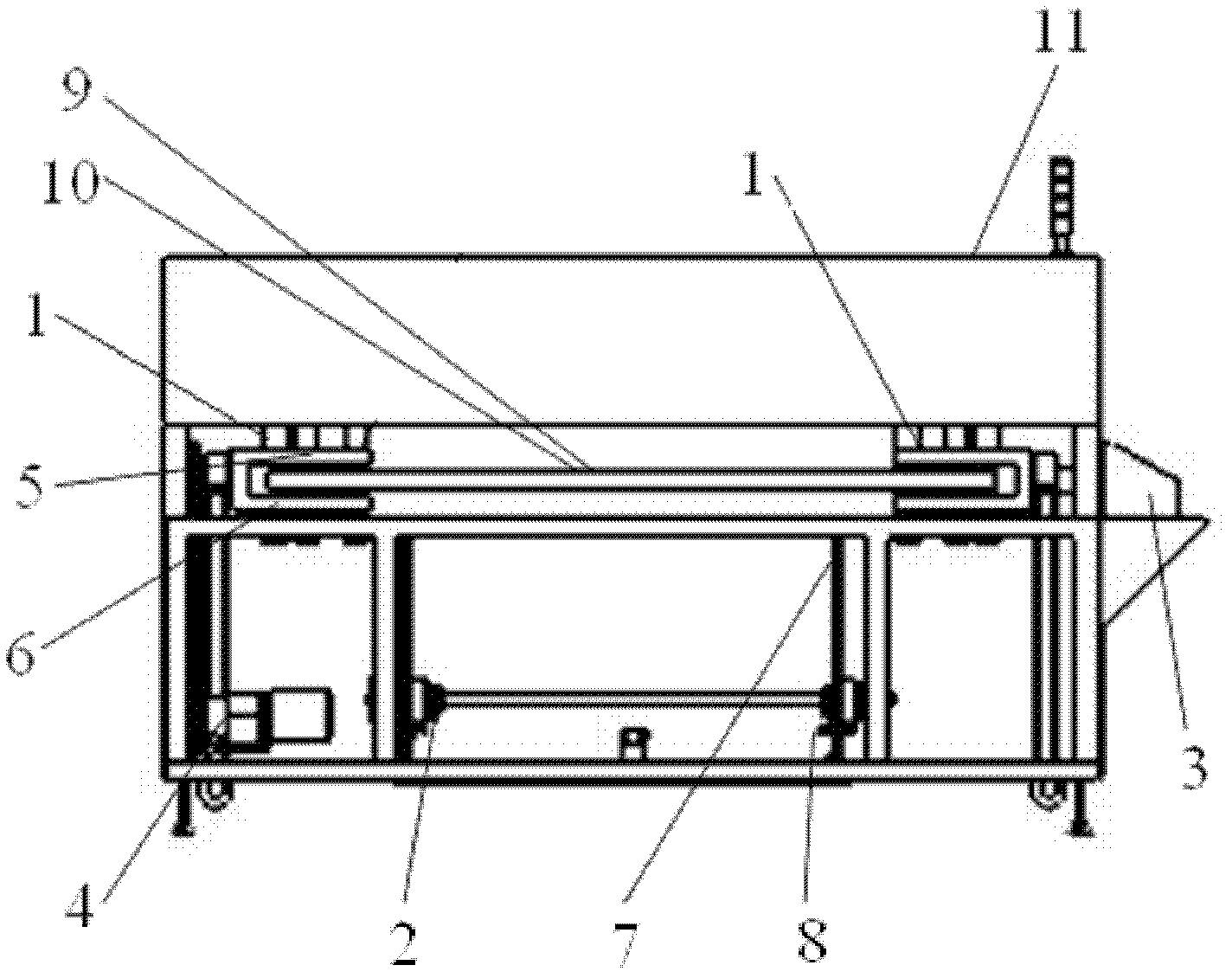

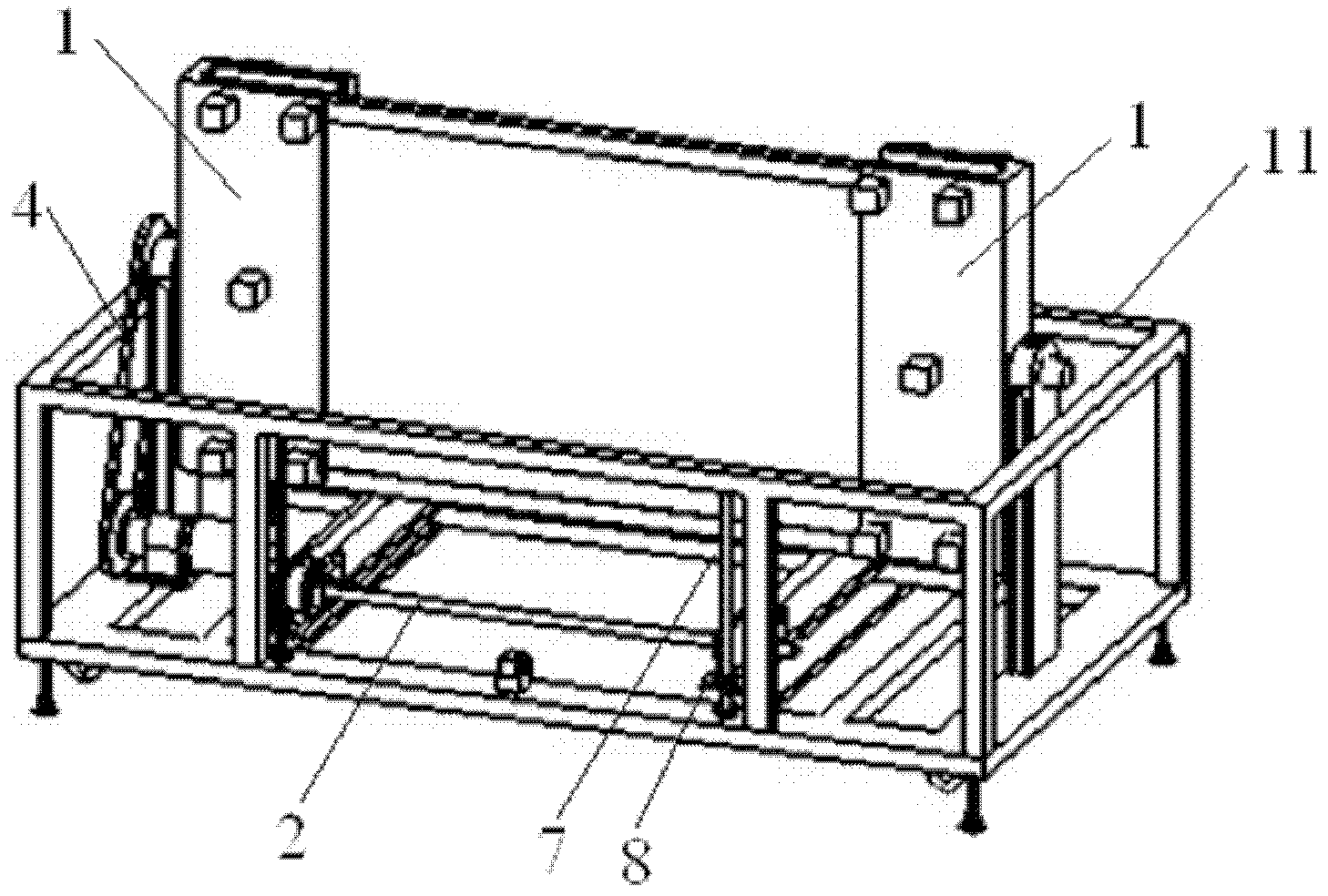

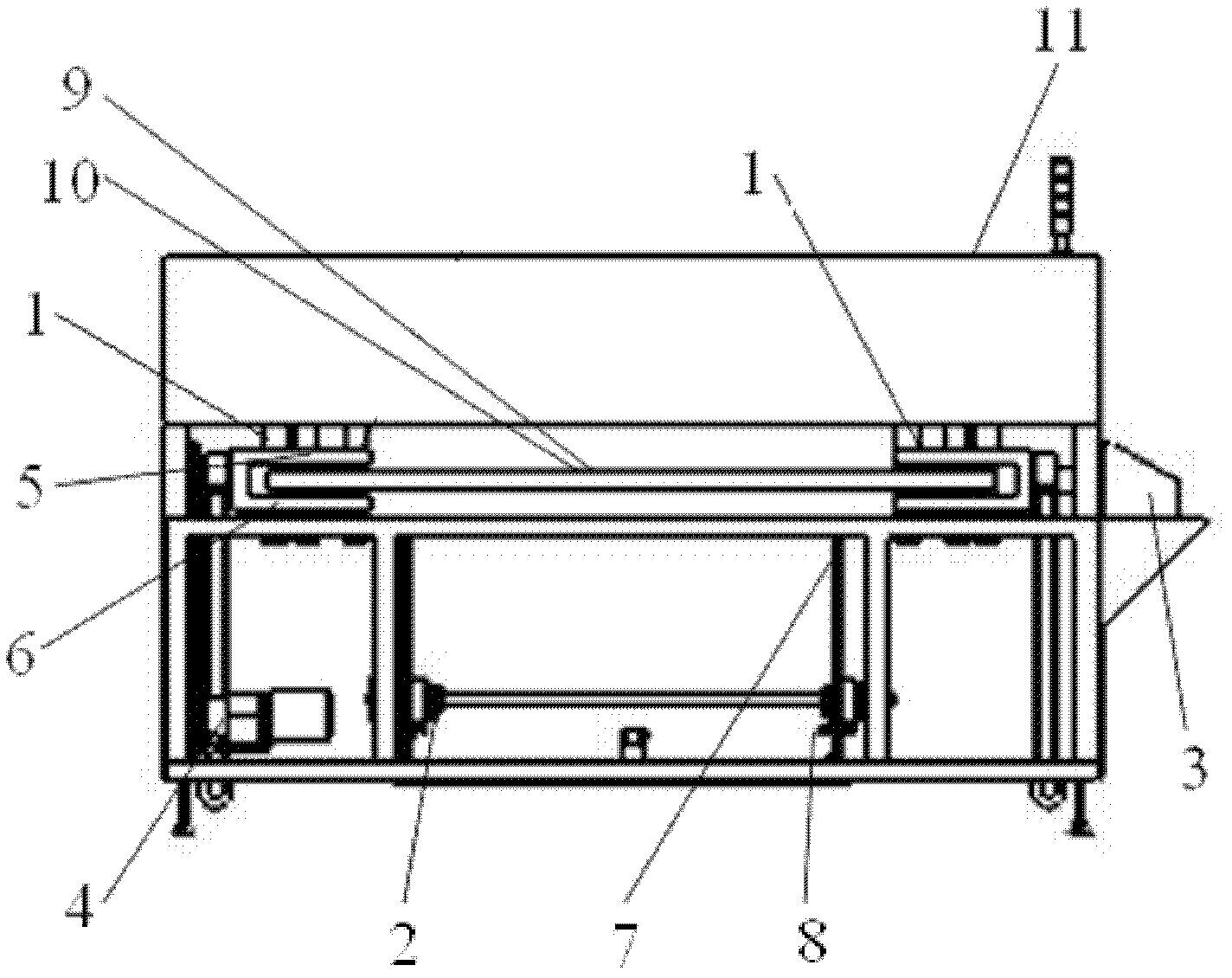

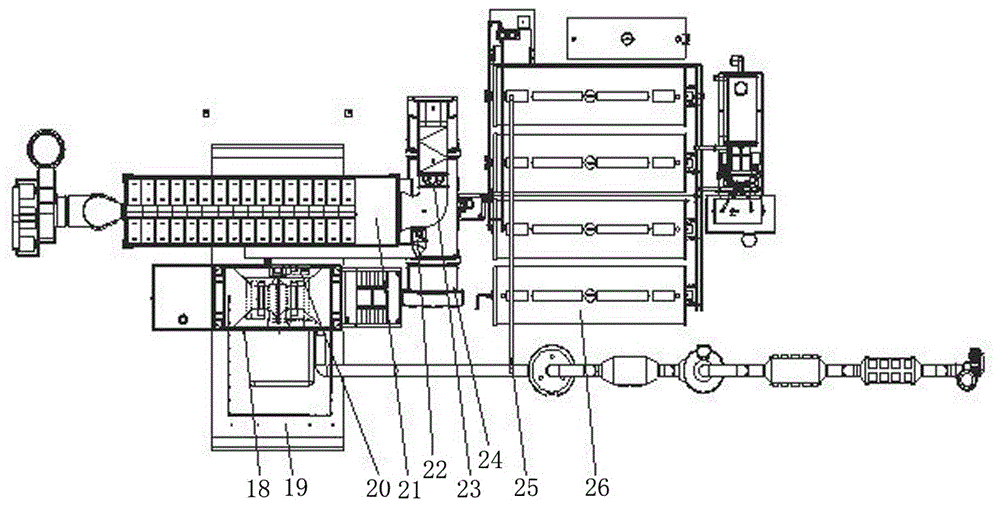

Mobile electron beam irradiation sterilizing installation

The invention relates to an electron beam irradiation sterilization equipment. The movable electron beam irradiation sterilization equipment of the invention consists of an electron beam irradiation accelerator and the control system, a vehicle chassis, a cabin installed on the chassis, an exhaust equipment and a power system installed in the cabin. The electron beam irradiation accelerator is installed in the cabin. The active effects of this invention are that: the electron beam irradiation accelerator and the control system, exhaust equipments and power system are all installed in the cabin of the vehicle chassis with small volume and mobility and flexibility, which can quickly shift in short time and has no special requirements on the applying environment and no extra construction. The invention can rapidly and thoroughly sterilize various kinds of documents and mails to keep them safe, without any damage on the radiated articles or any radiation remaining. Due to high automated integration, easy operation and safety, the invention is suitable to be applied in many domestic and international important organs.

Owner:TSINGHUA UNIV +1

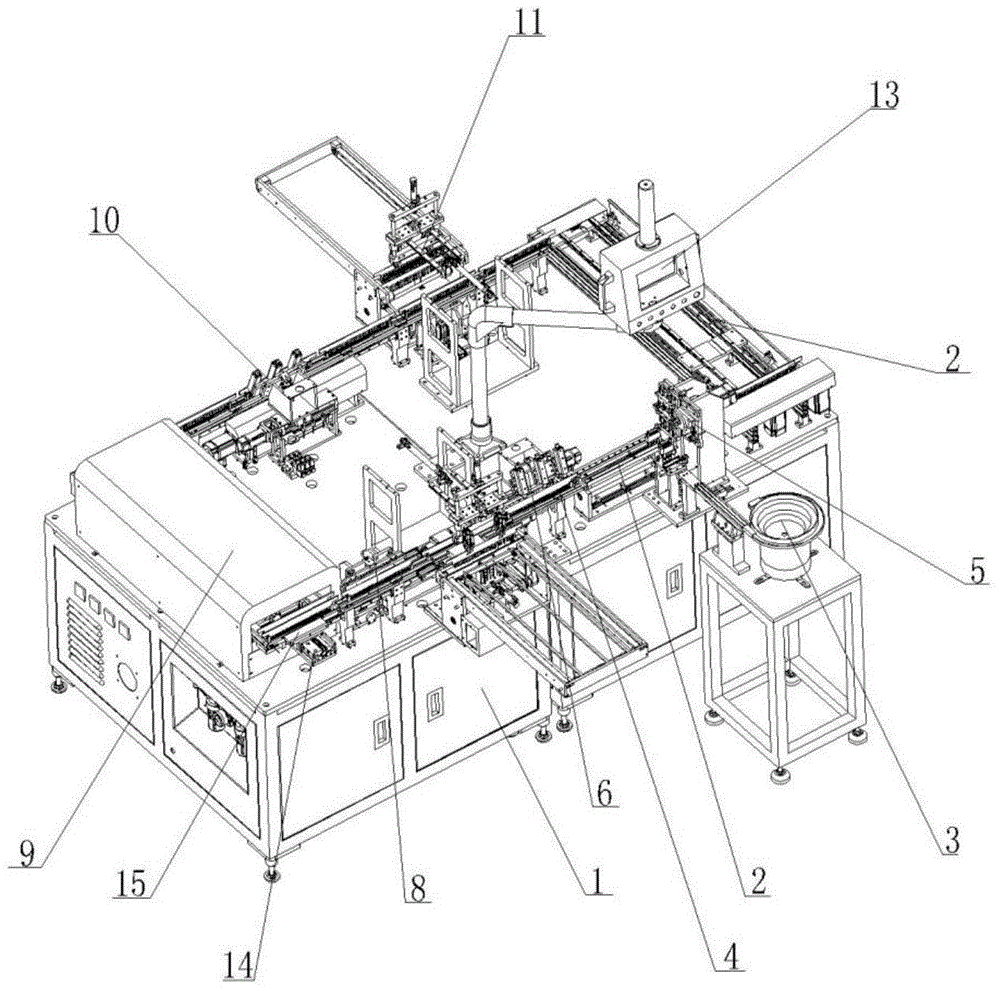

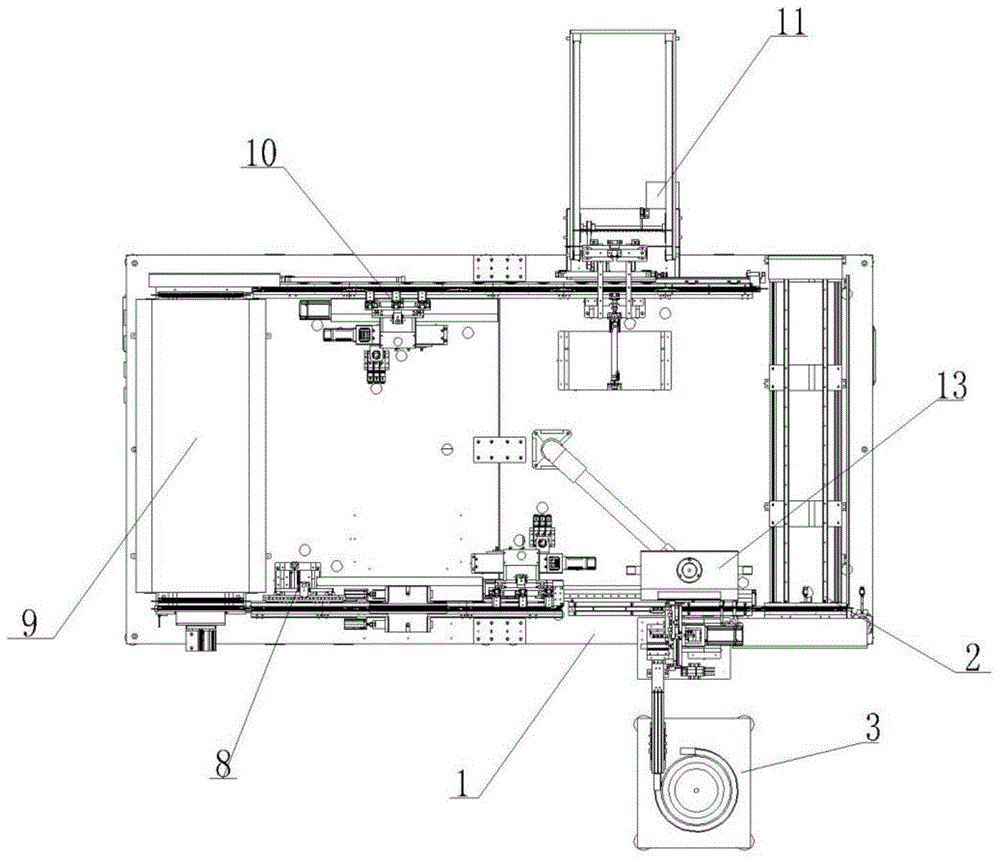

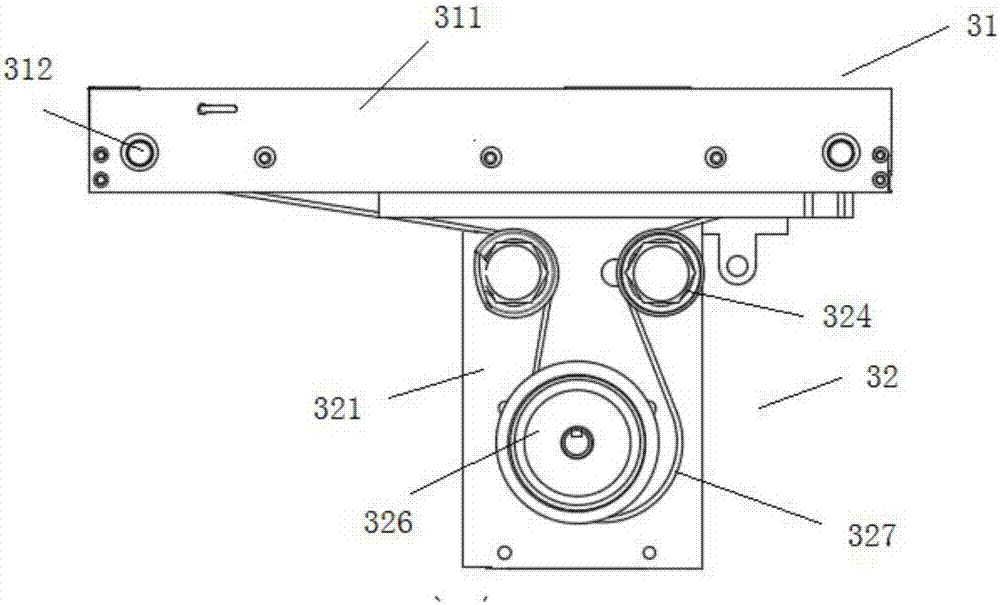

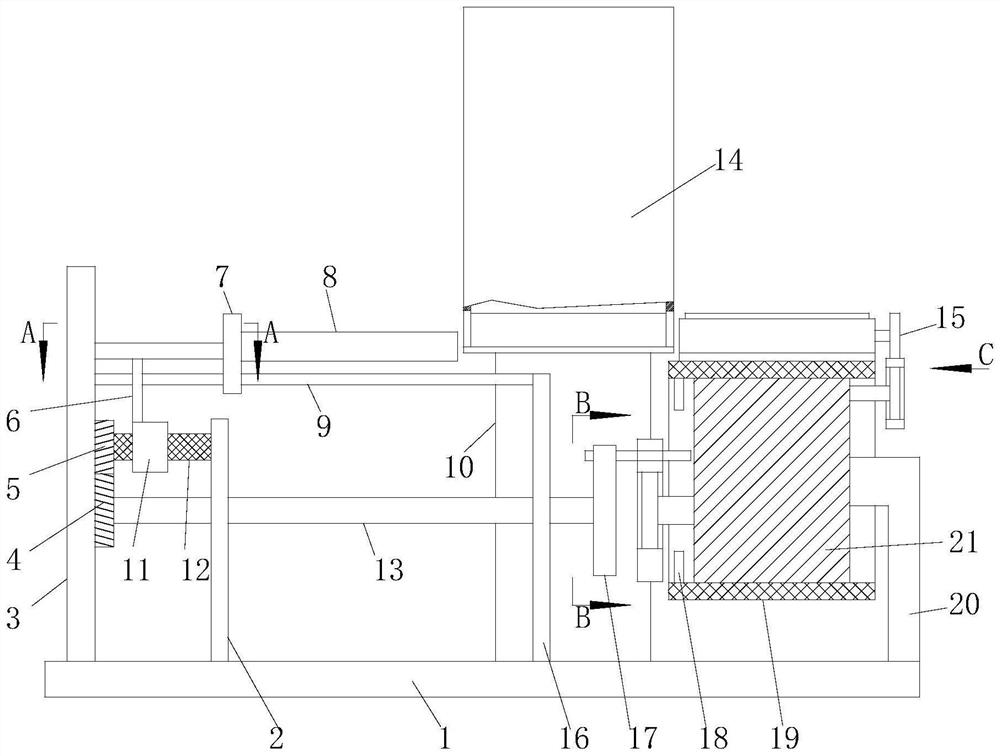

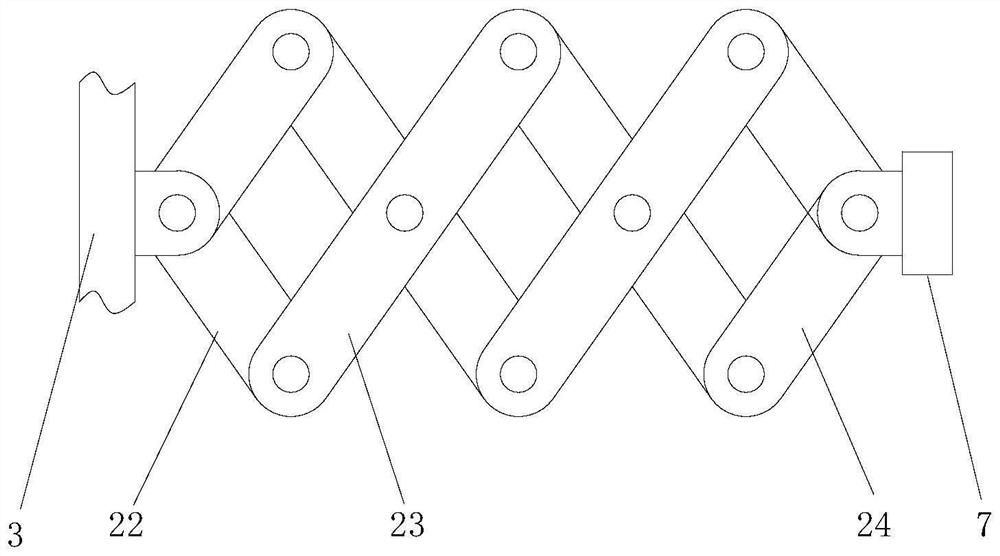

Air cylinder rod machining device and machining control method

ActiveCN105881019AImprove efficiencyImprove qualityAssembly machinesMetal working apparatusMachine controlEngineering

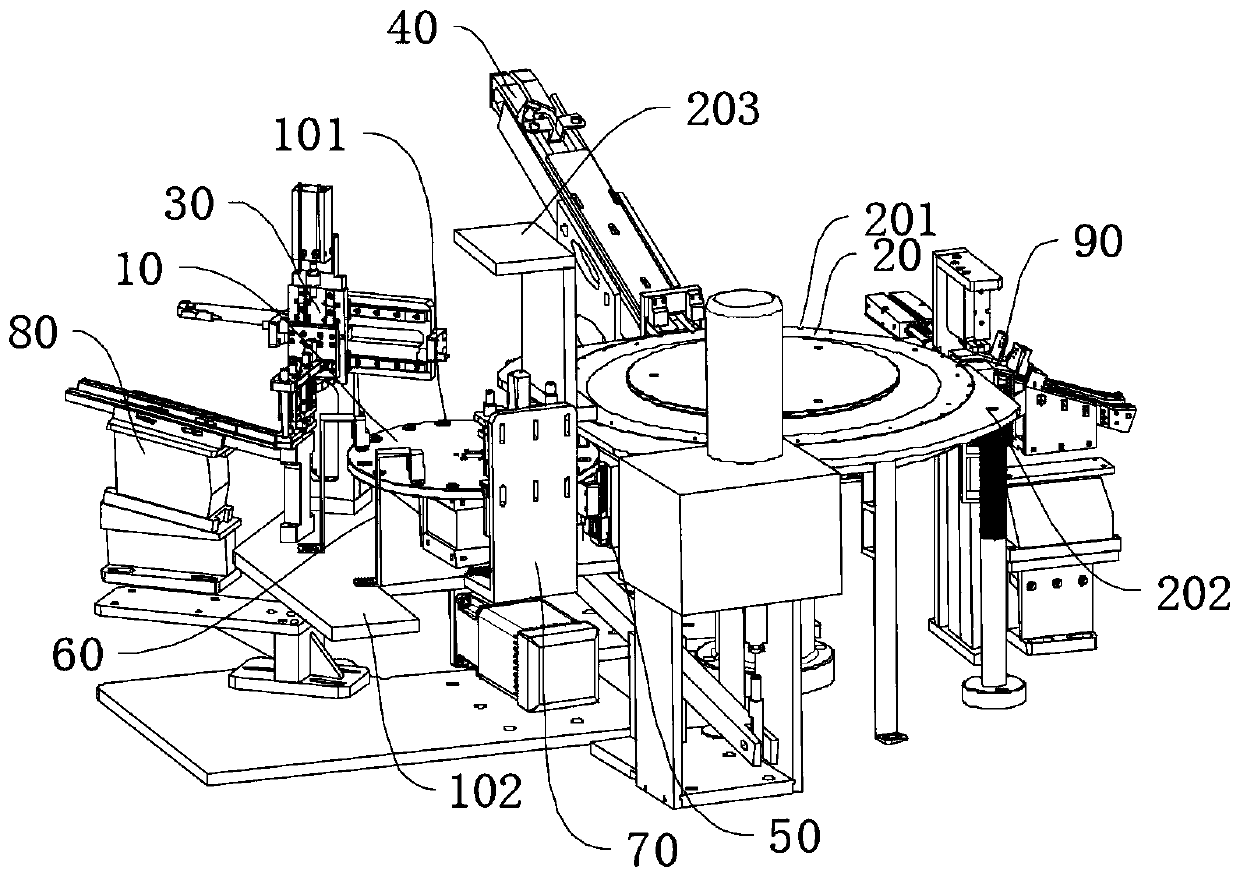

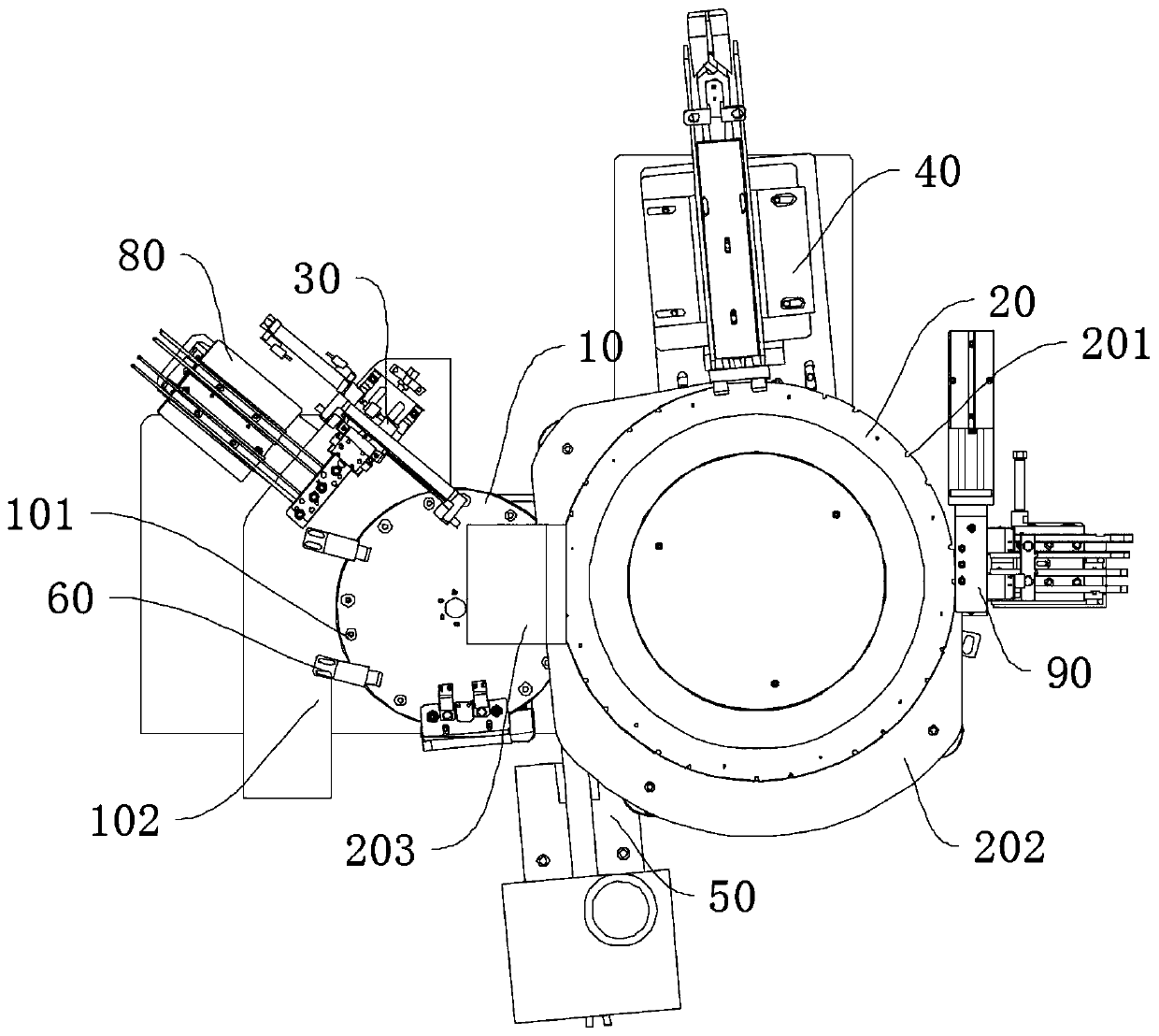

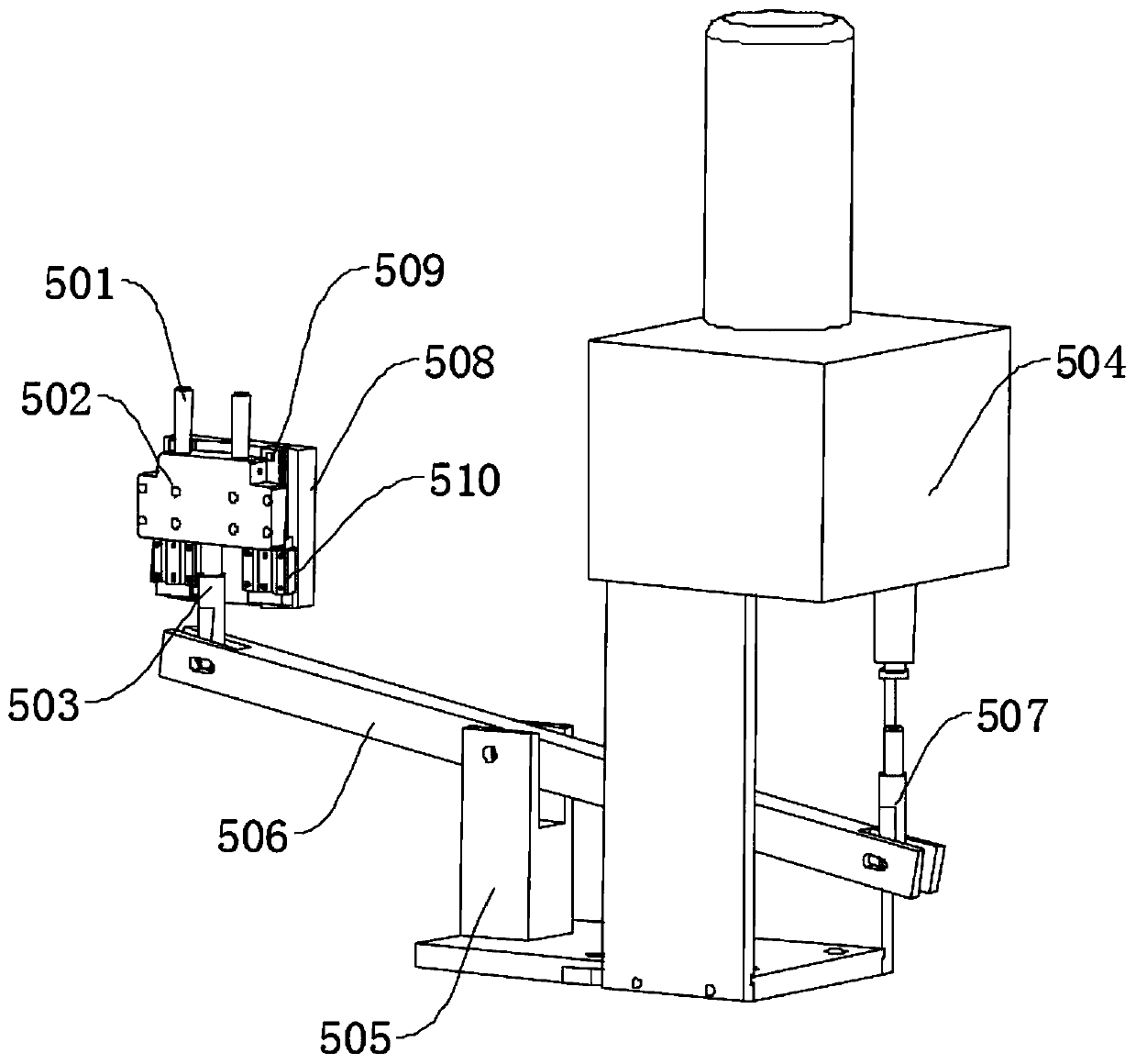

The invention discloses an air cylinder rod machining device and machining method, and belongs to the technical field of air cylinder rod assembly devices. The air cylinder rod machining device comprises a rotary plate cutting mechanism and an electric control system, and further comprises an air cylinder rod automatic feeding and placing mechanism, an automatic feeding and mounting mechanism, a piston rod automatic riveting mechanism and a product discharging system, wherein the electric control system is used for controlling operation execution procedures of the rotary plate cutting mechanism, the air cylinder rod automatic feeding and placing mechanism, the automatic feeding and mounting mechanism, the piston rod automatic riveting mechanism and the product discharging mechanism respectively; the rotary plate cutting mechanism is used for receiving to-be-machined air cylinder rods from the air cylinder rod automatic feeding and placing mechanism; the automatic feeding and mounting mechanism and the rotary plate cutting mechanism are matched with each other to mount and machine the to-be-machined air cylinder rods; the piston rod automatic riveting mechanism is used for riveting the air cylinder rod equipped with components; the product discharging system is used for discharging the machined air cylinder rods. According to the air cylinder rod machining device and machining method, the air cylinder rods are precisely placed by mechanical arms, so that the manual work omitted, automation is achieved, and the production efficiency and the quality are improved.

Owner:ANHUI LAITE GAS SPRING CO LTD

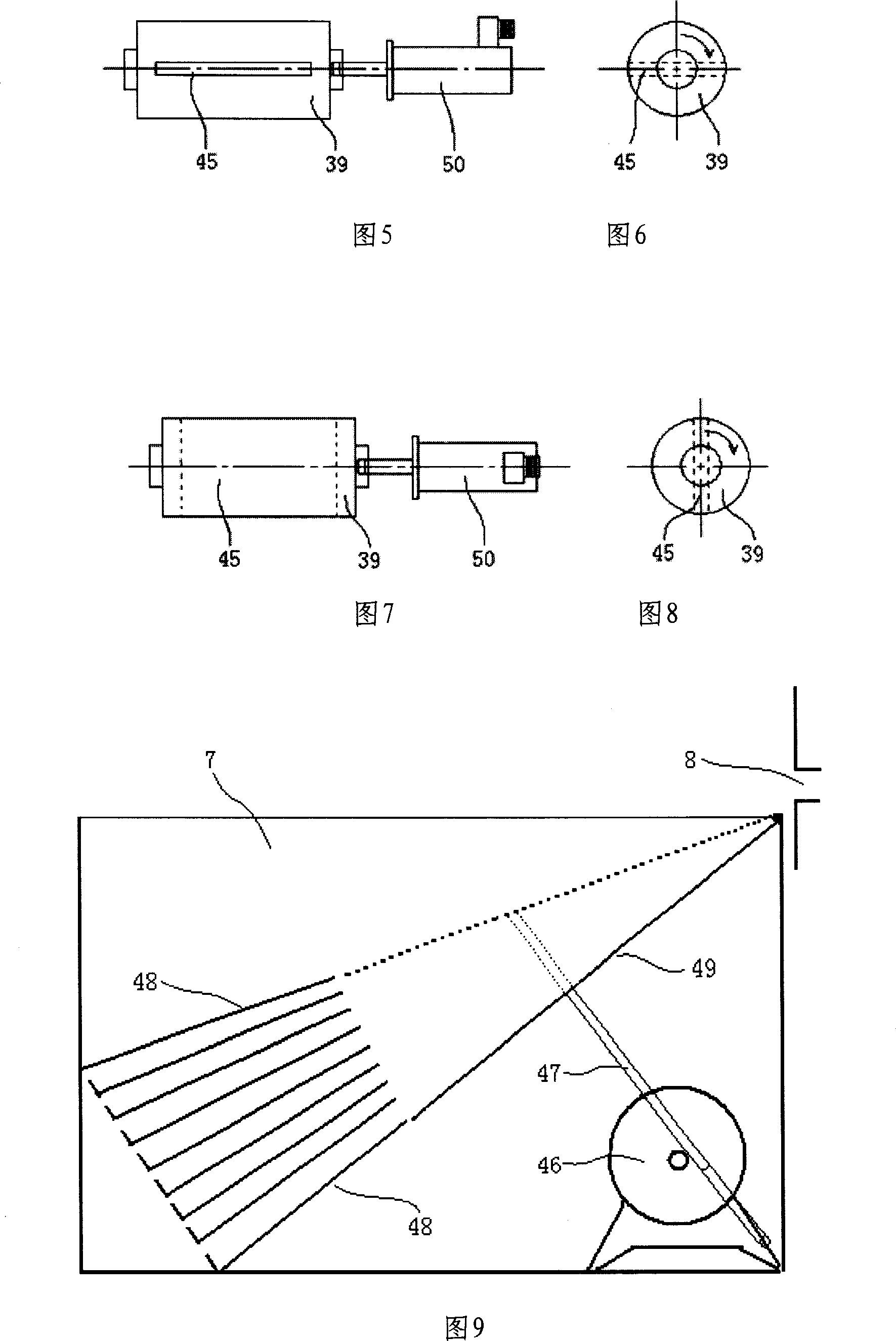

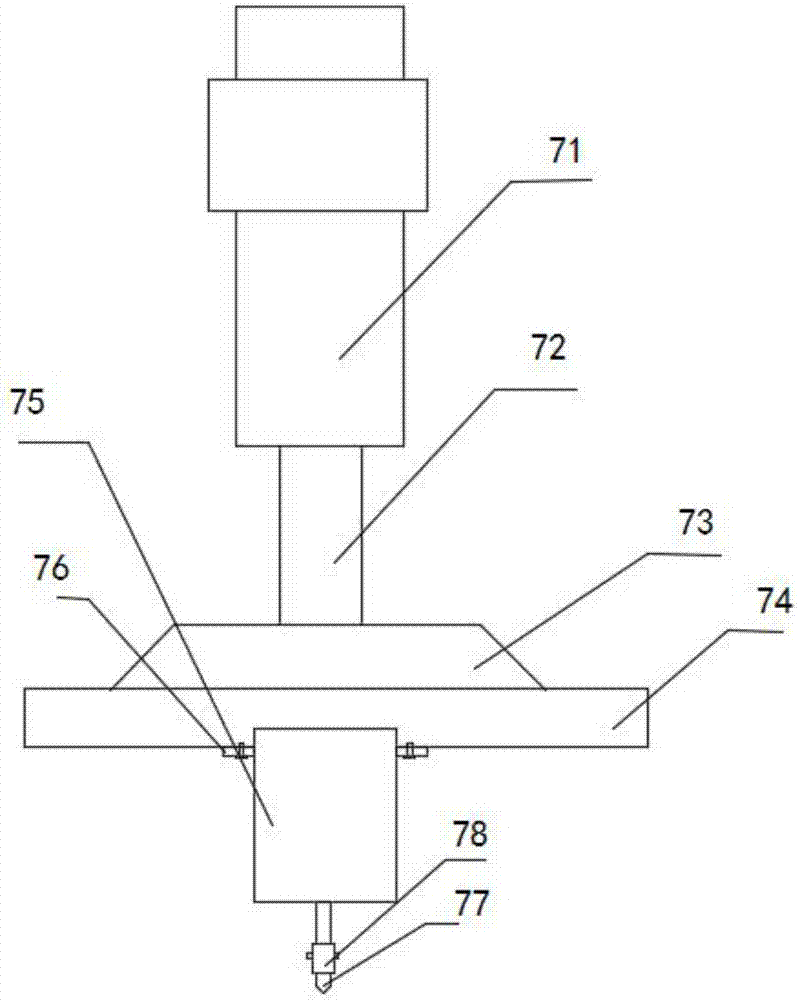

New material surface trepanning equipment

InactiveCN107309456AHigh degree of automation integrationIncrease productivityLarge fixed membersBoring/drilling machinesElectric machineEngineering

The invention provides new material surface trepanning equipment comprising a base and a movable drilling assembly arranged at the upper end of the base. A clamp is inserted in a clamp fixing groove and clamps flocked cloth needing to be drilled through to a sliding panel. The sliding panel moves in the left and right direction through a servo motor, and then the movable drilling assembly moves through a control shaft fixed seat of the servo motor. A lifting cylinder controls a drill bit to move downwards, and at the moment, the motor controls the drill bit to rotate for drilling. The new material surface trepanning equipment is high in automation integration level, production efficiency can be improved, and the defective rate is lowered greatly. Meanwhile, the new material surface trepanning equipment adopts a multi-shaft drilling mode, the adjustability of the equipment is improved greatly, and drilling efficiency can be improved.

Owner:嘉善梦溪服饰辅料厂(普通合伙)

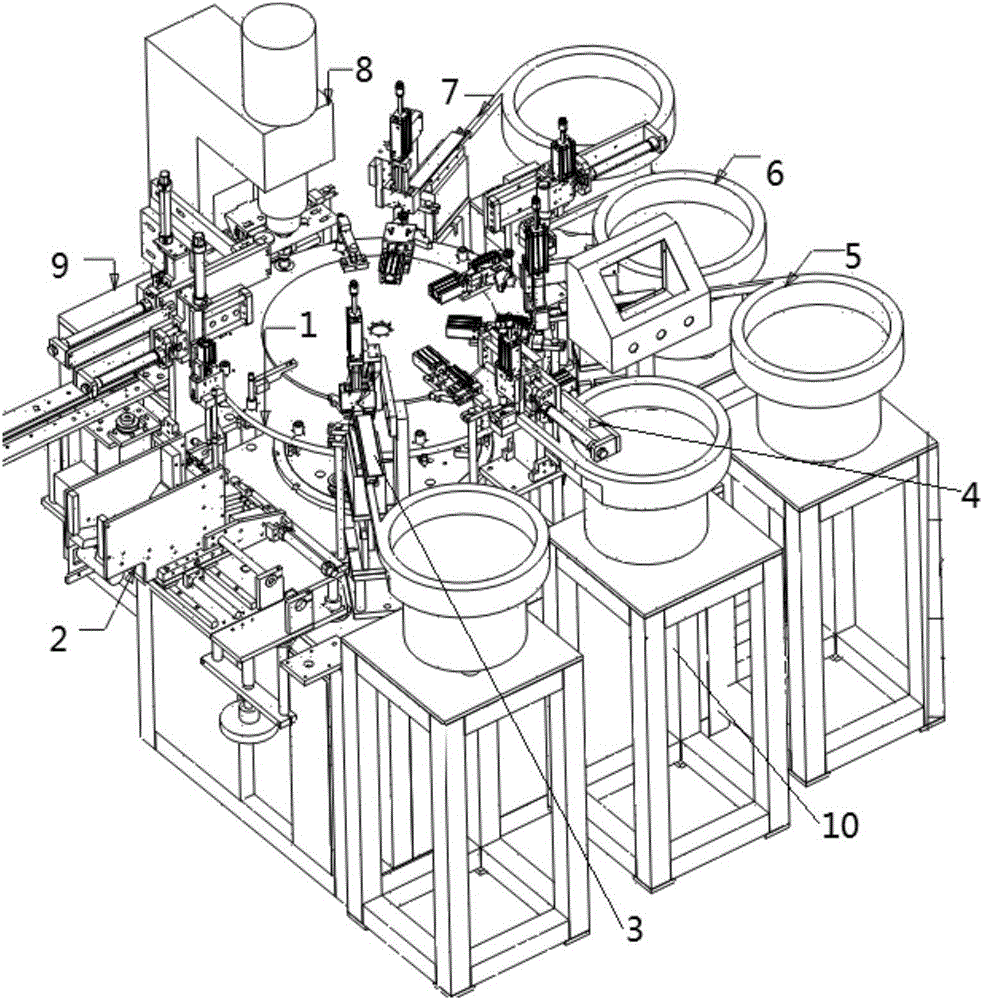

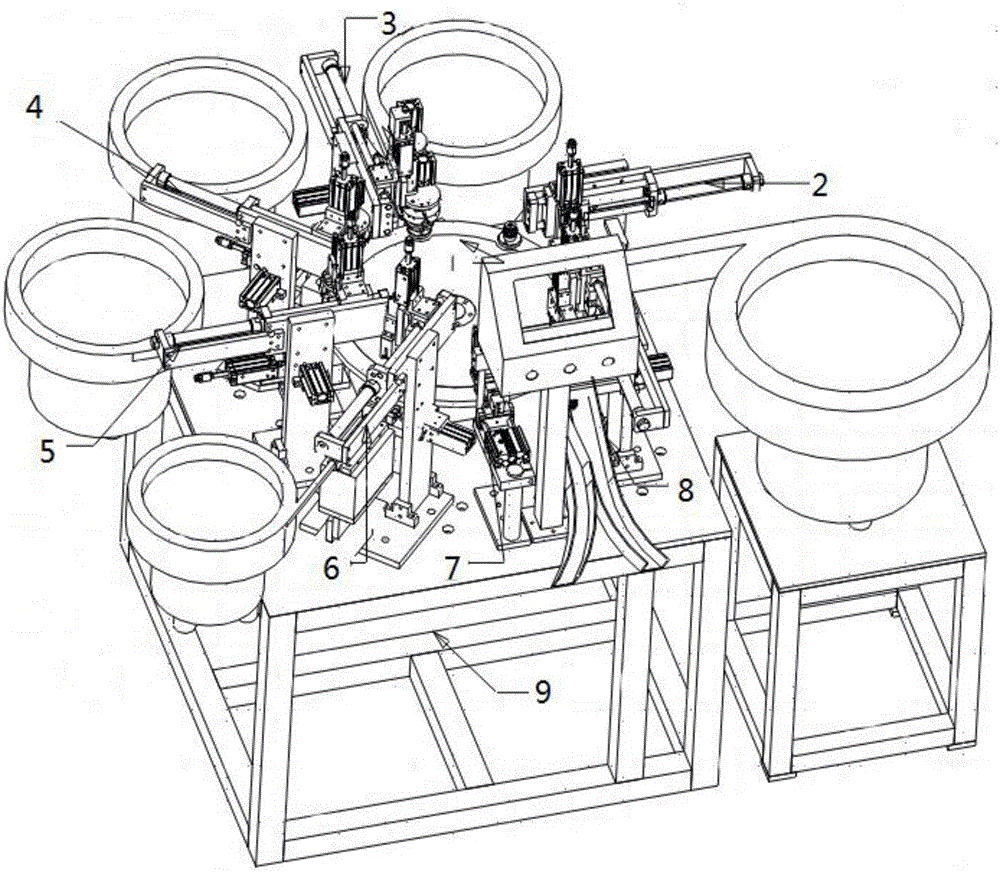

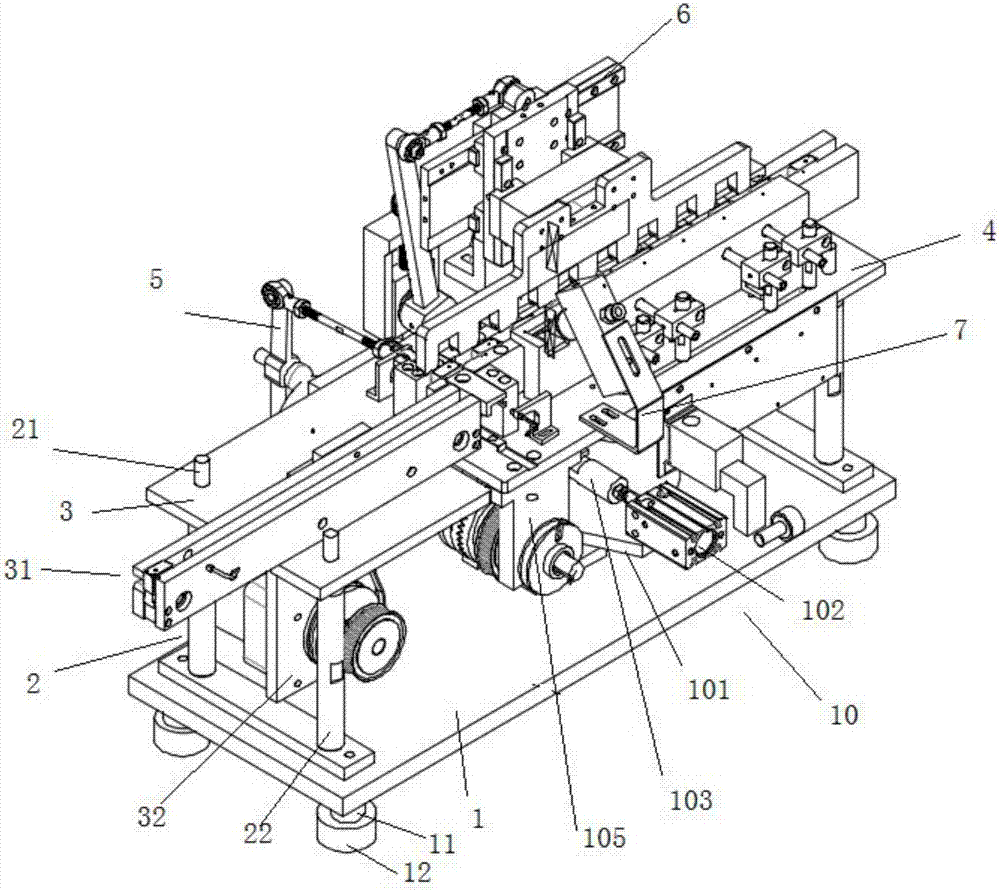

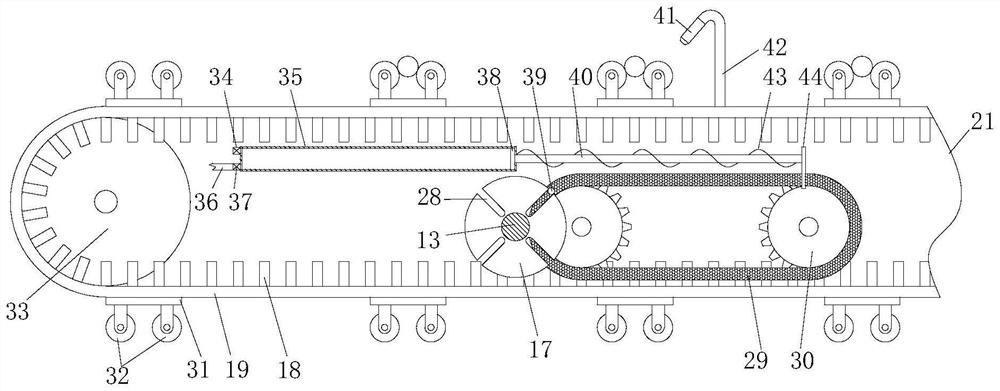

Assembly machine of T-shaped bushes and bolts

InactiveCN110549098AHigh degree of automation integrationReduce manufacturing costMetal working apparatusEngineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to an assembly machine of T-shaped bushes and bolts. According to the technical scheme, the assembly machine of theT-shaped bushes and the bolts comprises a first rotating disc and a second rotating disc located above the first rotating disc; multiple fixed holes allowing the T-shaped bushes to be placed are formed in the circumferential portion of the first rotating disc; multiple locating holes allowing the bolts to be placed are formed in the circumferential portion of the second rotating disc; a first C-shaped protection plate is further arranged on the outer portion of the second rotating disc; a T-shaped bush feeding mechanical arm grabs and places the T-shaped bushes to the fixed holes, and a bolt feeder conveys the bolts to the locating holes; a press-fitting mechanism is further arranged below the first rotating disc; a press plate is further arranged above the second rotating disc; and when the first rotating disc drives the T-shaped bushes to move to the positions below the locating holes with the bolts, an ejector rod of the press-fitting mechanism jacks up the T-shaped bushes and sleeve the outer portions of the bolts with the T-shaped bushes, and the press plate is used for limiting the bolts.

Owner:华磊(嘉兴)智能科技有限公司

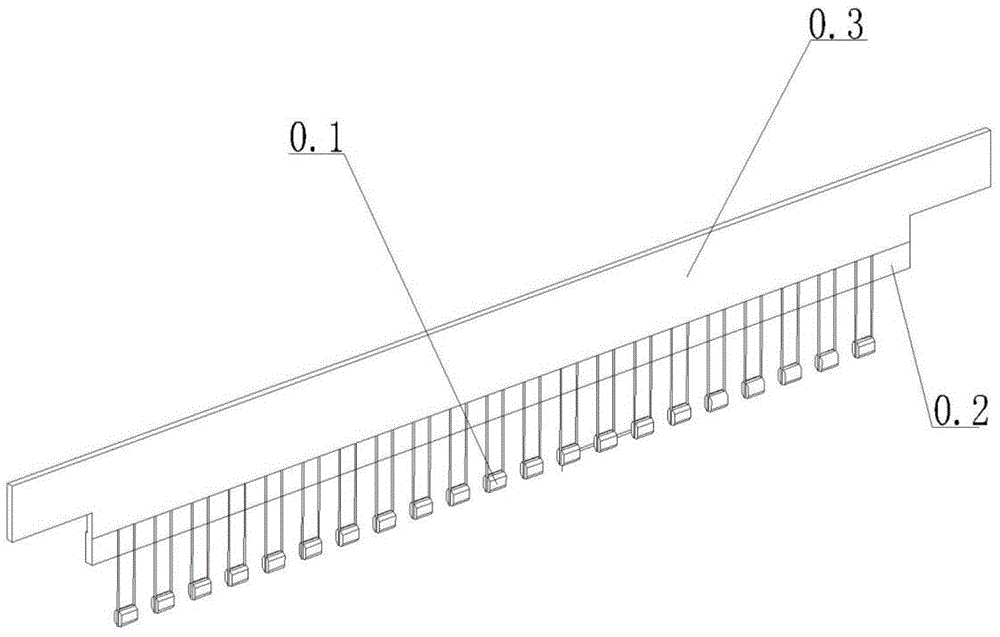

Capacitor shell-inserting machine

InactiveCN105321735AOvercoming technical difficultiesReduce the possibilityCapacitor manufactureCapacitanceMechanical engineering

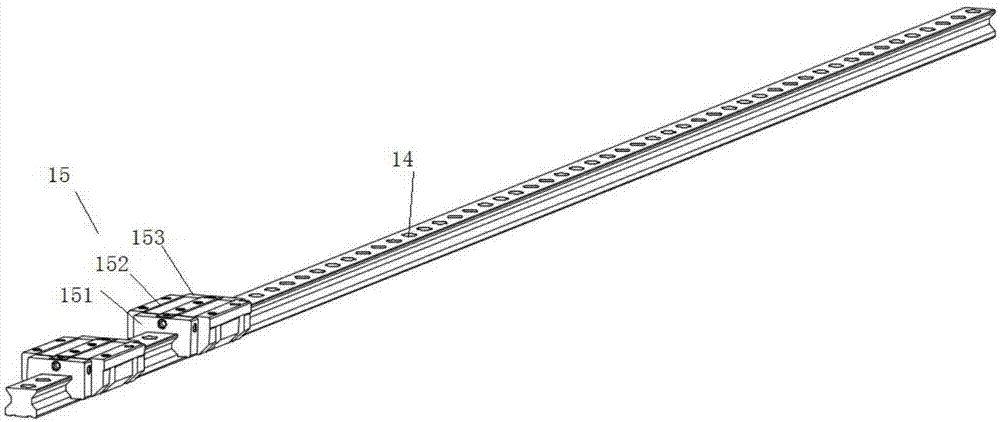

The invention relates to the field of capacitor production processes, in particular to a capacitor shell-inserting machine which is capable of performing mechanical automatic shell-inserting package on a plurality of granular capacitors without the need for a manual operation and is extremely low in defective rate. The capacitor shell-inserting machine comprises a machine body, a guide rail, a vibratory feed plate, a carrier with a groove, a first conveying arm capable of conveying sleeving shells at a discharge hole of the vibratory feed plate onto the carrier, a plurality of first dispensing machines, a limiting apparatus used for limiting the spacings and positions of the granular capacitors when falling into the carrier, a pressing apparatus used for pressing the capacitors and the sleeving shells, a drying apparatus, a plurality of second dispensing machines, a second conveying arm used for removing the capacitors sleeved with the shells, and a center console, wherein the guide rail is mounted on the machine body; the carrier is positioned in the guide rail and is in sliding fit with the guide rail; and the first conveying arm, the first dispensing machines, the limiting apparatus, the pressing apparatus, the drying apparatus, the second dispensing machines and the second conveying arm are mounted on the machine body in sequence.

Owner:WUXI YUANCHUANG TECH CO LTD

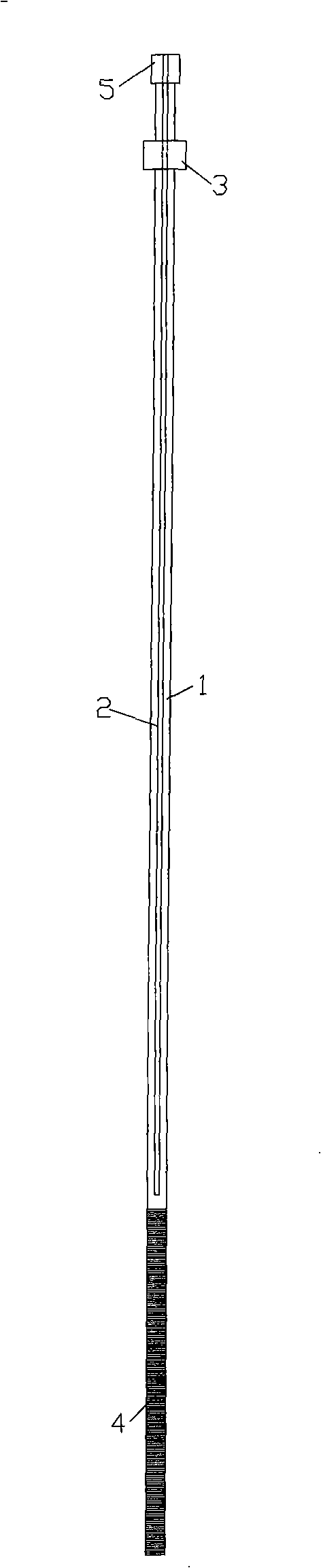

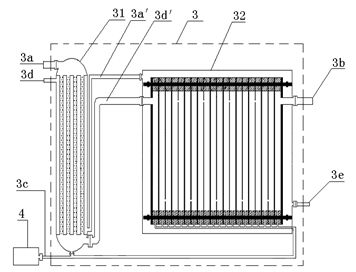

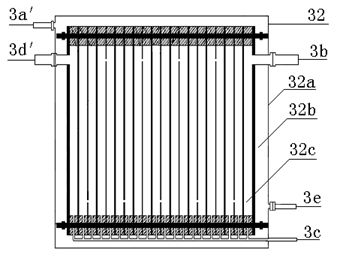

Optical fiber grating sensing mine safe monitoring technique with novel anchoring rod as sensing medium

InactiveCN101354445AIncreased durabilityLong transmission distanceOptical detectionFiberInformation transmission

The invention provides a fibre grid sensing mine safety monitoring technique which uses a novel anchor rod as sensing medium; the fibre grid is used as information transmission medium; simultaneously, the anchor with a concave trough is used for encapsulating and protecting the fibre grid so as to solve the problems of moist metal mine environment and severe condition; a round ring is welded at a position which has a certain distance away from the end of the anchor rod so as to protect the fibre grid sensor against the damage of external force. The safety of the mine is improved and the safe production of the mine is ensured by analysing the transmission data and monitoring the mine. The technique of the invention has the advantages of high precision, strong anti-interference capability, low cost, high automatic integration level, being convenient for arrangement and installation, simple operation, remote monitoring and long-term monitoring and the like.

Owner:宋波

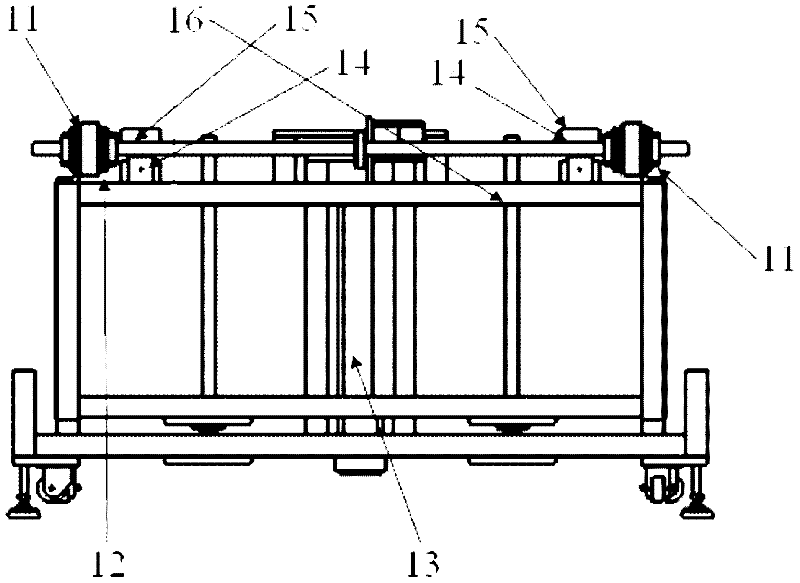

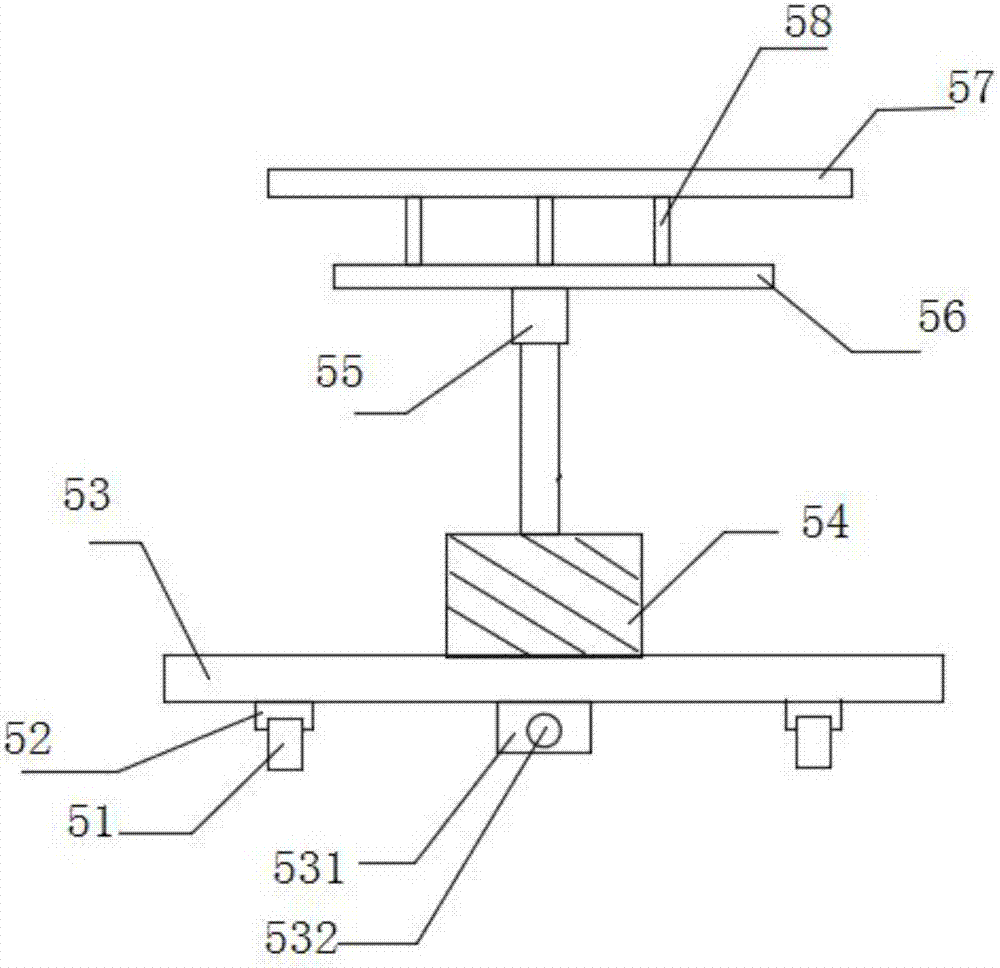

Turnover device of solar battery assembly

InactiveCN102208494ATakes up little work spaceSmall range of motionSemiconductor devicesLower limitControl system

The invention relates to a turnover device of a solar battery assembly. The turnerover device comprises a clamp turnover mechanism, a conveyor belt lifting mechanism, a control system, a chain wheel drive mechanism, an upper limit position sensor, a lower limit position senor and a protective outer frame, wherein a clump sensor and an assembly judgment sensor are installed on the clamp turnover mechanism; the chain wheel drive mechanism and the conveyor belt lifting mechanism are located below the clamp turnover mechanism; the upper limit position sensor and the lower limit position senor are respectively installed on the upper part and lower part of the conveyor belt lifting mechanism; the protective outer frame is arranged at the periphery of the turnover device; and the control system is arranged on the side part of the outer frame. Compared with the prior art, the turnover device has the advantages of enhanced compatability, high equipment utilization ratio, low cost and the like, and is convenient for use; and relative friction dose not occur in the processes of turnover and transportation, the edges and frames of the assembly have no rubber imprints, and the fragment rate is controlled at 0%, thereby effectively avoiding the pollution and breakage of a battery.

Owner:SHANGHAI WEISONG IND AUTOMATION

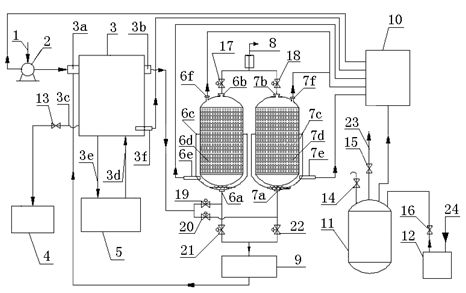

Solvent oil-gas reclaiming device

InactiveCN102553284ARealize compound multi-stage condensation recoveryImprove regenerative abilityDispersed particle separationVapor condensationEngineeringLow vacuum

The invention discloses a solvent oil-gas recovering device, wherein the oil-gas can be desorbed and recovered under a lower vacuum condition completely. The invention adopts an oil-gas isolation technology of combination of a traditional condenser and a jacket cooling metal wire net membrane filter, thereby realizing composite multistage condensation reclaiming; and meanwhile a heater is arranged outside the lower part of an absorption tank, and the heater is controlled by a micro computer to heat the absorption tank after an adsorbing material is saturated under on-line monitoring, so that the technical problems that a drying vacuum pump has a lower vacuum degree and the absorbing material is desorbed incompletely are solved effectively. The whole set of the device provided by the invention has a high atomization integration level, a saved investment, security and reliability; the recovering effect of the absorbing material is higher than 99%; the oil-gas reclaiming rate is more than 99%; and the gas emission pollutant can reach the national standard completely.

Owner:SUZHOU DA LING ENVIRONMENTAL TECH CO LTD

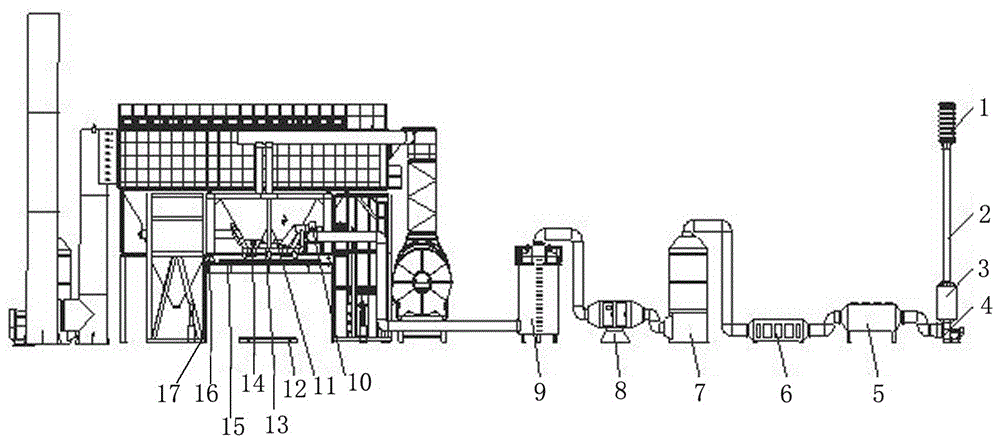

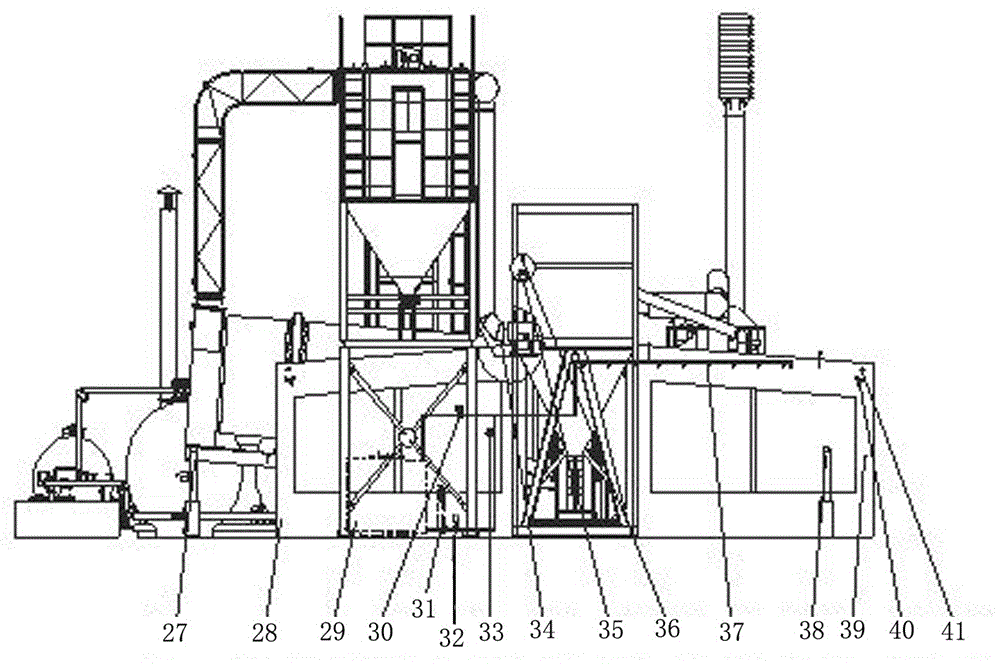

An intelligent environmental protection asphalt mixing equipment loading system and its method of use

ActiveCN106480806AStop and contain spillsPrevent and isolate damageRoads maintainenceAtmospheric emissionsSuspended particles

The invention discloses intelligent environmental protection asphalt mixing equipment loading system, through the driveway adaptive closed module building half closed / closed loading environment, effectively avoiding the pollution spillover, and reducing the spread of noise; Through the finished intelligent load module product to ensure the uniformity and continuity of the aggregate load, and ensure the quality of the load; Through the asphalt smoke processing module to get rid of the harmful material in asphalt gas rapidly, efficiently and thoroughly, and make it reach the standard atmospheric emissions; Through the dust processing module, reducing the environment pollution; Through the dry fog dust module effectively reducing the load of dust and the concentration of suspended particles, then improving the comfort of finished product loading zone . Compared with the existing technology, the present invention is simple and practical, with high integration automation, simple operation, which is used to solve the problems of difficult loading, low efficiency, material segregation, noise, dust and asphalt gas pollution and other issues in loading process.

Owner:河南亚龙智能装备有限公司

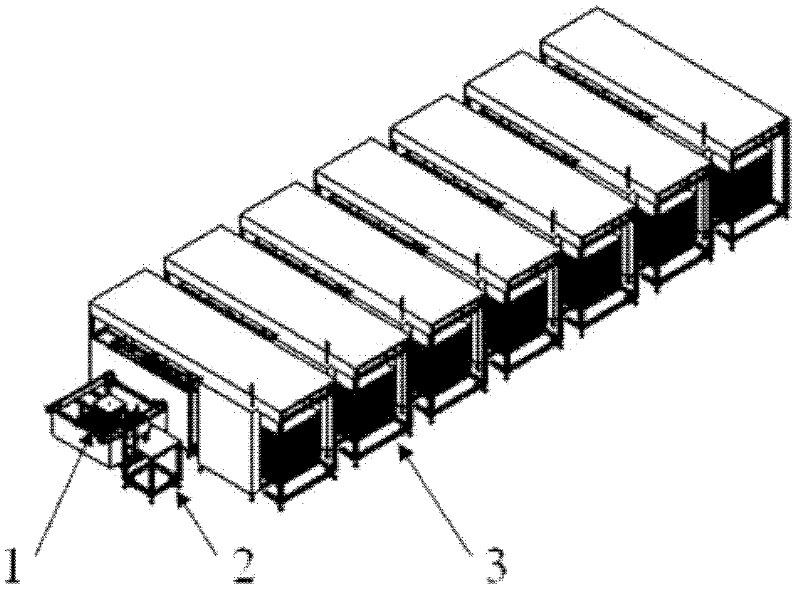

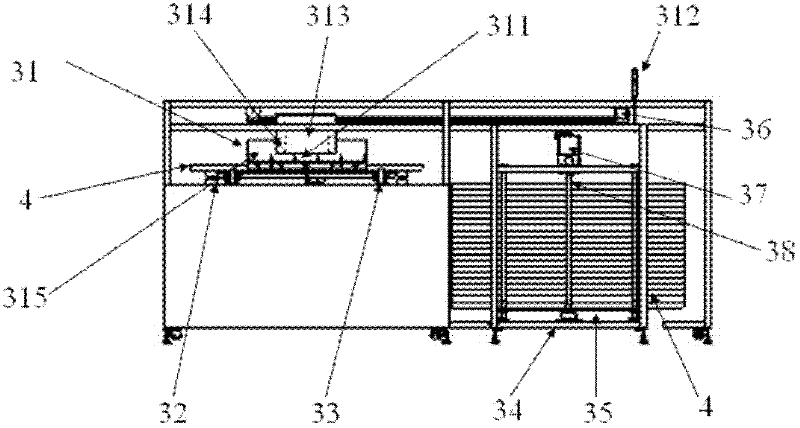

Sorting device for solar battery pack

The invention relates to a sorting device for a solar battery pack. The sorting device consists of a transferring component, an electric control component and seven sorting components, wherein the sorting components are arranged side by side; and the transferring component and the electric control component are arranged on the side of one sorting component. Compared with the prior art, the sorting device has small movement range, and is stable in carrying and transportation, quick in movement, high in compatibility and applicable to components of different specifications, the equipment utilization rate is improved, relative friction during sorting and transportation is avoided and orientation performance is high; the border edges of the components are free of rubber marks, so the fragmentrate of the sorting device is controlled to be zero, the automatic integration degree of a production line is increased and the preparation for automatic package is made; furthermore, the production efficiency is improved and the labor cost is saved.

Owner:SHANGHAI WEISONG IND AUTOMATION

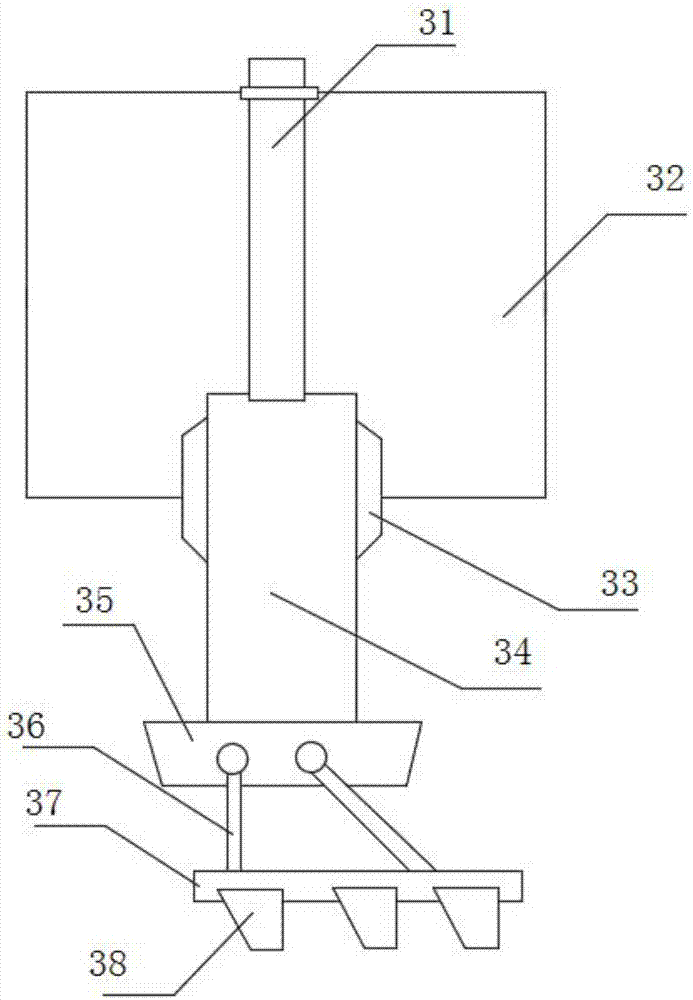

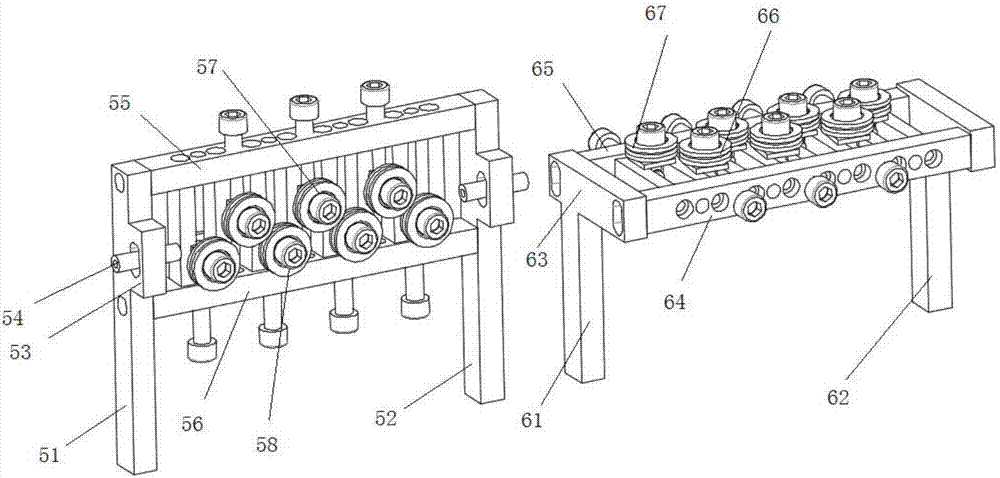

Surface drilling device for flocked cloth

InactiveCN107097292AHigh degree of automation integrationIncrease productivityLiquid surface applicatorsCoatingsDrill bitSurface plate

The invention discloses a surface drilling device for flocked cloth. The surface drilling device comprises a base and a movable drilling assembly arranged at the upper end of the base, wherein a fixture is inserted into a fixture fixed groove; the flocked cloth needing to drill is clamped on a sliding panel; the sliding panel is controlled by a servo motor to move leftwards and rightwards; successively, the movable drilling assembly moves by a control shaft fixed base of the servo motor; a drilling head is controlled by a lifting air cylinder to move downwards; and the drilling head is controlled by the motor to rotate to carry out drilling. The surface drilling device for the flocked cloth is high in automatic integration degree, is beneficial for improving production efficiency, and greatly reduces defective rate; meanwhile, by adopting a multi-shaft drilling way, the surface drilling device for the flocked cloth greatly improves the adjustability of the device, and is beneficial for improving the drilling efficiency.

Owner:JIASHAN SHENGLAISI CASHMERE

Industrial robot teaching station

PendingCN106782008ASimple structureImprove compactnessEducational modelsVisual inspectionWorkstation

The invention discloses an industrial robot teaching station and relates to the field of teaching equipment. The industrial robot teaching station comprises an industrial robot body, a visual inspection controller, a material assembly position platform, a driving device, a sliding rail, a PLC, a detection device and a detection result prompt device. The visual inspection controller inspects the color, outline and size data and the position of a material and transmits the data and position information to an industrial robot controller. A sliding chute matched with the sliding rail is arranged on the bottom of the material assembly position platform. The detection device can detect whether a material at a detection position is assembled correctly. The PLC controls the driving device to drive the material assembly position platform to move along the sliding rail to the detection position, receives a detection signal detected by the detection device, and transmits the detection signal to the industrial robot controller. The PLC controls the detection result prompt device to be started according to the detection result of the detection device. The industrial robot teaching station is high in structural integrity and compactness, high in automatic assembly precision and integration level, and capable of fully meeting teaching requirements.

Owner:BEIJING C H L ROBOTICS CO LTD

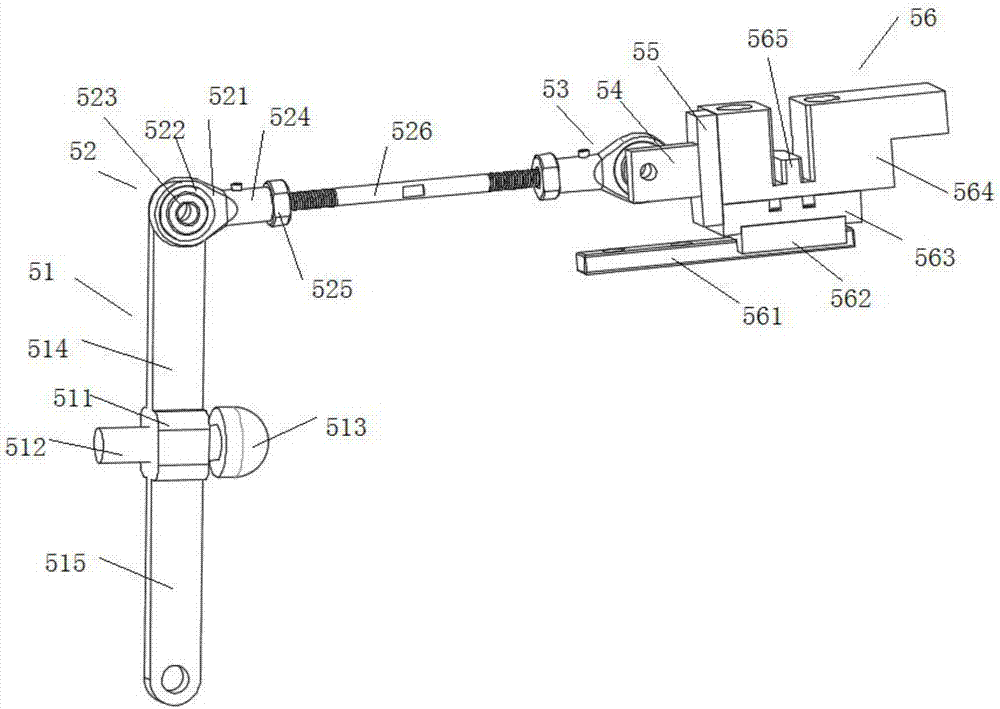

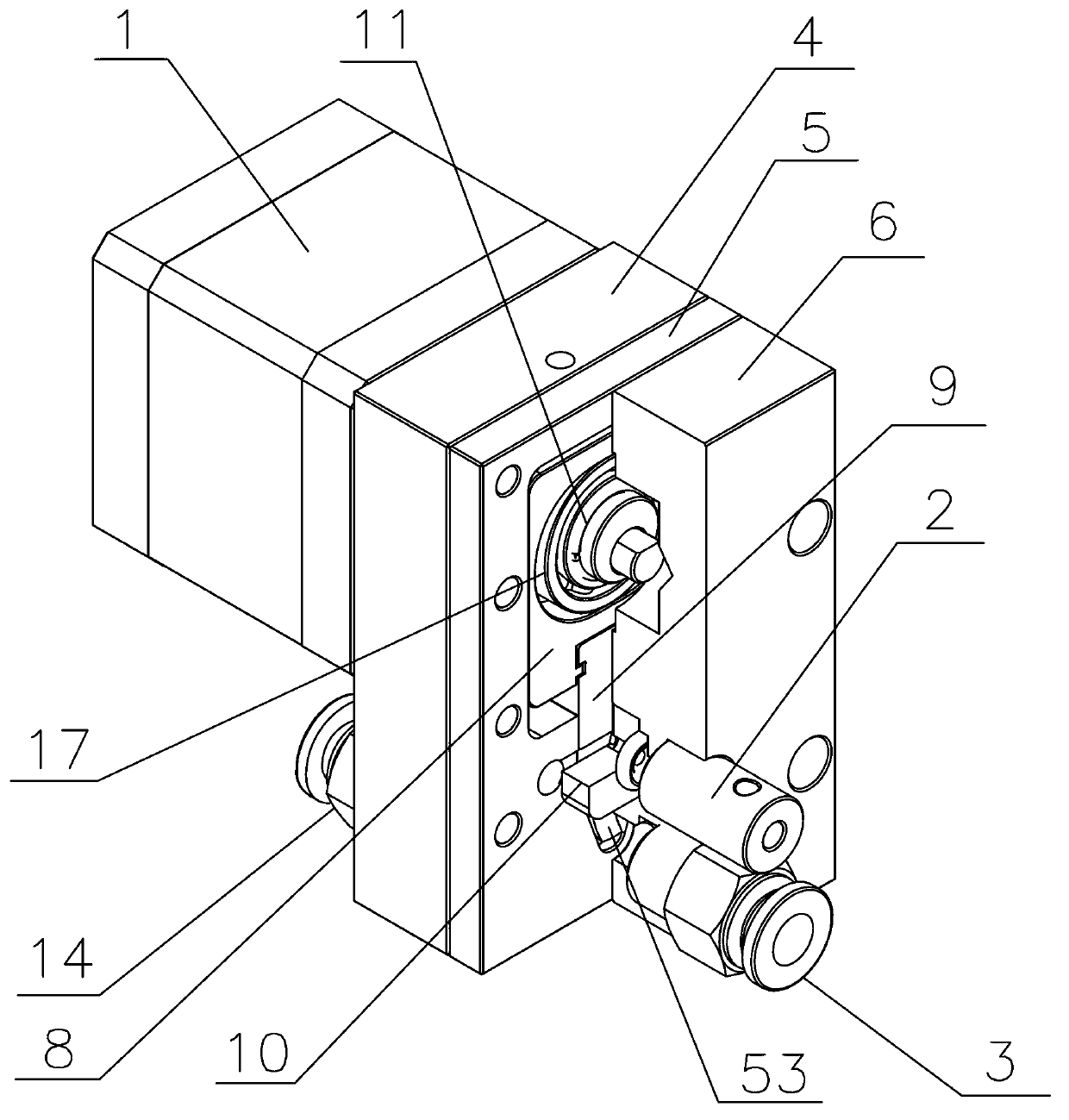

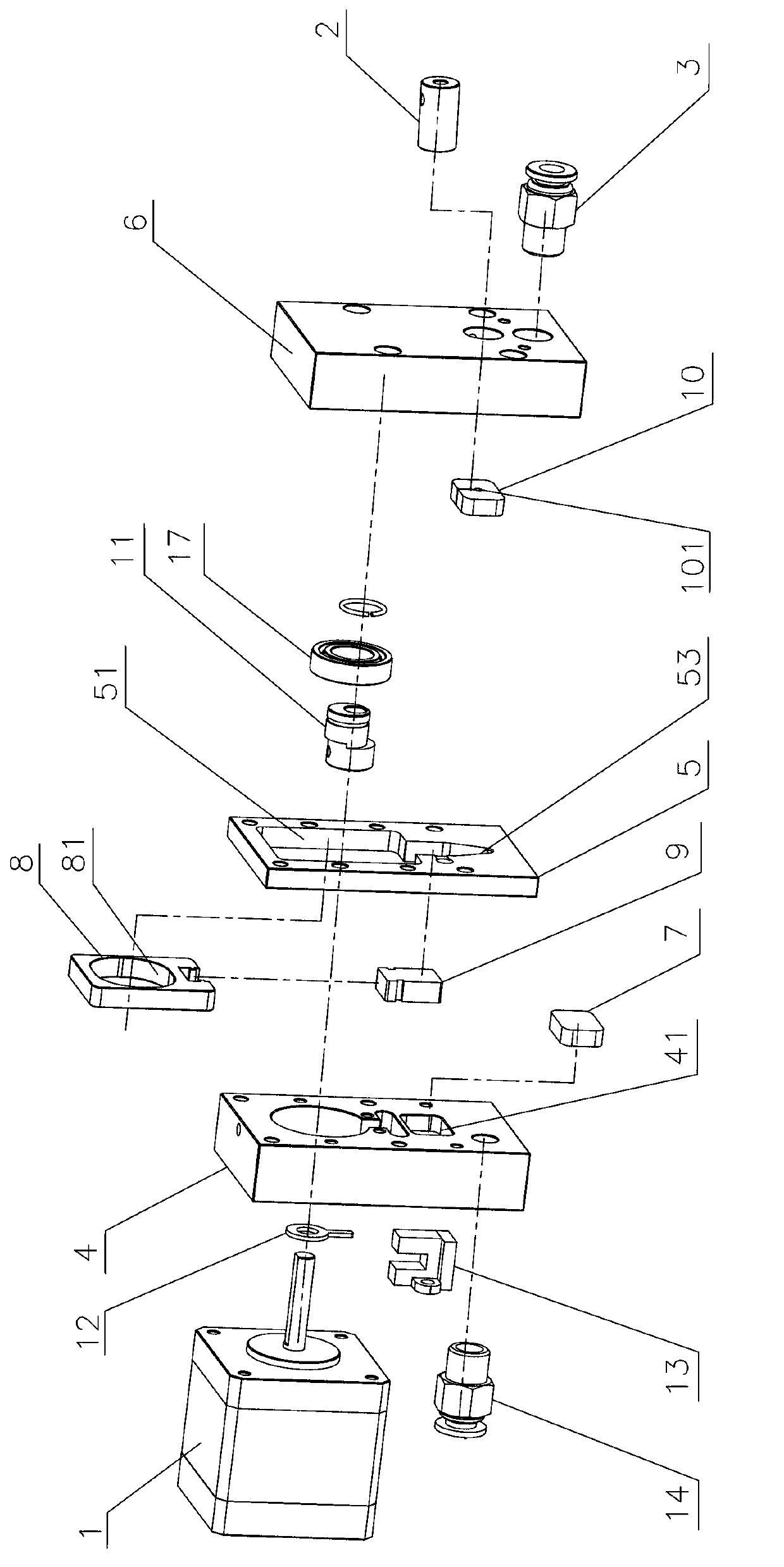

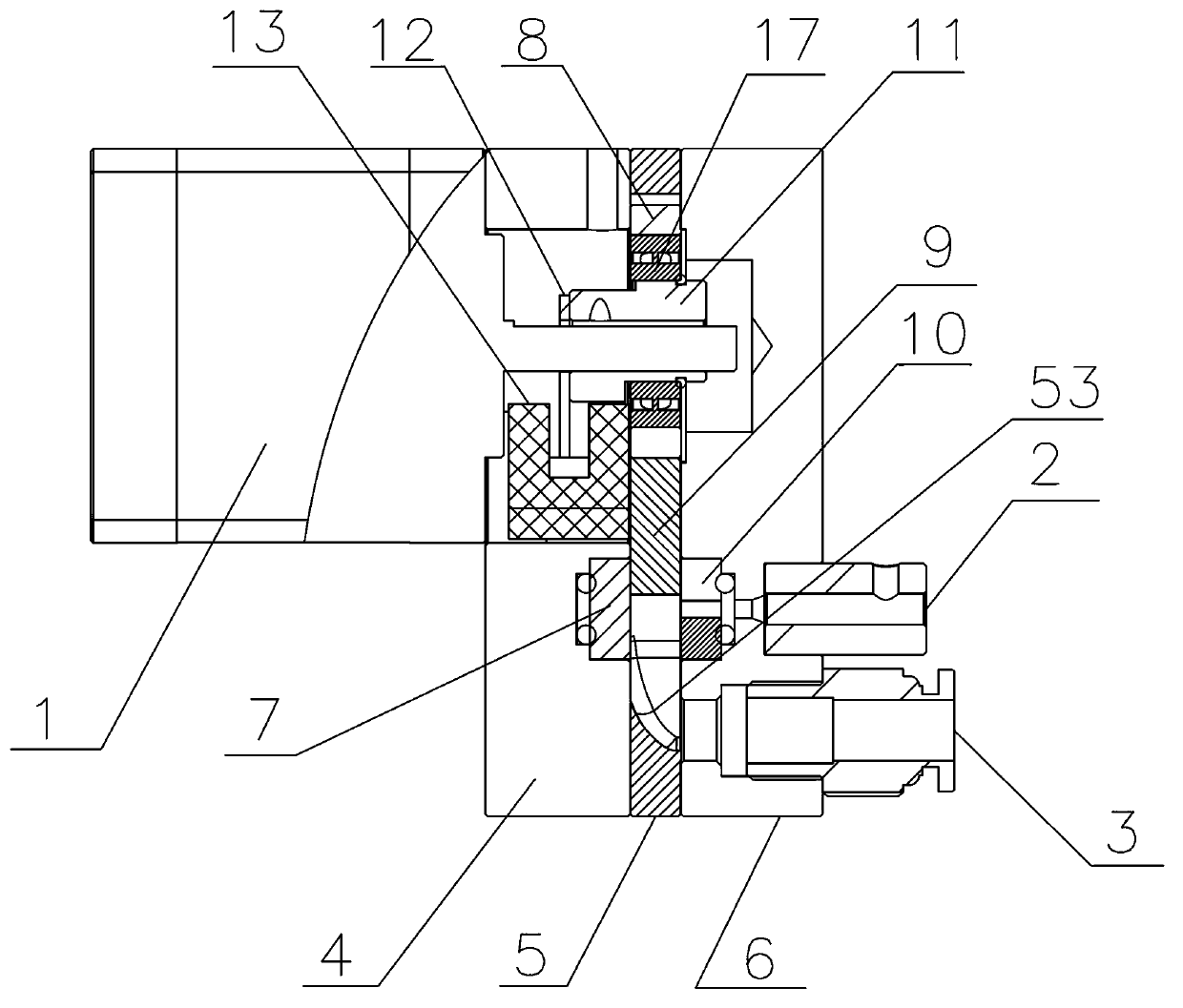

Control valve superior and inferior product checking and sorting mechanism, control valve machining equipment and machining and control method

InactiveCN105881020AIncrease productivityImprove product qualityAssembly machinesGeological measurementsMachine controlEngineering

The invention discloses a quality control valve inspection and classification mechanism, control valve processing equipment and a processing and control method, and belongs to the technical field of control valve assembly equipment. It includes a turntable dividing mechanism and an electric control system, as well as an automatic feeding and installation mechanism and a valve control outlet mechanism. The automatic feeding equipment of the mechanism receives the control valve to be processed, and the installation equipment of the automatic feeding and installation mechanism installs and processes the components on the control valve. The control valve is discharged, and the turntable dividing mechanism is evenly equipped with control valve fixtures, and the automatic feeding equipment of the automatic feeding and installation mechanism places the control valves on the control valve fixtures. It uses a manipulator to place it precisely, saves labor, realizes automation, and improves production efficiency and quality.

Owner:ANHUI LAITE GAS SPRING CO LTD

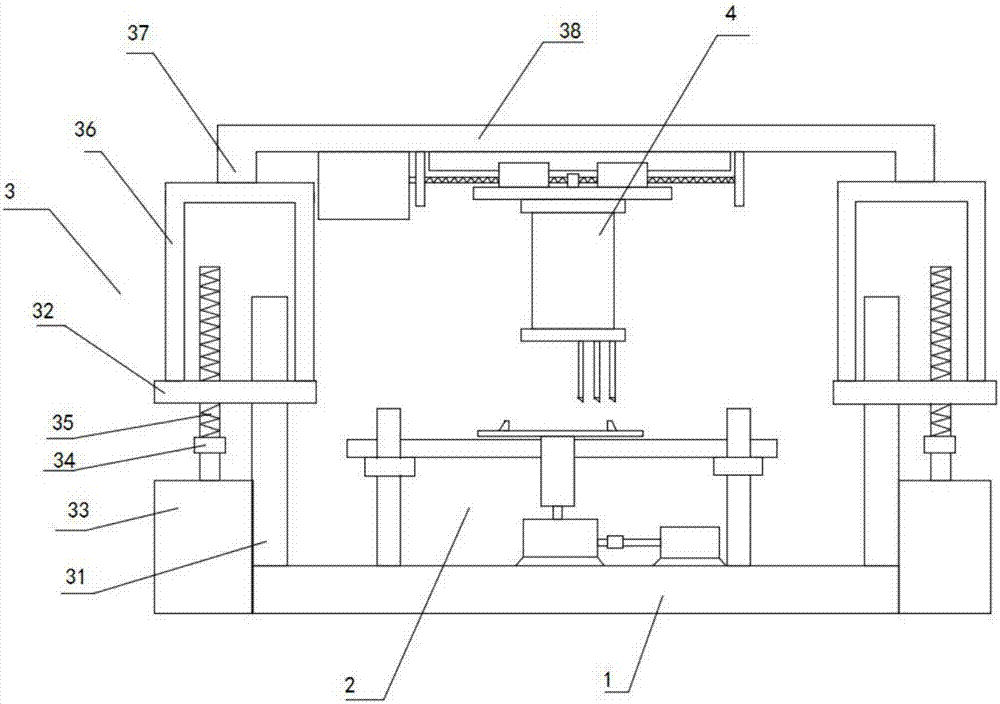

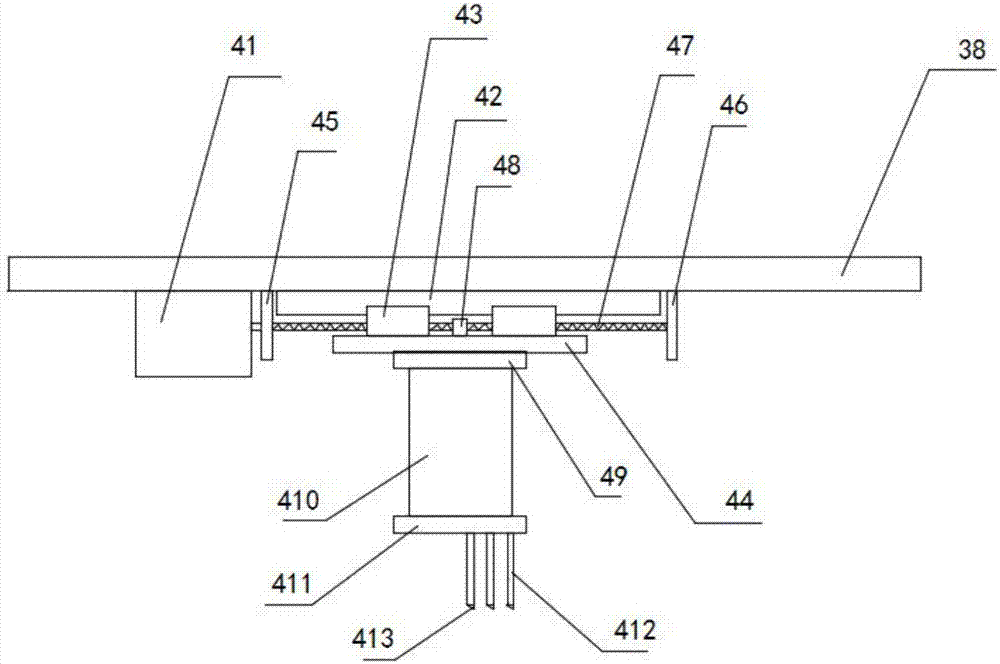

Double-station surface treatment equipment

InactiveCN107511878AHigh degree of automation integrationIncrease productivityMetal working apparatusFace sheetSurface finishing

The invention provides double-station surface treatment equipment comprising a base, lifting assemblies, a top face plate, a first displacement assembly and a second displacement assembly. The lifting assemblies are arranged on the left and right sides of the base correspondingly; the top face plate is arranged at the upper ends of the lifting assemblies; and the first displacement assembly and the second displacement assembly are arranged on the lower surface of the top face plate. The double-station surface treatment equipment further comprises a slotting assembly arranged at the lower end of the first displacement assembly, a perforating assembly arranged at the lower end of the second displacement assembly, and a conveying assembly fixed to the upper end of the middle of the surface of the base. The double-station surface treatment equipment is novel in structure, ingenious in design, high in slotting and perforating efficiency, capable of increasing the finished product rate greatly and beneficial for saving the manpower resource.

Owner:嘉善中正电子科技有限公司

Cam carrying and blowing-dedusting device

The invention provides a cam carrying and blowing-dedusting device. The device comprises a base. Supporting battens are fastened to the left side and the right side of the upper end of the base through bolts correspondingly. Two grooves are formed in the surface of each supporting batten. The inner wall of each groove is of a threaded structure. The upper ends of the supporting battens are in screw connection with supporting rods. The top ends and the bottoms of the supporting rods are all of threaded structures. The upper ends of the supporting rods are in screw connection with a working platform. The outsides of the supporting rods are further sleeved with stabilizing barrels. The working platform comprises a left working platform body and a right working platform body connected with the left working platform body through fasteners. The left working platform body comprises a conveying part and a drive part. The conveying part is located at the upper end of the left working platform body, and the drive part is located at the lower end of the left working platform body. A material distributor, a cam propelling and moving device and a deduster are further arranged on the right working platform body.

Owner:JIASHAN JINYI PRECISION CASTING

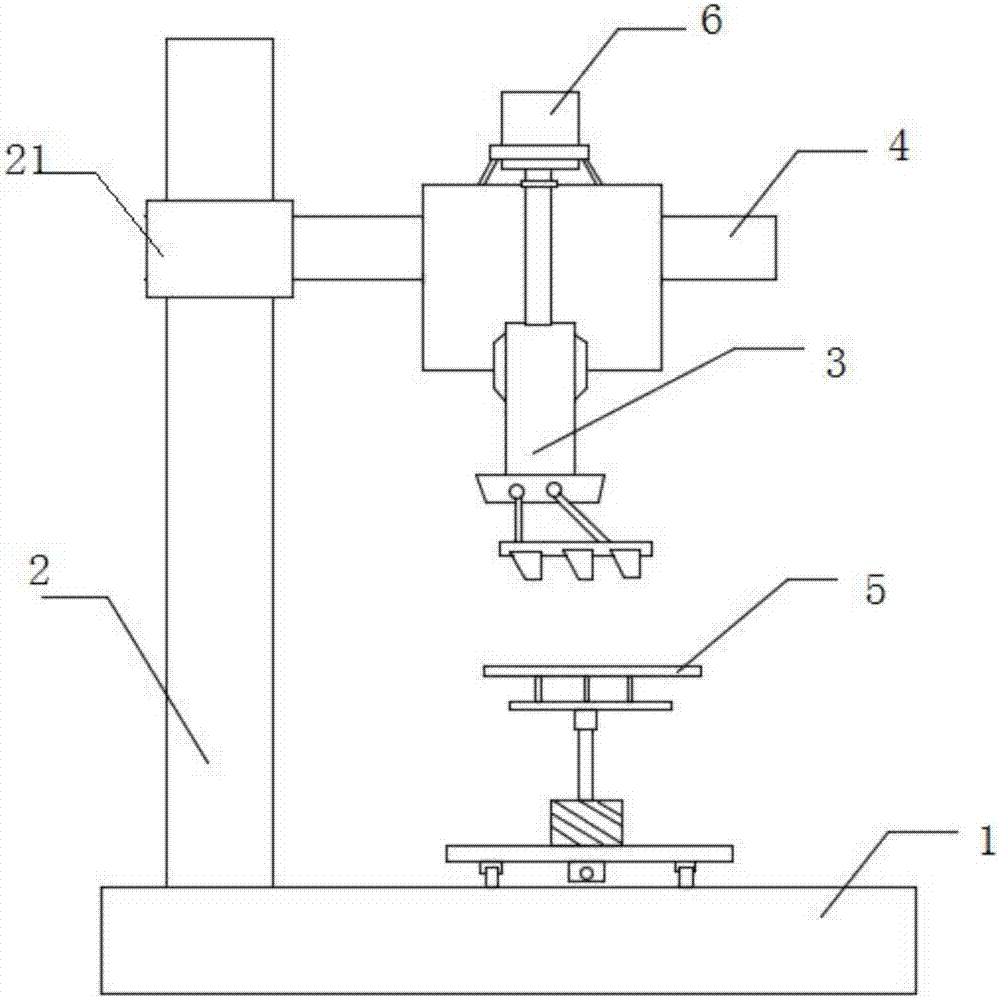

Adjustable annular groove forming device

ActiveCN107322669AHigh degree of automation integrationIncrease productivityMetal working apparatusBiochemical engineering

The invention provides an adjustable annular groove forming device. The adjustable annular groove forming device comprises a main substrate, and further comprises a rotary workpiece pre-fixing assembly, lifting assemblies and an adjustable groove forming assembly, wherein the rotary workpiece pre-fixing assembly is arranged at the middle part of the surface of the main substrate; the lifting assemblies are arranged at the left side of the main substrate and the right side of the main substrate; and the adjustable groove forming assembly is fixed on the lifting assemblies. According to the adjustable annular groove forming device, the automatic integration degree is high, annular grooves can be formed only by one operator, and the production efficiency is greatly improved; and grooves with different specifications and grooves with different depths can be formed through the device, the productivity can be improved, and the yield of products is improved.

Owner:嘉善梦溪服饰辅料厂(普通合伙)

Withdrawing mechanism for air tightness detection equipment

ActiveCN107826633ASimple structureHigh degree of automation integrationConveyorsFluid-tightness measurement using fluid/vacuumEngineeringAir tightness

The application discloses a withdrawing mechanism for air tightness detection equipment. The withdrawing mechanism comprises a base, a supporting seat, a quick connector and a first cylinder, whereina sliding platform is movably arranged on the base; the supporting seat is arranged on the sliding platform and used for fixing a workpiece to be detected, and an air cock is arranged on the supporting seat; the quick connector is arranged on the moving path of the supporting seat; the first cylinder is arranged on one side of the supporting seat; a push block is arranged on the side, opposite tothe first cylinder, of the sliding platform; a piston rod of the first cylinder is connected with a buffering mounting plate; and when the air cock moves to the inlet of the quick connector, the pushblock is in contact with the buffering mounting plate to control the entering speed of the air cock into the quick connector. The withdrawing mechanism has the function of conveying the workpiece to be detected, and has the advantages of small size, high automatic integration degree, stable running and high precision.

Owner:SUZHOU RS TECH

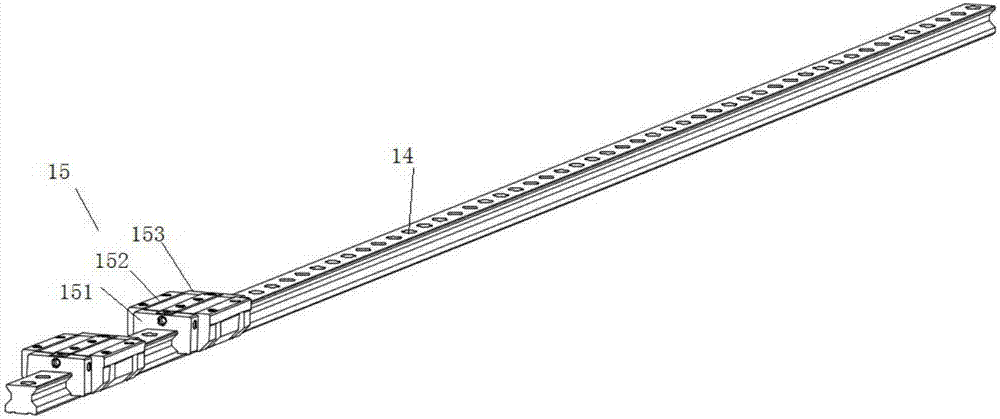

Angle shaft workpiece processing system

PendingCN108820424AHigh degree of automation integrationImprove working accuracyLabelling machinesEngineeringMechanical engineering

The invention discloses an angle shaft workpiece processing system. A packaging mechanism is arranged on a rack; the packaging mechanism comprises a first loading and adhering mechanism, a first tailoring mechanism and a second loading and adhering mechanism which are controlled by a control device; the first loading and adhering mechanism comprises a first loading mechanism, a guiding and conveying mechanism and a film removing mechanism; the first tailoring mechanism is located between the first loading and adhering mechanism and the second loading and adhering mechanism and is used for tailoring double-sided sticky tape and a steel strip; the second loading and adhering mechanism comprises a second loading mechanism and a rolling mechanism and is used for tightly adhering an angle shaftworkpiece to the double-sided sticky tape. The angle shaft workpiece processing system disclosed by the invention is high in automatic integration degree and can replace multi-stage working procedures of traditional handicraft, the working accuracy is high, the quality can be more easily controlled, and the production can be more easily standardized; meanwhile, the percent of pass is also improved, the production cost is controllable, and the production efficiency is greatly improved.

Owner:YUXINDA (SHENZHEN) INTELLIGENT EQUIP CO LTD

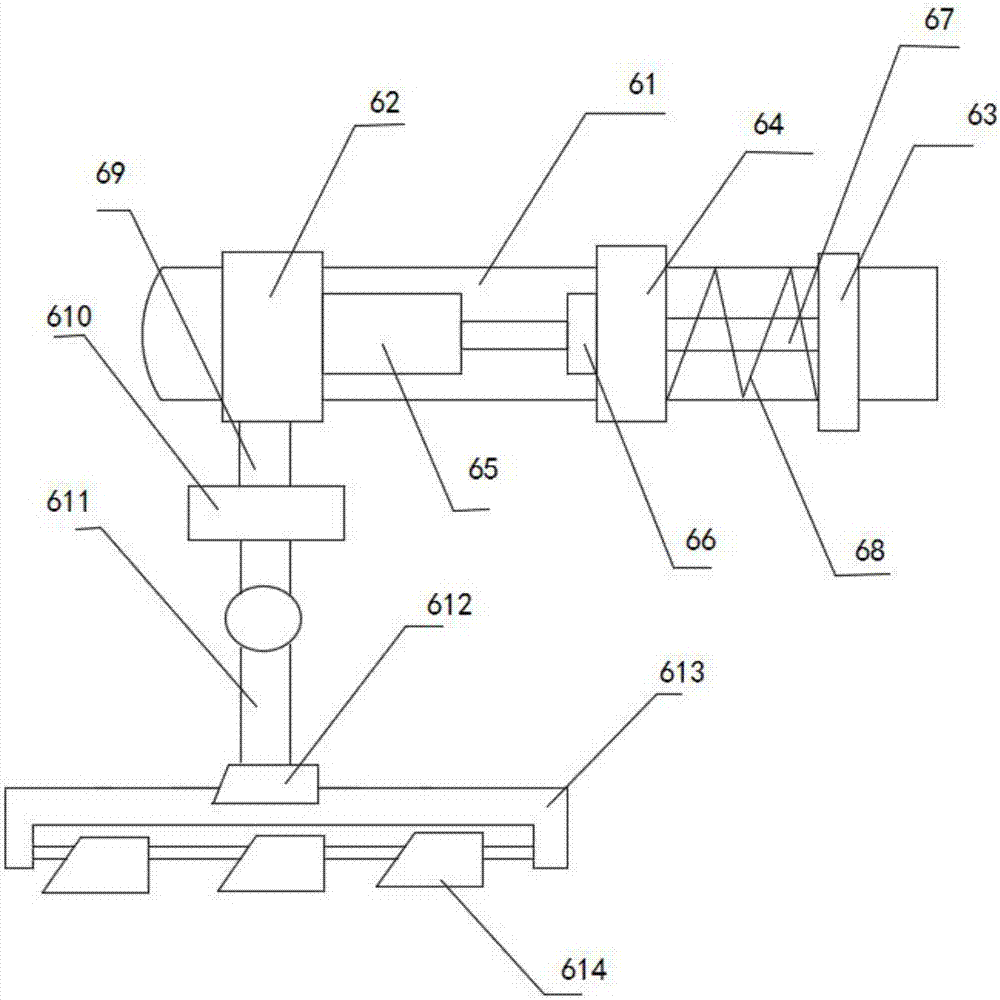

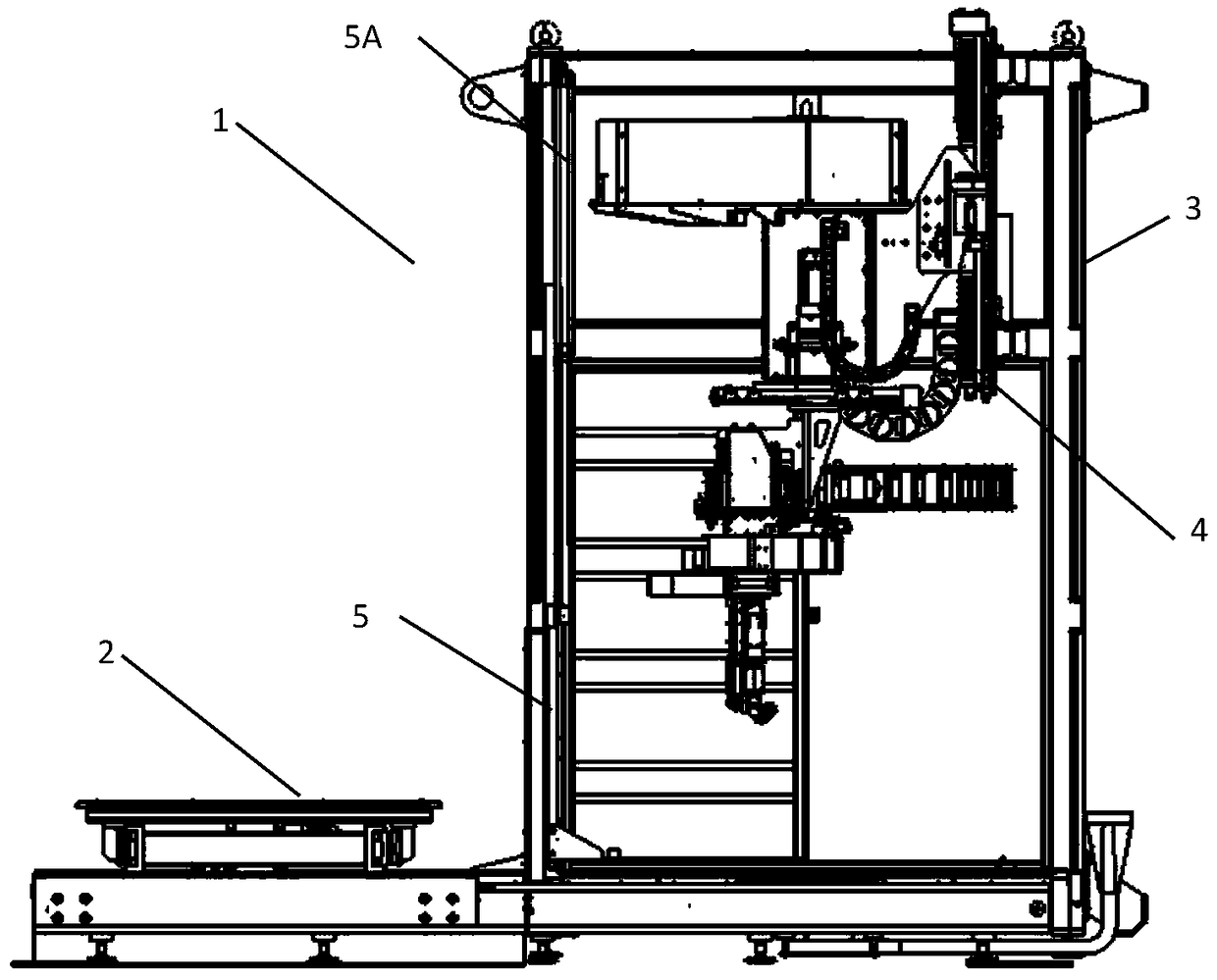

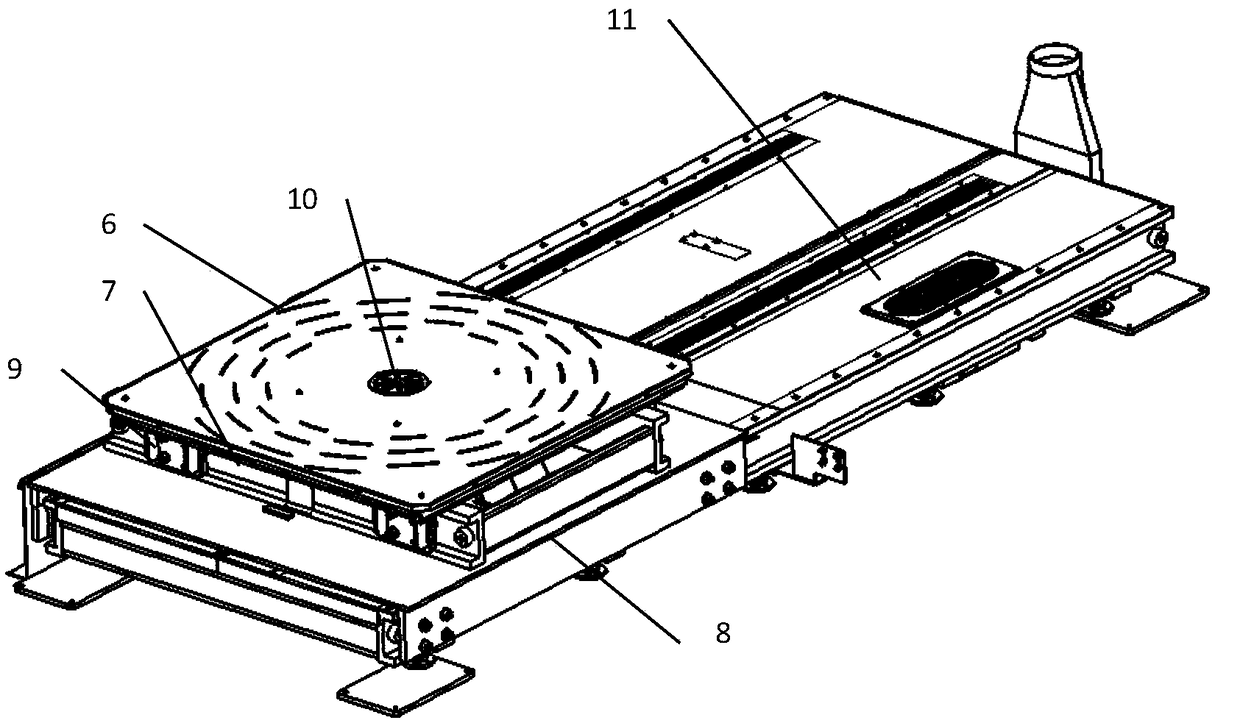

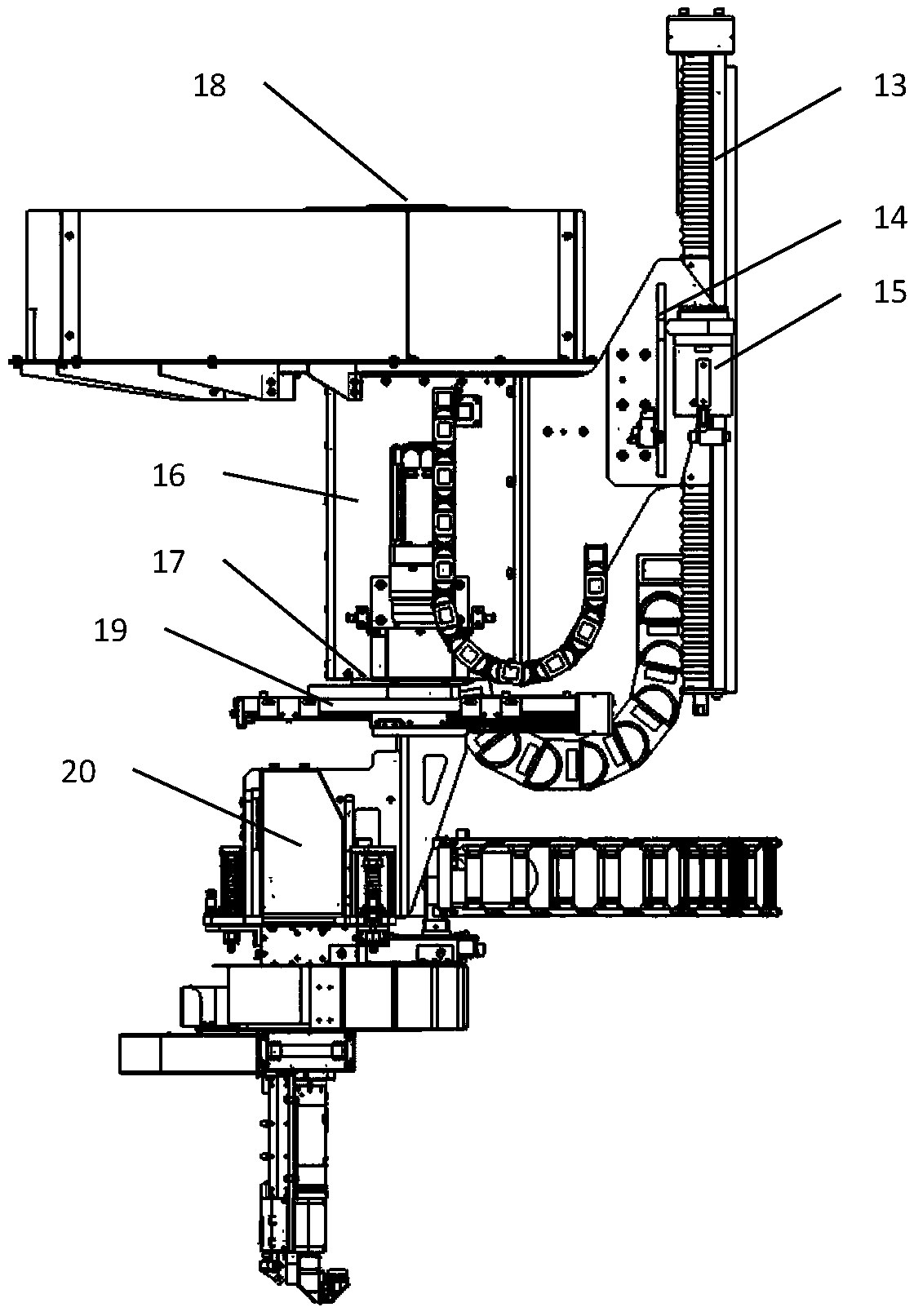

Laser cleaning equipment for tire mold

PendingCN109435115AReduce repair and replacement costsHigh degree of automation integrationCleaning processes and apparatusOptical pathEngineering

The invention discloses cleaning equipment for a tire mold. The cleaning equipment comprises an X1,Y1 platform, a whole machine bracket, a vertical adjustment of a Z-axis processing head, a C-axis processing head rotation, an X-axis processing head horizontal adjustment, a D-axis focusing mechanism, a B-axis laser tube rotation, an A-axis light beam exit adjustment, an optical path system, a dustremoval system, a gas path system, a control system, a cooling system and the like. The cleaning equipment is used for removing all or part of residue deposited on the molds due to the tire manufacturing process (vulcanization) in various types of tire molds. The cleaning equipment can further be used for cleaning rust, greasy dirt and paint.

Owner:沈阳慧远自动化设备有限公司

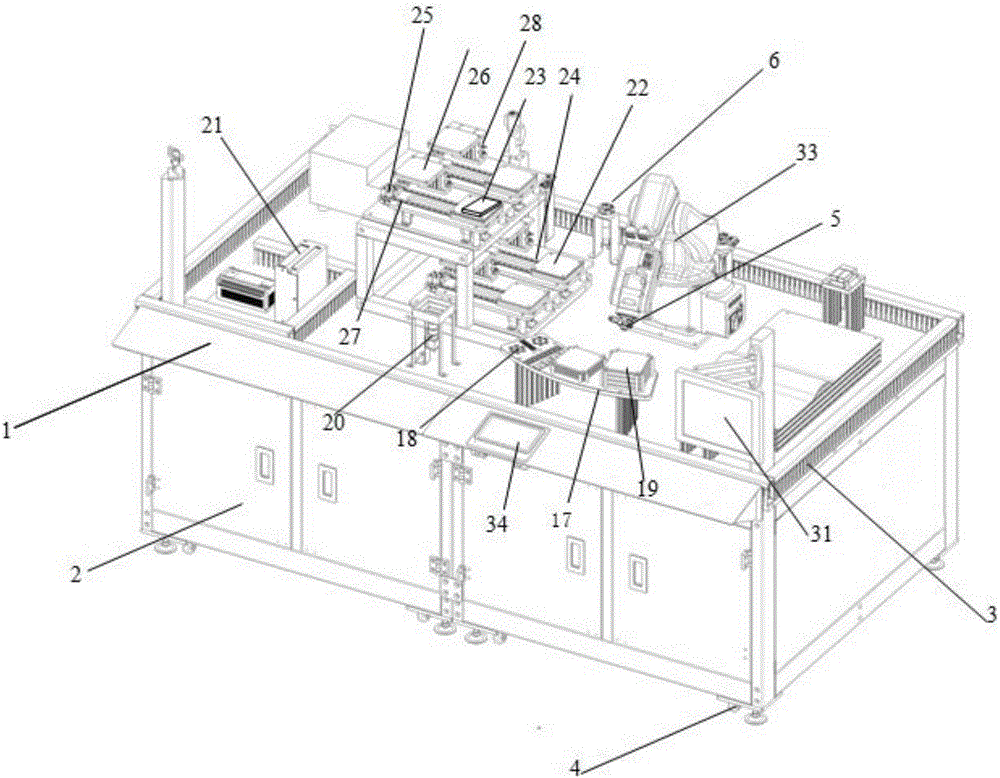

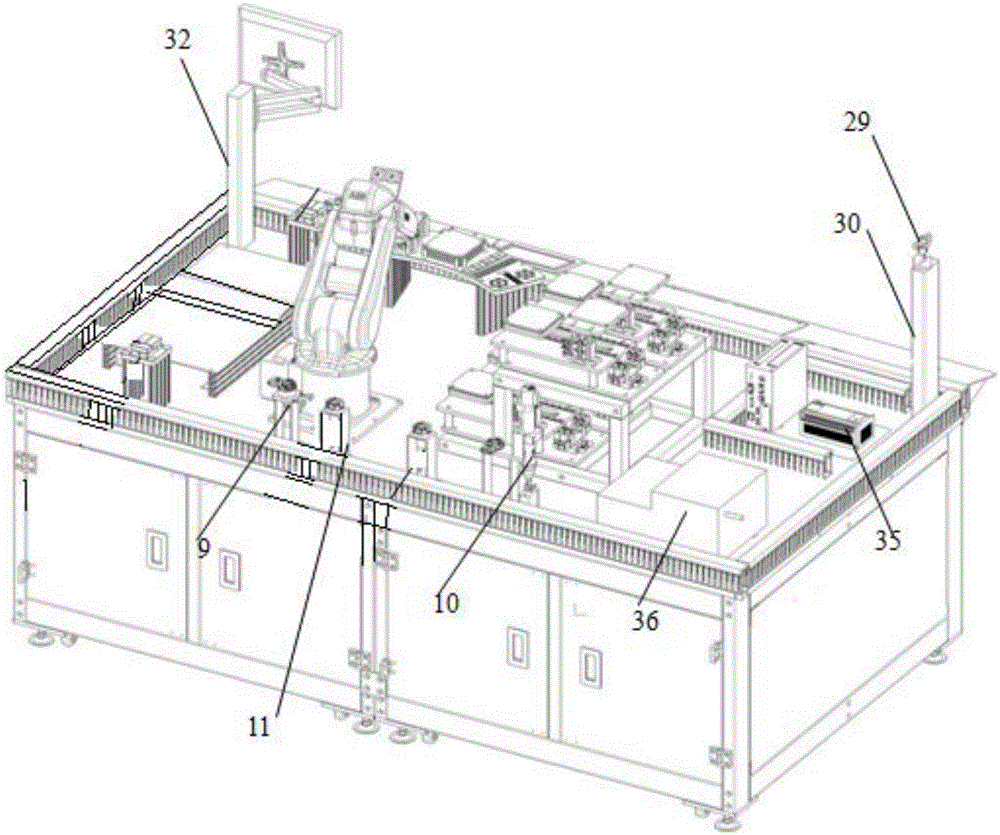

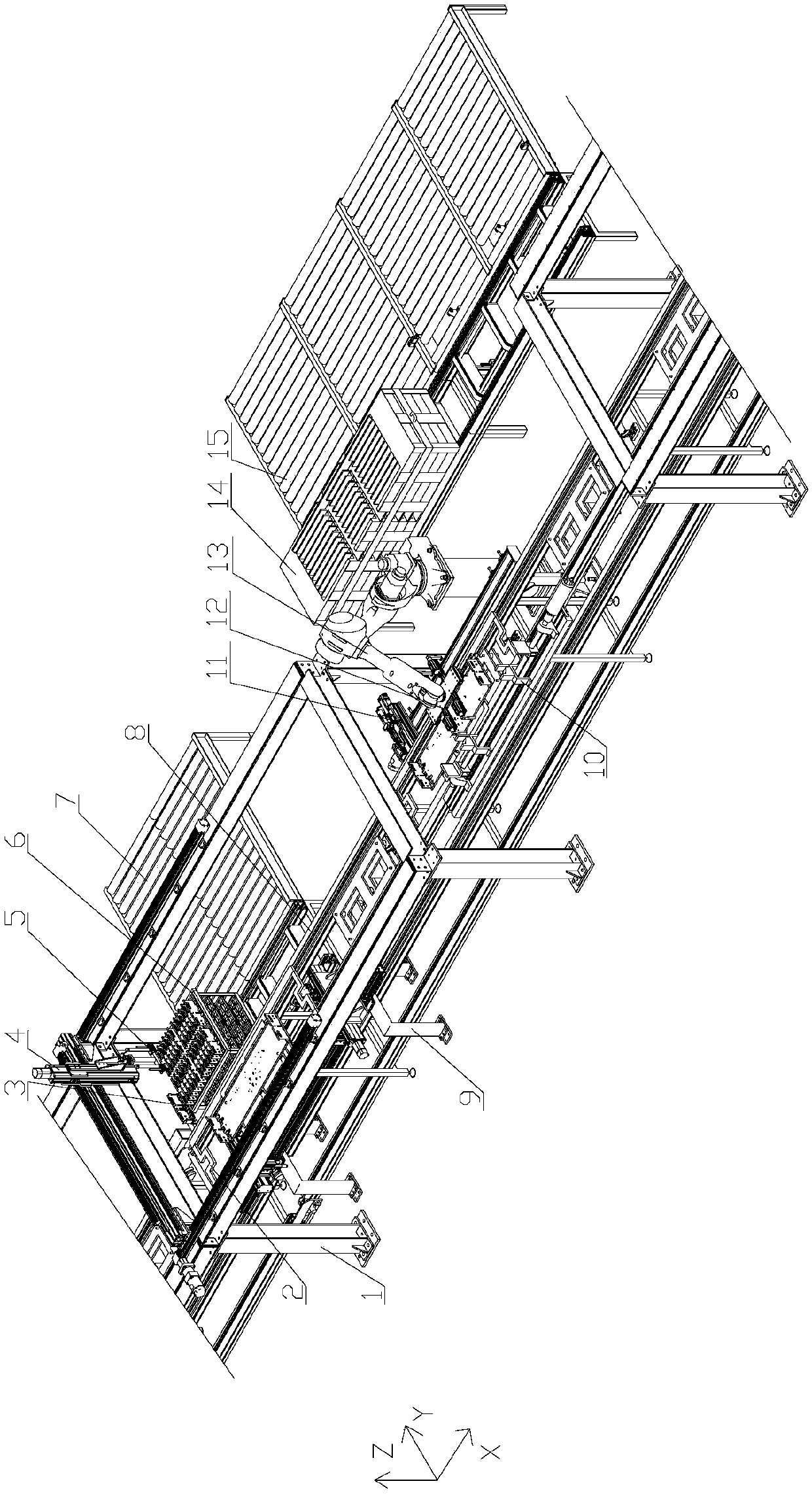

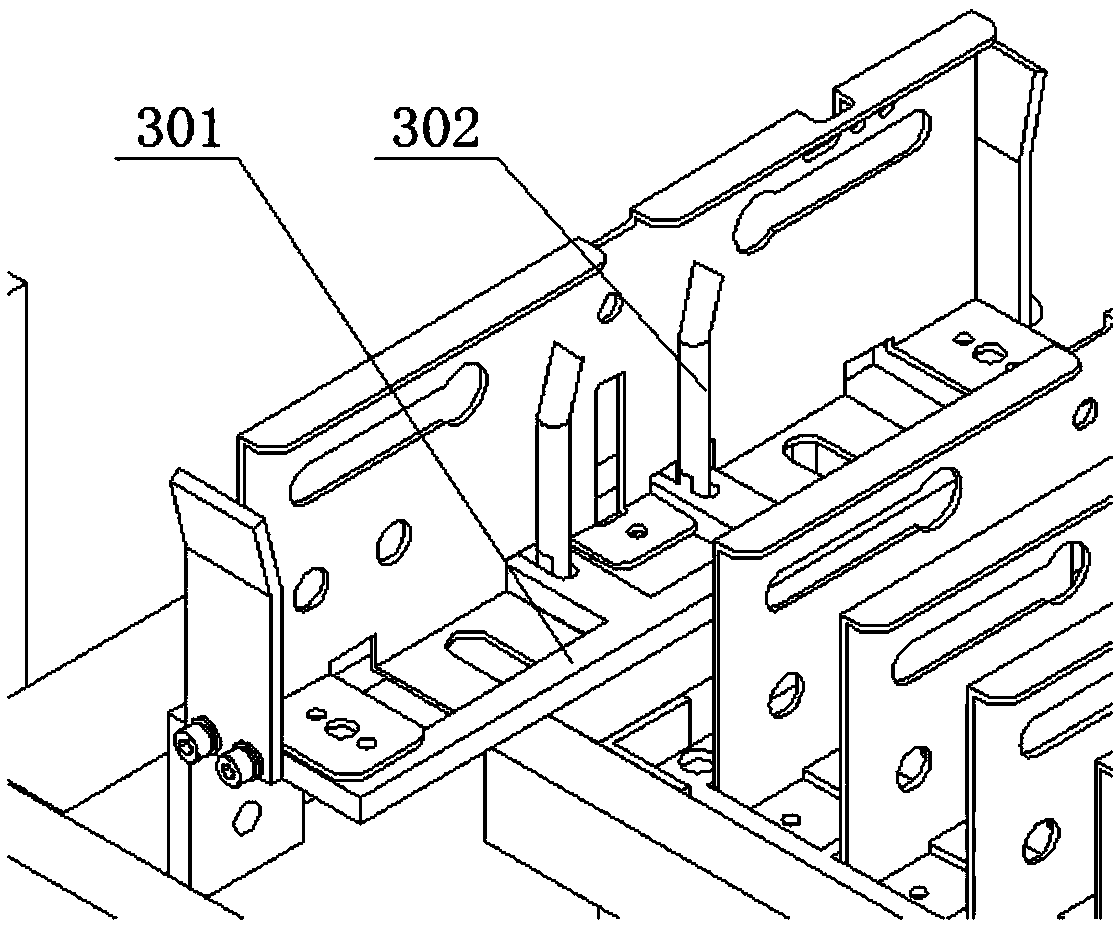

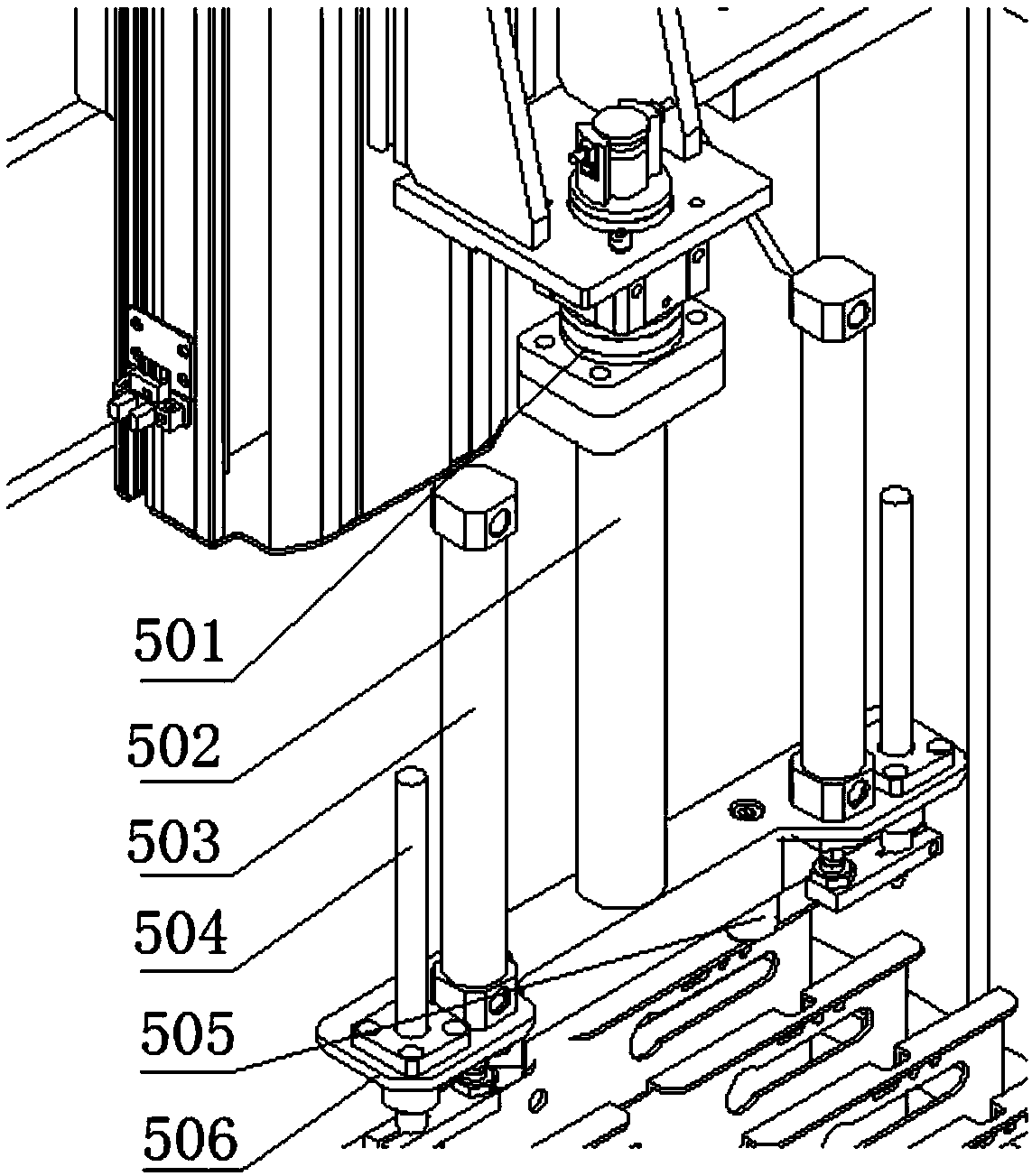

Automatic production line for clothes drying machine

ActiveCN111376044AHigh degree of automation integrationIncrease productivityAssembly machinesMetal working apparatusProduction lineMachine

The invention belongs to the technical field of automatic production lines, and particularly discloses an automatic production line for a clothes drying machine. The automatic production line comprises a main roller way conveyor line and a tray arranged on the main roller way conveyor line, the tray is used for bearing an assembly main body, and a plurality of installation stations are arranged onthe main roller way conveyor line. Each installation station is provided with a positioning assembly, an auxiliary roller way conveyor line, an automatic screwdriving mechanism, a robot and a clamp assembly arranged at the tail end of the robot, wherein the auxiliary roller way conveyor line is arranged on one side of the main roller way conveyor line and used for conveying parts needing to be assembled at the stations to the main roller way conveyor line, the robot grasps the parts onto the positioning assembly through the clamp assembly for positioning and then grasps the positioned parts onto the assembly main body in the tray, and the automatic screwdriving mechanism connects the parts to the assembly main body through screws. The automatic production line is high in automated integration level, meanwhile, the production efficiency is greatly improved, the manual operation is reduced, and the safety is improved.

Owner:中国科学院沈阳计算技术研究所有限公司

Material taking and feeding device for mechanical automatic part machining

PendingCN114380002ARealize continuous feedingImprove processing qualityConveyorsCleaning using toolsSurface cleaningEngineering

The invention relates to the technical field of machining, in particular to a mechanical automatic part machining, taking and feeding device which comprises a base and further comprises a taking mechanism arranged on the base. The feeding mechanism is arranged on the base, the feeding mechanism can drive the material taking mechanism to place the workpieces on the feeding mechanism, and the feeding mechanism feeds the workpieces in an intermittent operation mode; the cleaning mechanism is arranged on the feeding mechanism, and the feeding mechanism drives the cleaning mechanism to clean the surfaces of the workpieces on the cleaning mechanism in the feeding process. According to the mechanical automatic part machining material taking and feeding device, the cyclic automatic working state of material taking, feeding and cleaning is achieved, continuous feeding of workpieces is achieved, meanwhile, the production efficiency is improved, the automation integration degree is high, the labor intensity of workers is reduced, the surfaces of the workpieces can be cleaned, the workpiece machining quality can be improved, and the production cost is reduced. And manual cleaning treatment is not needed.

Owner:NANJING JULONG STEEL PIPE

Flocking fabric scratch device

ActiveCN107245870AImprove processing efficiencyHigh scratch efficiencyMarking textilesEngineeringDrive motor

The invention provides a flocking fabric scratch device, which comprises a supporting base. The flocking fabric scratch device further comprises a supporting rod, a carrying frame, a cross beam, a scratch component and a driving motor, wherein the supporting rod is arranged at one side of the upper end of the supporting base, the carrying frame is arranged at the other side of the supporting base; the cross beam is vertically connected with the supporting rod, and the scratch component is arranged at the cross beam; the driving motor s arranged at the top end of the scratch component. The flocking fabric scratch device is high in automated integration level; the servo motor at the carrying frame can control a second cushion plate to horizontally displace in a square form; the first motor can control the rotation of the second cushion plate, thus the adjustable form of the device is greatly improved, the surface treatment on the flocking fabric can be carried out conveniently, and the flocking fabric is placed at the upper end of the second cushion plate to perform the scratching work.

Owner:JIASHAN SHENGLAISI CASHMERE

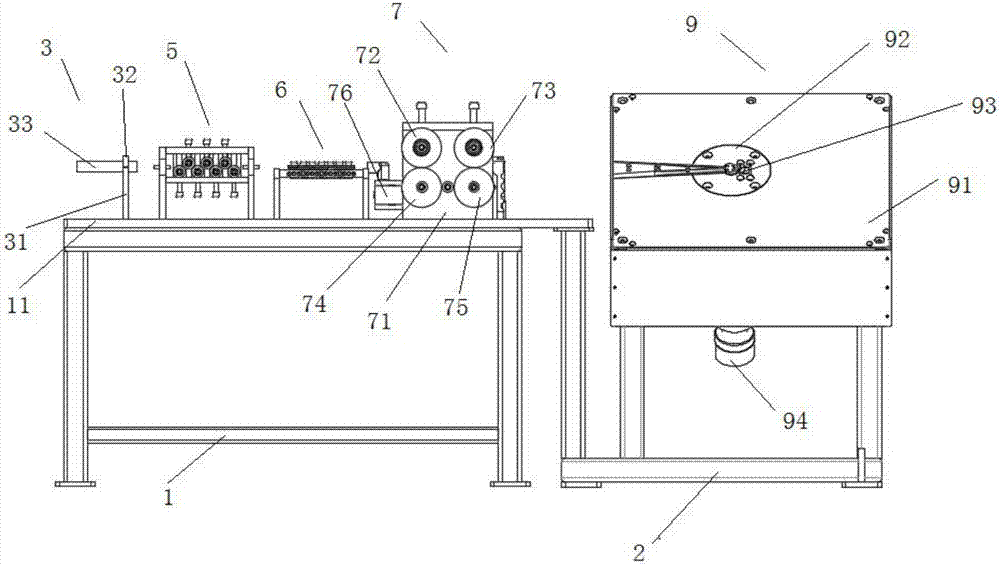

Tin wire cutting machine controllable in tin amount

ActiveCN103100612ACut off accuratelyPrecise tin volume controlSoldering auxillary devicesReciprocating motionWire cutting

The invention relates to a tin wire cutting machine controllable in tin amount. The tin wire cutting machine comprises a motor. A motor shaft of the motor is provided with a wire cutting device capable of being in reciprocating motion in the radial direction relative to the motor. A wire cutting position of the cutting device is provided with a tin wire feeding tube pile for consecutive feeding of wires. A blanking position of the wire cutting device is provided with a tin outlet tube connector. The tin wire cutting machine is precise and quantitative in tin wire, completely uniform in tin amount, reasonable in structure, and capable of discharging cut tin wires quickly, removing tin blocking phenomena, and improving automation working efficiency.

Owner:QUICK INTELLIGENT EQUIP CO LTD

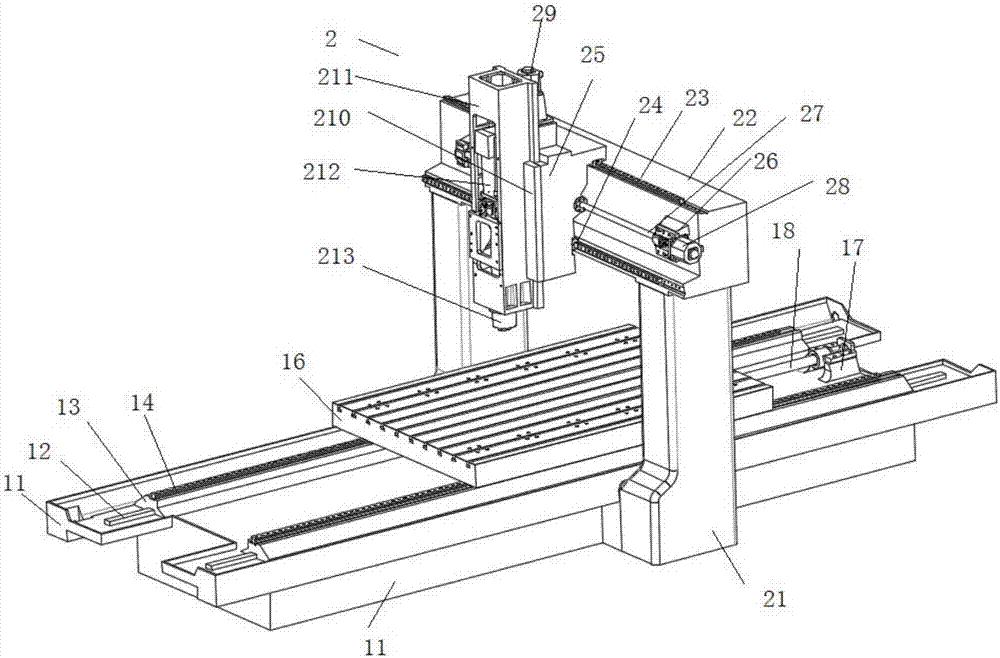

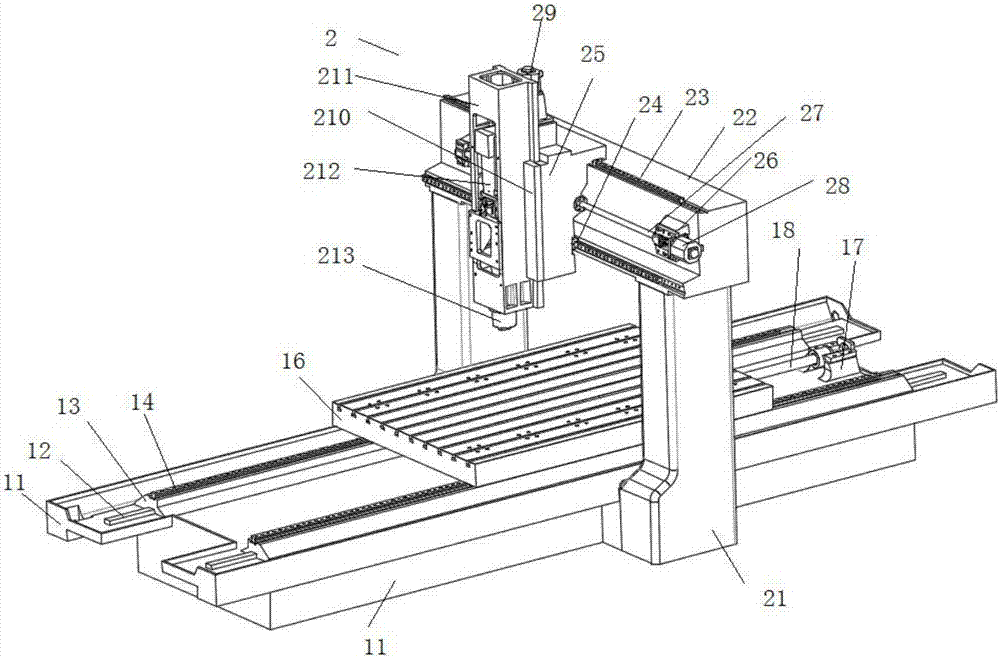

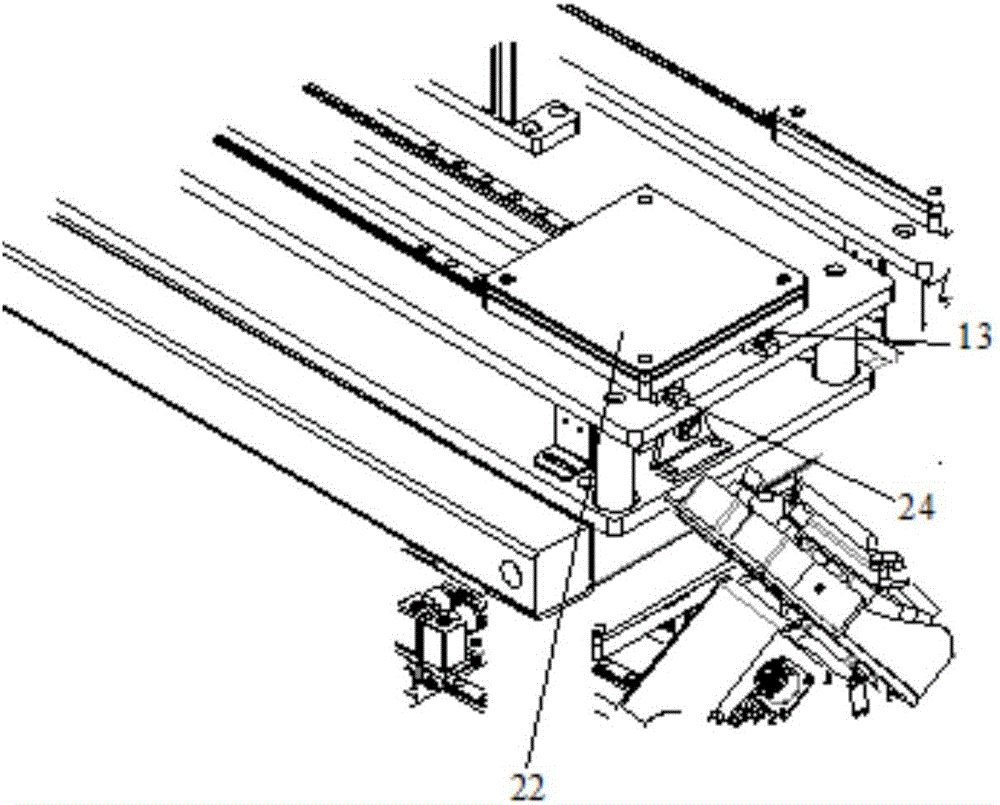

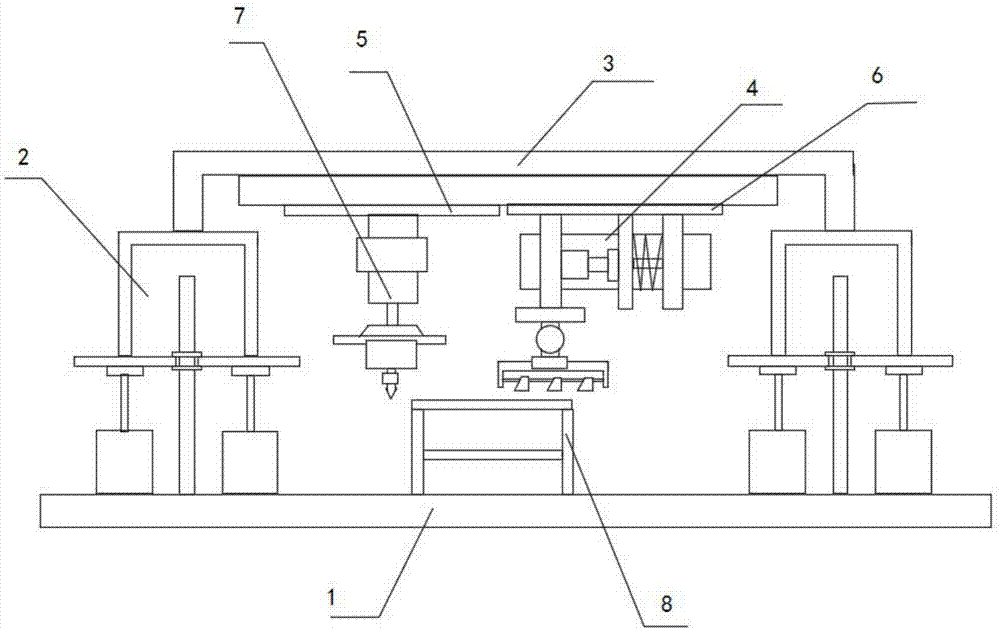

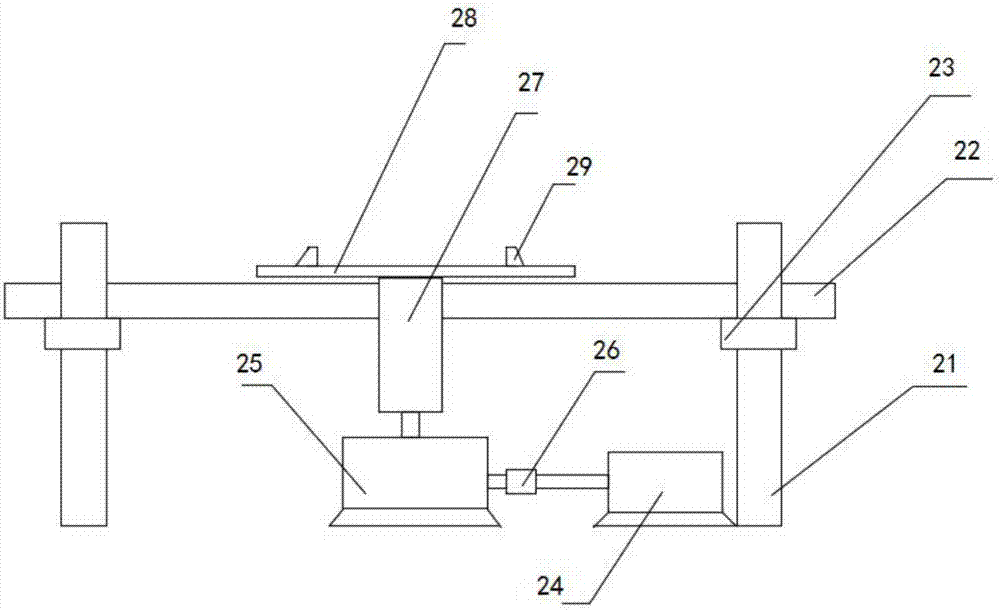

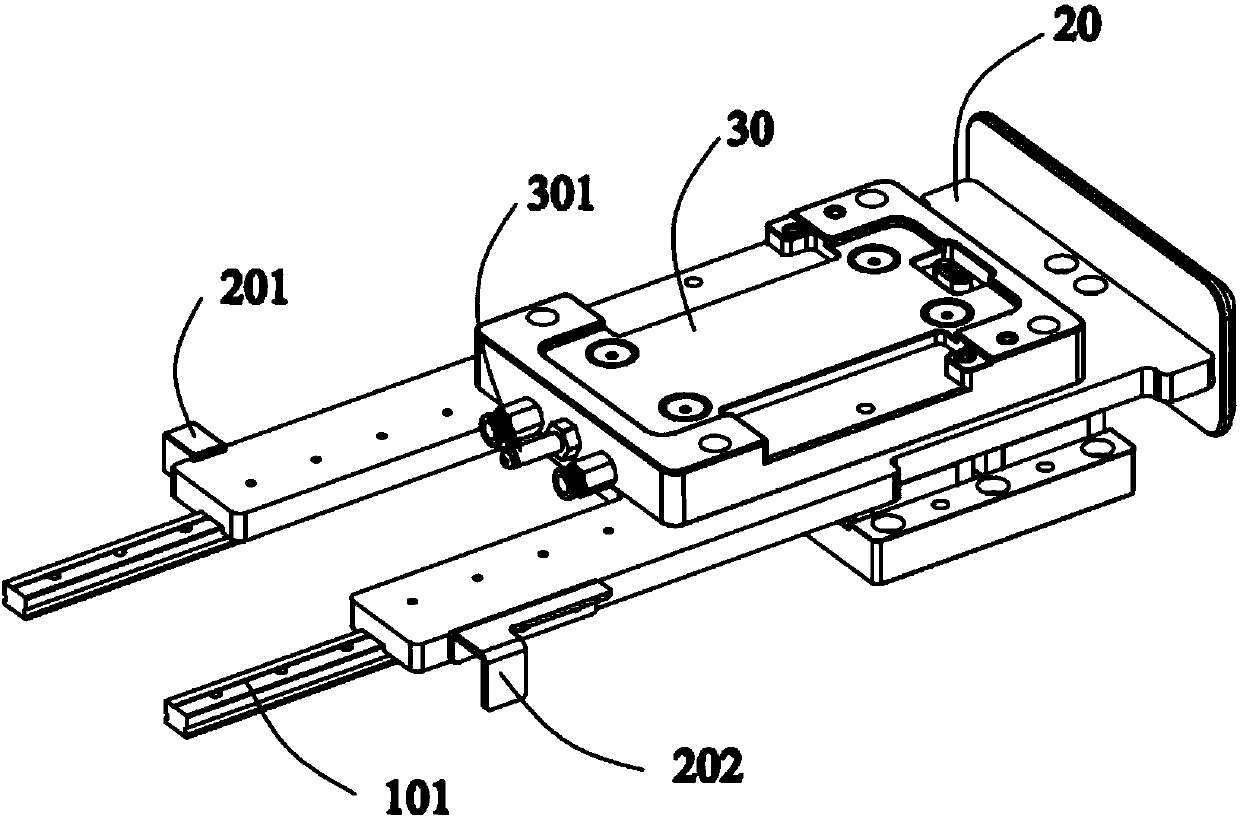

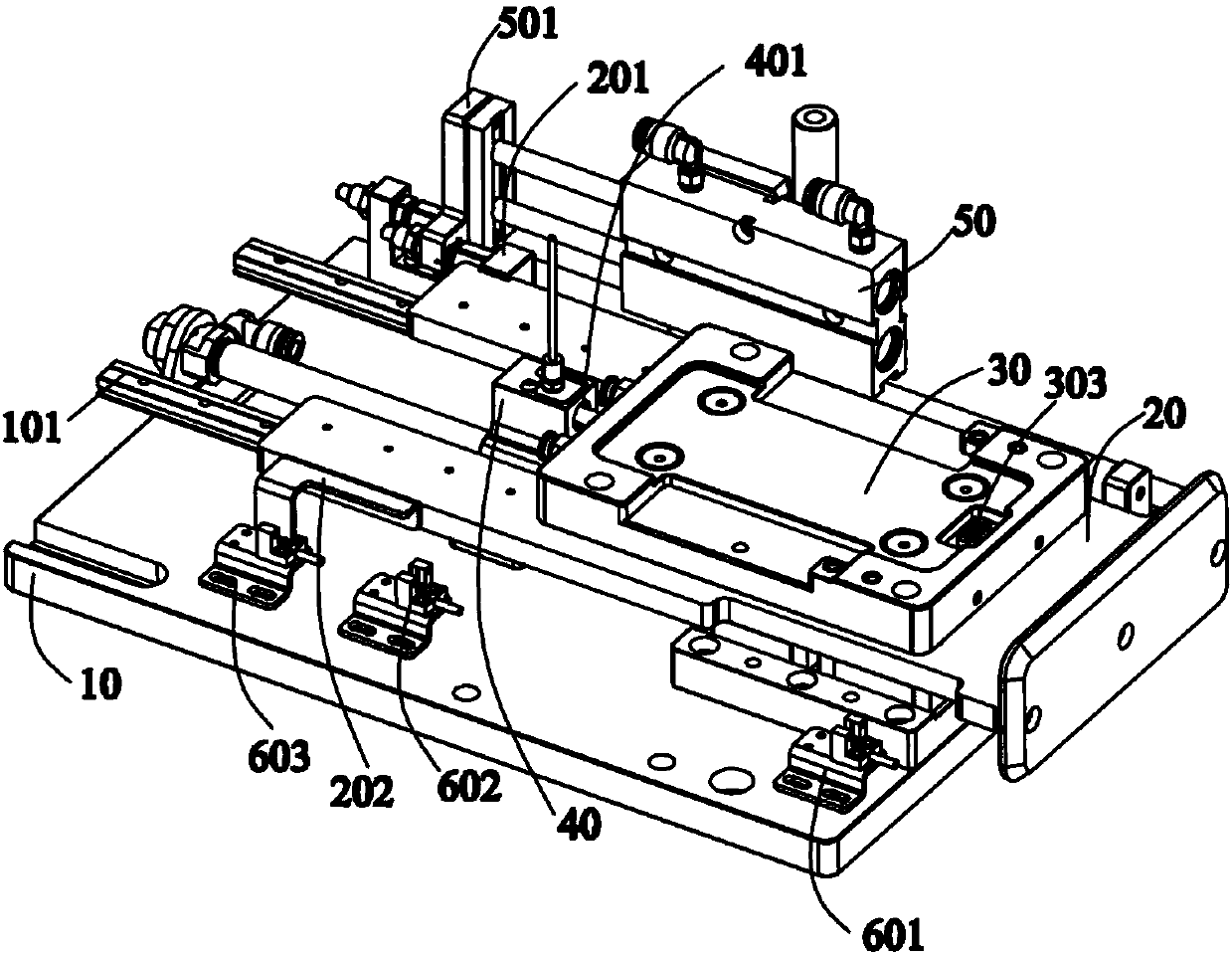

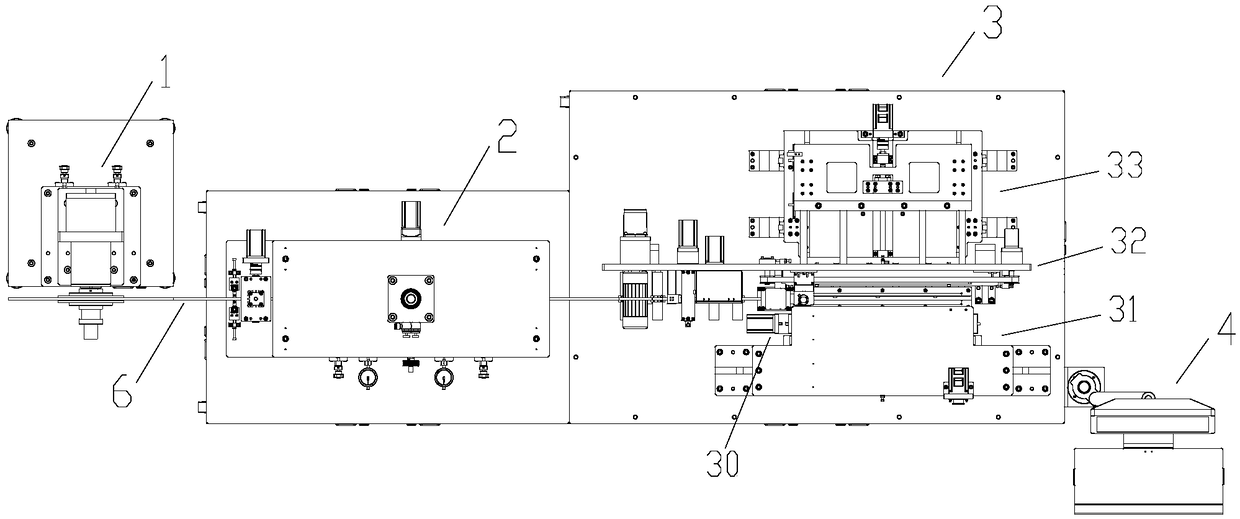

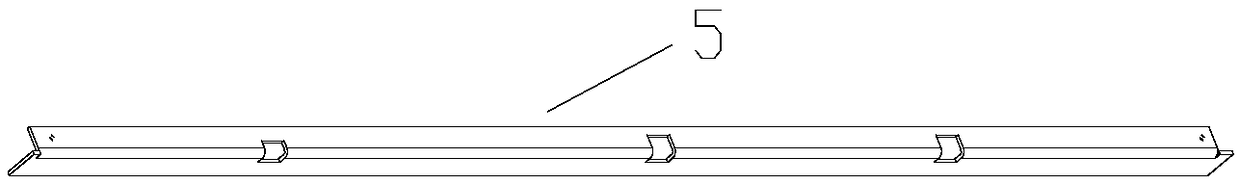

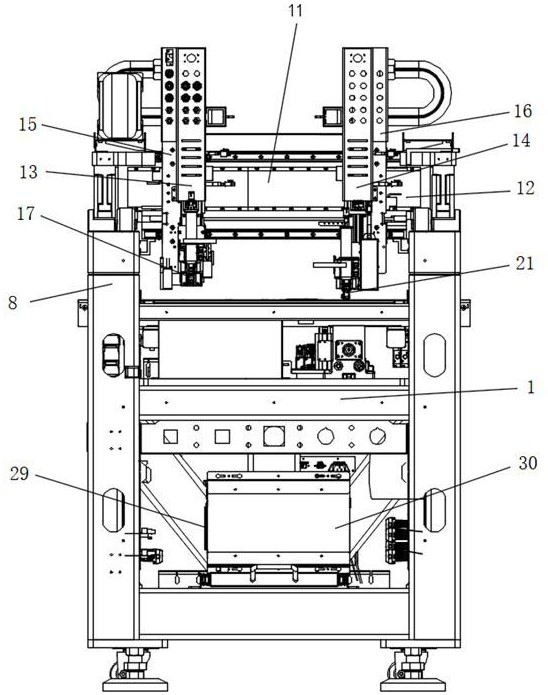

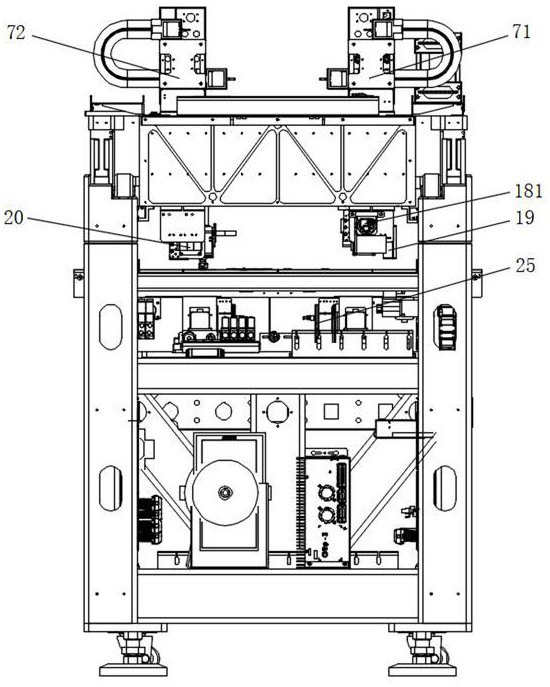

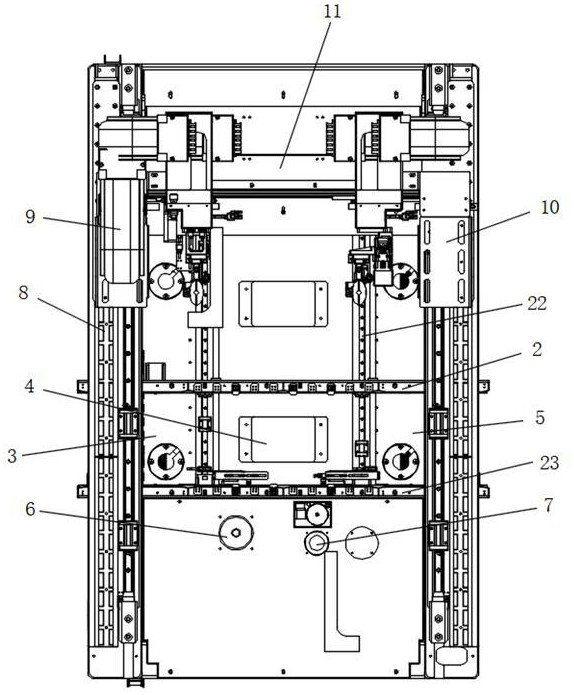

Gantry double-drive dynamic double-head high-speed high-precision dispensing equipment and gantry double-drive dynamic double-head high-speed high-precision dispensing control system

ActiveCN113856992AHigh degree of automation integrationGuaranteed running stabilityLiquid surface applicatorsCoatingsControl cellData acquisition

The invention discloses gantry double-drive dynamic double-head high-speed high-precision dispensing equipment and a gantry double-drive dynamic double-head high-speed high-precision dispensing control system. The gantry double-drive dynamic double-head high-speed high-precision dispensing equipment comprises a cabinet, a conveying track is arranged in the middle of the top surface of the cabinet, the conveying track is sequentially provided with a feeding station, a dispensing station and a discharging station from left to right, and a Y1 axis and a Y2 axis are arranged on the top surface of a rack; an X-axis stator is arranged on a cross beam between the Y1 axis and the Y2 axis, an X1-axis rotor and an X2-axis rotor are arranged on the X-axis stator, a first dispensing valve, visual equipment and a laser displacement sensor are arranged on a Z1 axis, a macro motor is arranged on a Z2 axis, and a second dispensing valve is arranged at the working end of the macro motor; and according to the equipment, a motion control unit, a transmission control unit, a machine vision system and a signal data acquisition and dispensing control unit are gathered in a bus manner, communicate with each other and transmit data, so that the high-speed and high-precision dispensing process of products is completed, the operation stability of the dispensing process is ensured, and the automation integration level of the control system is improved.

Owner:SHENZHEN AXXON AUTOMATION

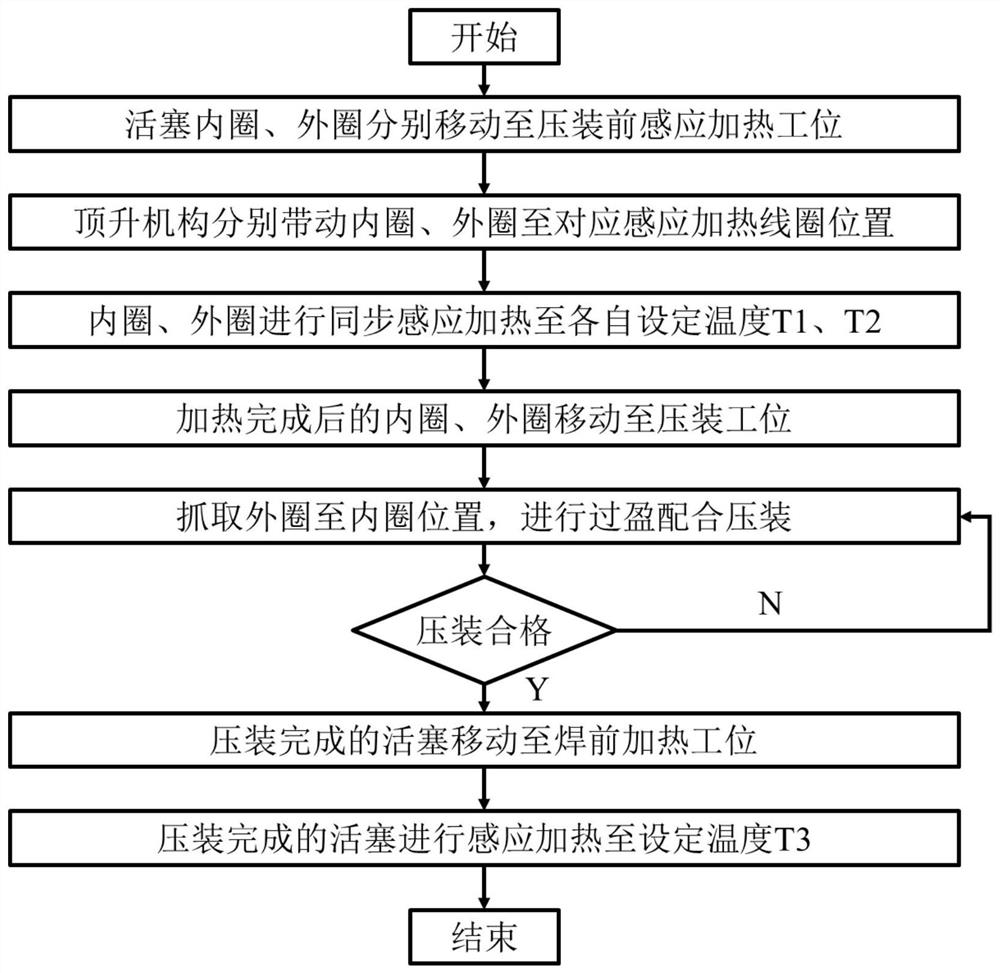

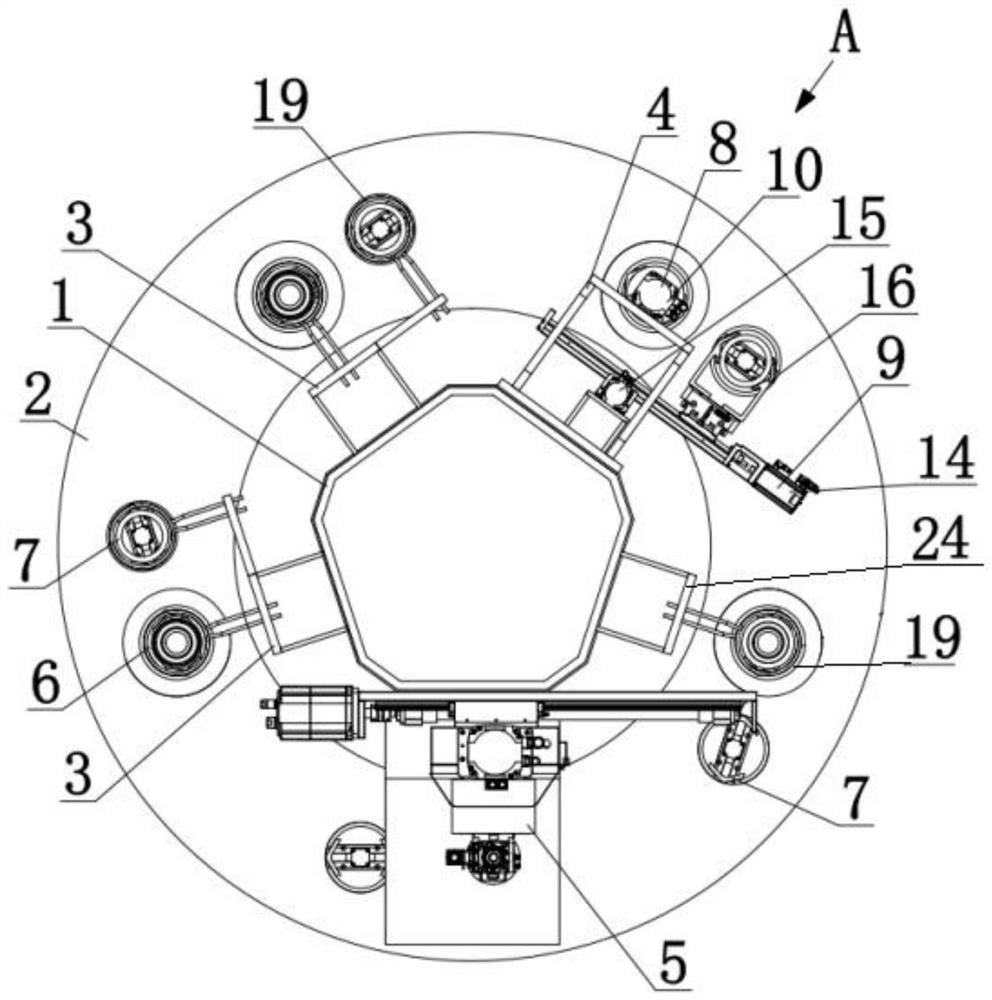

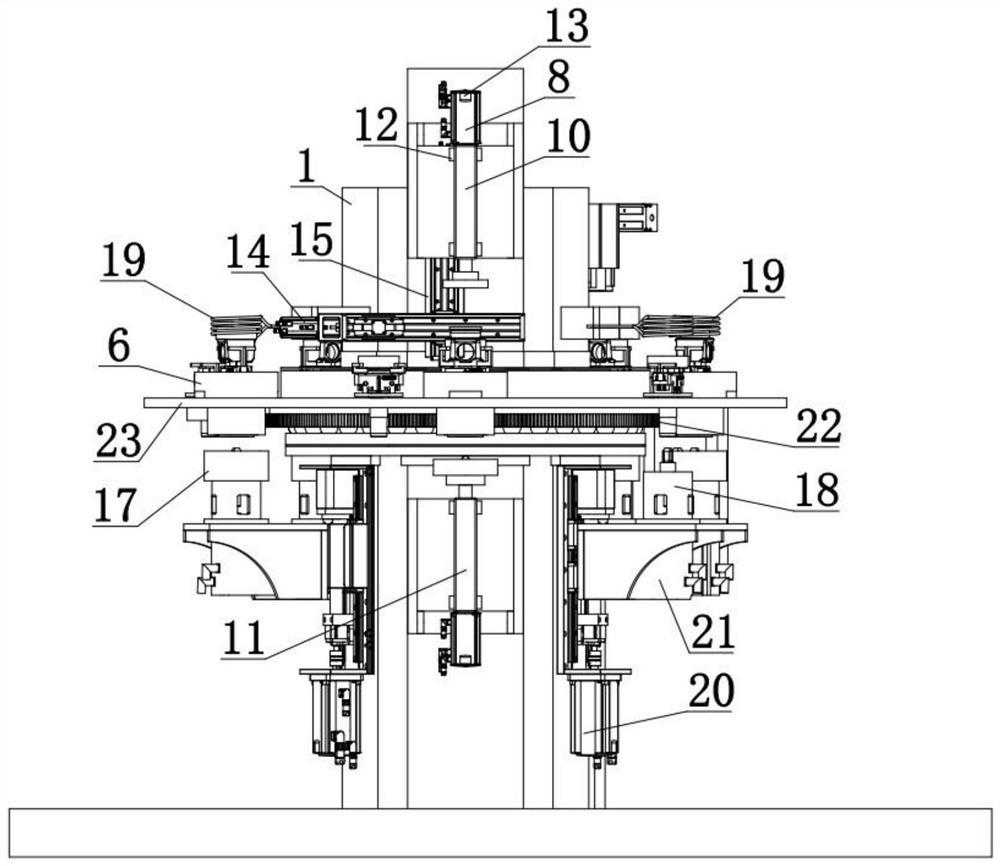

Pre-welding sectional type heating and press-fitting method and device

PendingCN112222759AImprove processing efficiencyEfficient heatingMetal working apparatusLaser beam welding apparatusInterference fitEngineering

The invention discloses a pre-welding sectional type heating and press-fitting method and device which are are used for heating and press-fitting of interference fit of an inner ring and an outer ringof an automobile engine steel piston. The method comprise the following steps that S1, the inner ring and the outer ring of the steel piston are moved to induction heating stations before press-fitting, the number of the induction heating stations is multiple, gradient heating is synchronously carried out on the inner ring and the outer ring, the temperature uniformity of the inner ring and the outer ring is guaranteed, and the temperature difference is reduced; S2, the heated inner ring and the heated outer ring are moved to a press-fitting station, and a steel piston is formed through press-fitting; and S3, the steel piston formed through press-fitting is moved to a pre-welding preheating station, and the steel piston is integrally heated to the temperature needed by welding. The multiple induction heating stations are adopted, the pre-welding heating time (only 1 / 4 of the time needed by single-station induction heating) can be greatly shortened, the temperature difference (within + / -10 DEG C) of the inner ring and the outer ring is further reduced, the steel piston part achieves the more efficient heating process, and the overall machining efficiency of the steel piston is improved.

Owner:武汉光谷航天三江激光产业技术研究院有限公司

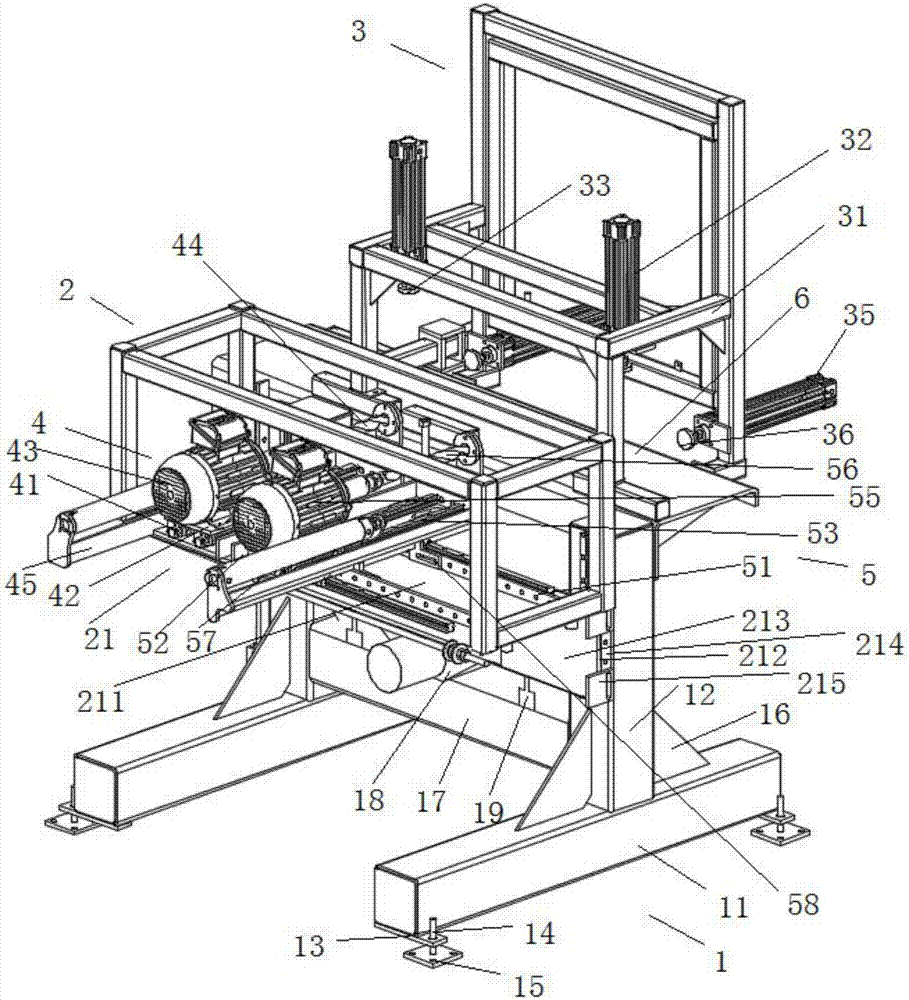

Automatic pipe bending device

The present invention proposes an automatic pipe bending device, which includes a first frame and a second frame arranged on the right side of the first frame, the first frame is fixed above the ground, and the first frame The surface of the working platform is fixed with a pipe feeding assembly, a first straightening assembly, a second straightening assembly and a third straightening assembly on the surface of the working platform from left to right. A pipe bending device is fixed. This kind of automatic pipe bending device has a novel structure and a high degree of automation integration. Before the pipe is bent, the pipe is straightened in multiple directions so that the pipe can be bent well, and the defective rate of the product is greatly reduced, which is beneficial Increase productivity.

Owner:嘉善中正电子科技有限公司

Multi-machining-station automatic tapping device

InactiveCN107159928AHigh degree of automation integrationImprove hole efficiencyBoring/drilling machinesEngineeringNew materials

The present invention proposes a multi-processing station automatic drilling device, which includes a first frame, the first frame includes two parallel bottom plates, the middle part of the surface of the bottom plate is vertically connected with a support plate, and the bottom plate and the bottom plate are connected vertically. The contact surface end of the support plate is also fastened with a triangular fixed plate, and the two support plates are closely connected through the connecting plate. The multi-processing automatic hole opening device also includes a mobile hole opening component and a new material fixing component. The front surface of the support plate Slide rails are fixed, and a working platform is fixed on the top of the back surface of the support plate. This kind of multi-processing position automatic hole opening device has a high degree of automation integration, and only needs to manually place the new material on the working platform, and then the new material will be fixed and pressed; the invention has novel design, ingenious structure, high hole opening efficiency, and can be adjusted Strong.

Owner:JIASHAN SHENGSHIDE FUR GARMENT

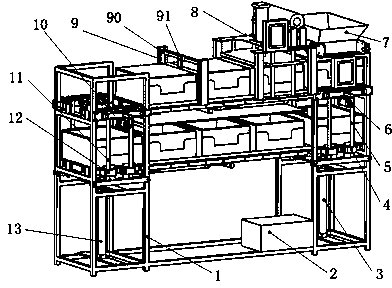

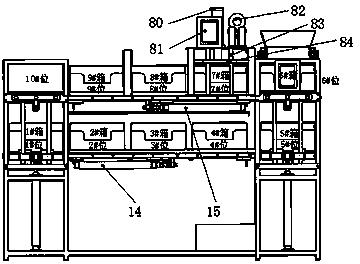

Automatic discharging and receiving machine for injection molding machine

ActiveCN104176316AReduce investmentReduce manual involvementPackaging automatic controlSolenoid valvePacking procedure

An automatic discharging and receiving machine for an injection molding machine comprises a frame consisting of an upper layer, an intermediate layer and a lower layer, wherein the upper layer is provided with a receiving hopper, a hot-melting sealing machine and a film cutting machine and further provided with a bearing device for bearing charging baskets and a basket withdraw device for pushing the charging baskets to move; the intermediate layer is provided with a positioning device for lifting the charging baskets; a basket supply device for pushing the charging baskets to move is further arranged at the lower part of the intermediate layer; the lower layer is provided with a descending cylinder and a lifting cylinder; a hot-melting electric cabinet is arranged at the bottom of the lower layer. The automatic discharging and receiving machine can realize continually automatic basket replacement and material receiving, and the maximal quantity of replaced baskets can be up to 9; when one basket is full, a PLC gives a command to control a corresponding solenoid valve and a corresponding cylinder mechanism to automatically send out the full charging basket, and then an empty charging basket is automatically fed in, so that the whole material receiving and replacing process needs no manual intervention; meanwhile, the full charging basket can be automatically sealed and packed, so that follow-up sealing and packing procedures are eliminated, the labor intensity of workers is lowered, and the operational efficiency is improved.

Owner:SICHUAN RUITENG ELECTRONICS

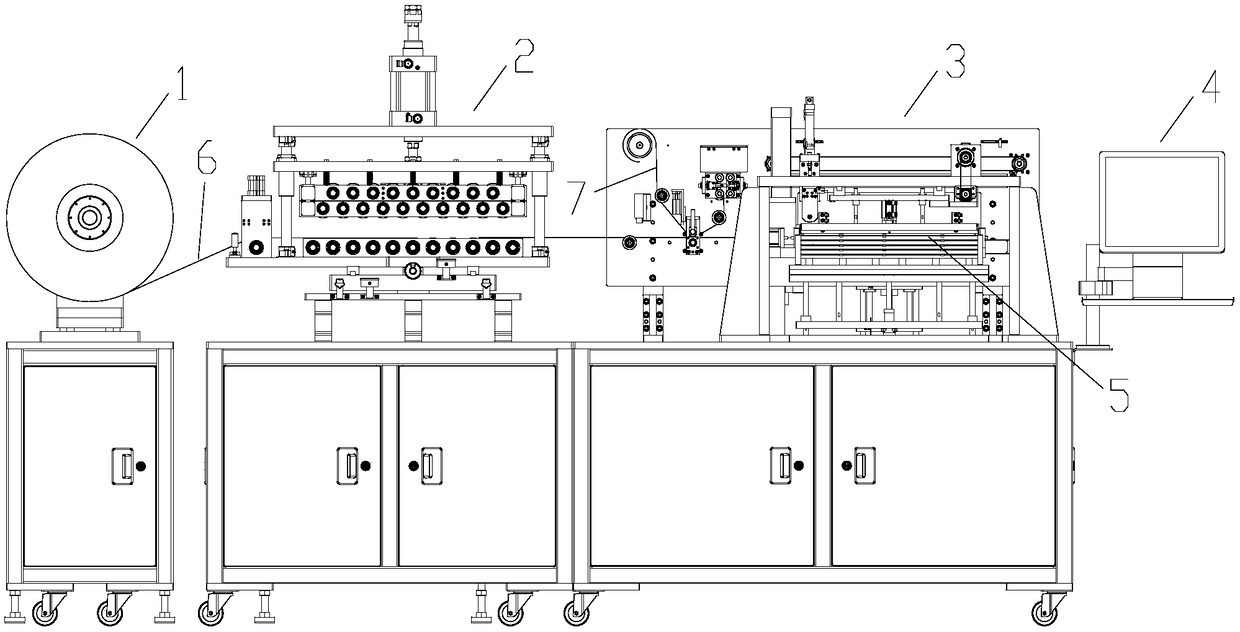

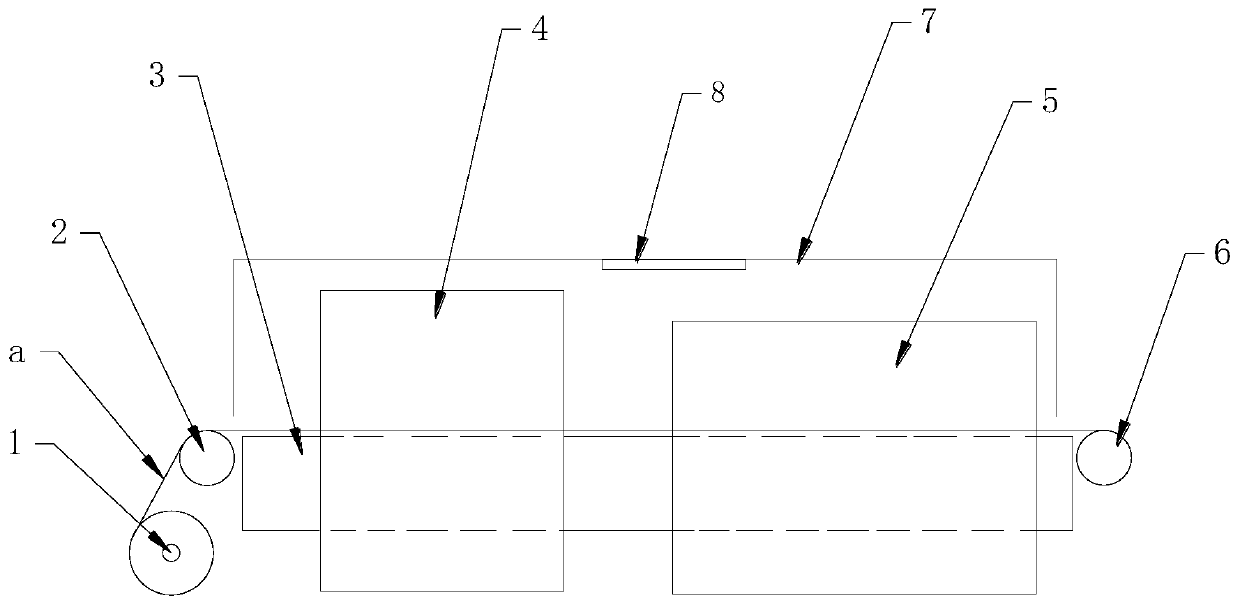

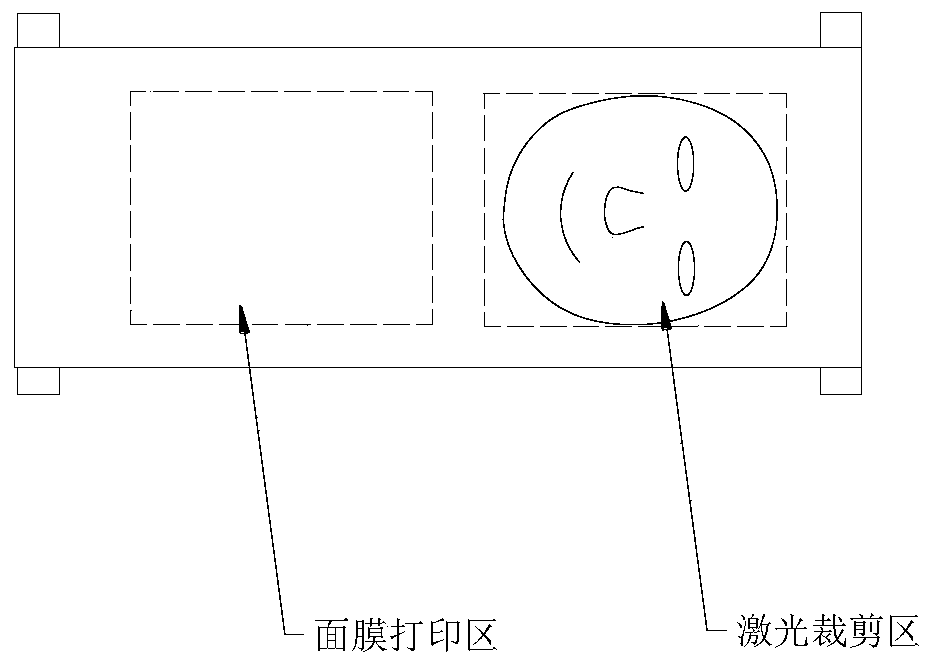

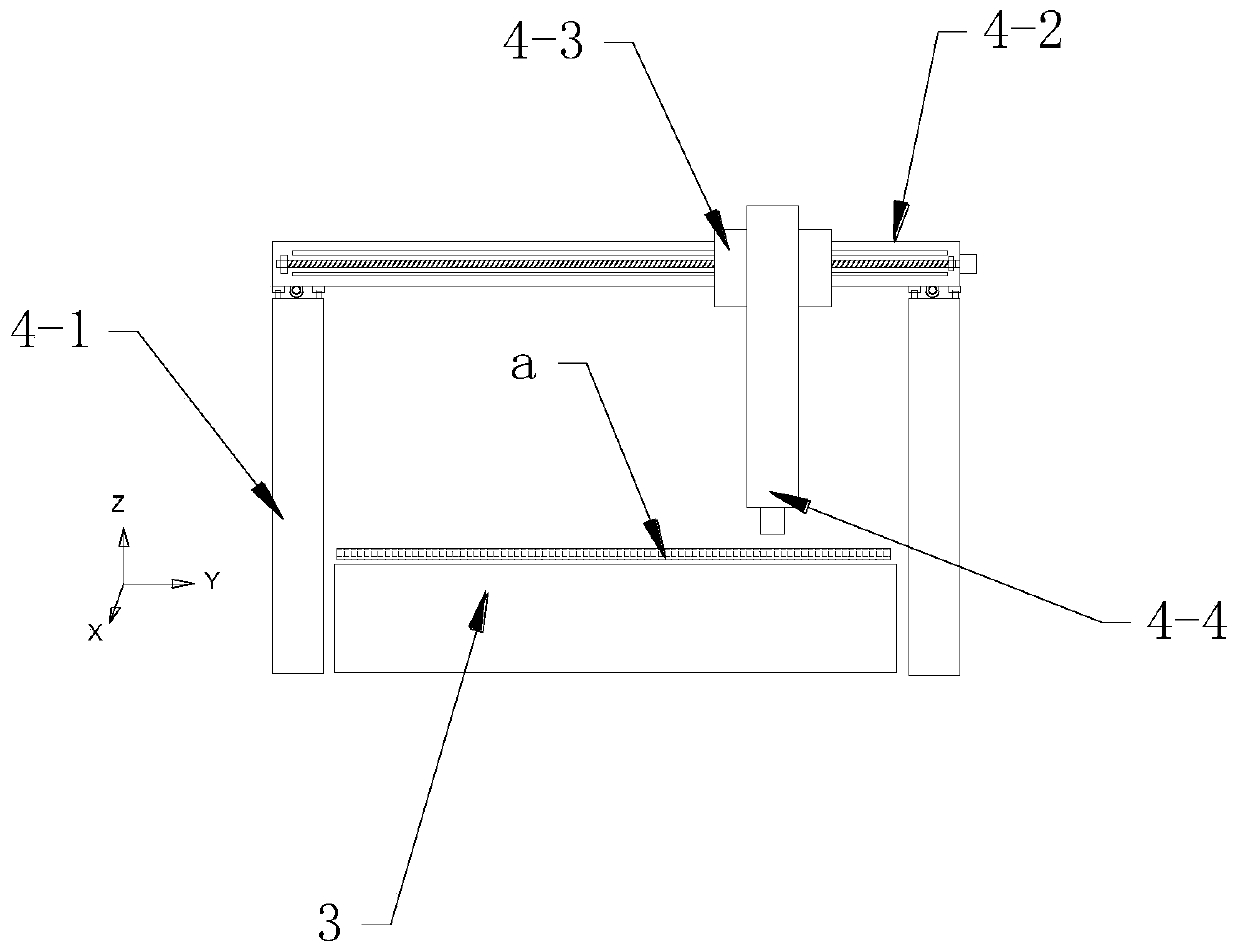

Personalized mask printing device and mask making and use method

PendingCN110711950ADry fastMeeting Facial Care NeedsPretreated surfacesLiquid spraying apparatusEngineeringLaser cutting

The invention discloses a personalized mask printing device and a mask making and use method. The printing device comprises a mask cloth roll placing part, a guide roller, a driving roller, a supporting platform, a mask printing unit, a laser cutting unit and a cover body. The guide roller is arranged on the tail side of the supporting platform, the driving roller is arranged on the tail side of the supporting platform, and the mask cloth roll placing part is also located on the tail side of the supporting platform, so that mask cloth sequentially passes through the guide roller and the supporting platform and is fixed to the driving roller, and the mask cloth is pulled by the driving roller for feeding. The mask printing unit is arranged above the supporting platform in a crossing mode and is used for printing various kinds of skin care essence on the mask cloth on the supporting platform according to needs. The laser cutting unit is arranged above the supporting platform in a crossing mode and is used for cutting the printed mask cloth. According to the device, corresponding positions of the mask cloth can be accurately sprayed with corresponding repair and care functional components and cut later, the automation integration degree is high, and face care requirements of different users can be better met.

Owner:李和伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com