Sorting device for solar battery pack

A technology of solar cells and sorting devices, which is applied in sorting and other directions, can solve the problems of low automation integration, increased probability of machine fragmentation, and waste of manpower for manual sorting components, so as to improve automation integration, avoid pollution and fragmentation, The effect of improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

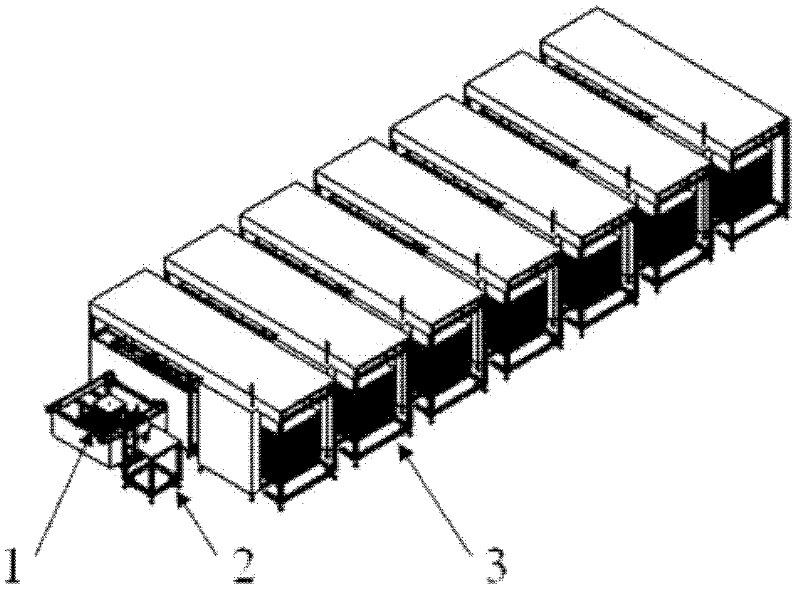

[0028] A kind of sorting device of solar battery module, its structure is as follows figure 1 As shown, the sorting device is composed of a transfer component 1, an electrical control component 2 and a sorting component 3, wherein there are 7 sorting components 3 arranged side by side, and the transfer component 1 and the electrical control component 2 are arranged on the sorting side of the component.

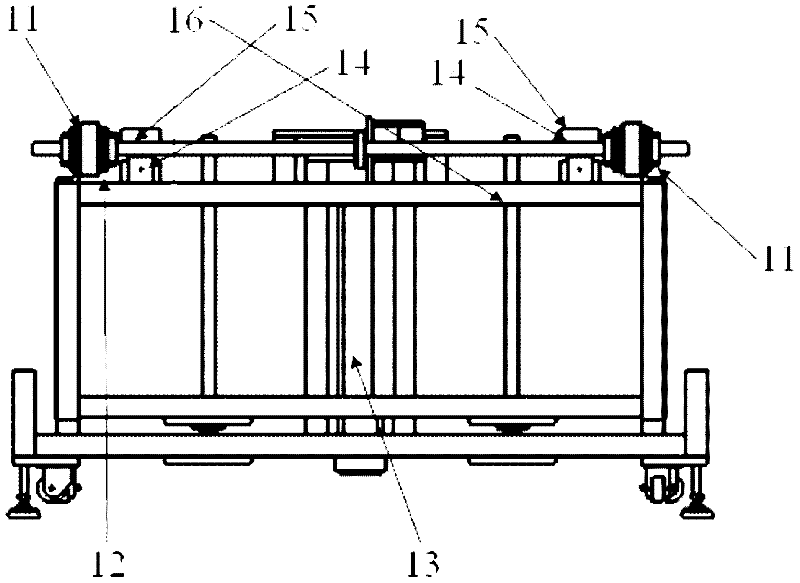

[0029] The structure of transport component 1 is as follows figure 2 As shown, it includes a transfer conveyor belt 11, a conveyor belt drive motor 12, a lifting cylinder 13, a material retaining cylinder 14, a material retainer plate 15, and a material retainer sensor 16, and the transfer conveyor belt 11 is sleeved on the shaft of the conveyor belt drive motor 12 , the conveyor belt drive motor 12 drives the transfer conveyor belt 11 to move, the stopper plate 15 and the stopper sensor 16 are arranged on the inner side of the transfer conveyor belt 11, the stopper cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com