Workpiece turnover device

A workpiece turning device and workpiece technology are applied in the field of machinery, which can solve the problems of high production cost and complex structure, and achieve the effects of low production cost, small movement range and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

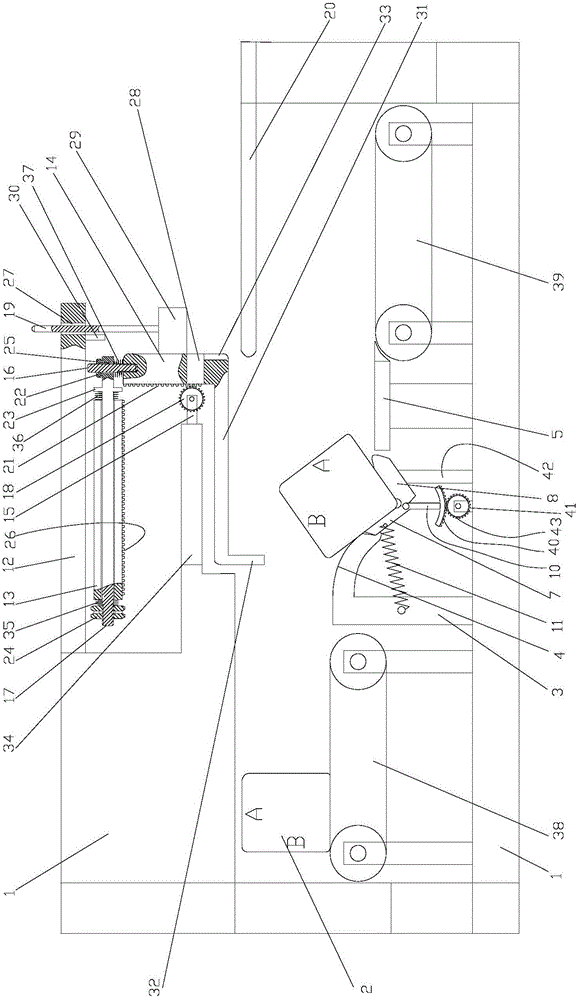

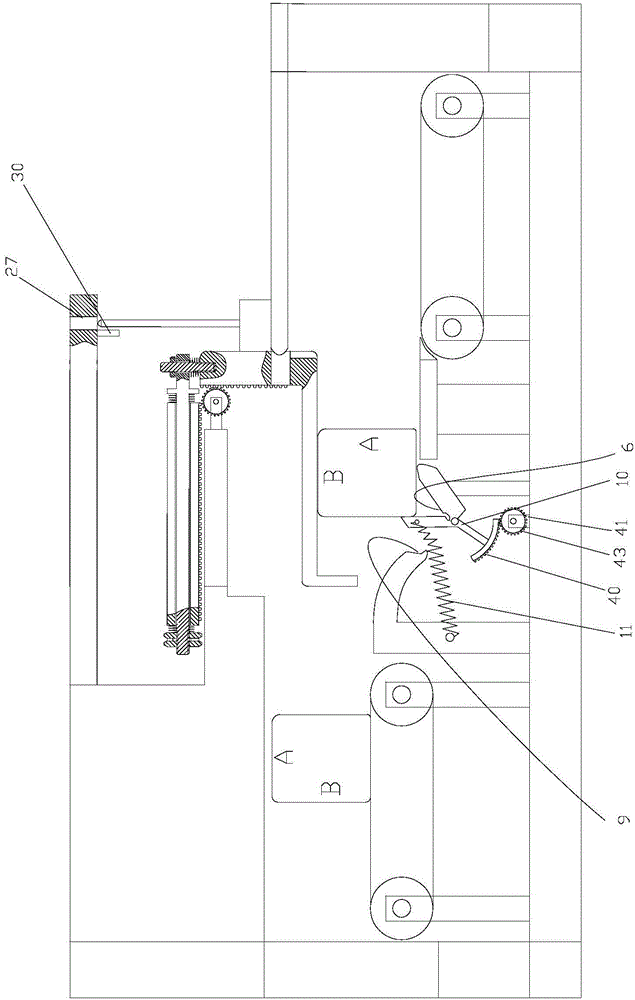

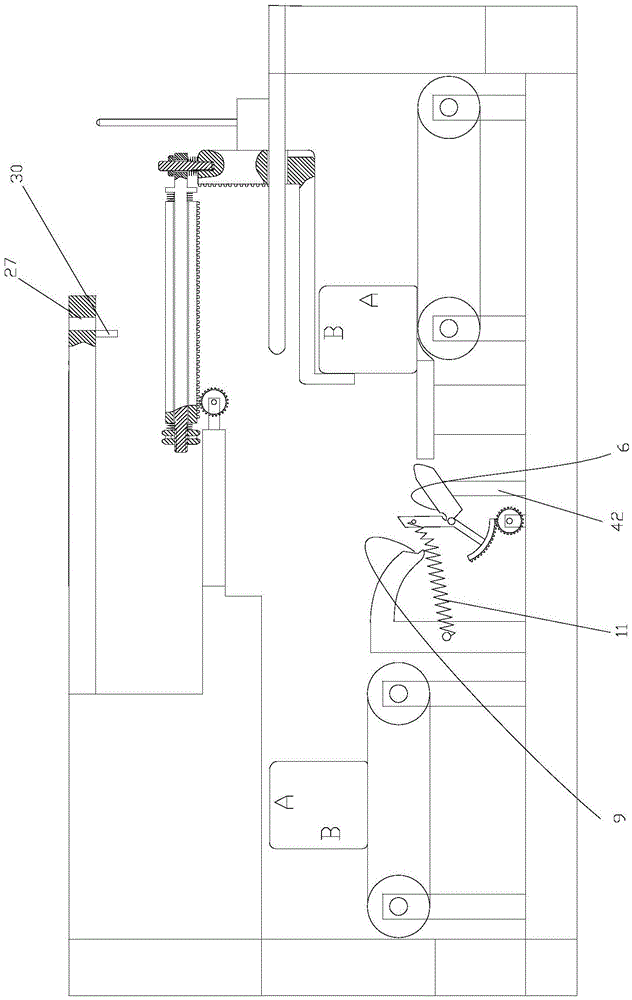

[0022] Working principle: as figure 1 , 2 , 3, the workpiece 2 with the A face upward and the B face left can continuously enter the arc segment 4 on the reversing table 3 under the drive of the first belt transmission structure 38 at the left end, and the bottom surface of the workpiece 2 is along the arc segment 4 and the first rotating plate 7 move and fall into the inner concave surface 6, and the right side of the workpiece 2 abuts against the second rotating plate 8; then, the first motor 41 drives the first gear 43 to rotate counterclockwise, and the first gear 43 drives the first rotating plate 7 and the extending rod 10 on the first rotating plate 7 to rotate clockwise by engaging with the arc rack 40, and the free end of the first rotating plate 7 is separated from the opening 9, causing the workpiece 2 Turn over, and extend the ext...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com