Solvent oil-gas reclaiming device

A recovery device, oil and gas technology, applied in the direction of steam condensation, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of low condensation recovery efficiency, high energy consumption, and influence on adsorption, and achieve high automation integration and superior electrical conductivity , the effect of investment saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with examples and specific implementation methods.

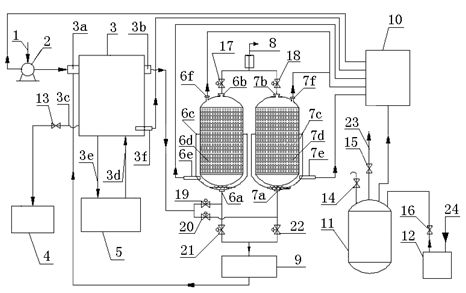

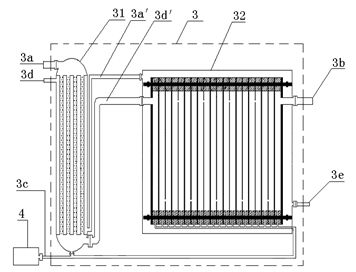

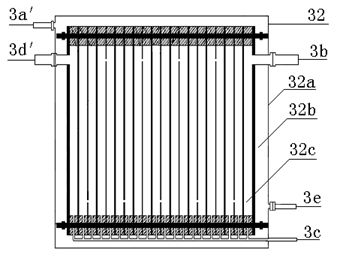

[0032] see figure 1 , a solvent oil gas recovery device, including fan 2, condensing part 3, solvent recovery tank 4, refrigerator 5, adsorption tanks 6 and 7, air discharge pipe 8 and vacuum pump 9, the inlet of fan 2 is connected to oil and gas source 1, and the outlet It communicates with the oil and gas inlet 3a of the condensing part, the oil and gas outlet 3b of the condensing part communicates with the oil and gas inlets 6a and 7a of the adsorption tank through pneumatic valves 19-22, and the solvent outlet 3c of the condensing part communicates with the solvent recovery tank 4 through the electric valve 13, and the refrigerant inlet of the condensing part 3d and the refrigerant outlet 3e of the condensing part are respectively communicated with the refrigerant machine 5, and the air discharge ports 6b and 7b of the adsorption tank a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com