Angle shaft workpiece processing system

A technology for processing systems and workpieces, applied in labeling, packaging, labeling machines, etc., can solve the problems of difficult standardization of production, high rework rate, and uncontrollable quality, and achieve easier standardization of production, high degree of integration, and low production costs. control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described below in conjunction with accompanying drawing and embodiment:

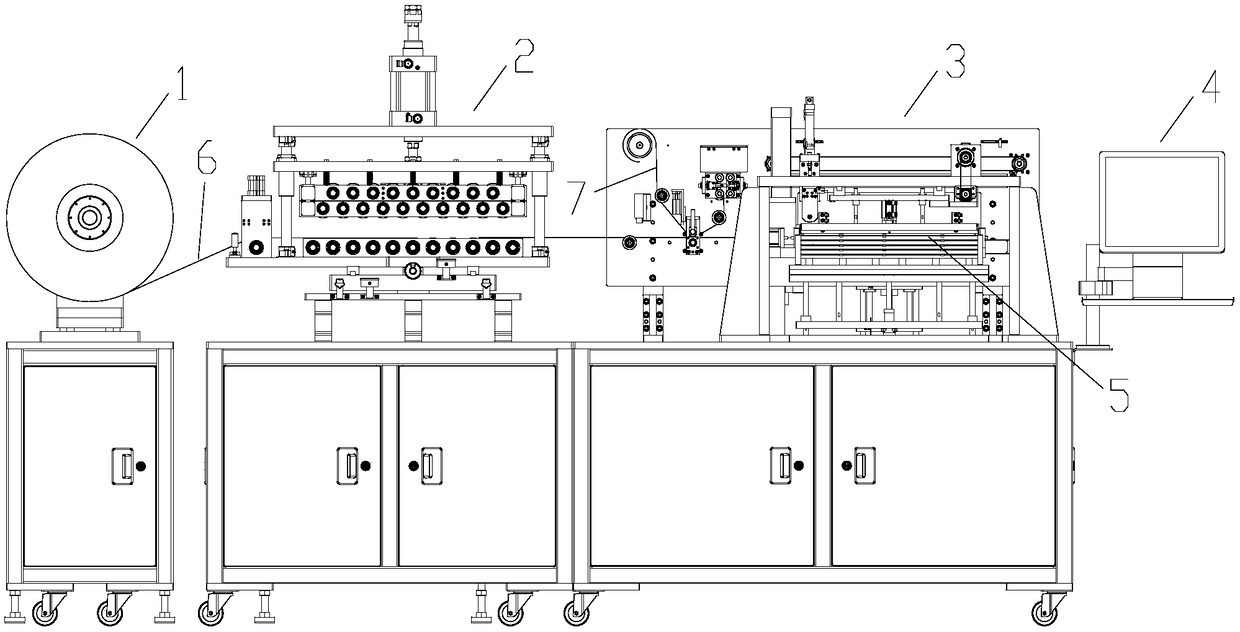

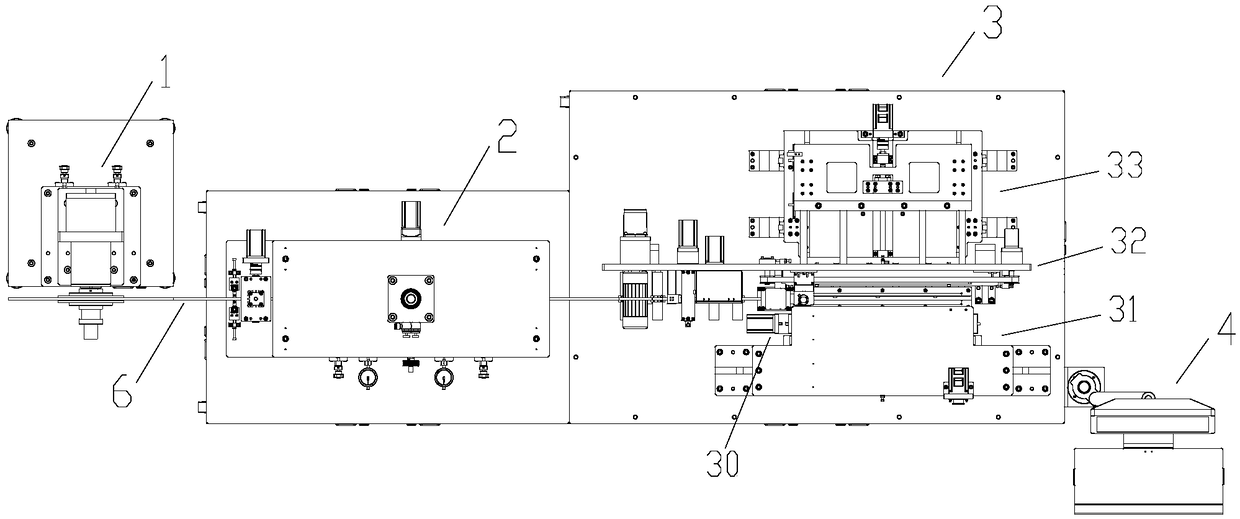

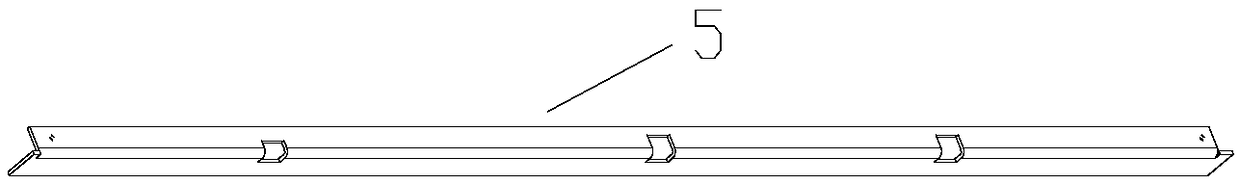

[0029] As an example, the corner bar workpiece processing system of the present embodiment, such as Figure 1~2 As shown, including a frame, the frame is provided with a strip feeding mechanism 1, a leveling mechanism 2, a packaging mechanism 3 and a manipulation device 4, wherein the packaging mechanism 3 includes a feeding and transporting mechanism 31, a rotating mechanism 30, a pasting The mechanism 32, the second conveying mechanism 33, and the control device 4 are used to comprehensively control the action sequence of each mechanism. The steel strip 6 is delivered to the leveling mechanism 2 by the steel strip feeding mechanism 1, and the leveling mechanism 2 levels the steel strip 6 and transports it to the packaging mechanism 3.

[0030] When the rigid strip feeding mechanism 1 is implemented, it preferably includes a uniform speed motor to feed the rigid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com