Patents

Literature

114results about How to "Improve hole efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

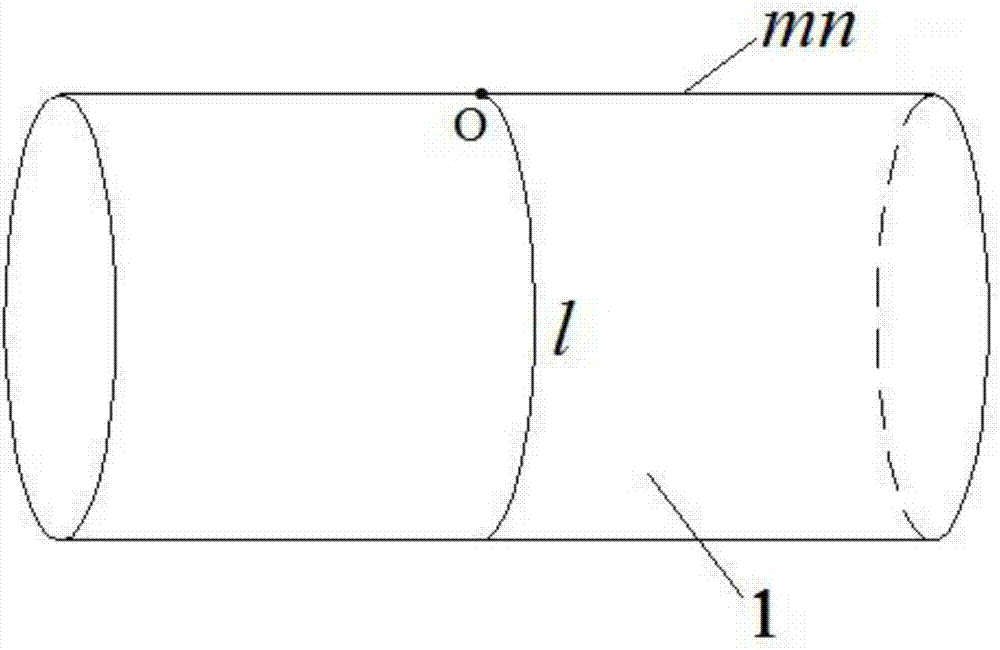

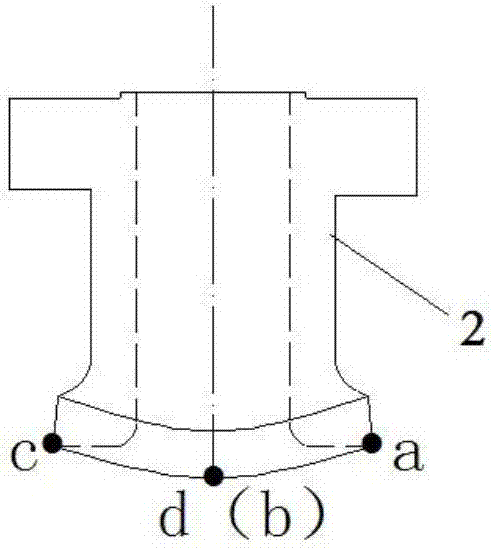

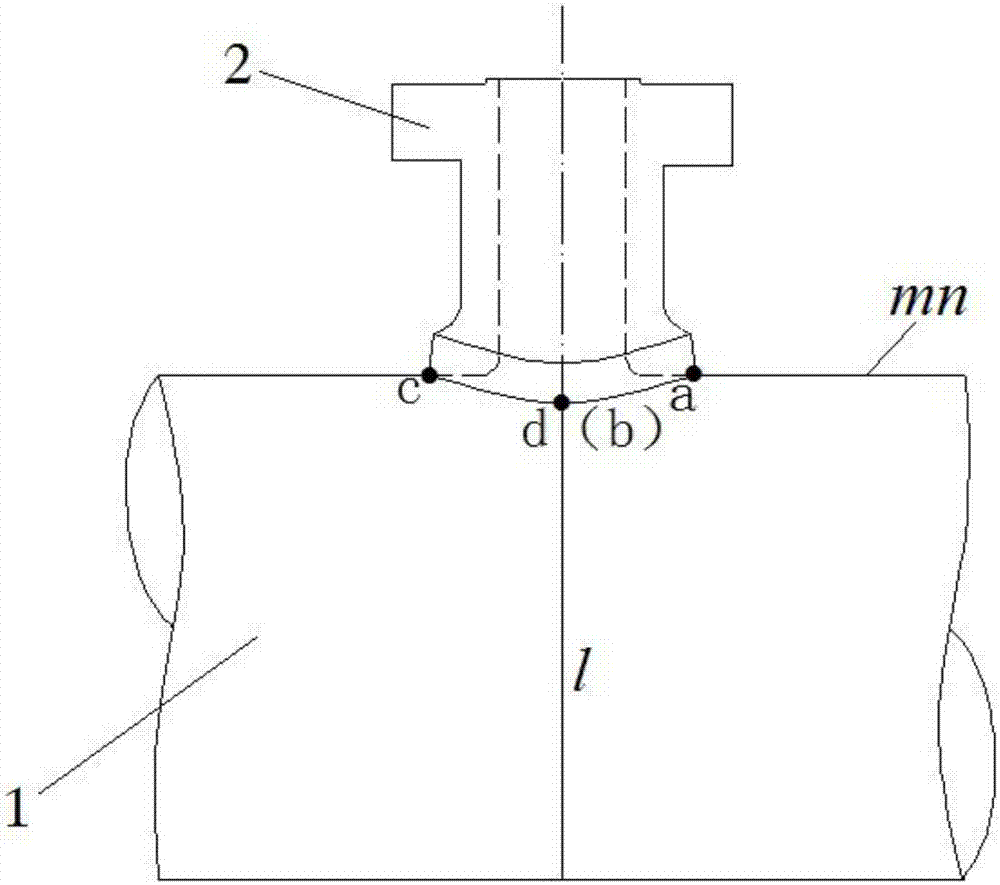

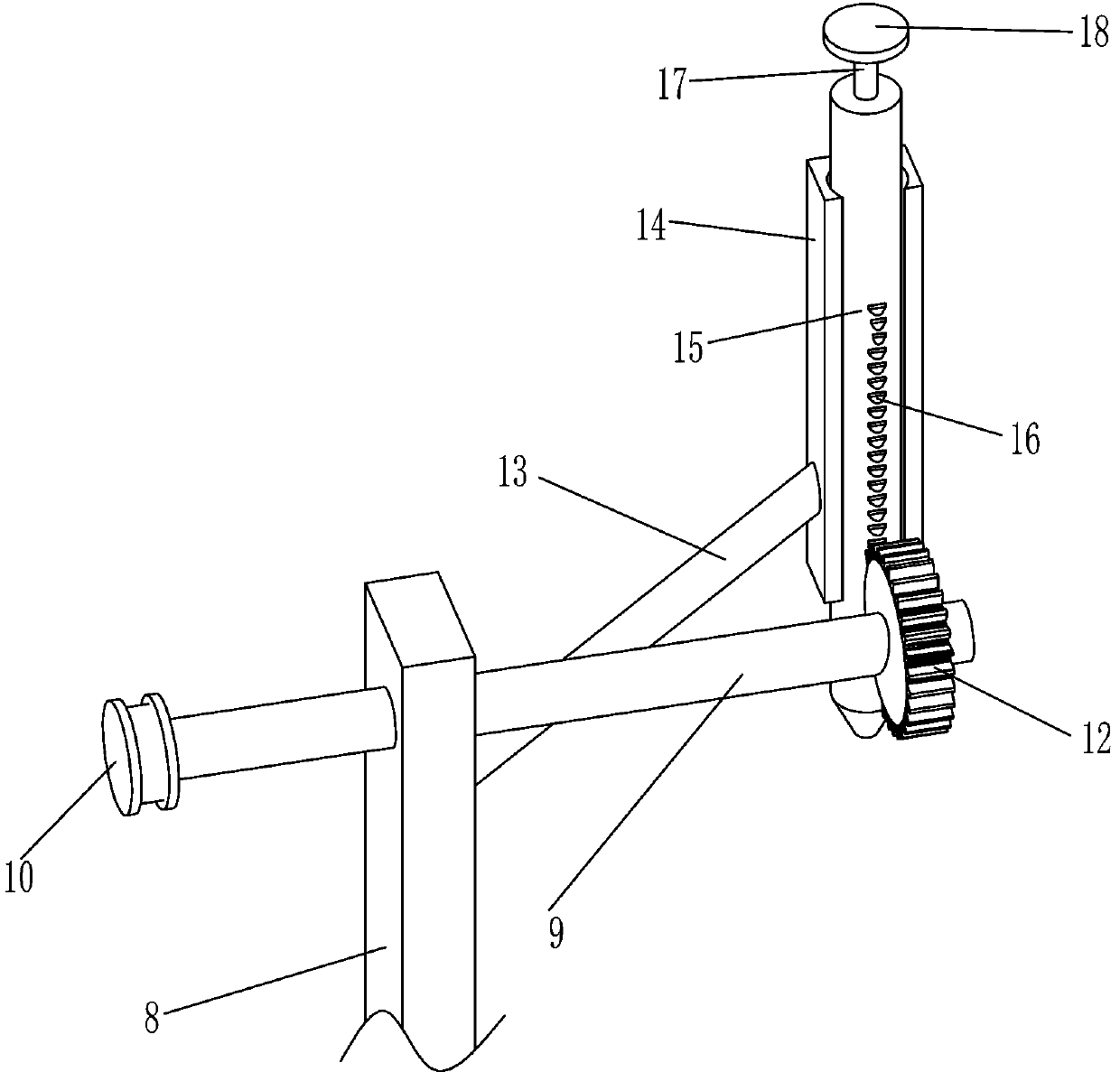

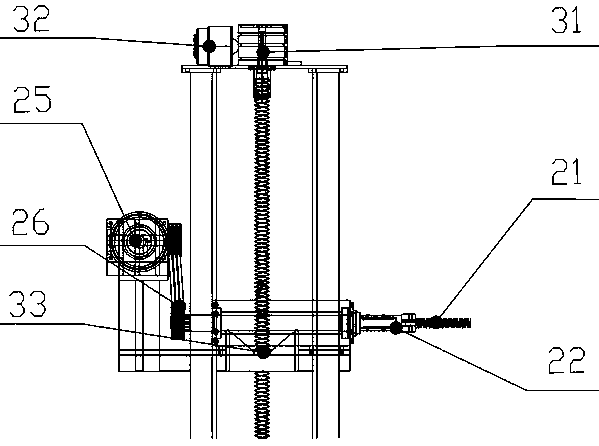

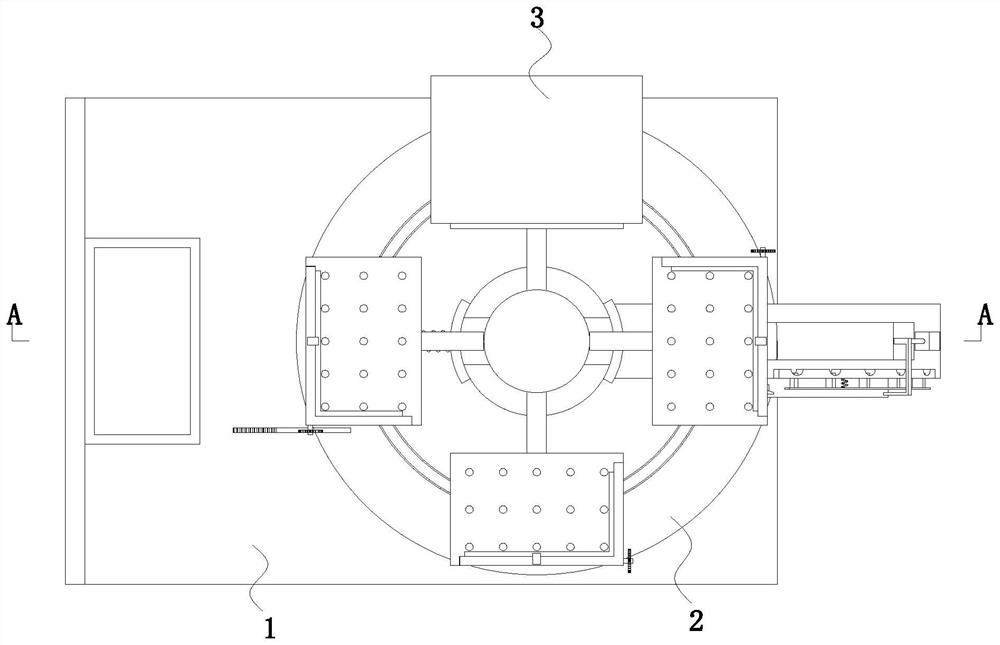

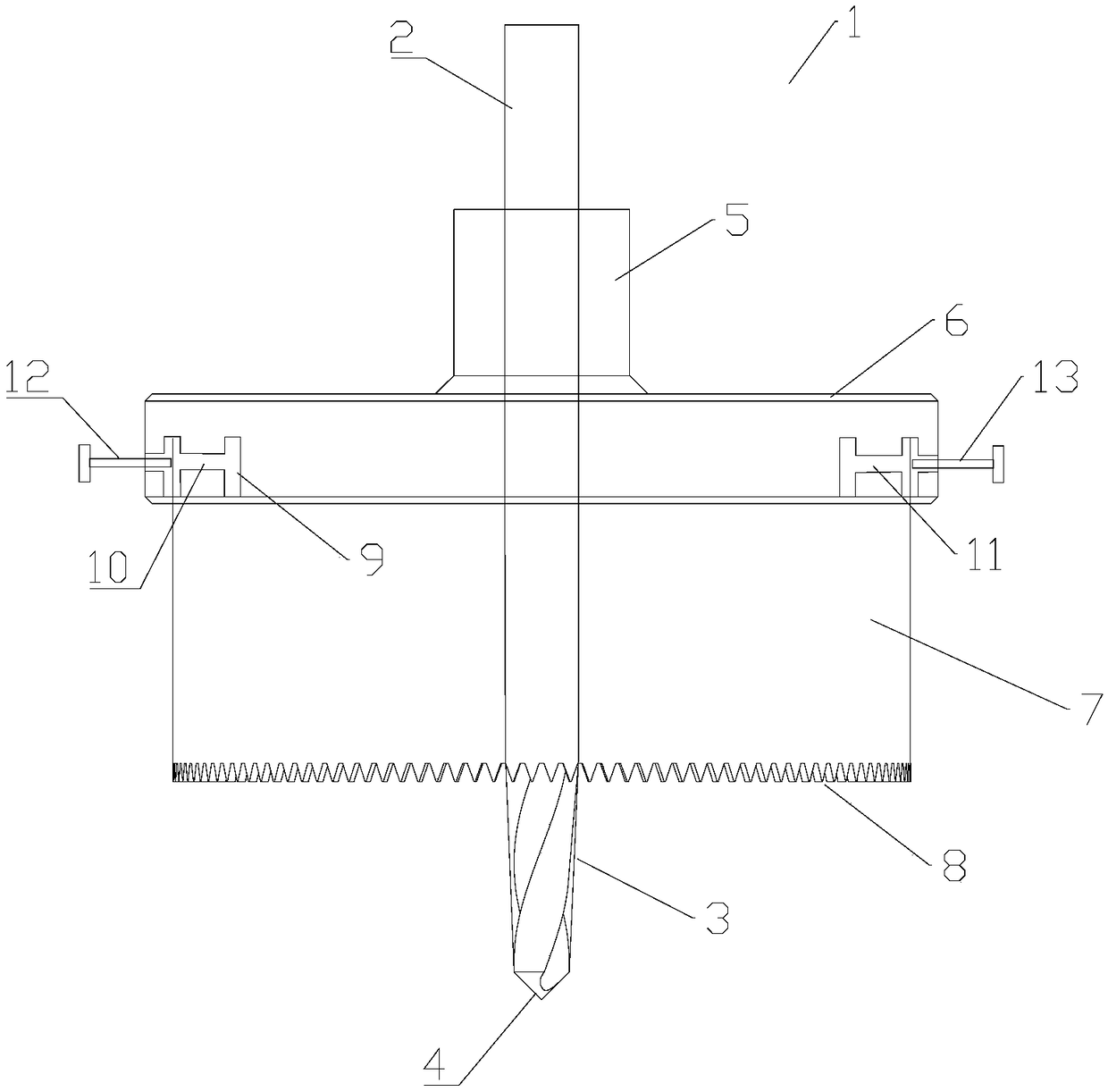

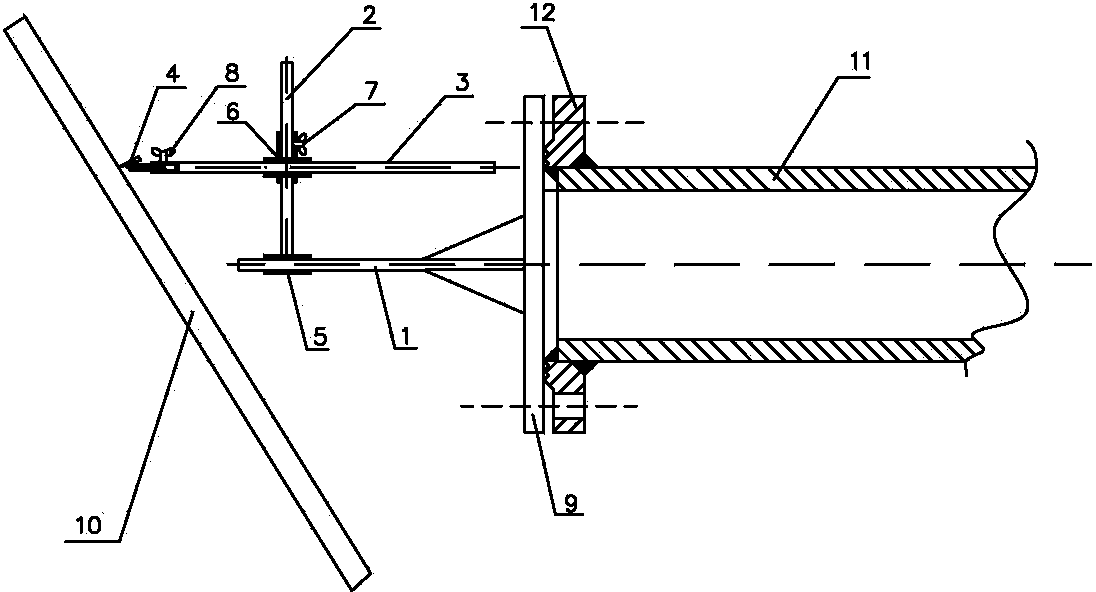

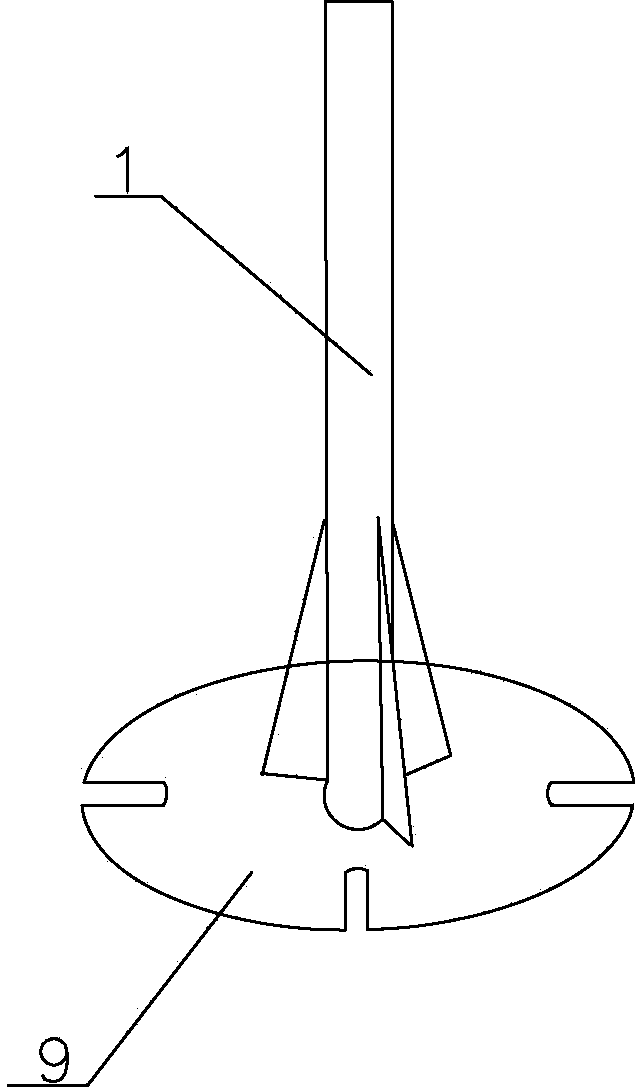

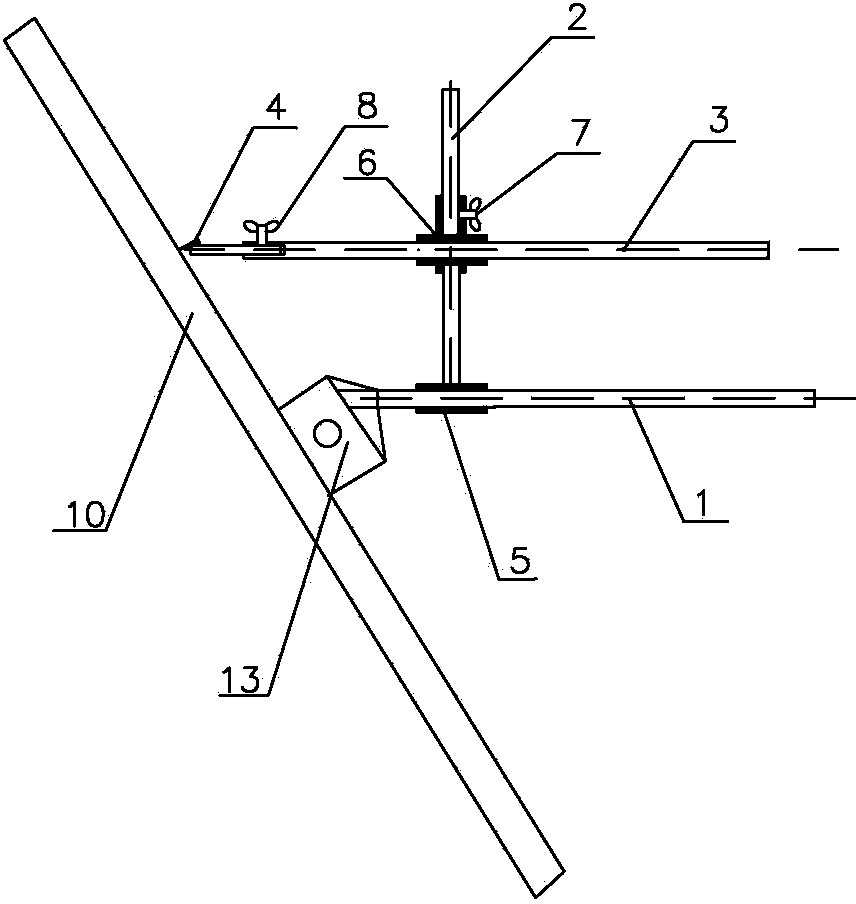

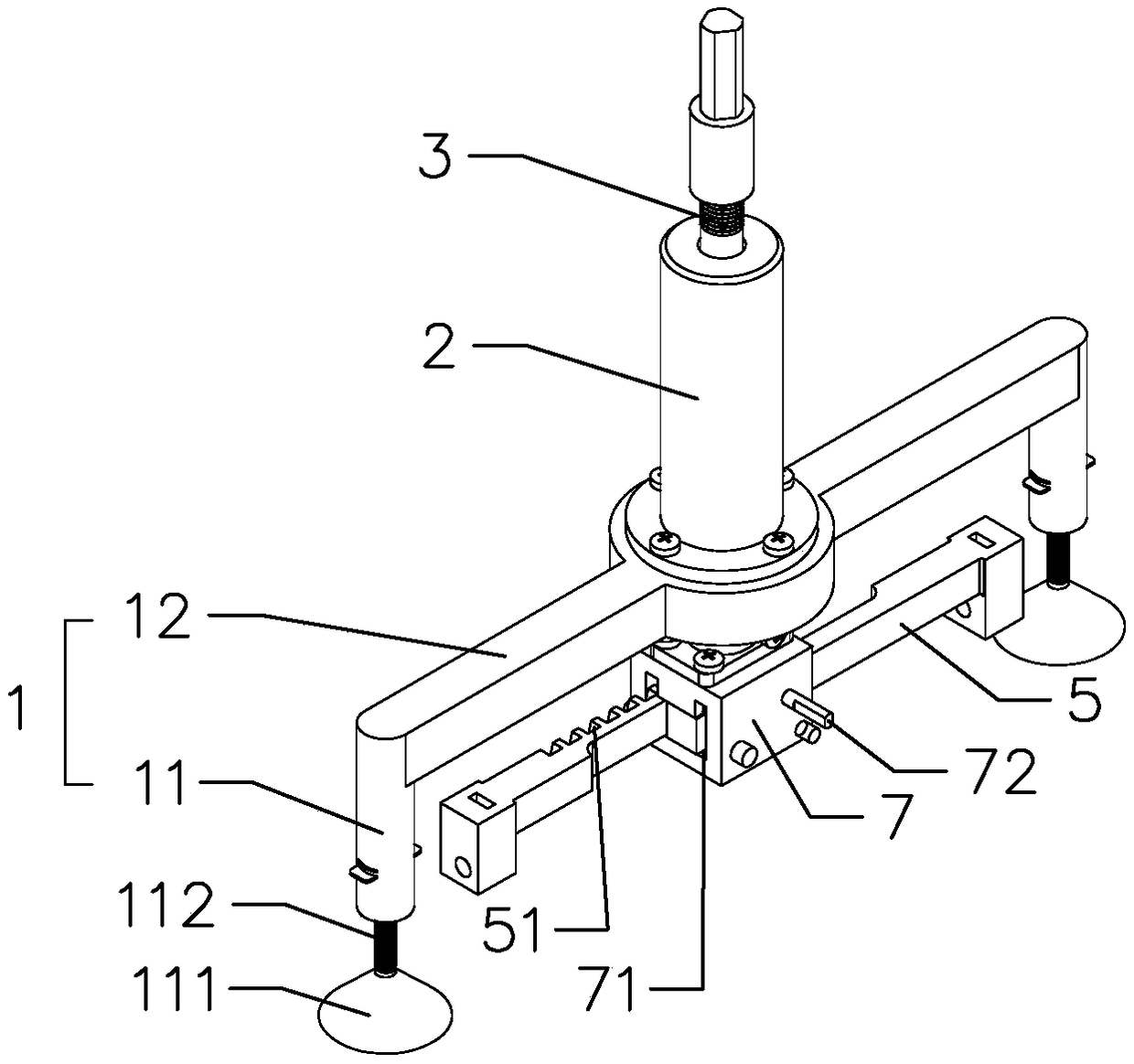

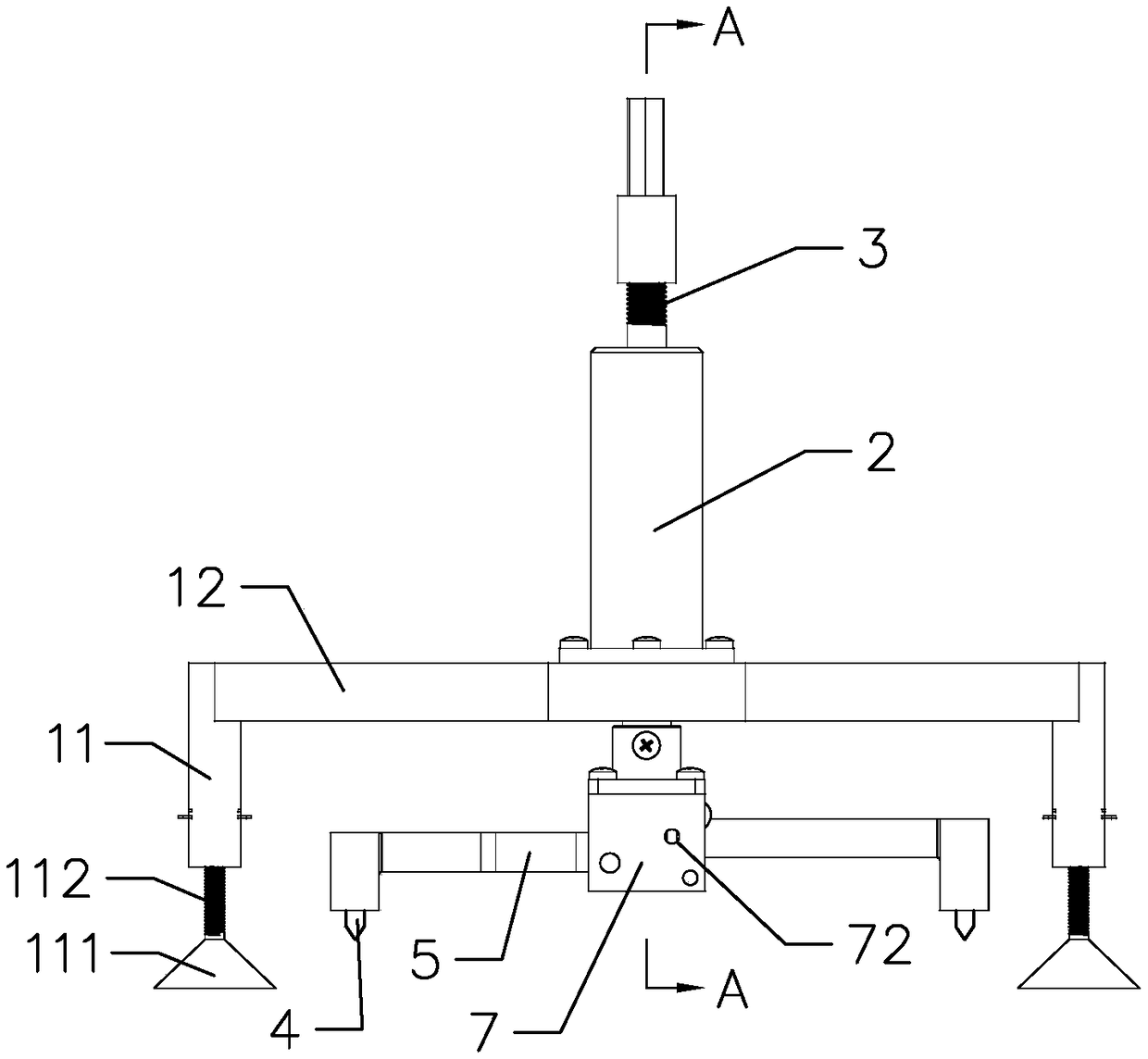

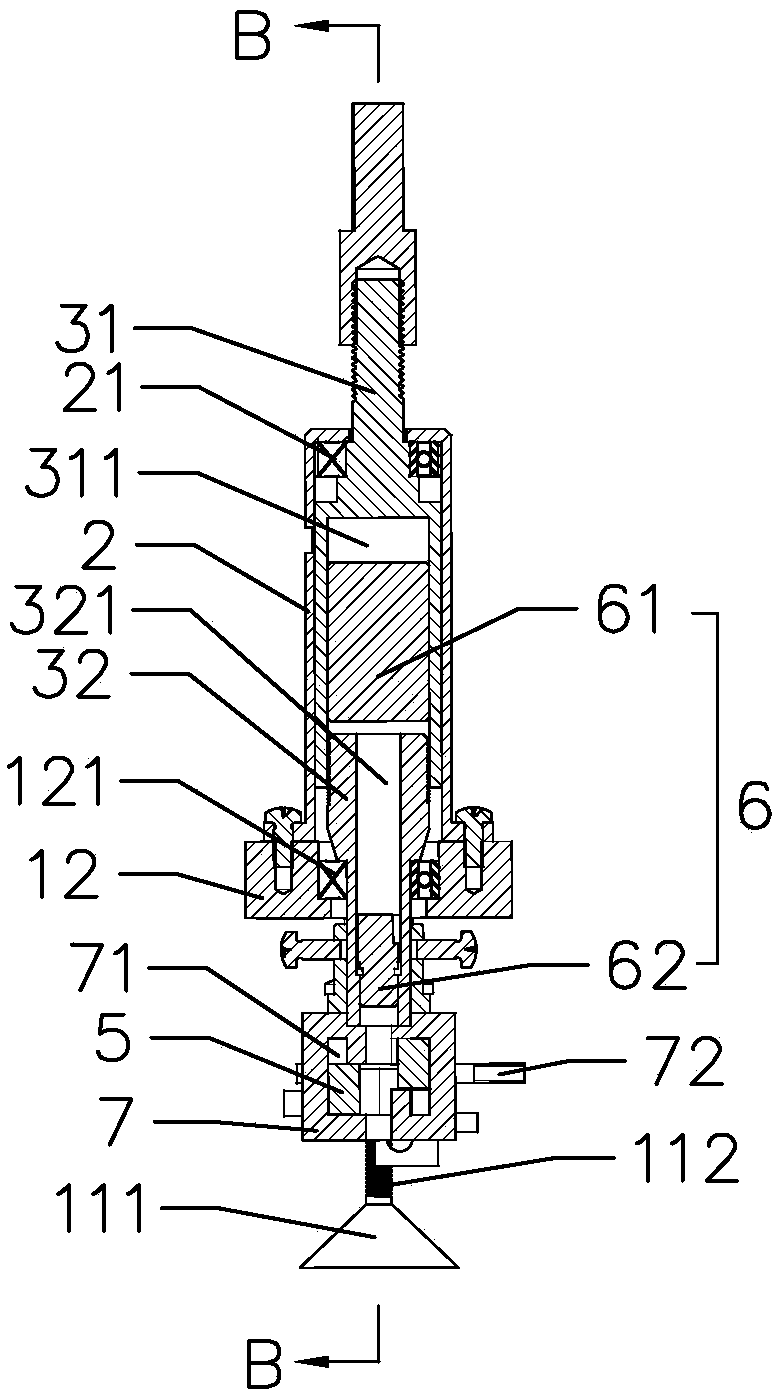

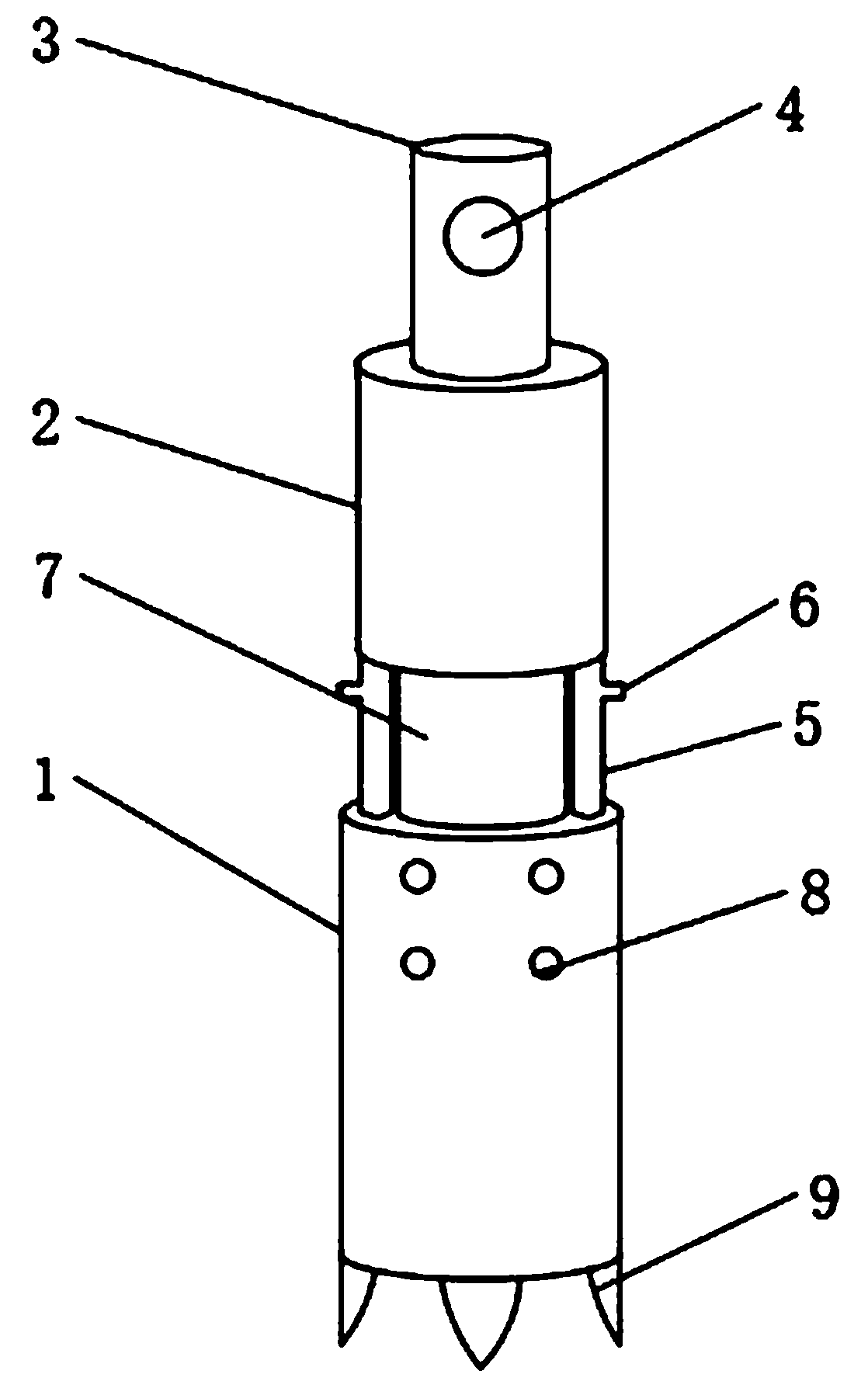

Tapping method for pipeline arc surface and cutting torch support adjusting device for tapping

The invention relates to the field of pipeline tapping. In order to improve tapping efficiency and tapping precision, the invention provides a tapping method for a pipeline arc surface. The method comprises drawing an axial positioning line, a peripheral positioning line, a profile line of a pipe platform mounting hole and a cutting line; setting cutting-starting points A' and B' and pre-stopping points C and D; mounting a cutting torch support adjusting device comprising a rotary shaft, an adjusting vertical rod and an adjusting cross rod on a tapping pipeline, and sleeving a fixing sleeve on the lower end of the rotary shaft and vertically fixing on the tapping pipeline; adjusting the cutting torch support adjusting device and starting cutting torque for preheating till a preheated region is in a range of 150-250 DEG C, and closing the cutting torch; adjusting the cutting torch support adjusting device, cutting from the cutting-starting points A' and B' to the pre-stopping points C and D along the cutting line, and closing the cutting torch; detaching the cutting torch support adjusting device, and handholding the cutting torch to cut the rest part along the cutting line till cutting is finished. By adopting such tapping method for a pipeline arc surface to tap the pipeline arc surface, the tapping efficiency and tapping precision are high and operation is simple and convenient.

Owner:CHINA NUCLEAR IND FIFTH CONSTR CO LTD

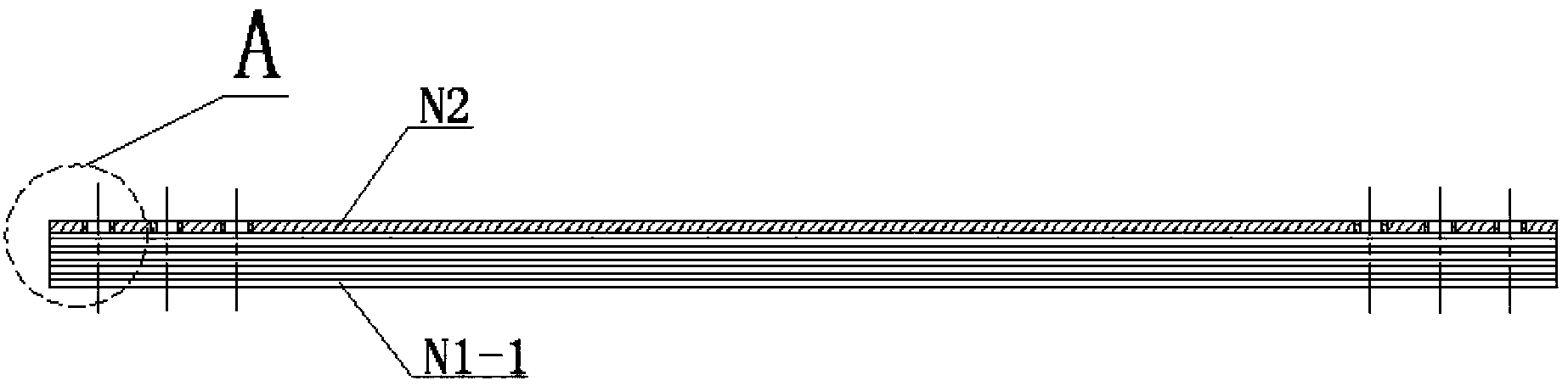

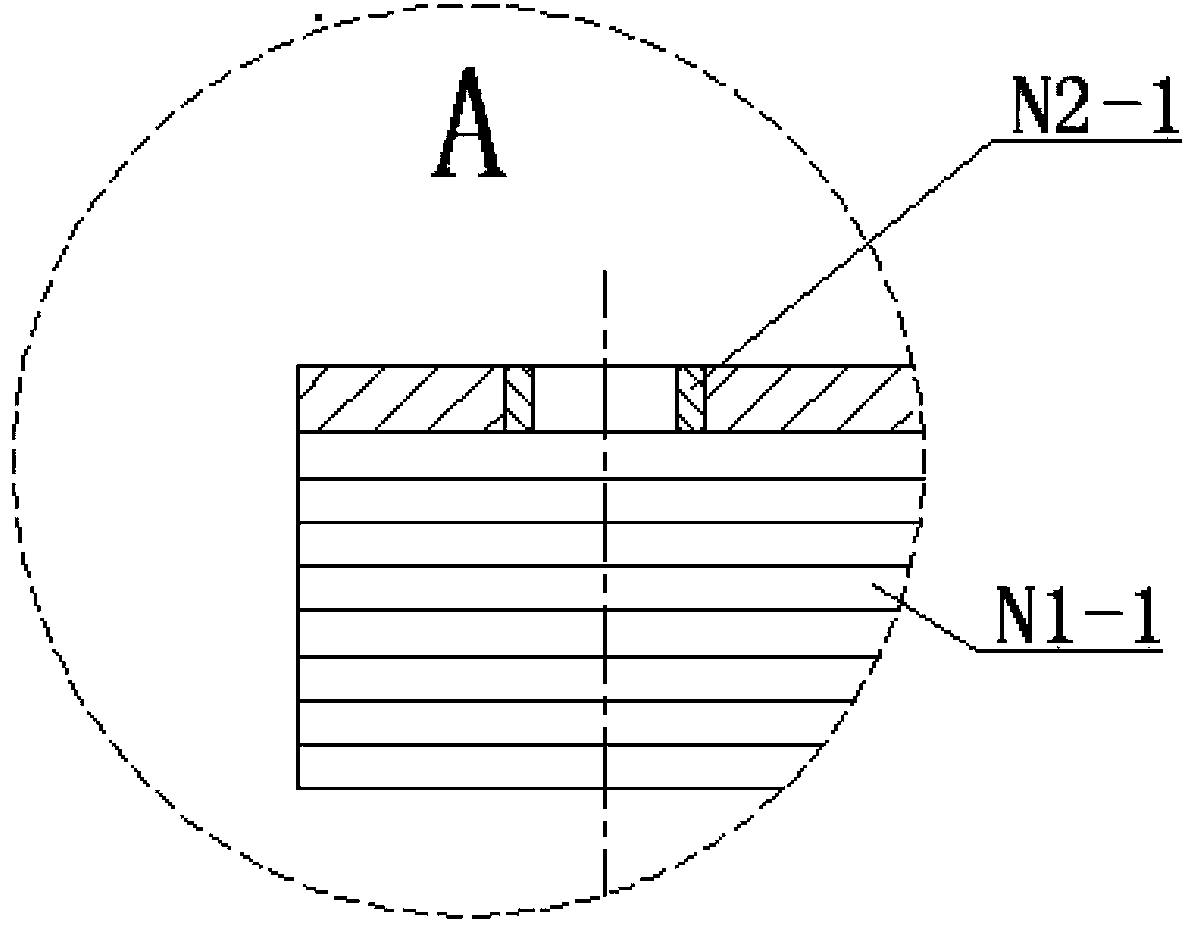

Machining method for perforated U-shaped rib

The invention relates to a machining method for a perforated U-shaped rib in manufacturing of a steel structure, in particular to a method for profiling a U-shaped rib after drilling before steel plate profiling, belonging to the technical field of plate forming. The machining method is implemented by the following steps: A, pretreating, flattening and feeding a steel plate; B, milling an edge in the length direction after stacking electric welding fixation; C, drilling a plurality of plates simultaneously and then milling an edge in the width direction; D, milling a plate groove; E, profiling the U-shaped rib. The machining method has the technological progress effects that (1) the machining difficulty for drilling after U-shaped rib forming can be reduced by drilling a hole group before profiling, (2) the hole group is simultaneously machined in a plurality of layers of plates through a drilling template to improve the hole forming efficiency, and (3) the internal stress of the steel plate is eliminated, the deformation before plate profiling is reduced and the positional accuracy of the hole group is guaranteed.

Owner:CHINA RAILWAY SHANQIAO GRP CO LTD

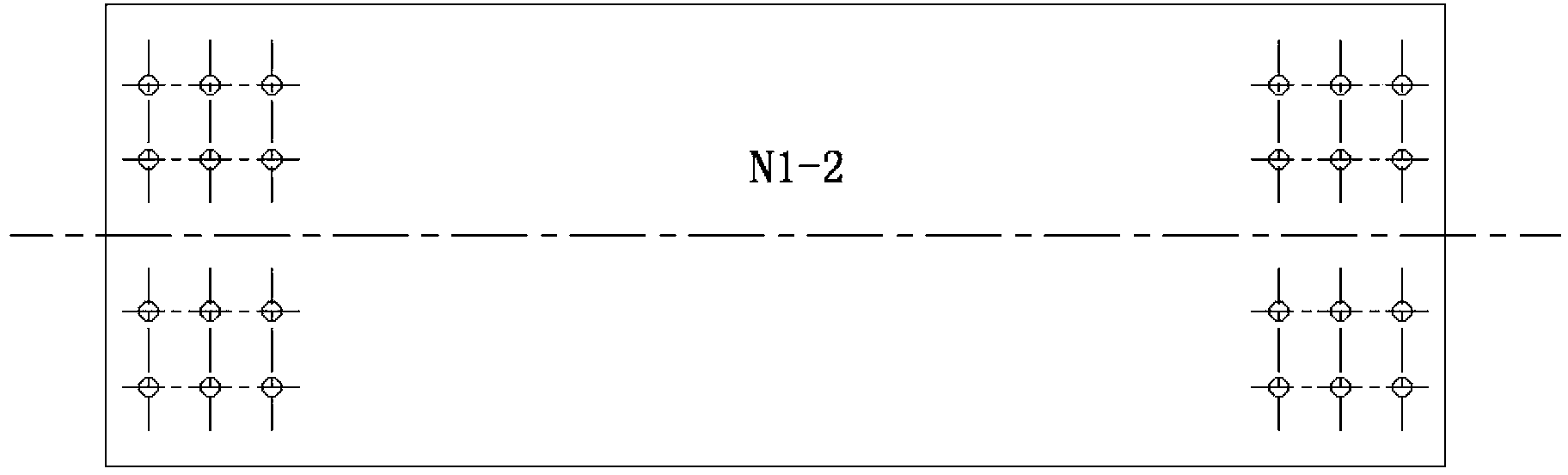

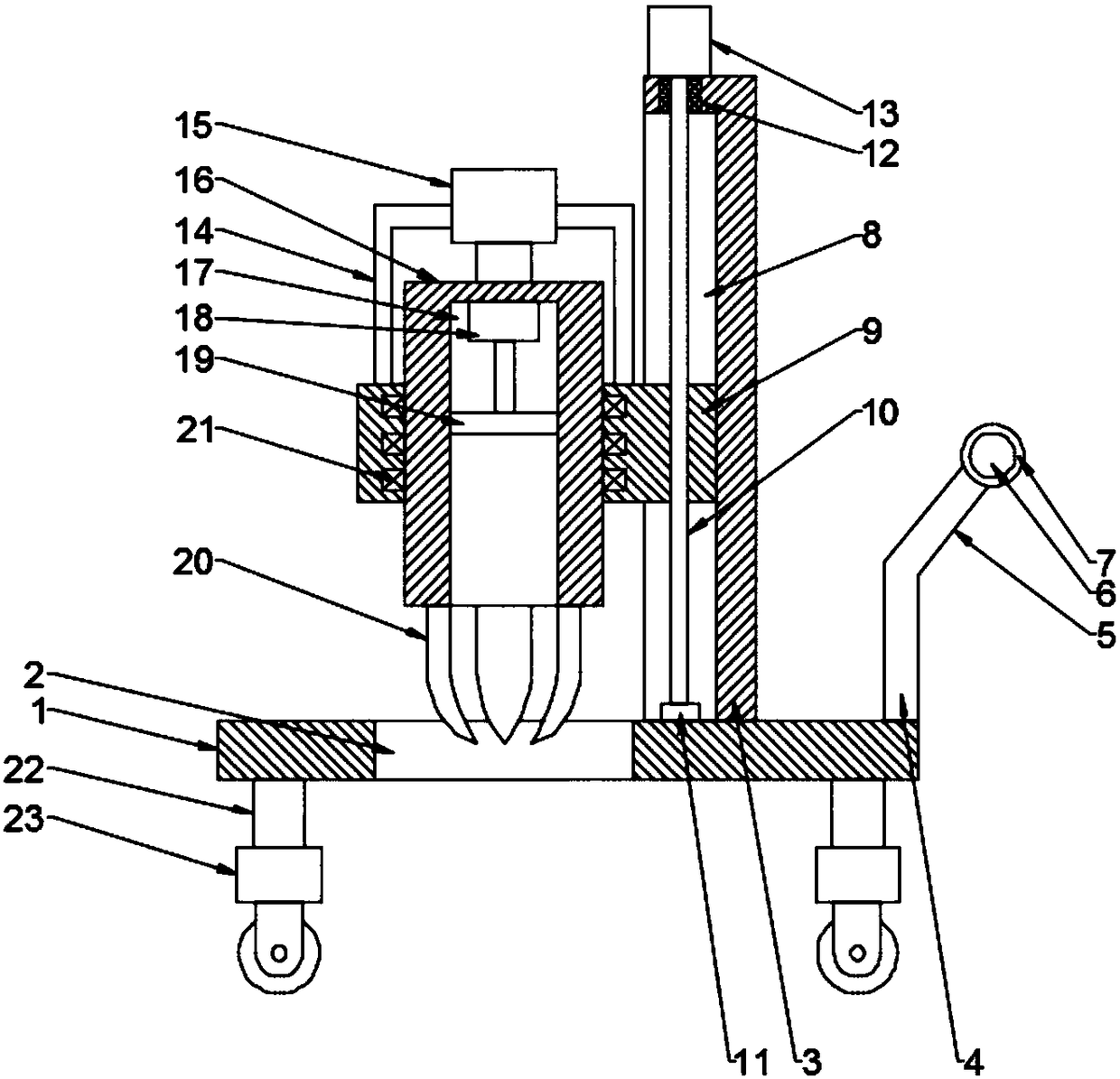

Plantation punching soil sampler having elevating function

InactiveCN108156890AEasy to operateLow manpower requirementPlantingFurrow making/coveringHydraulic cylinderTransverse plane

The invention discloses a plantation punching soil sampler having an elevating function. The plantation punching soil sampler comprises a base plate, a boring is arranged at the base plate, a column is arranged at one side of a top opening of the boring, a rail groove is arranged at one side end of the column close to the boring, a leading screw is arranged in the rail groove, a slide block cooperated with the rail groove is arranged on the leading screw, a rotating cylinder cooperated with the boring is embedded on the slide block, a soil-storage chamber is arranged at the bottom of the rotating cylinder, a hydraulic cylinder is arranged at an upper wall of an inner chamber of the oil-storage chamber, several hole-making blades cooperated with the soil-storage chamber are uniformly arranged at the bottom of the rotating cylinder, a support cooperated with the rotating cylinder is fixedly connected with the top of the slide block, a work motor is embedded at the top of the support, several legs are uniformly arranged at an edge of a bottom transverse plane of the base plate, a whole hole-making process is completely and automatically finished, has low requirement on manpower, shortens a hole-making period, greatly increases the hole-making efficiency, and increases the whole plantation efficiency; the hole-making blades are fixedly arranged, a specification of the hole is fixed, hole-making uniformity is high, and the plantation quality is increased.

Owner:ZHENGZHOU GUOZHI NETWORK TECH CO LTD

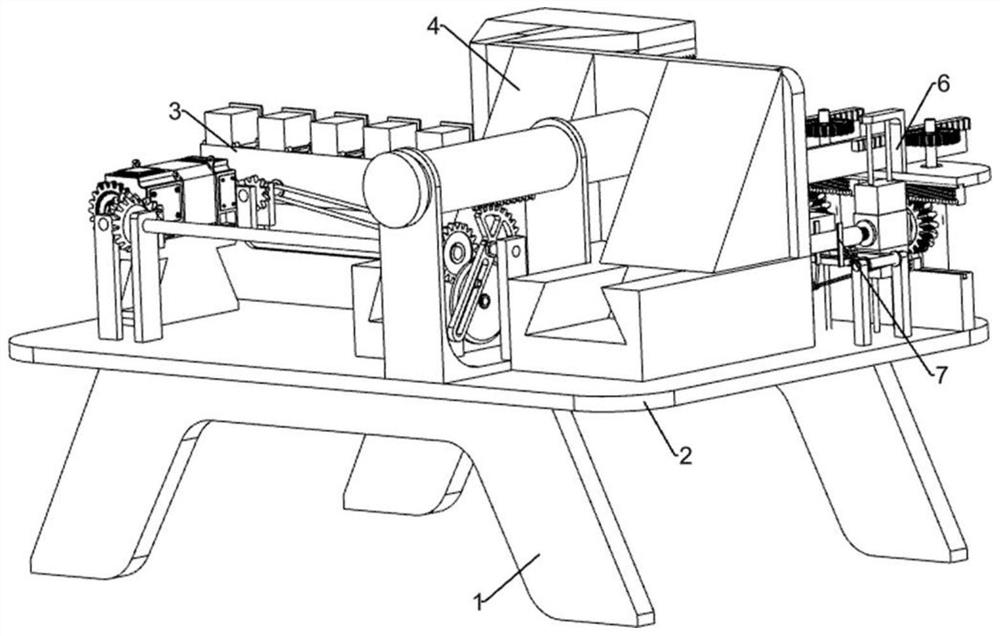

Full-automatic trimming and stamping equipment for hardware wire box

InactiveCN112122447AImprove work efficiencyImprove hole efficiencyPerforating toolsMetal-working feeding devicesComputer hardwareStructural engineering

The invention relates to the field of hardware, in particular to full-automatic trimming and stamping equipment for a hardware wire box. The full-automatic trimming and stamping equipment for the hardware wire box is provided . According to the technical implementation solution, the full-automatic trimming and stamping equipment for the hardware wire box comprises a bottom frame, a machine plate,a conveying mechanism, an auxiliary mechanism, a burr cutting mechanism block and the like, wherein the upper end of the bottom frame is fixedly connected to the machine plate, and one side of the upper end of the machine plate is fixedly connected to the conveying mechanism. According to the full-automatic trimming and stamping equipment for the hardware wire box, the effects that an upper stamping knife and a lower stamping knife which are used for replacing manual work are used for cutting off the hardware wire box, the four edges of the hardware wire box can be cut off at the same time, therefore the working efficiency is improved, and meanwhile when the device is used for stamping, wire holes in the two side faces can be stamped at the same time, and the perforating efficiency is improved.

Owner:赵鹏生

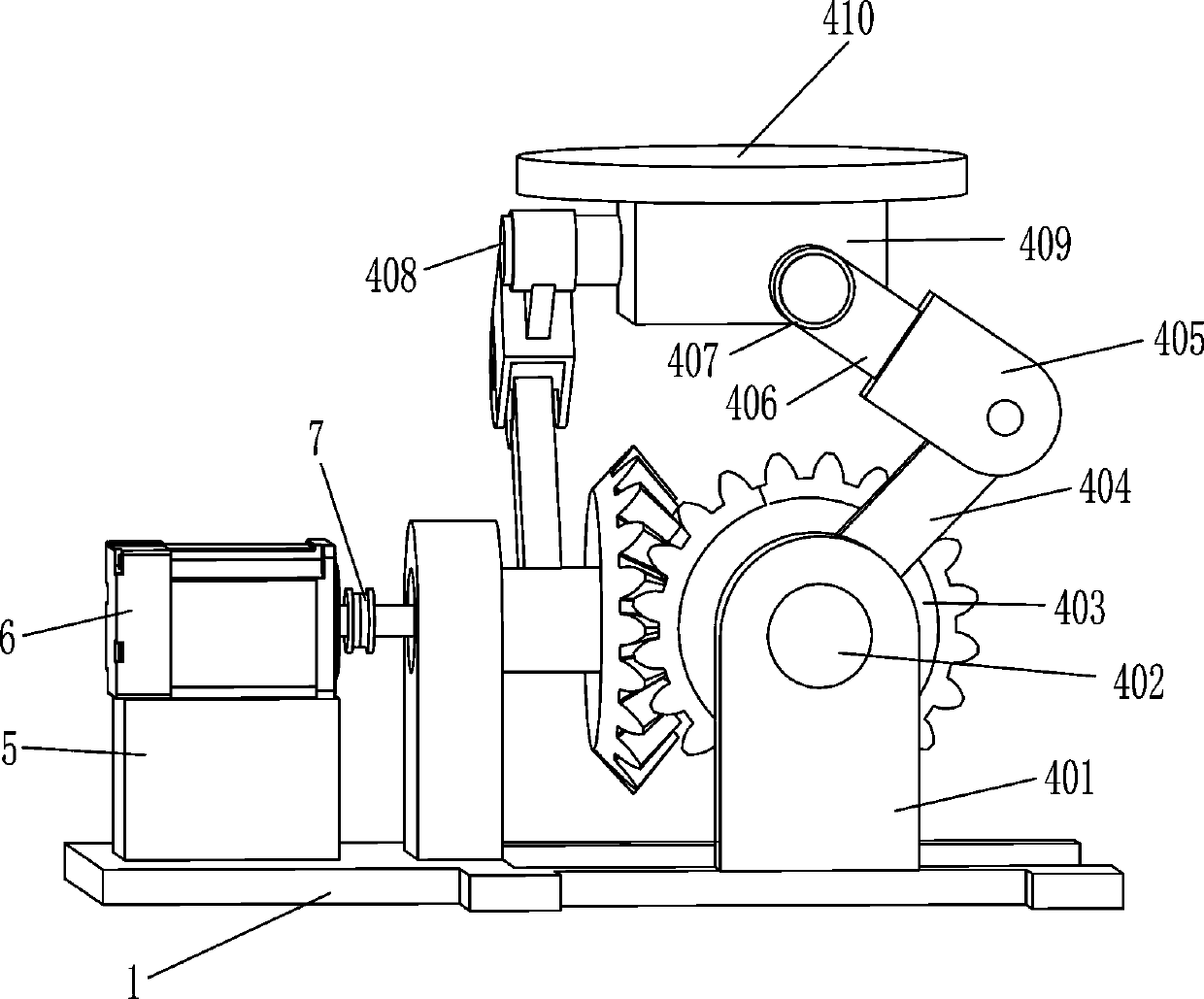

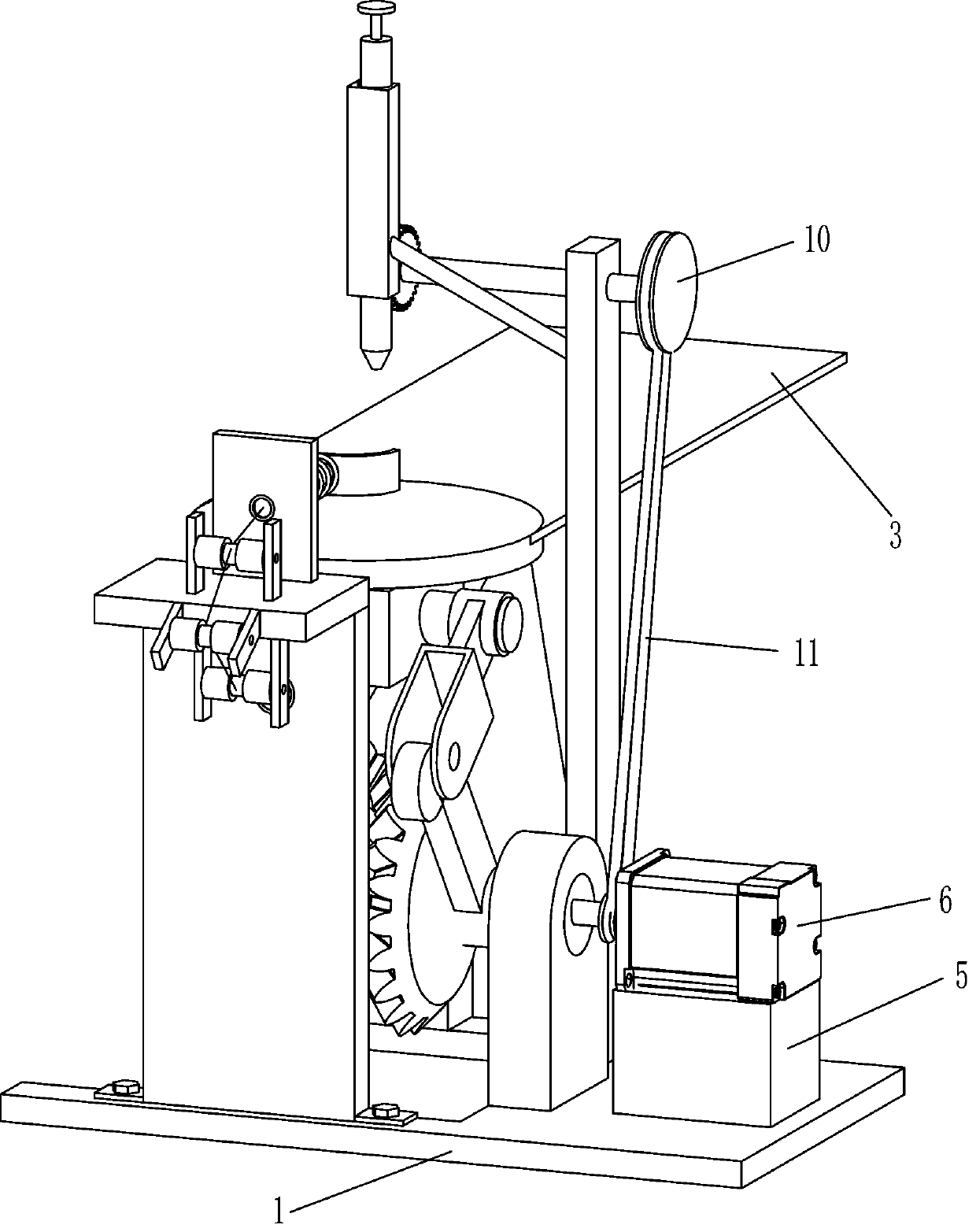

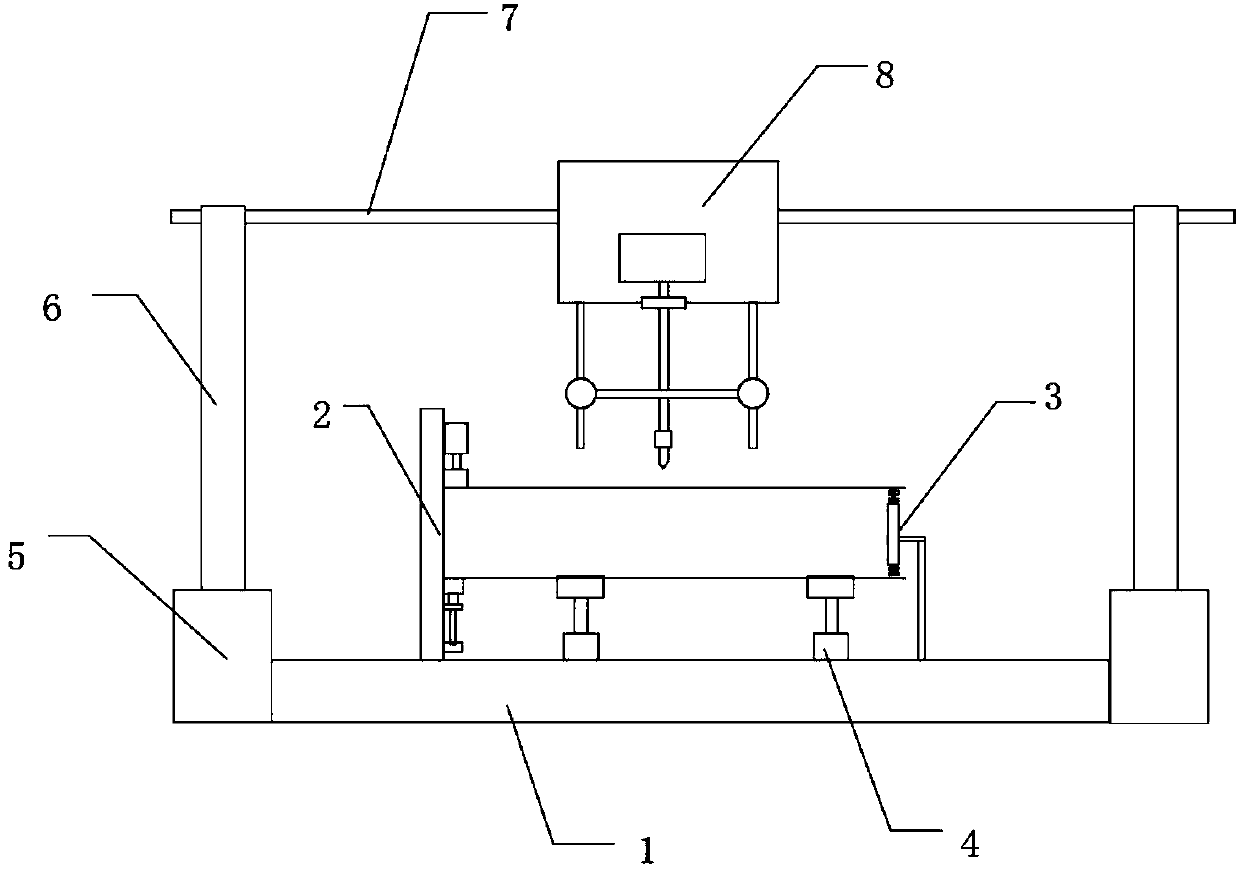

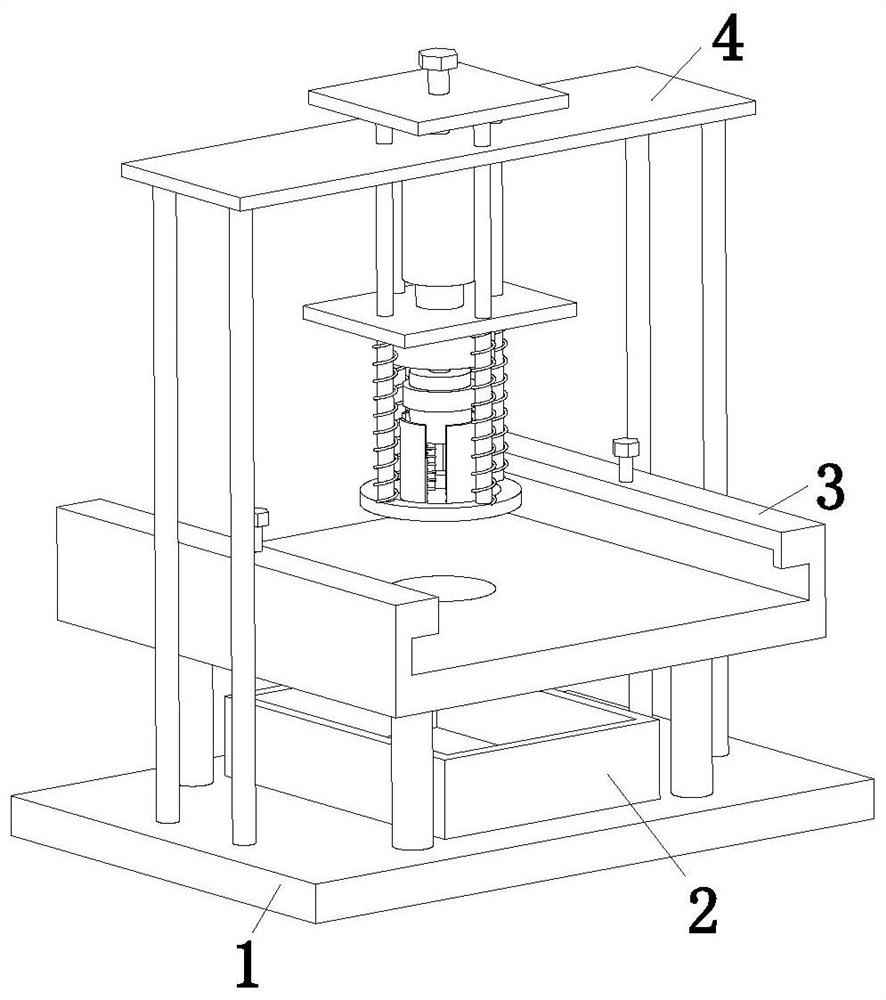

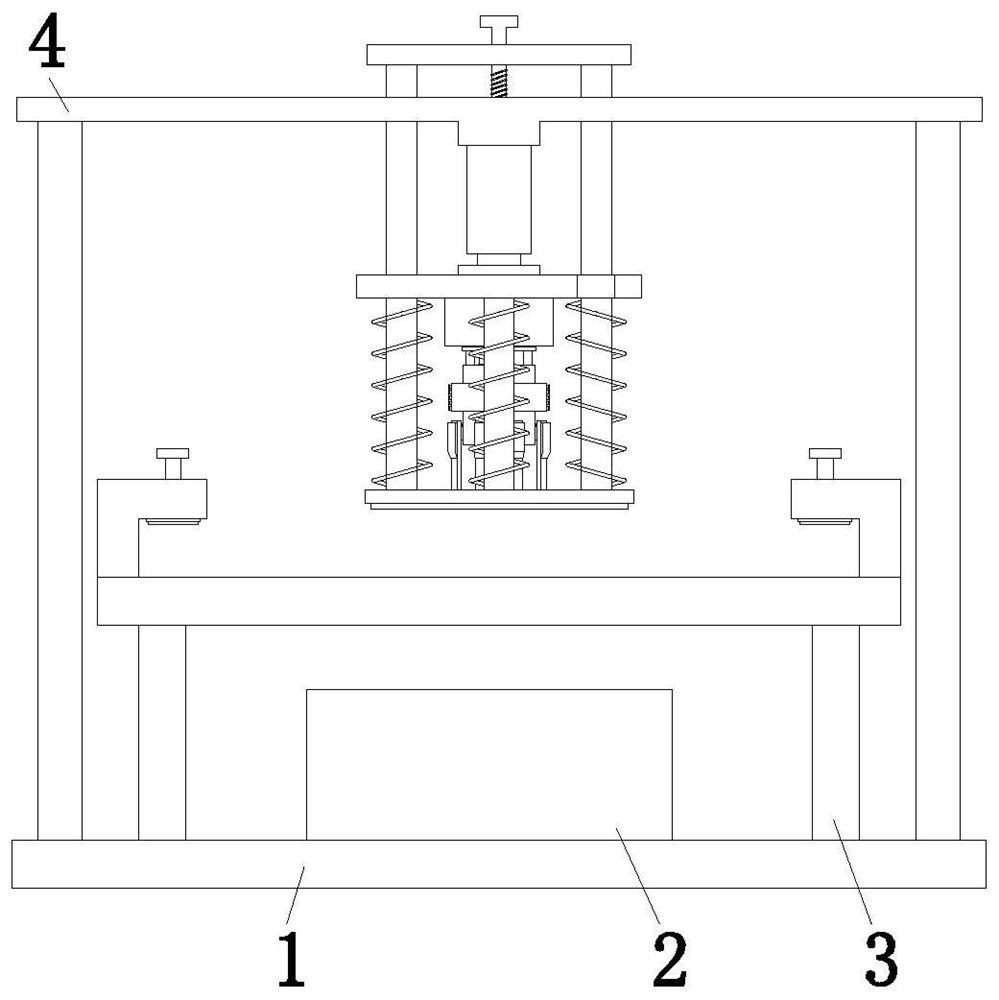

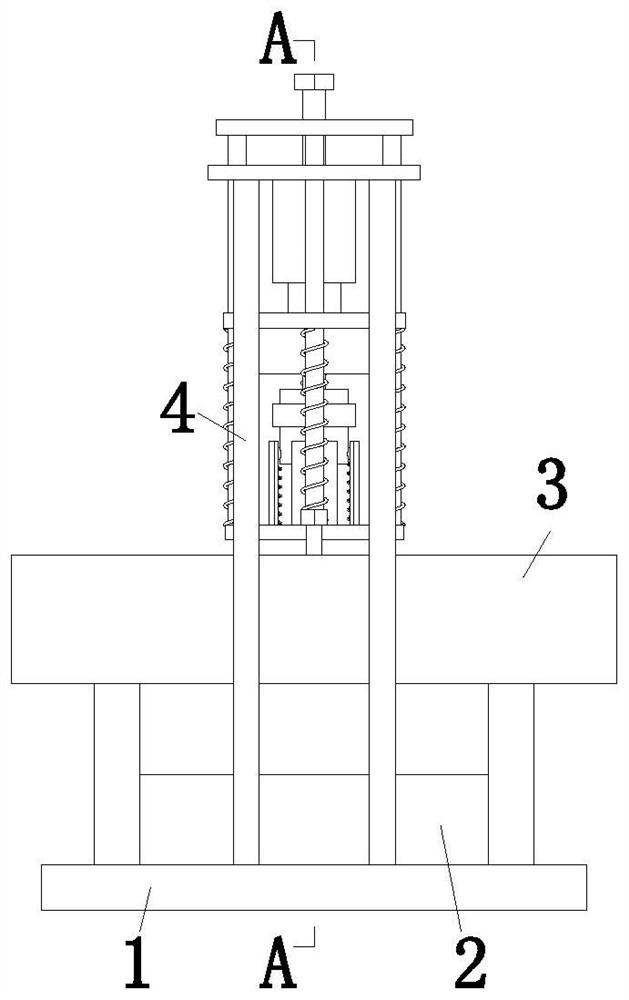

Flowerpot bottom perforating equipment

ActiveCN111113692AImprove hole efficiencyReduce workloadWorking accessoriesStone-like material working toolsElectric machineryFlowerpot

The invention relates to perforating equipment, in particular to flowerpot bottom perforating equipment. The invention aims to provide the flowerpot bottom perforating equipment capable of improving the working efficiency and reducing the working intensity. The flowerpot bottom perforating equipment comprises a bottom plate, supporting rods, a containing plate, a lifting mechanism, an installing base, a gear motor and the like, wherein the two supporting rods are arranged on the bottom plate, the containing plate is installed on the two supporting rods, the lifting mechanism is installed at the top of the bottom plate, the installation base is arranged on the bottom plate close to the lifting mechanism, and the gear motor is fixed to the installation base through bolts. According to the flowerpot bottom perforating equipment, the bottom of the flowerpot can be perforated by moving a flowerpot upwards through the placing table together with moving downwards a hollow rod, so that the perforating efficiency of the flowerpot can be improved.

Owner:方锦佳

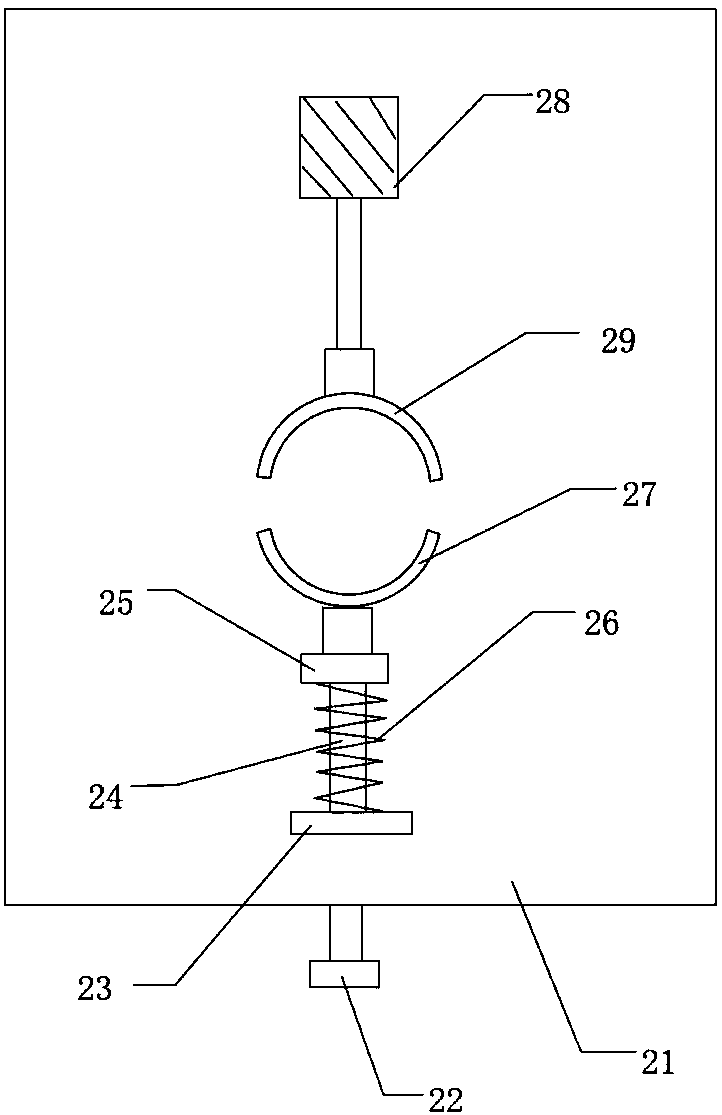

Processing mechanism of integrated circuit board

InactiveCN112135428AEasy to fixImprove hole efficiencyPrinted circuit manufactureSlide plateControl theory

The invention discloses a processing mechanism of an integrated circuit board, which belongs to the field of circuit board processing. The mechanism comprises two fixed guide rails, the fixed guide rails are fixedly mounted, sliding blocks are mounted on the fixed guide rails, the sliding blocks are slidably connected with the fixed guide rails, and clamping assemblies are fixedly mounted at the top ends of the sliding blocks. Each clamping assembly comprises a sliding plate, the bottom face of the sliding plate is attached to the top face of the sliding block, first fixed hinge blocks are fixedly installed on the two sides of the sliding plate, a rotating frame is installed on one sides of the first fixed hinge blocks, and a round rod matched with the first fixed hinge blocks is arrangedin the middle of the rotating frame. Two pressure springs are arranged at the bottom end of each rotating frame and connected with the top faces of the sliding plates, a ball head is arranged at the end of an output rod and attached to the side face of a push piece, and a positioning push rod is installed at the bottom end of each sliding plate. The integrated circuit board processing mechanism ishigh in trepanning efficiency and high in machining precision for the integrated circuit board.

Owner:刘玉

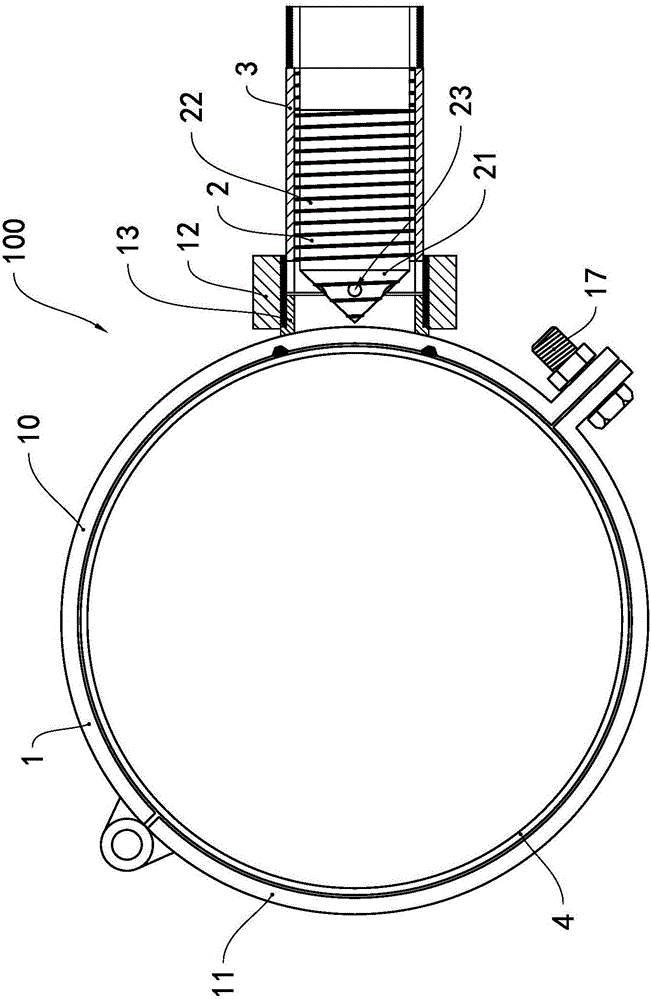

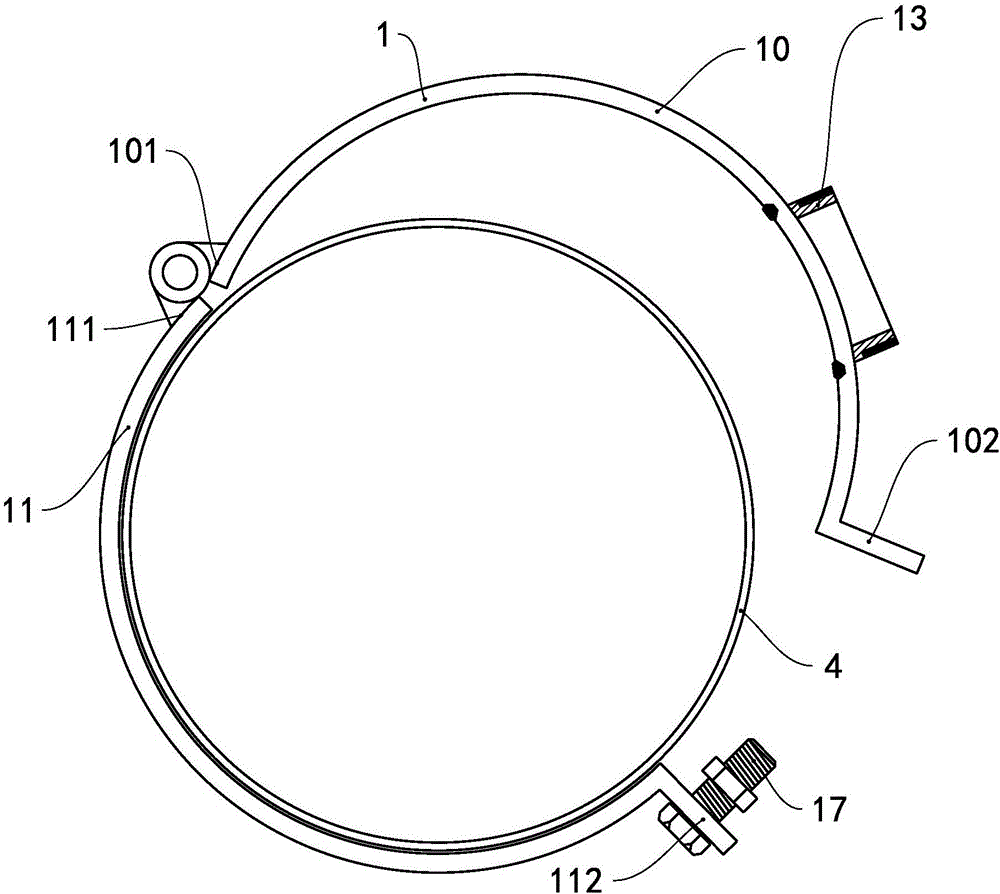

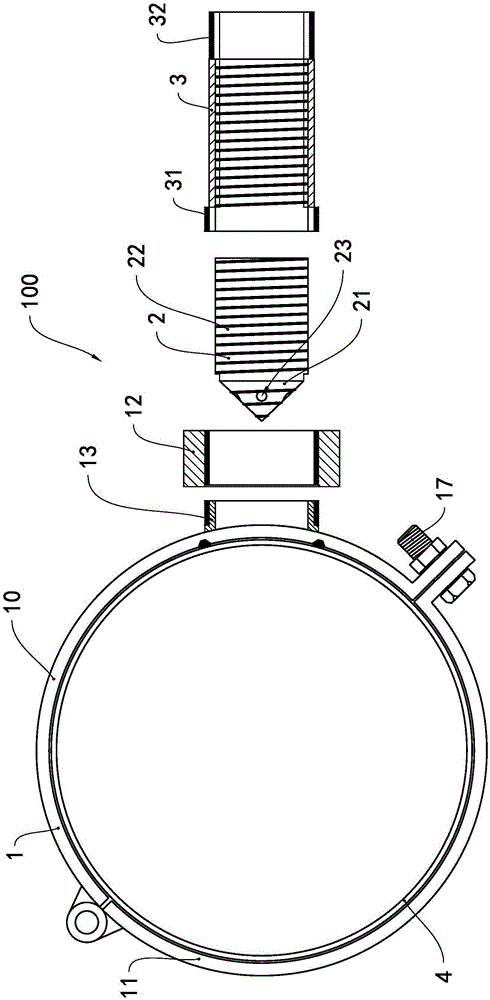

Pipeline hole opening device and pipeline hole opening method

InactiveCN106180806AEasy to determine the location of the holeEasy accessDrilling/boring measurement devicesBranching pipesDrill bitMechanical engineering

The invention provides a pipeline hole opening device and a pipeline hole opening method. The pipeline hole opening device comprises a hoop, a drill bit and a jacking sleeve; the hoop comprises a fast connection buckle and a fast connector; the end portion of the jacking sleeve and the fast connector are fixedly assembled in the fast connection buckle; and the drill bit is movably assembled in the jacking sleeve. The method comprises that the pipeline hole opening device is provided. The pipeline hole opening device comprises the hoop, the drill bit and the jacking sleeve; the hoop comprises an opening, the fast connection buckle and the fast connector; the end portion of the jacking sleeve and the fast connector are fixedly assembled in the fast connection buckle; and the drill bit is movably assembled in the jacking sleeve and comprises a hole drilling part which is arranged opposite to the opening. The method includes the steps that the hoop is fixedly connected to the outer side of a pipeline needing hole opening in a sleeving manner; and the drill bit in the jacking sleeve is rotated and propelled towards the opening so that hole opening of the pipeline can be completed. By means of the pipeline hole opening device and the pipeline hole opening method, the hole opening operation can be fast completed, air supply and water supply are performed through air holes, and operation is stable and easy.

Owner:NO 7 ENG CO LTD OF CHINA RAILWAY 19 BUREAU GRP +1

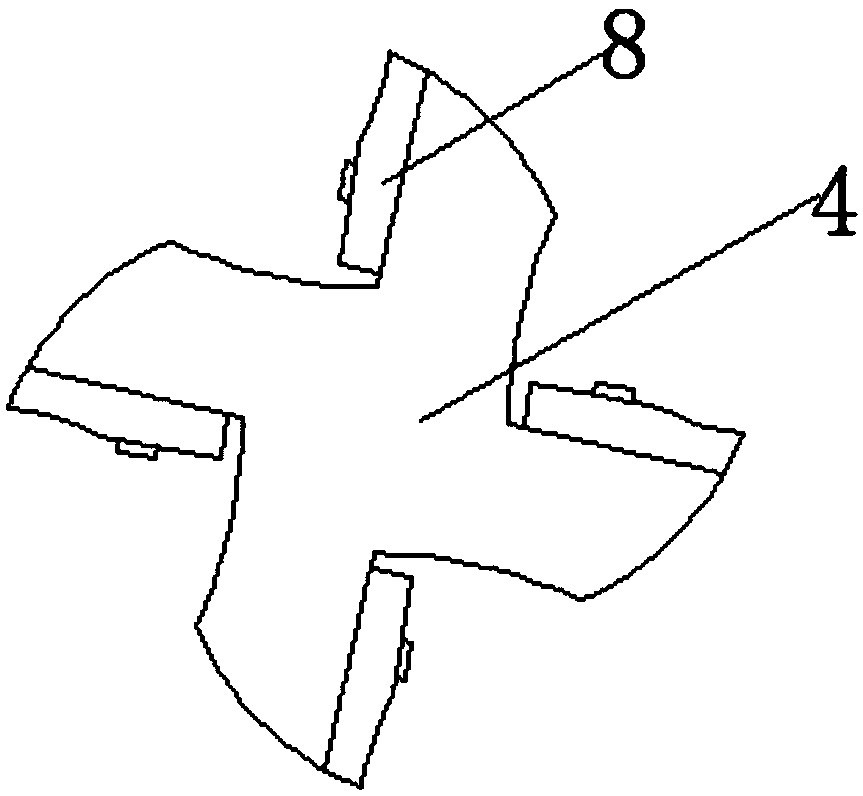

Tapper used for oscillation tool

InactiveCN102476222ABreak through the limitation that it is only suitable for opening round holesImprove hole efficiencyMetal sawing devicesTransportation and packagingEngineeringMaterials processing

The invention provides a tapper used for an oscillation tool, and the tapper comprises a fastening part, wherein the fastening part is provided with a receiver used for being installed on the oscillation tool, the receiver limits a longitudinal axis, and the tapper can be driven around the longitudinal axis in a vibration mode. The tapper also comprises a cutter which is connected with the fastening part and is provided with a material processing area, wherein the feeding direction of the cutter in a processed workpiece is substantially parallel to the longitudinal axis, and the material processing area is constructed into triangle, square or pentacle on the circumference. The application occasion of the oscillation tool is enlarged by arranging the tapper on the oscillation tool, and the tapping efficiency on the workpiece is improved. In addition, the tapper installed on the oscillation tool can be constructed into cutter forms, such as triangle, square and the like, and the limitation that the tapper is only suitable for tapping round holes in the prior art can be broken through.

Owner:NANJING CHERVON IND

Telescopic isolation switch upper conductive arm replacement tool

Owner:中国南方电网有限责任公司超高压输电公司柳州局

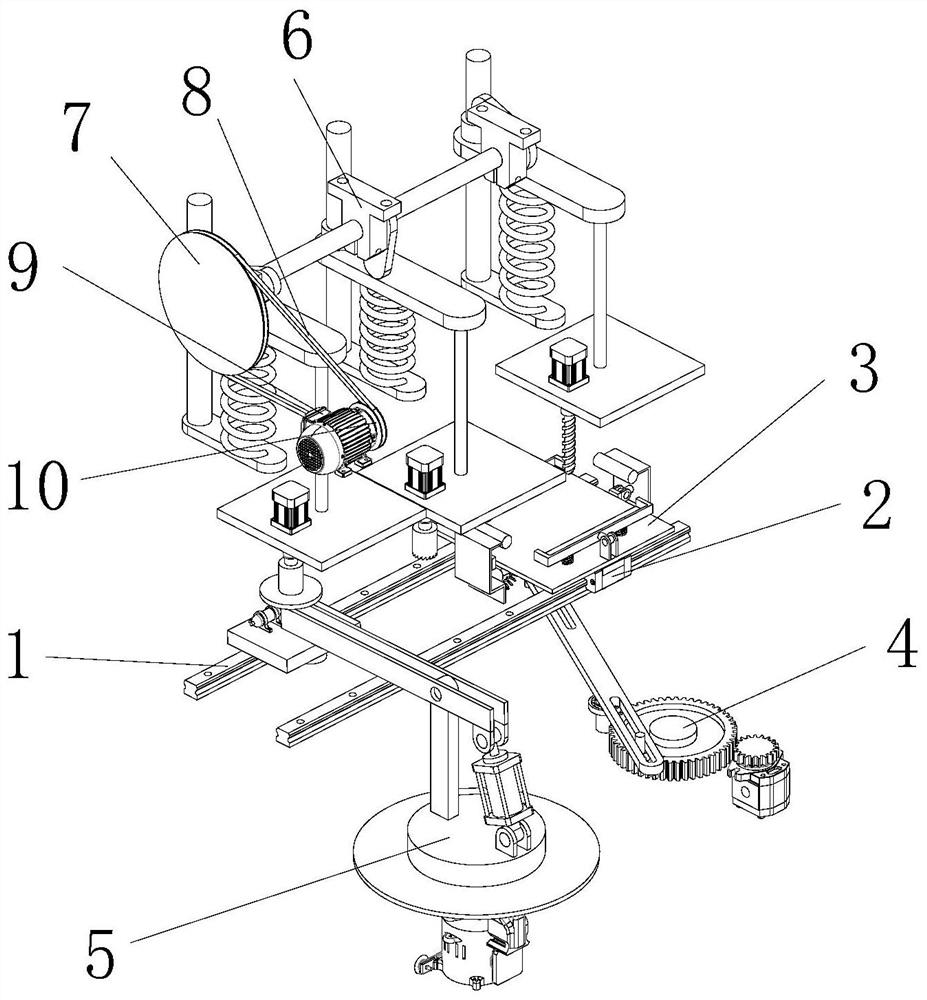

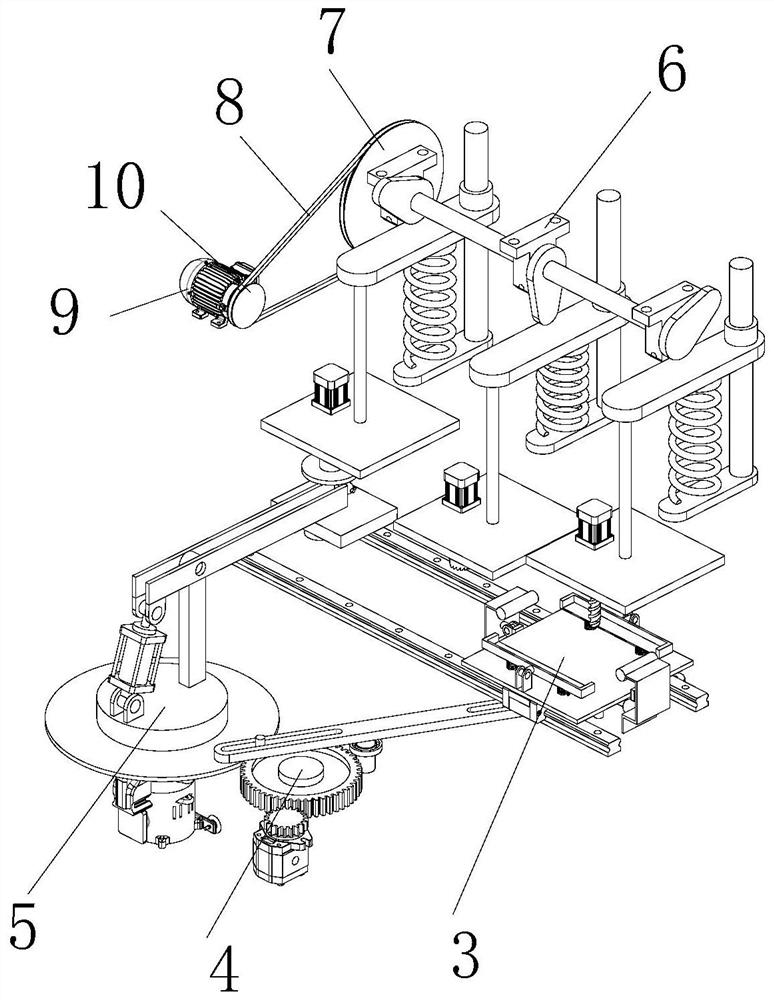

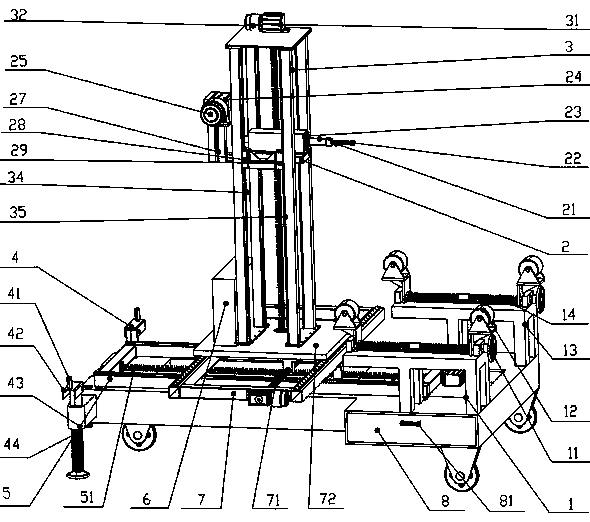

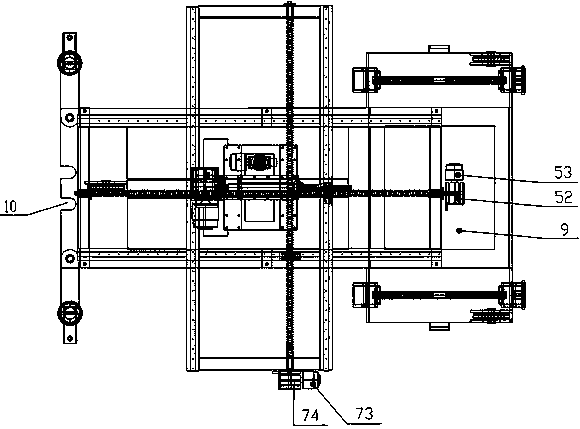

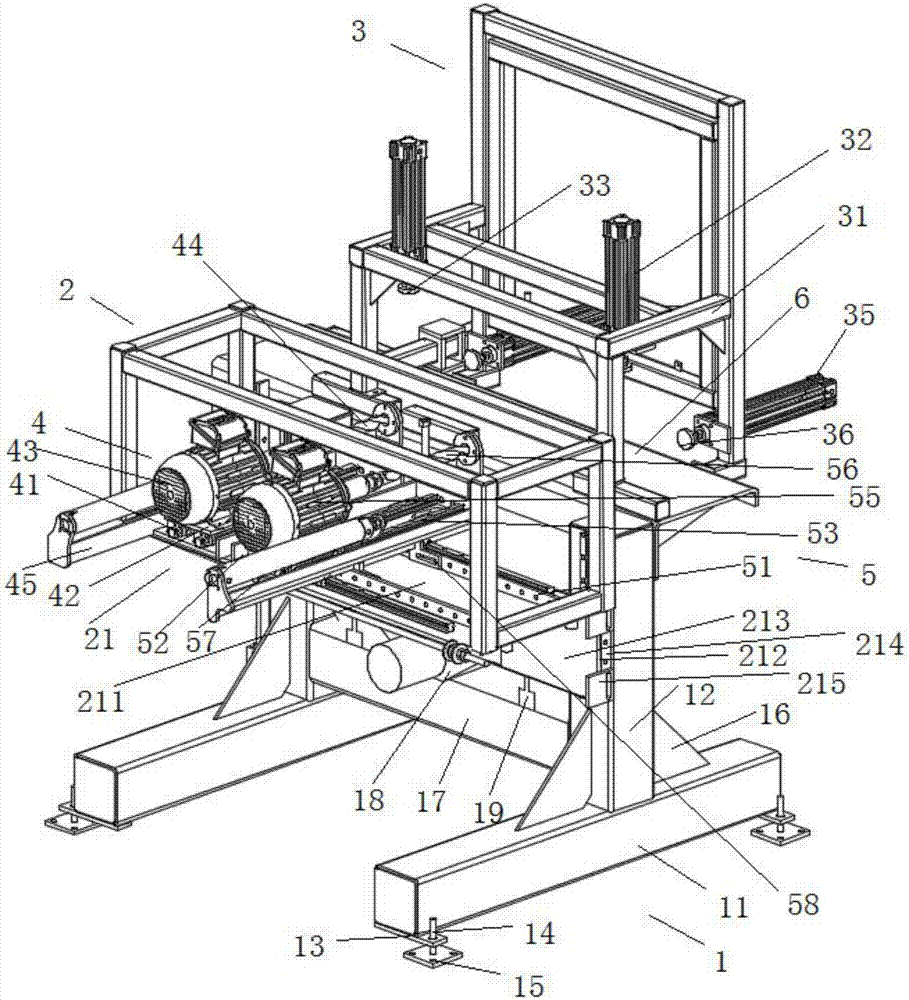

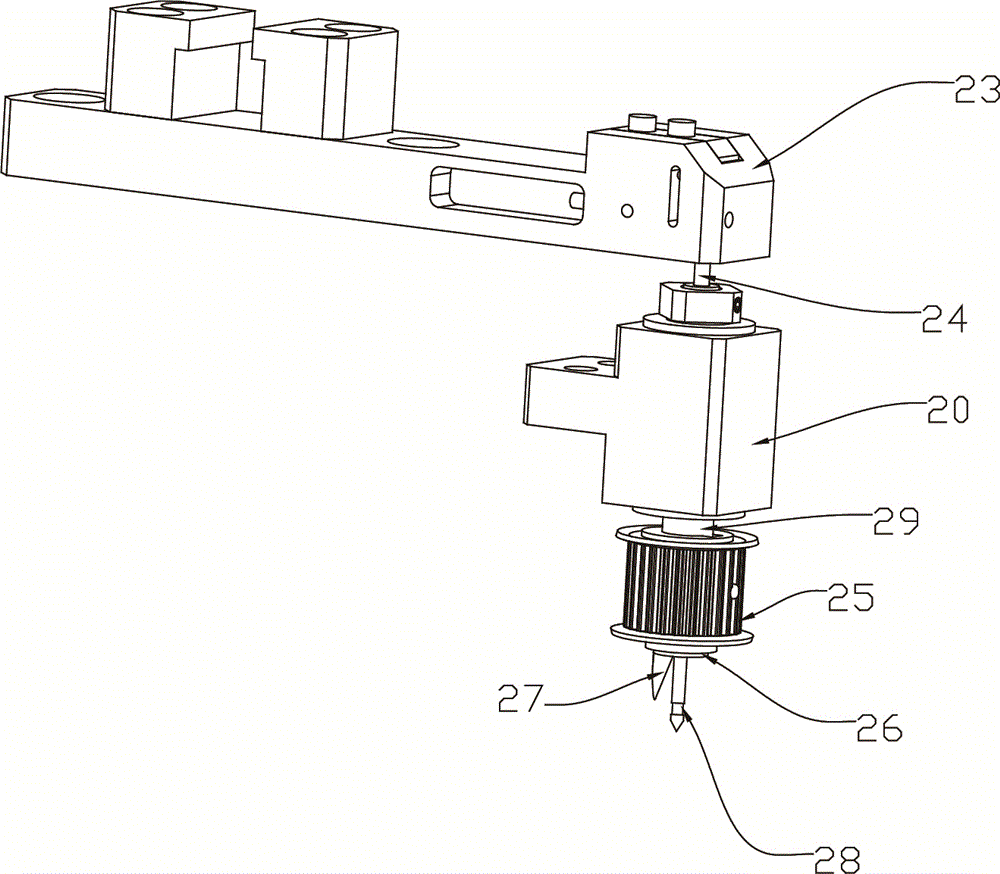

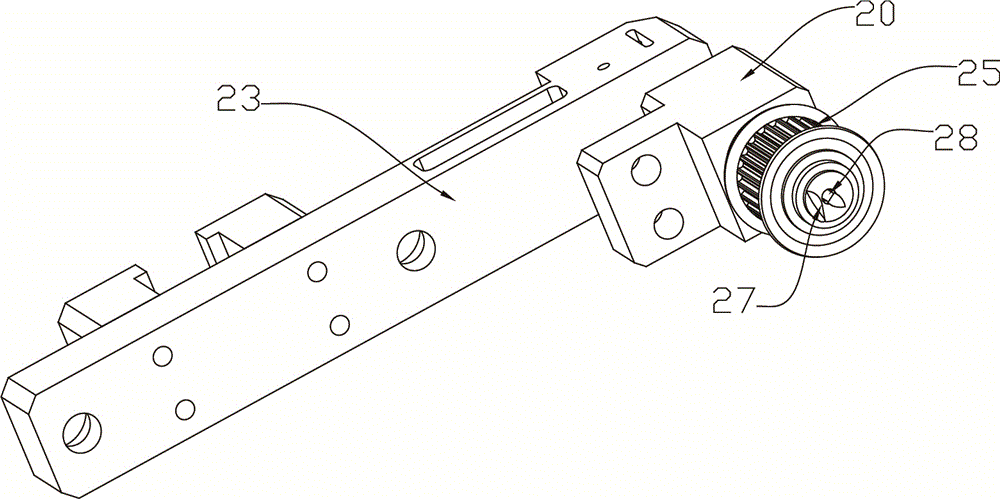

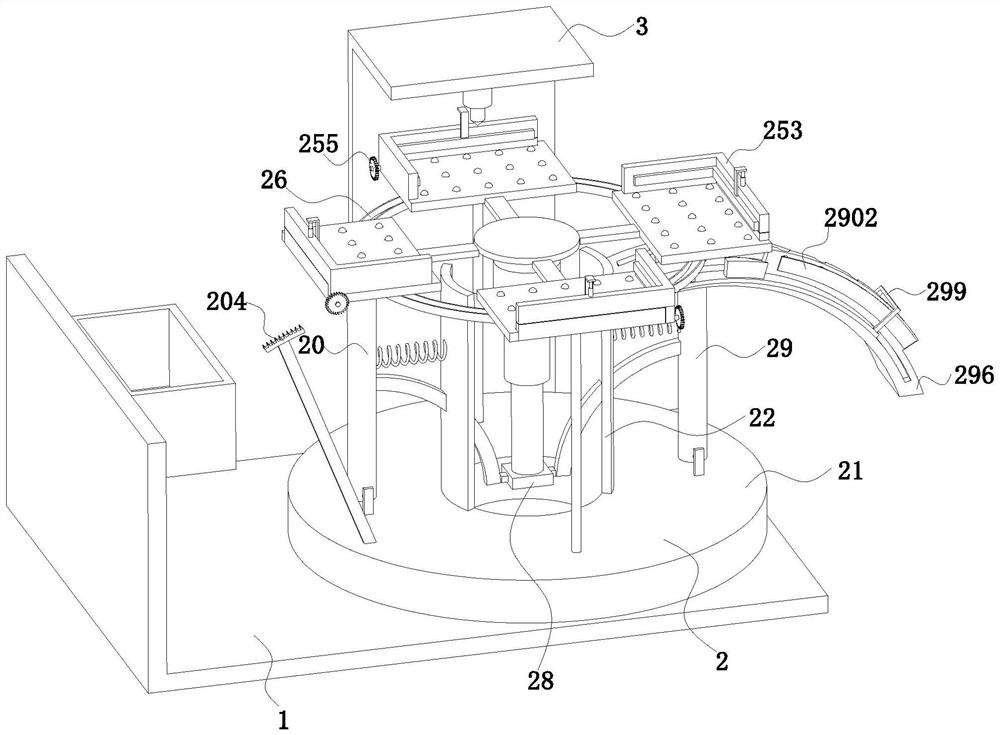

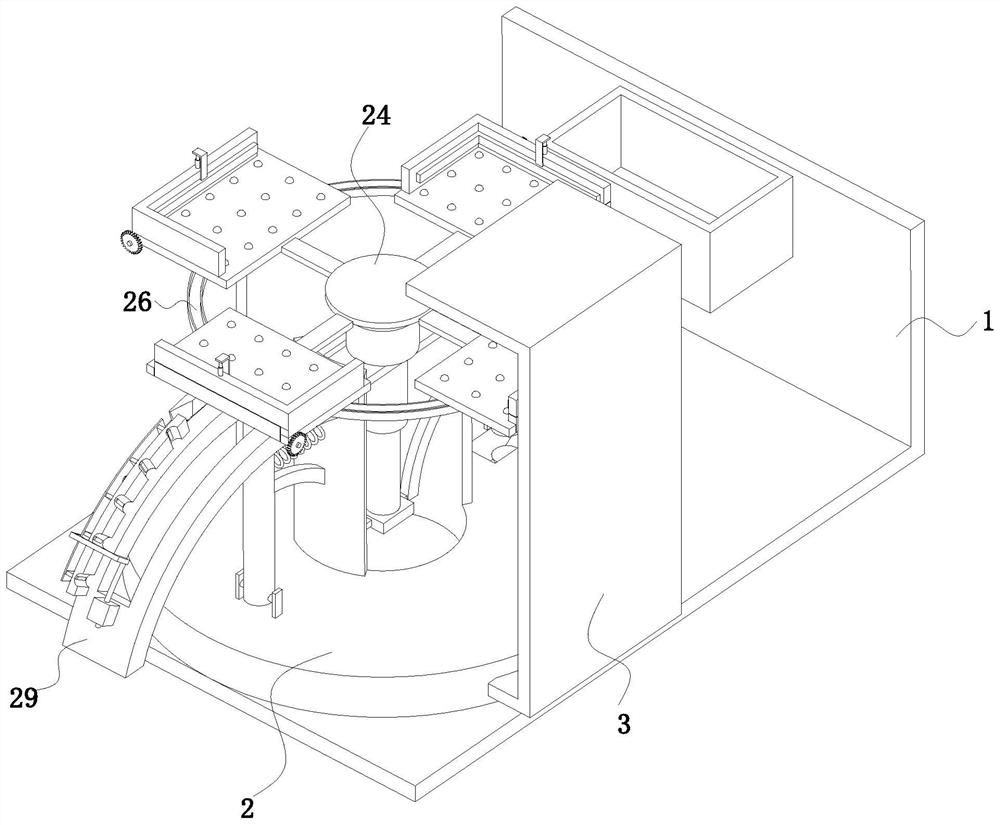

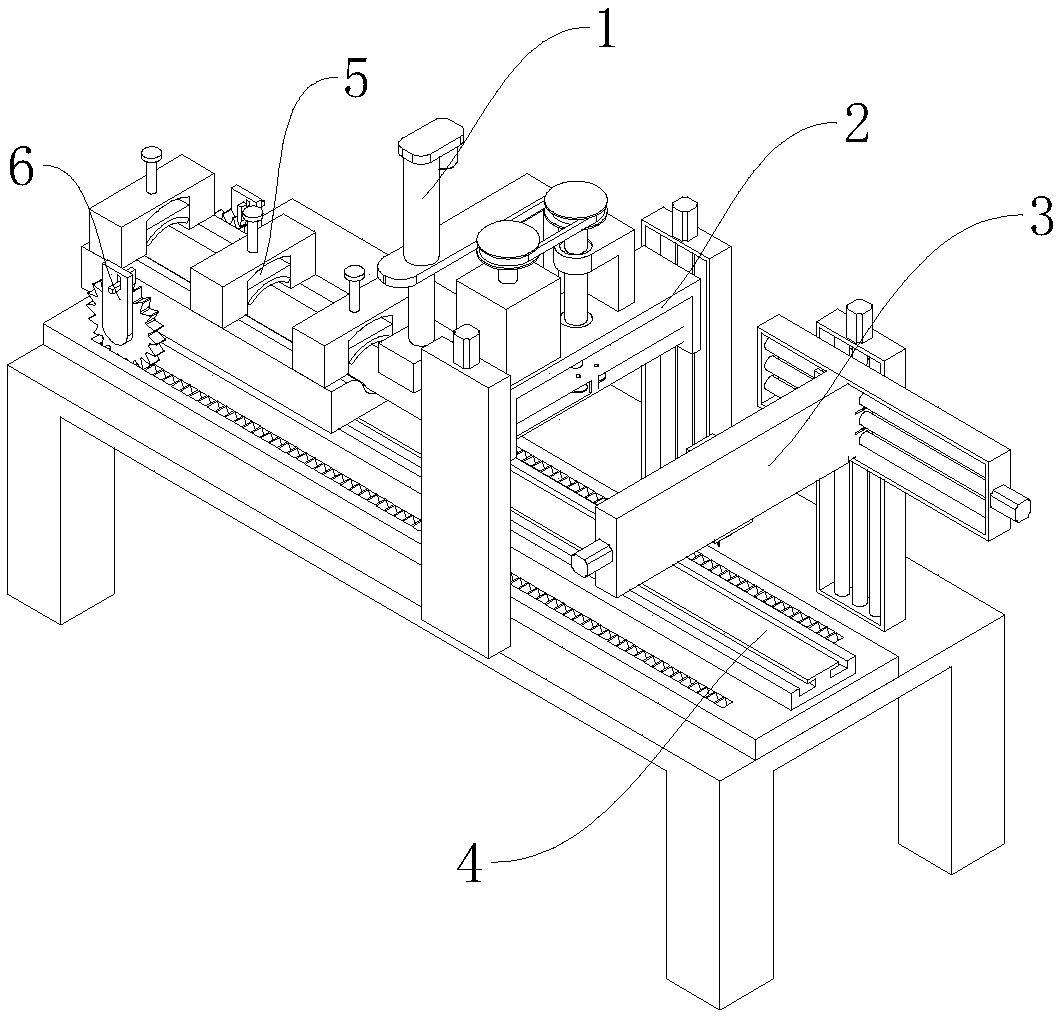

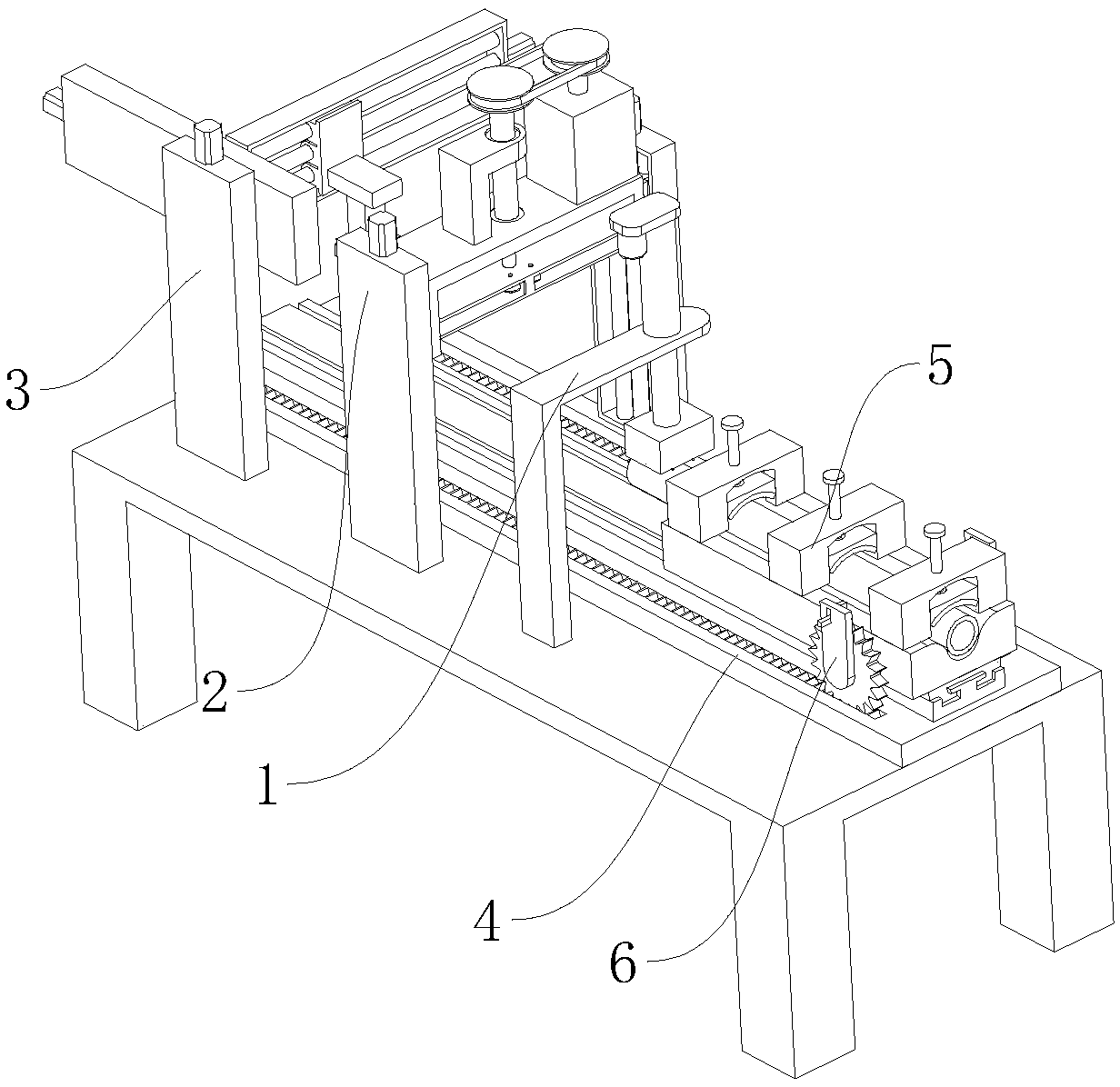

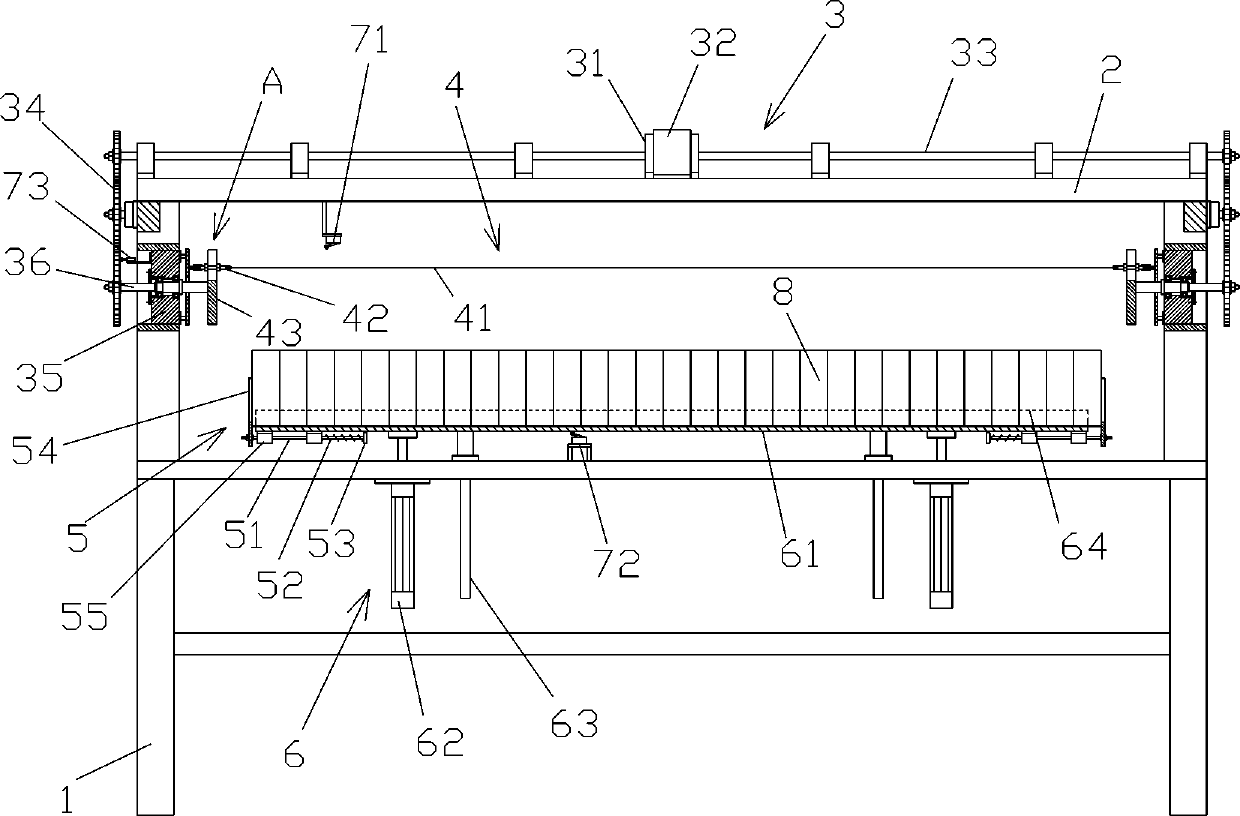

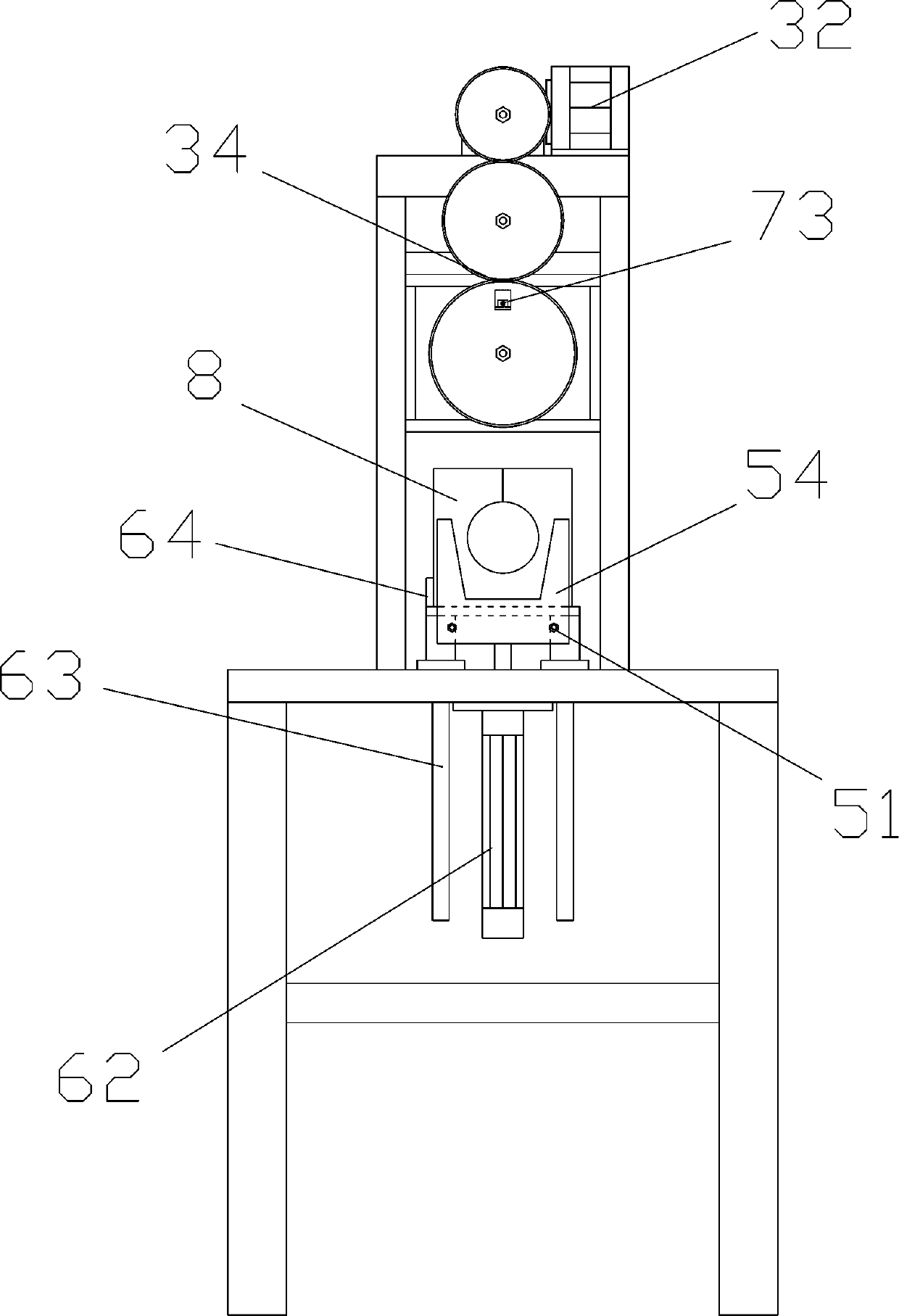

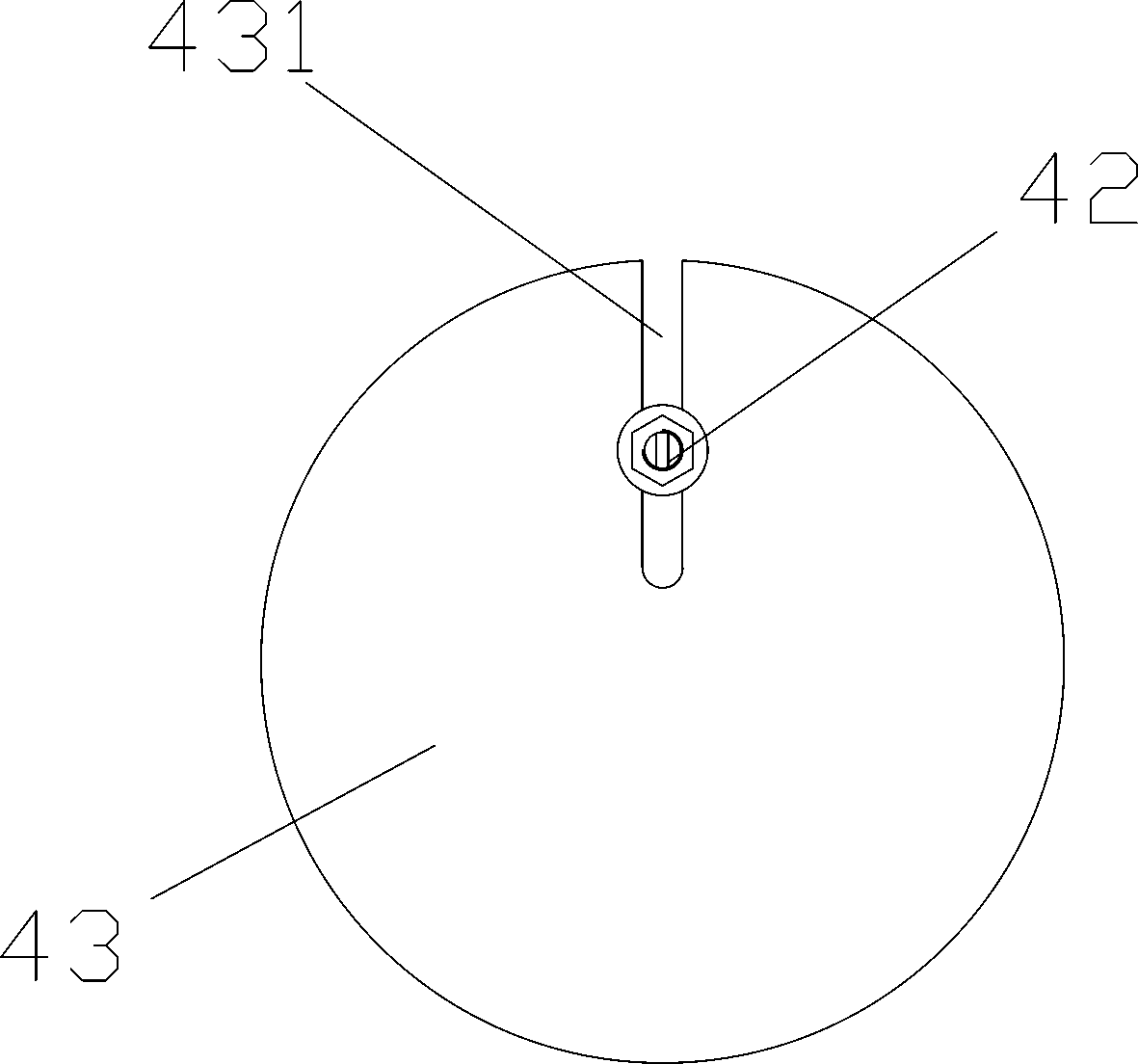

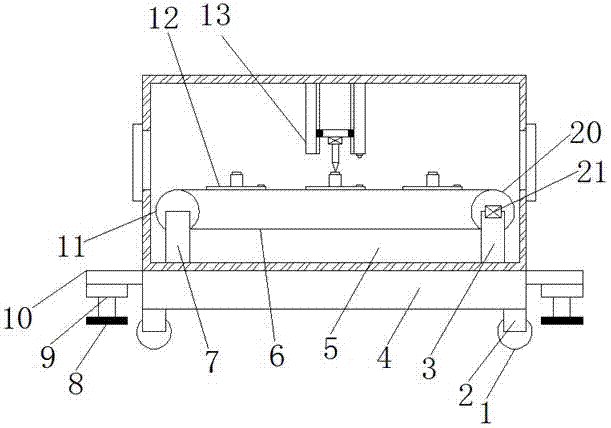

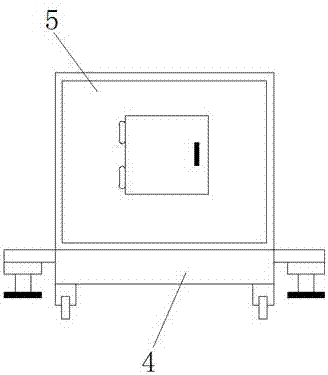

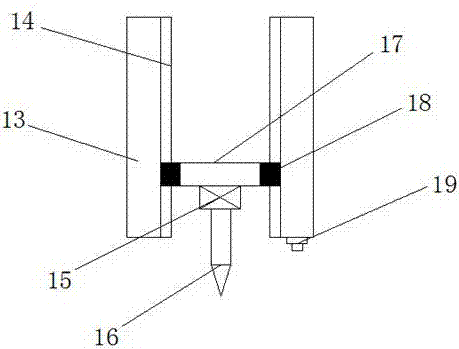

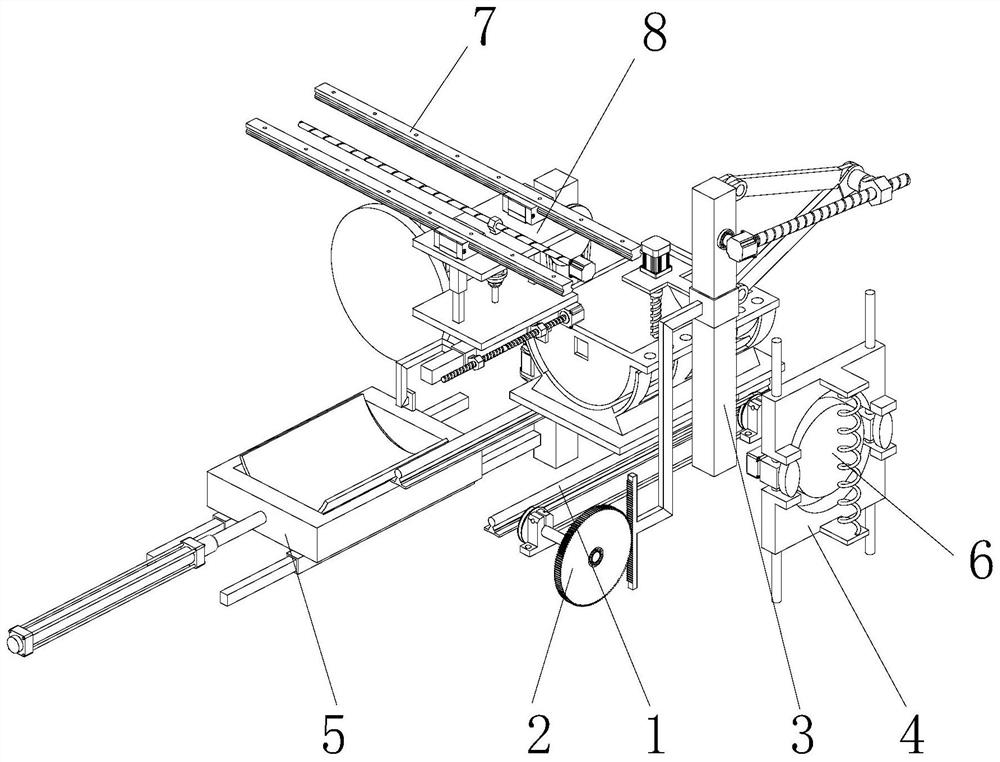

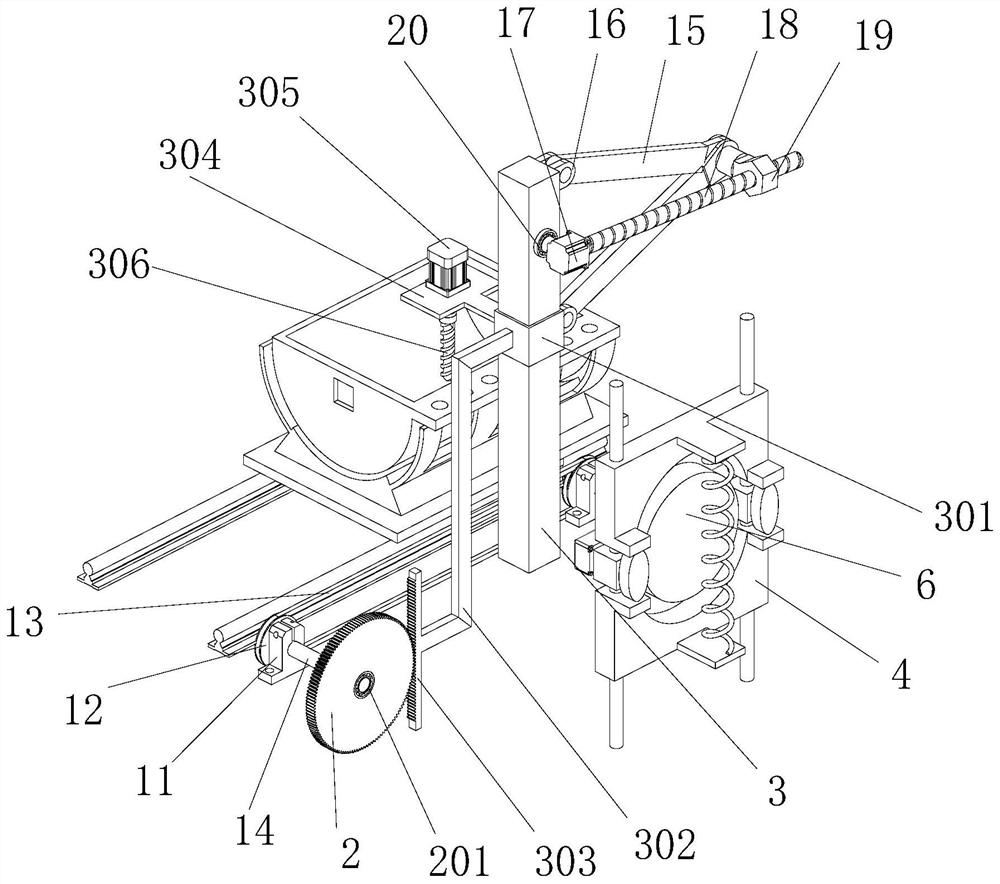

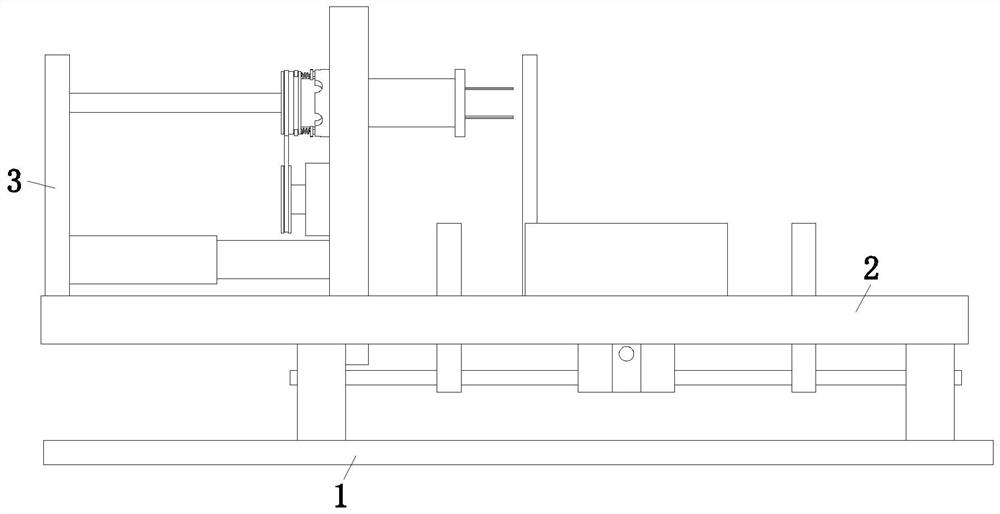

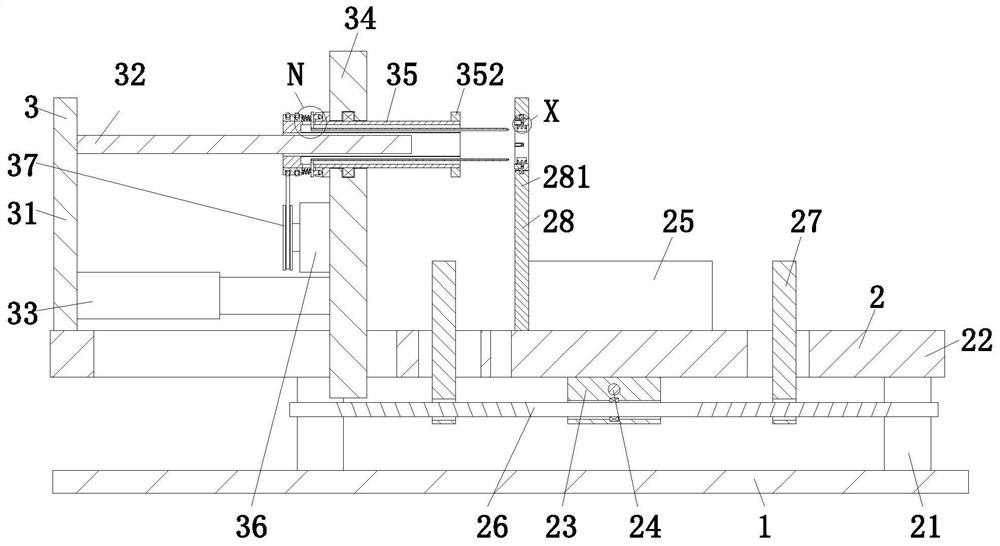

Movable ultra-large-diameter karat pipe wall punching device

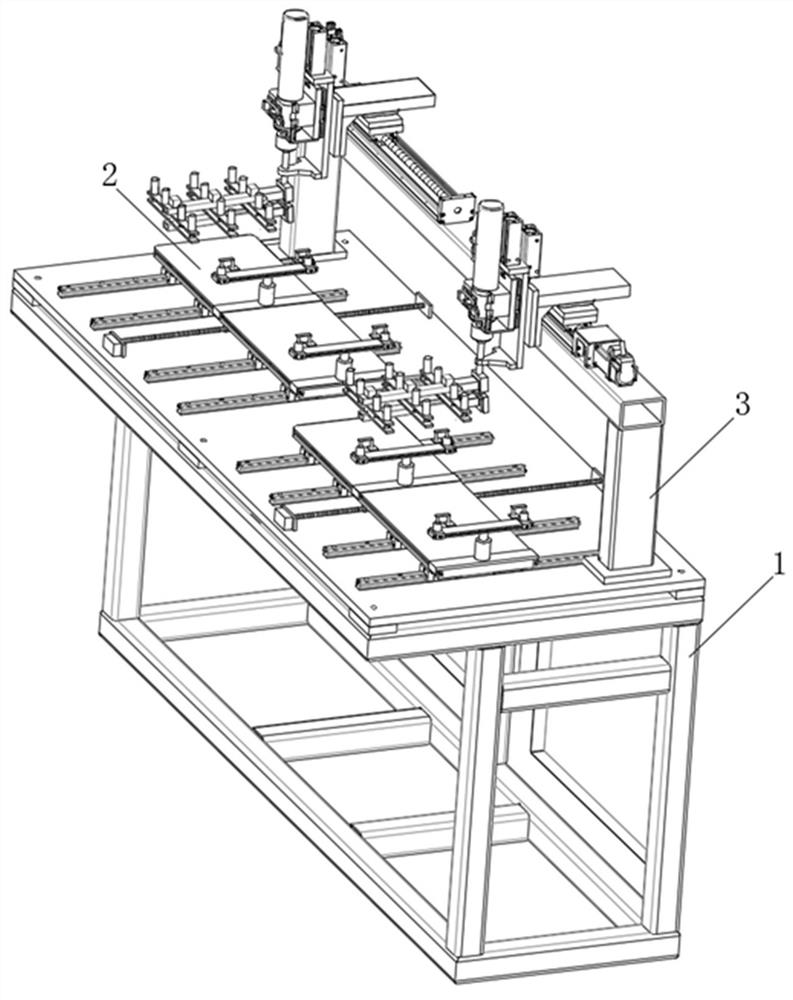

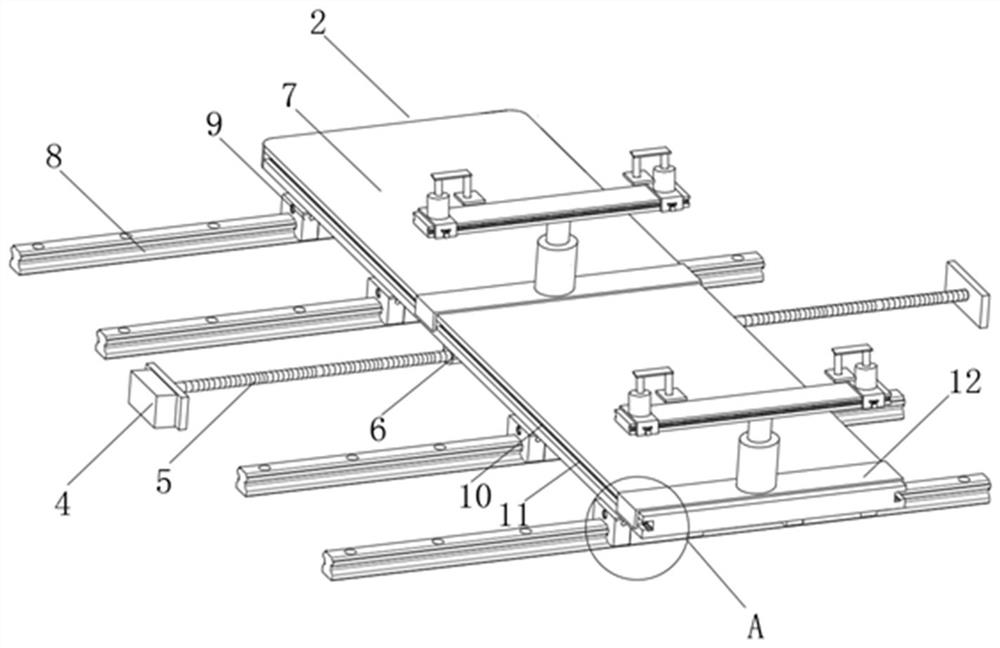

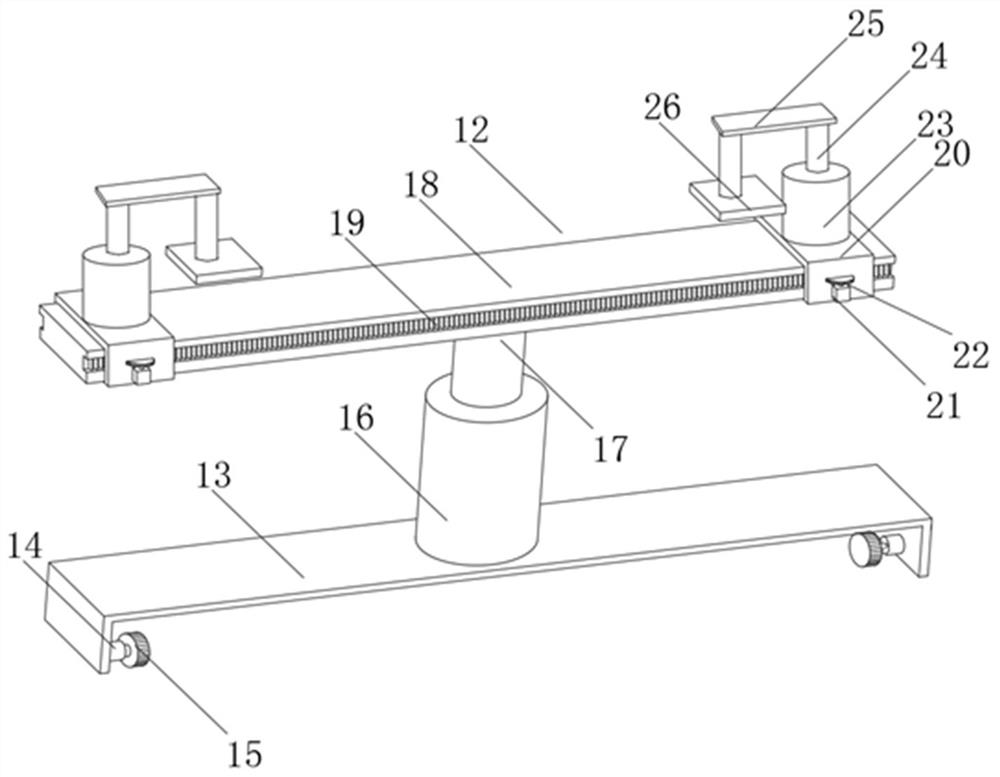

PendingCN109015883AImprove hole efficiencyIncrease flexibilityMetal working apparatusPunchingBody support device

The invention discloses a movable ultra-large-diameter karat pipe wall punching device which comprises a three-dimensional cutting platform and a movable trolley. A cutting tool rest, an X-axis movingdevice, a Y-axis moving device and a Z-axis moving device are arranged on the three-dimensional cutting platform, and the X-axis moving device, the Y-axis moving device and the Z-axis moving device are used for controlling the cutting too rest to move. The X-axis moving device, the Y-axis moving device, the Z-axis moving device and the cutting tool rest are connected with a master control box, the horizontal front-back motion, left-right motion and vertical up-down motion of the cutting tool rest are processed through cooperation of the X-axis moving device, the Y-axis moving device and the Z-axis moving device, and punching automation is achieved. The movable trolley is arranged below the three-dimensional cutting platform, the movable trolley is provided with a pipeline supporting device, a chip storage box and a trolley body supporting device, and the punching flexibility of the punching device and the stability of the cutting process are improved. The movable ultra-large-diameterkarat pipe wall punching device is high in cutting precision, convenient to operate and high in flexibility, and is greatly helpful to improving the karat pipe side wall punching efficiency and reducing the labor intensity.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Metal pipe production equipment

InactiveCN107639260AEasy to adjustEasy to operatePositioning apparatusMetal-working holdersArchitectural engineeringMetal

The invention provides metal pipe production equipment. The metal pipe production equipment comprises a base, a first clamping component, a second clamping component, multiple supporting components, lifting cylinders, lifting columns, a support plate and a holing component, wherein the first clamping component is embedded into the left side of the upper end of the base in a sliding mode, the second clamping component is embedded into the right side of the upper end of the base in a sliding mode, the supporting components are embedded to the upper end of the base in a sliding mode and located between the first clamping component and the second clamping component, the lifting cylinders are welded to the outer sides of the two ends of the base, the lifting columns are rotationally arranged atthe upper ends of the lifting cylinders, and the support plate is erected at the upper ends of the lifting columns and is sleeved with the holing component. A first transverse sliding groove is formed in the surface of the base and is of a T-shaped structure. The metal pipe production equipment is convenient to adjust and operate and high in drilling efficiency.

Owner:嘉善惠龙金属制品有限公司

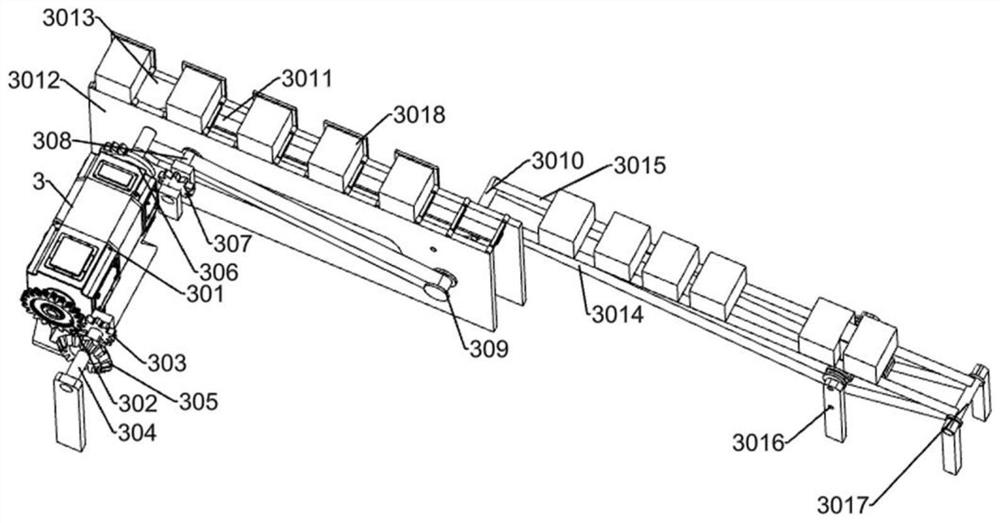

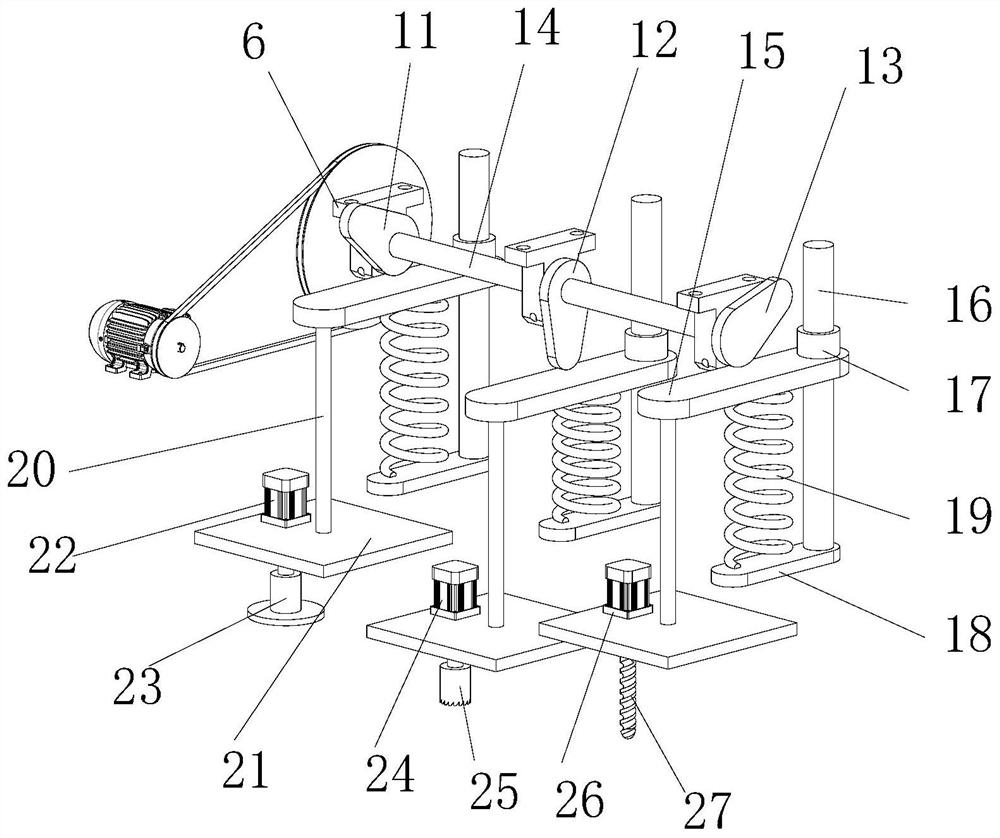

Multi-machining-station automatic tapping device

InactiveCN107159928AHigh degree of automation integrationImprove hole efficiencyBoring/drilling machinesEngineeringNew materials

The present invention proposes a multi-processing station automatic drilling device, which includes a first frame, the first frame includes two parallel bottom plates, the middle part of the surface of the bottom plate is vertically connected with a support plate, and the bottom plate and the bottom plate are connected vertically. The contact surface end of the support plate is also fastened with a triangular fixed plate, and the two support plates are closely connected through the connecting plate. The multi-processing automatic hole opening device also includes a mobile hole opening component and a new material fixing component. The front surface of the support plate Slide rails are fixed, and a working platform is fixed on the top of the back surface of the support plate. This kind of multi-processing position automatic hole opening device has a high degree of automation integration, and only needs to manually place the new material on the working platform, and then the new material will be fixed and pressed; the invention has novel design, ingenious structure, high hole opening efficiency, and can be adjusted Strong.

Owner:JIASHAN SHENGSHIDE FUR GARMENT

Leather product trepanning treatment equipment and process

InactiveCN111793725APrevent movementImprove integrityLeather clicking/perforating/clickingSkins/hides/leather/fur manufacturing apparatusMachiningIndustrial engineering

The invention relates to leather product trepanning treatment equipment and process. The leather product trepanning treatment equipment comprises a bottom plate, a collecting frame, a clamping deviceand a drilling device. The collecting frame is mounted at the upper end of the bottom plate, the clamping device is arranged above the collecting frame, the clamping device is mounted on the bottom plate, the drilling device is arranged above the clamping device, and the drilling device is mounted on the bottom plate. The problems that when leather products are subjected to trepanning machining inthe prior art, leather around holes cannot be pressed during leather drilling, the leather easily moves during drilling, thus, the success rate of drilling is reduced, the side walls of the holes areeasily damaged, thus, the integrity of the drilled leather is reduced, meanwhile, the hole walls of the drilled leather cannot be ground on the same equipment, thus, the smoothness of the hole wallsis reduced, the working steps of trepanning machining are increased, and the trepanning efficiency is reduced can be solved.

Owner:尹梦雅

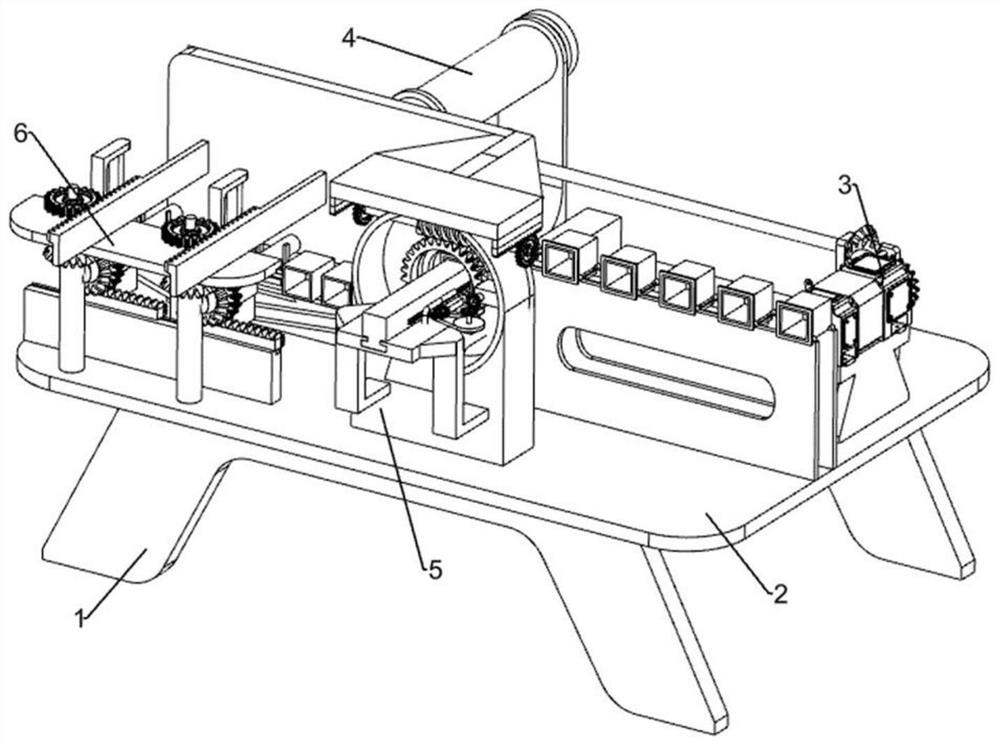

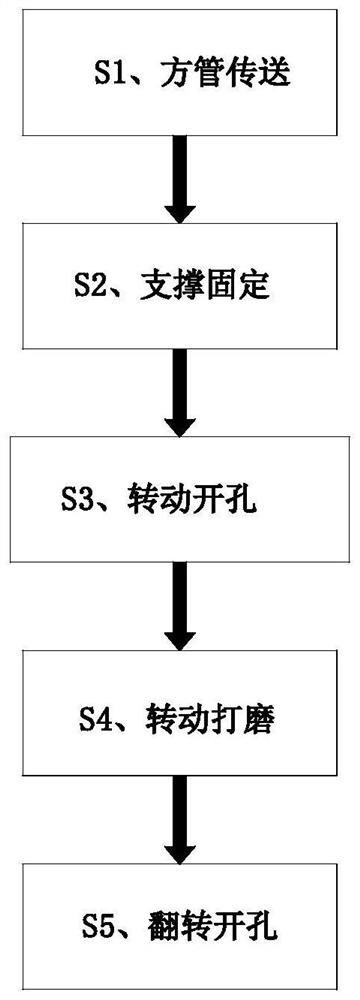

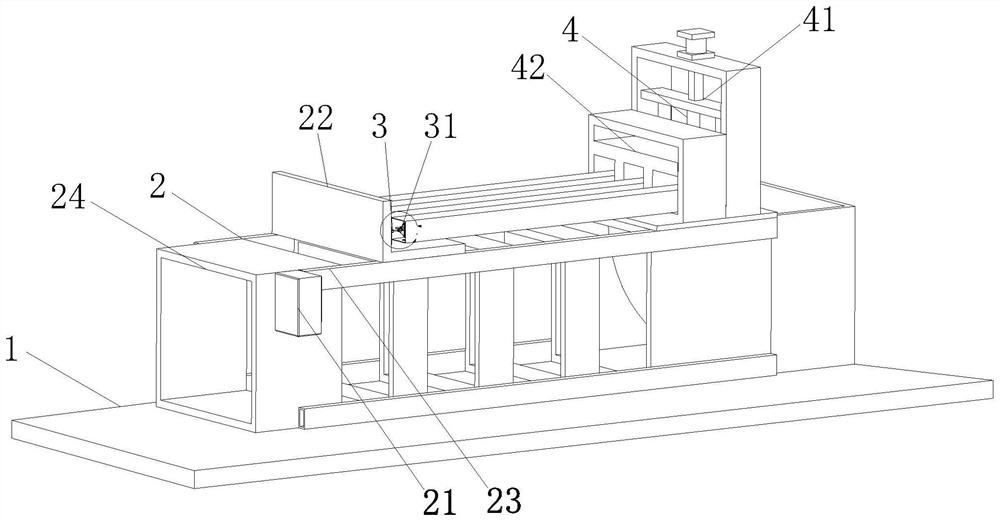

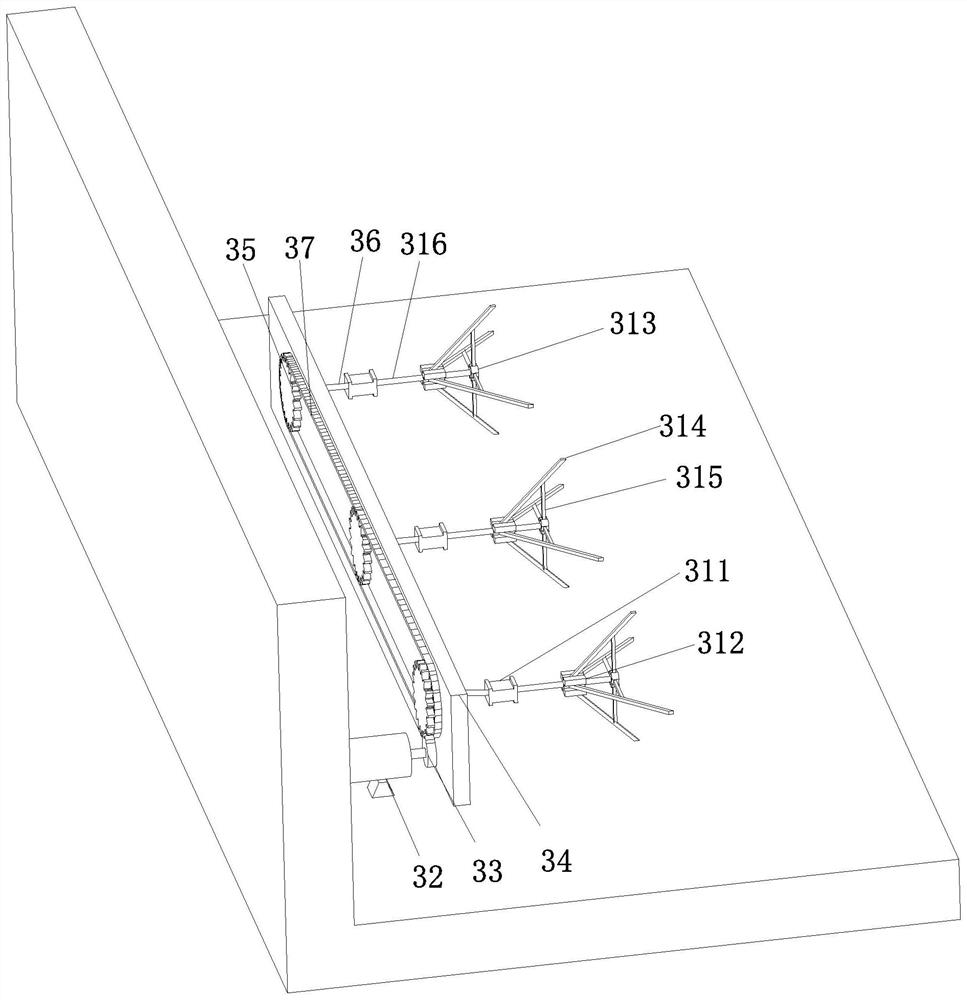

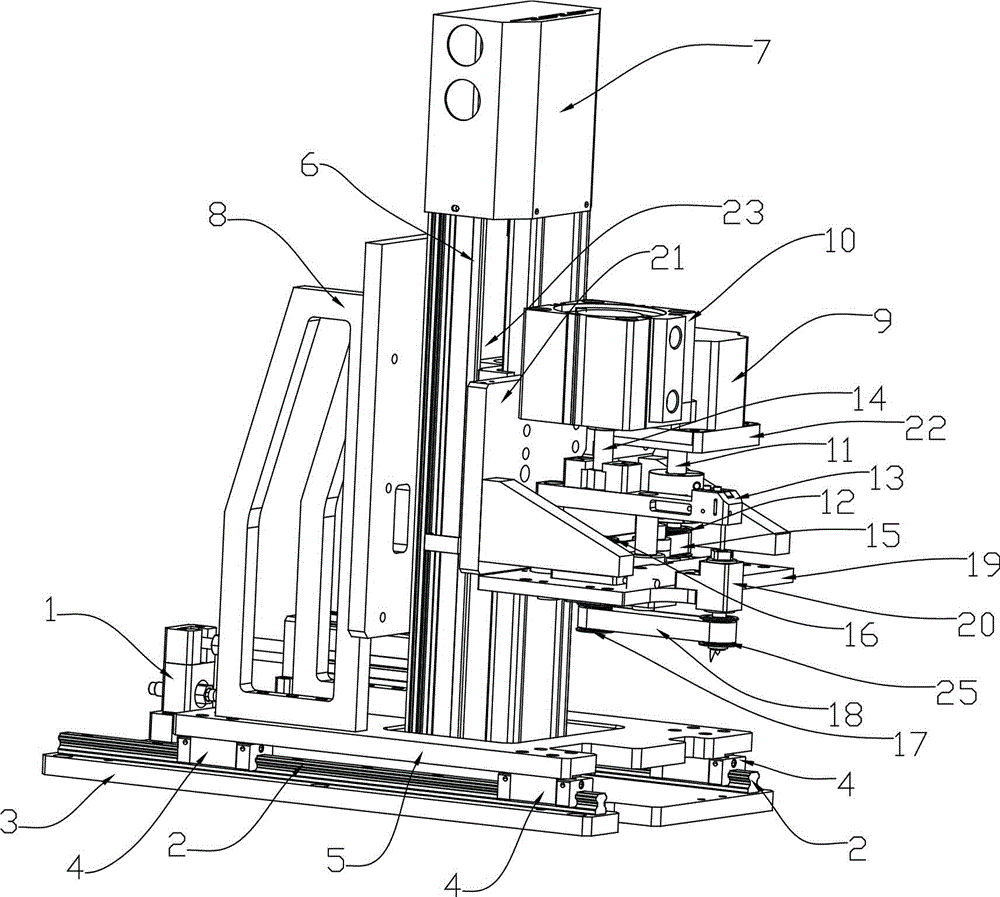

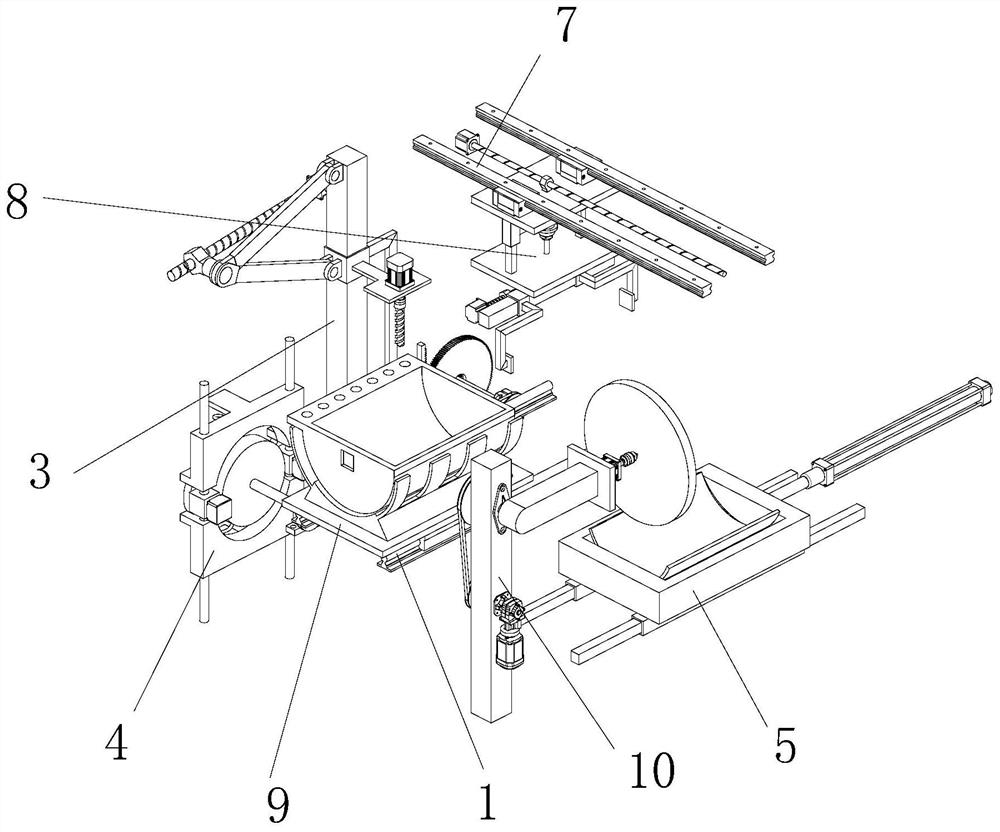

Automatic building steel processing technology

InactiveCN111922730AReduce security risksImprove hole efficiencyWork clamping meansOther manufacturing equipments/toolsPolishingConstruction engineering

The invention provides an automatic building steel processing technology which is mainly completed by a steel processing machine cooperatively. The steel processing machine comprises a bottom plate, aconveyor, a turnover device, a supporting mechanism, a fixing mechanism, a trepanning mechanism and a polishing mechanism. The conveyor is used for intermittently and forwards conveying a square steel tube; the fixing mechanism is used for fixing the front end of the square steel tube; the trepanning mechanism is used for trepanning; when a trepanning cutter successfully trepans a round hole in the square steel tube, the polishing mechanism in the trepanning cutter works to polish burs; and after finishing polishing, the fixing mechanism loosens the square steel tube, and the turnover mechanism intermittently drives the square steel tube to turn over ninety degrees, so that repeated drilling and polishing is realized. According to the automatic building steel processing technology provided by the invention, automatic trepanning and polishing of the equipment is realized, the trepanning problem is solved at one time, the potential safety hazard of manual work is reduced, and meanwhile,the working efficiency of the equipment is effectively improved.

Owner:西安数科天芯科技有限公司

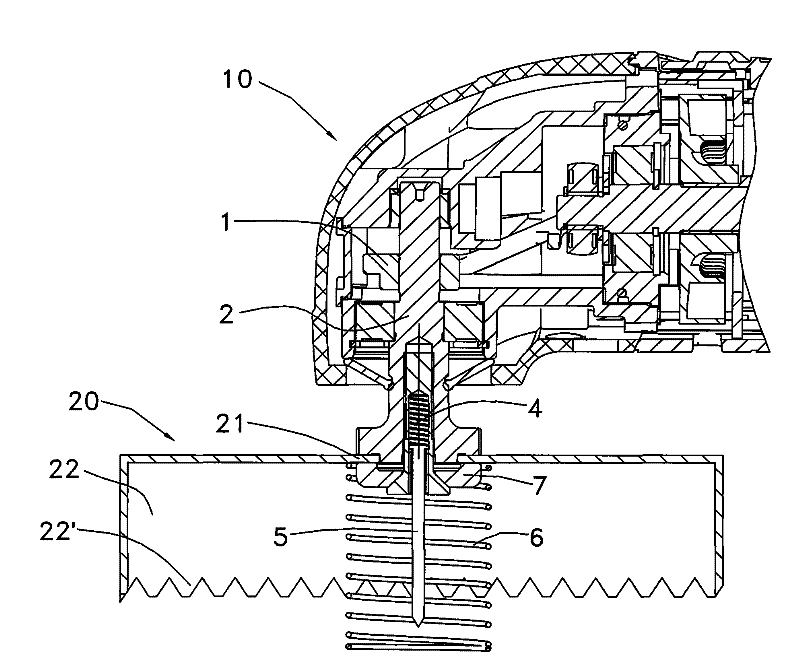

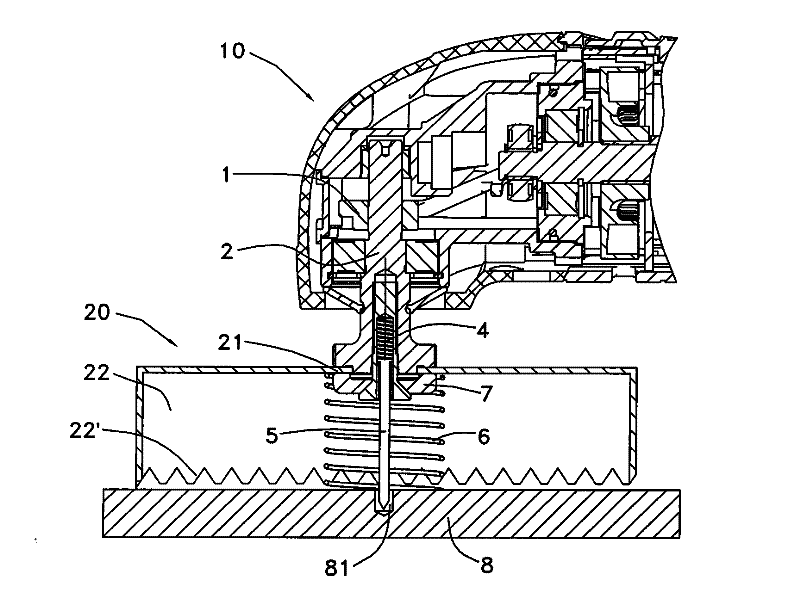

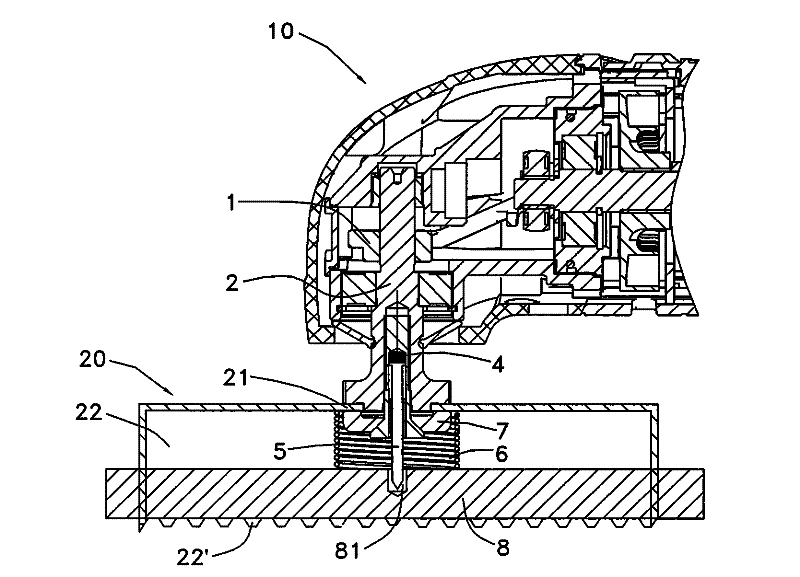

Punching device for plastic tanks

InactiveCN105415434AReduce scrap rateImprove hole efficiencyMetal working apparatusPunchingNeedle puncture

The invention discloses a punching device for plastic tanks. The punching device comprises a base, the base is provided with a moving part, the moving part is provided with a supporting part, the supporting part is provided with a first lifting part, the first lifting part is provided with a rotating part and a second lifting part, and the rotating part and the second lifting part are connected with a tool bit device. The tool bit device comprises a puncturing needle, a stabilizing part, a first rotating wheel, a rotating plate and a cutter, wherein the puncturing needle sequentially penetrates through the stabilizing part, the first rotating wheel and the rotating plate and is arranged in the stabilizing part, the first rotating wheel and the rotating plate, the rotating plate is arranged under the first rotating wheel, and the cutter is arranged under the rotating plate; the tool bit device is adjusted to the proper position through the first lifting part and the moving part, the puncturing needle punctures into the positions to be punched of the plastic tanks through the second lifting part, the rotating part rotates so that the first rotating wheel can drive the rotating plate to rotate, the cutter on the rotating plate rotates accordingly so as to cut holes in the plastic tanks, waste cannot fall into the plastic tanks after cutting is completed because the puncturing needle punctures into the waste, and therefore the rejection rate of the plastic tanks is lowered, and the punching efficiency of the plastic tanks is improved.

Owner:NINGBO PUTAI AUTOMATION TECH CO LTD

Method for machining sapphire special-shaped hole

The invention discloses a method for machining a sapphire special-shaped hole. The surface of a sapphire workpiece semi-finished product is firstly washed with absolute ethyl alcohol; the surface of a base plate aluminum sheet is then washed with absolute ethyl alcohol; the base plate aluminum sheet is heated, and the base plate aluminum sheet and the sapphire workpiece semi-finished product are naturally radiated and cooled to be at the indoor temperature; the base plate aluminum sheet is fixed on a trepanning working platform; suspensions are mixed at the indoor temperature; a trepanning mold head is fixed on a trepanning machine head; a circulating pump is then started, and the trepanning process is automatically completed by the trepanning mold head under the gravity effect of the trepanning machine head; then the sapphire workpiece semi-finished product is separated from the base plate aluminum sheet, and the base plate aluminum sheet and the sapphire workpiece semi-finished product are naturally cooled to be at the indoor temperature. The method is high in trepanning efficiency, crystals are not prone to being cracked in the trepanning process, the trepanning surface accuracy is high, the trepanning process is easy to operate, and the device cost is low.

Owner:TUNGHSU GRP

Preparation device of mobile phone protective film

PendingCN114505911AAvoid misalignmentPrecise positioningMetal working apparatusEngineeringMechanical engineering

The invention relates to the technical field of film processing, in particular to a mobile phone protective film preparation device which comprises a placing plate, a transmission part and a trepanning part, the placing plate is of an L-shaped structure, the transmission part is installed at the upper end of the horizontal section of the placing plate, and the trepanning part is installed at the rear end of the transmission part. According to the device, the problems that after an existing protective film is formed and cut, the protective film is usually placed at an opening in a manual mode, the position of the protective film is positioned through a right-angle clamping plate, a large amount of labor needs to be consumed to repeat the same operation, and the phenomenon that the protective film is placed and positioned inaccurately due to fatigue of workers is caused can be solved. According to the preparation device of the mobile phone protective film, it can be ensured that the protective film at any position on the placing mechanism can be aligned, so that manual placing and positioning operation is reduced, the phenomenon that the protective film cannot be aligned due to manual placing is avoided, and the protective film positioning effect is improved.

Owner:深圳市阿尔拓科技有限公司

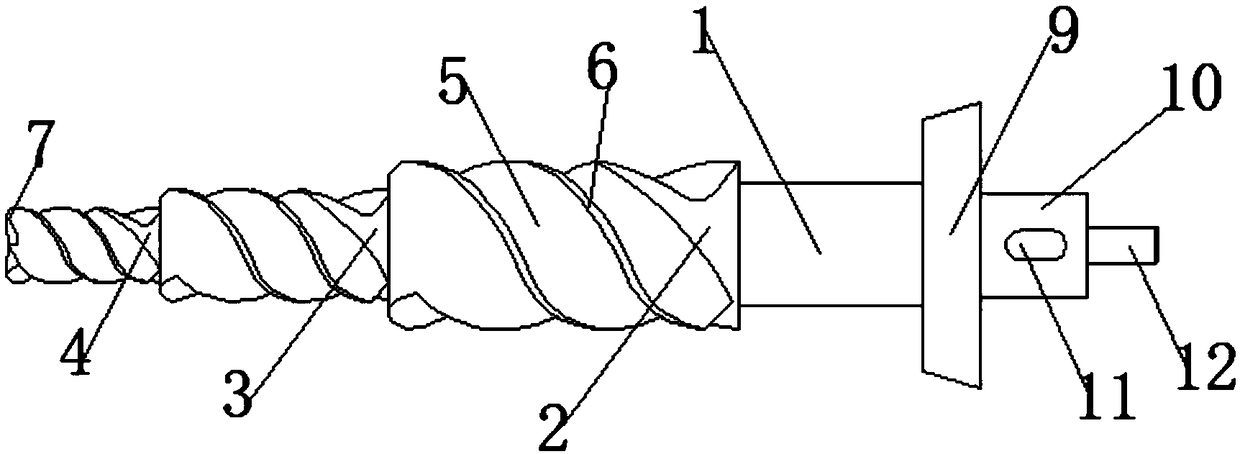

Drill bit used for forming through holes in flake ice

The invention discloses a drill bit used for forming through holes in flake ice. A rod body of a metal rod is fixedly sleeved with a metal pipe. The bottom end of the metal pipe is fixedly connected with a metal disc. Multiple ring-shaped grooves are formed in the bottom face of the metal disc. A metal cylinder matched with the diameter of the ring-shaped groove is connected in each ring-shaped groove in an inserted manner. Each metal cylinder is of a structure with openings formed in the two ends. The lower opening of each metal cylinder is provided with a circle of teeth. The outer wall of the metal disc is provided with a left screw hole and a right screw hole. The left screw hole and the right screw hole extend to the ring-shaped groove in the innermost layer. A left screw rod is arranged in the left screw hole. A right screw rod is arranged in the right screw hole. The left screw rod and the right screw rod are used for fixing the metal cylinders. According to the drill bit, one metal disc is arranged on a body, the metal cylinders with the different diameters can be connected to the bottom face of the metal disc in an inserted manner according to needs, and the lower openingof each metal cylinder is provided with the teeth. The through holes with the different hole diameters can be formed in the flake ice according to needs only by connecting the drill bit with an electric tool, the holing efficiency is high, and hole bodies are attractive.

Owner:FOCUSUN REFRIGERATION JIANGSU

Hole opening tool for pipe holes on inclined wall of ship

InactiveCN104070515ASimple structureImprove hole efficiencyOther workshop equipmentMarine engineering

The invention relates to the technical field of shipbuilding tooling, particularly to a hole opening tool for pipe holes on an inclined wall of a ship. The hole opening tool for the pipe holes on the inclined wall of the ship comprises a positioning hole, a supporting rod and a scribing cutting rod, wherein the supporting rod is perpendicularly connected with the positioning rod and can rotate around the positioning rod, the scribing cutting rod is perpendicularly connected with the supporting rod and can slide in a direction parallel with the positioning rod, the distance between the scribing cutting rod and the positioning rod can be adjusted, and the end portion of the scribing cutting rod is provided with a scribing and cutting device. The hole opening tool can be mounted at site and be positioned at the end of a pipe or an inclined wallboard according to conditions of the site through selection, is not only capable of scribing or cutting in real time but also greatly improves the accuracy of hole opening, and is simple in structure, capable of being used repeatedly, high in hole opening efficiency and low in costs.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

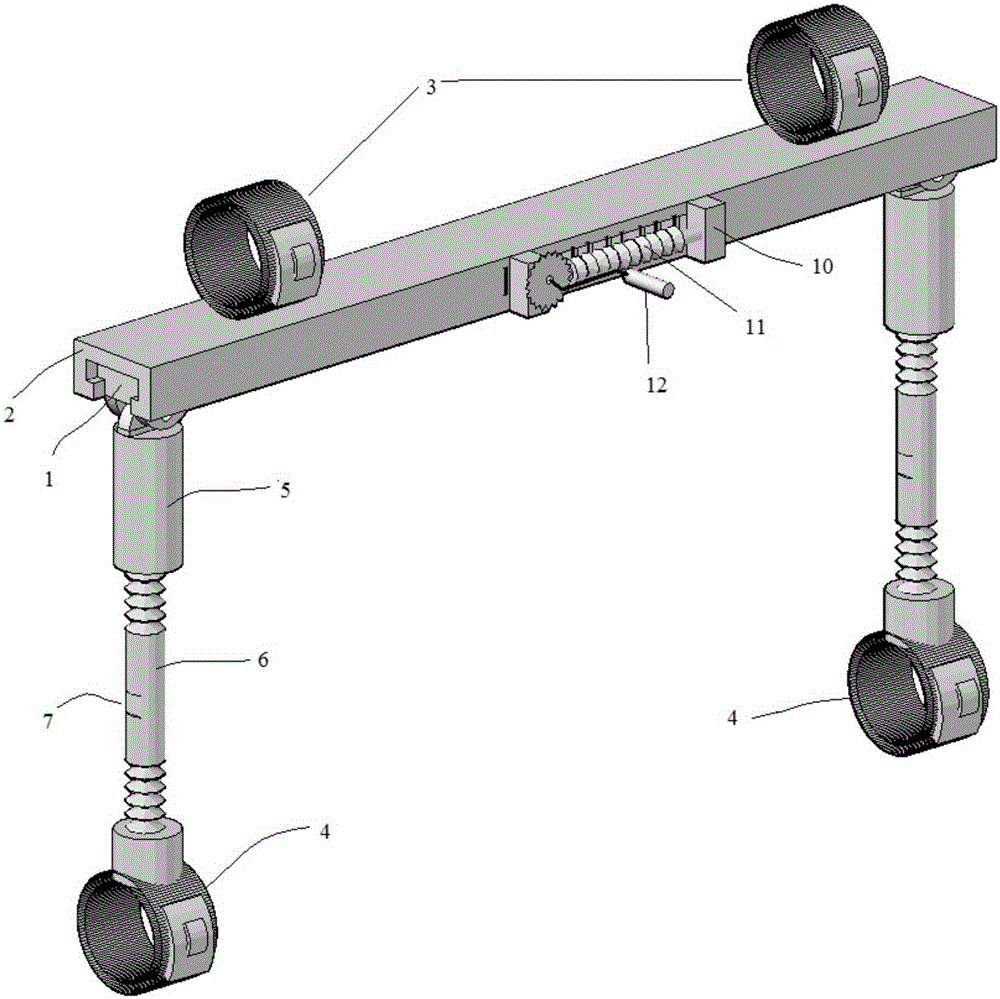

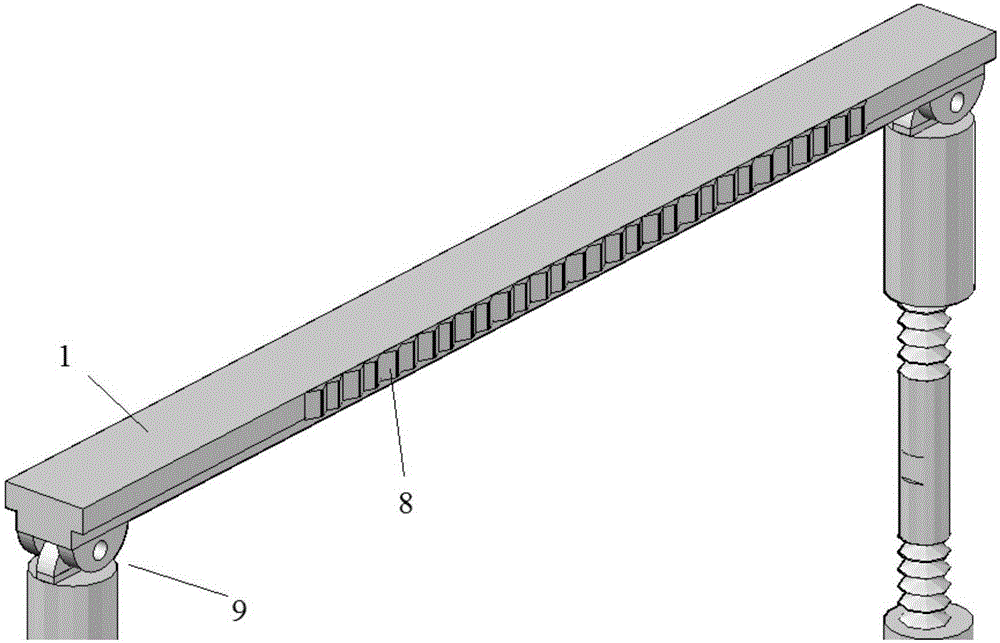

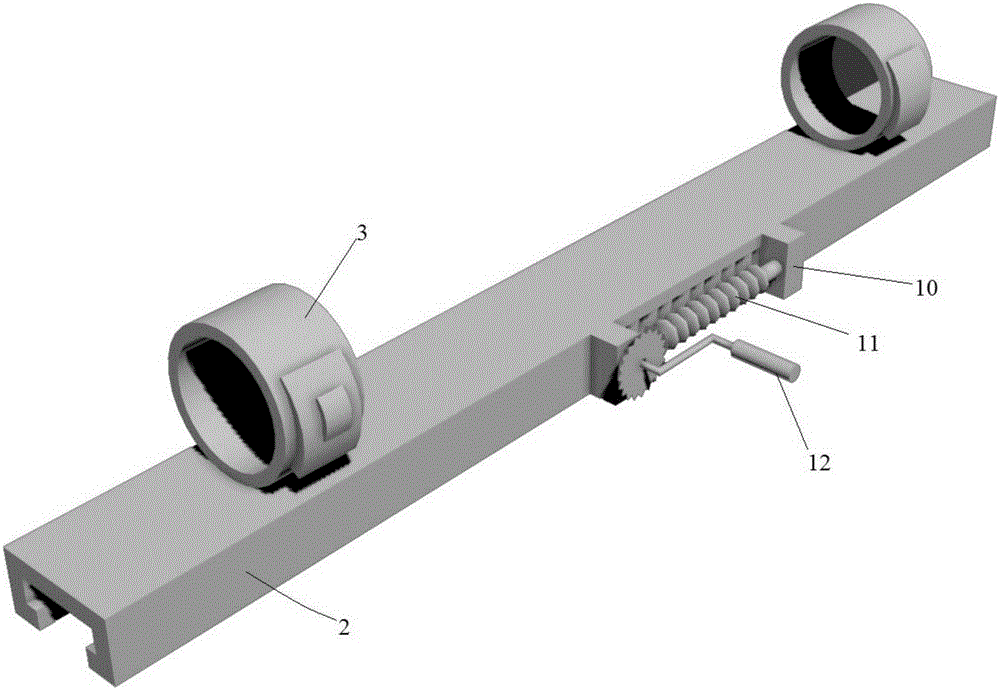

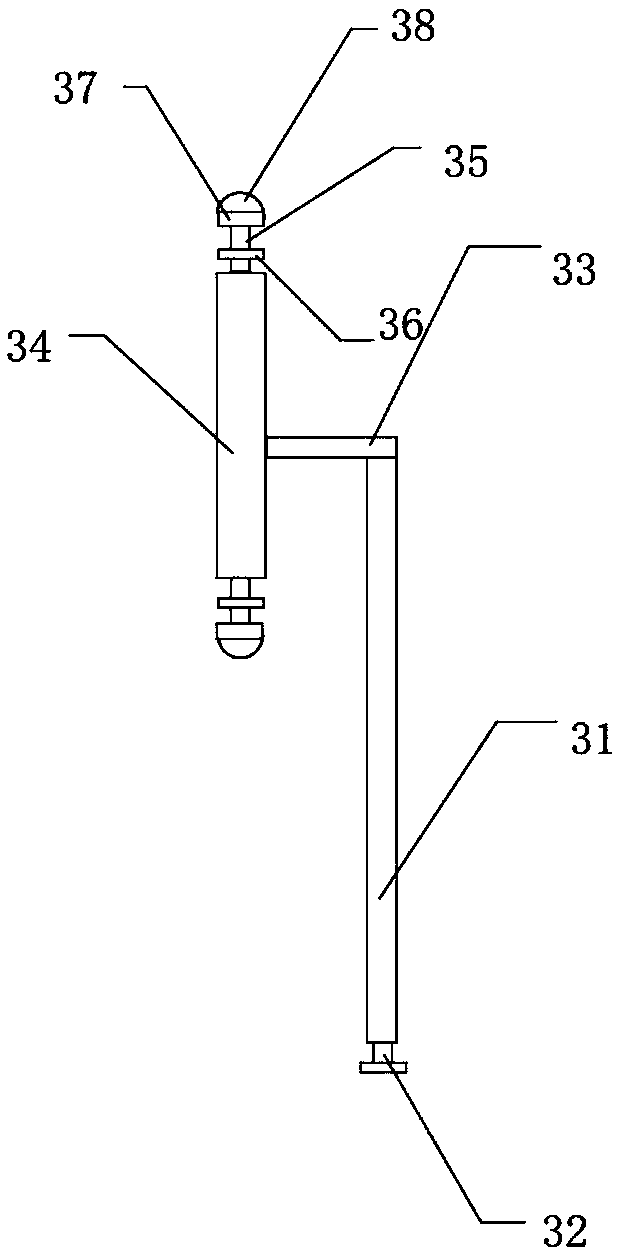

Trepanning device used for copper bar insulation sleeve and use method thereof

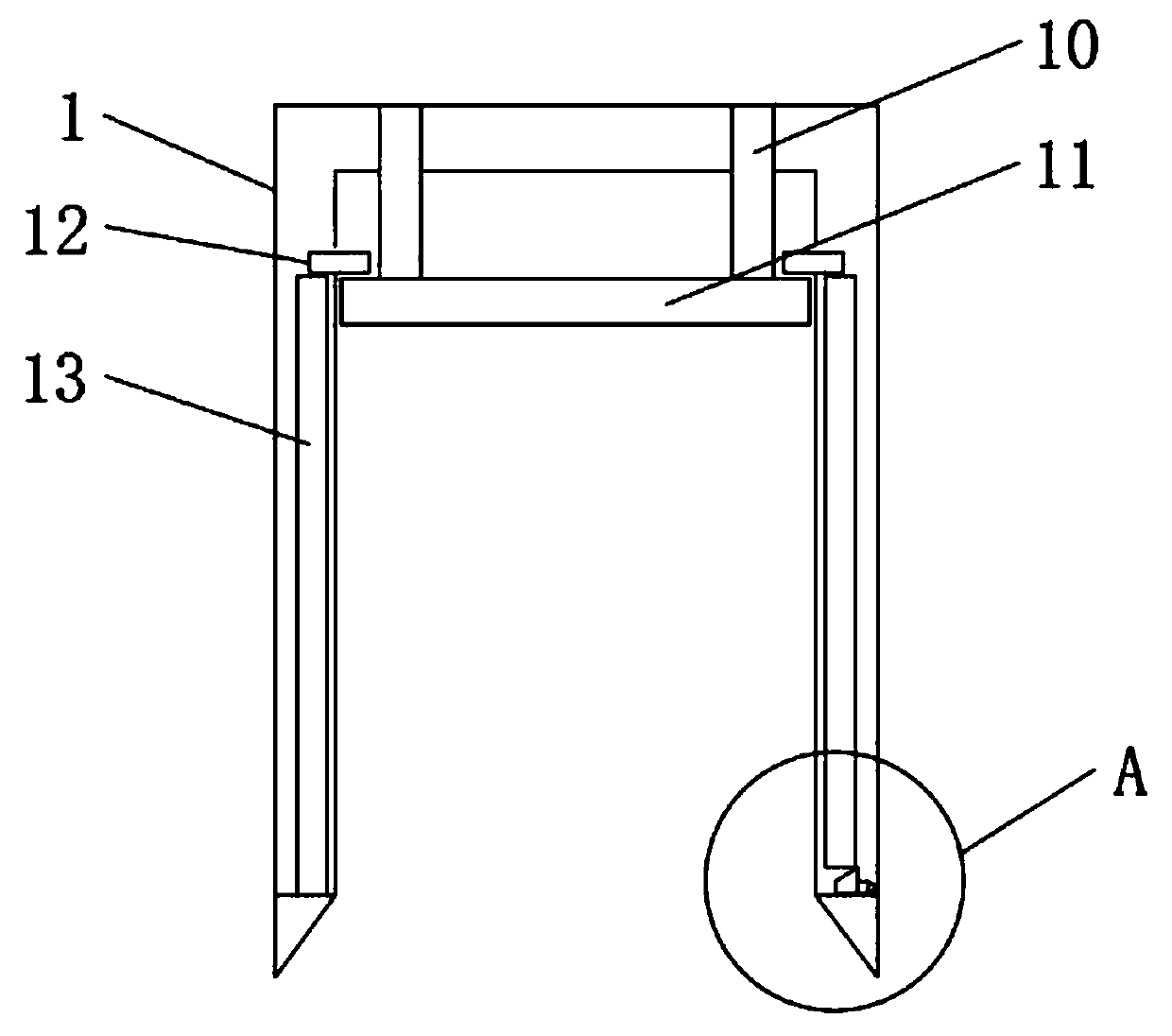

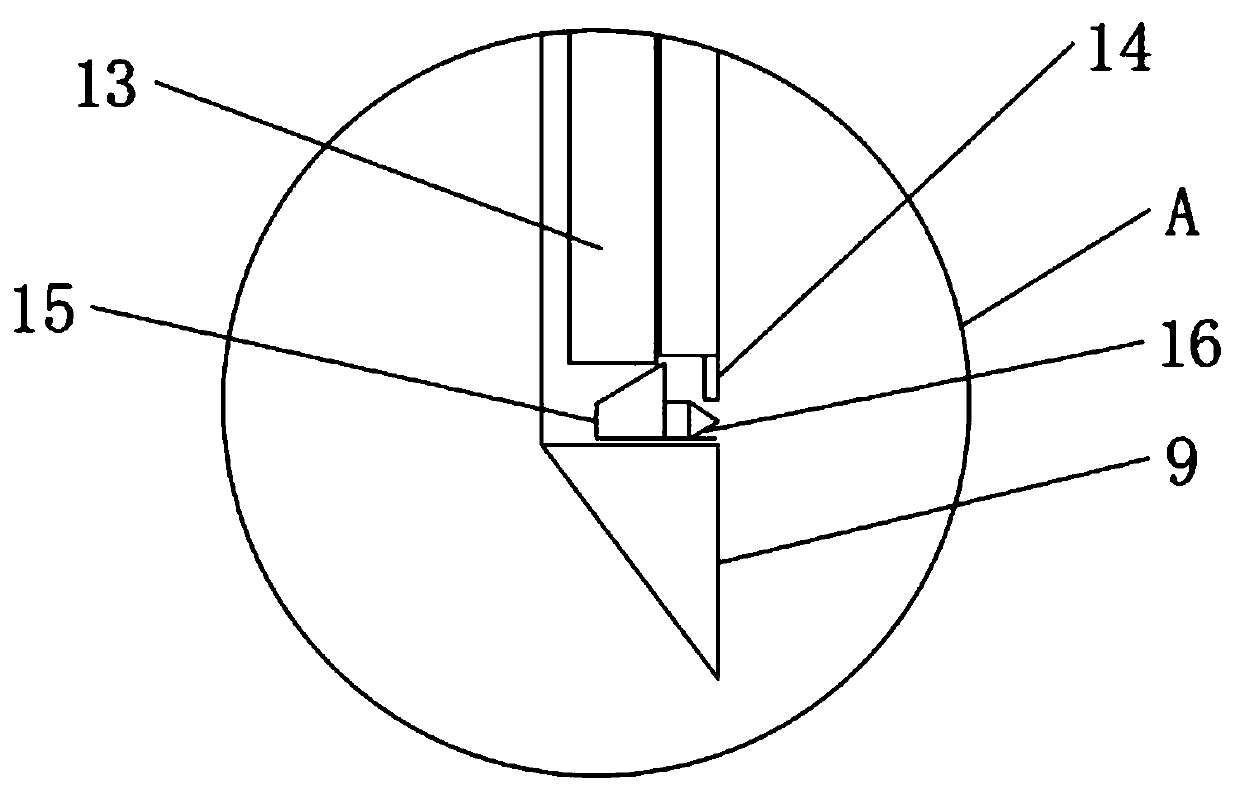

PendingCN108746745AEven by forceAvoid scratchesDrilling/boring measurement devicesLarge fixed membersEngineeringCopper

The invention provides a trepanning device used for a copper bar insulation sleeve. The device comprises a mounting frame and a trepanning device; the mounting frame comprises two supporting feet anda cross beam for connecting the two supporting feet, the trepanning device comprises a sleeve, a connecting screw rod and trepanning knives, the trepanning knives are vertically placed, knife bits face downwards, the two trepanning knives are arranged and are symmetrically arranged along the connecting screw rod, the lowest points of the knife bits of the two trepanning knives are located on the same horizontal plane, the trepanning knives and the connecting screw rod are connected through connecting strips, the connecting strips are horizontally arranged and move in the length direction, theinteriors of the connecting screw rod is hollow to form a mounting cavity, a laser assembly is arranged in the mounting cavity, when the two trepanning knives rotate, the cutting thicknesses of the insulation sleeve are the same, in the trepanning process, the copper bar stress is uniform, a zinc coating of the copper bar is prevented from being scratched, and use is reliable. The invention further provides a use method of the trepanning device. The rotating type trepanning work is adopted, and in the trepanning process, the damage to the zinc coating of the copper bar is avoided.

Owner:杭州电力设备制造有限公司临安恒信成套电气制造分公司 +2

Tapping equipment for machining automobile oil pan guard plate, and working method thereof

InactiveCN112157457AGuaranteed tightnessHigh precisionFeeding apparatusPositioning apparatusElectric machineryDrill floor

The invention discloses tapping equipment for machining an automobile oil pan guard plate, and a working method thereof. The tapping equipment comprises a supporting frame, two supporting tables and adrill moving table; the two supporting tables are arranged on the two sides of the top of the supporting frame separately, and the drill moving table is arranged at one end of the top of the supporting frame; each supporting table comprises a motor I, a sleeve rail and a sliding disc I; and the motor I is arranged at one end of the middle part of the supporting table, and one end of the motor I is rotatably connected with a lead screw I through an output shaft. The tapping equipment has the beneficial effects that four drilling bases are arranged on each rotary disc, and drill bits in different sizes and models can be installed on each drilling base; it is guaranteed that the equipment can be used for rapidly drilling holes in different diameters in an oil pan guard plate, and the use diversity of the equipment and the efficiency of drilling holes in different oil pan guard plates are improved; the equipment is higher in tapping precision and efficiency for oil pan guard plates in different sizes; and the equipment is high in working automation degree, has good social benefits, and is suitable for popularization and application.

Owner:马鞍山贺辉信息科技有限公司

Boring device for planting trees in green belt

PendingCN110036721AEasy plantingImprove hole efficiencyPlantingFurrow making/coveringGasolineEngineering

The invention discloses a boring device for planting trees in the green belt. The boring device comprises a borer and a gasoline engine, a connecting column is arranged at the top of the gasoline engine and is welded with the housing of the same, a rotating shaft is arranged at the bottom of the gasoline engine and is fixedly connected with the borer, each of two sides of the rotating shaft is provided with a hydraulic rod, tops of the hydraulic rods is fixedly connected with a rotating piece on the rotating shaft of the gasoline engine, and telescopic rods are arranged in the borer and are embedded in the corresponding hydraulic rods to penetrate the borer. The boring device adopts the gasoline engine as the power source to rotate the borer, cutting the land with blades is quite beneficial to boring, a push plate is pushed by the hydraulic rods to have mud in the borer led out, manpower is saved, and high boring efficiency is achieved.

Owner:安徽省大地园林股份有限公司

Square hole processing device for fiber-reinforced pipes

InactiveCN109623940AAvoid difficultyImprove hole efficiencyMetal working apparatusEngineeringFiber reinforcement

The invention relates to the technical field of fiber-reinforced pipe processing, in particular to a square hole processing device for fiber-reinforced pipes. The square hole processing device for thefiber-reinforced pipes comprises a workbench, a pipe clamping device, a hole location marking component, a vertex angle drilling component and a square hole forming component. The pipe clamping device comprises a horizontal movement component and a clamping component, wherein the horizontal movement component is installed at the top end of the workbench horizontally, and the clamping component isinstalled at the top end of the horizontal movement component. The vertex angle drilling component is installed at the top end of the workbench and stretches over the middle section of the horizontalmovement component. The hole location marking component is installed at the top end of the workbench and arranged at the input end of the horizontal movement component. The square hole forming component is installed at the top end of the workbench and located at the output end of the horizontal movement component. Through mutual cooperation of the pipe clamping device, the hole location marking component, the vertex angle drilling component and the square hole forming component, the difficulties of drilling square holes in the fiber-reinforced pipes is reduced, and the drilling efficiency isimproved.

Owner:刘慧玲

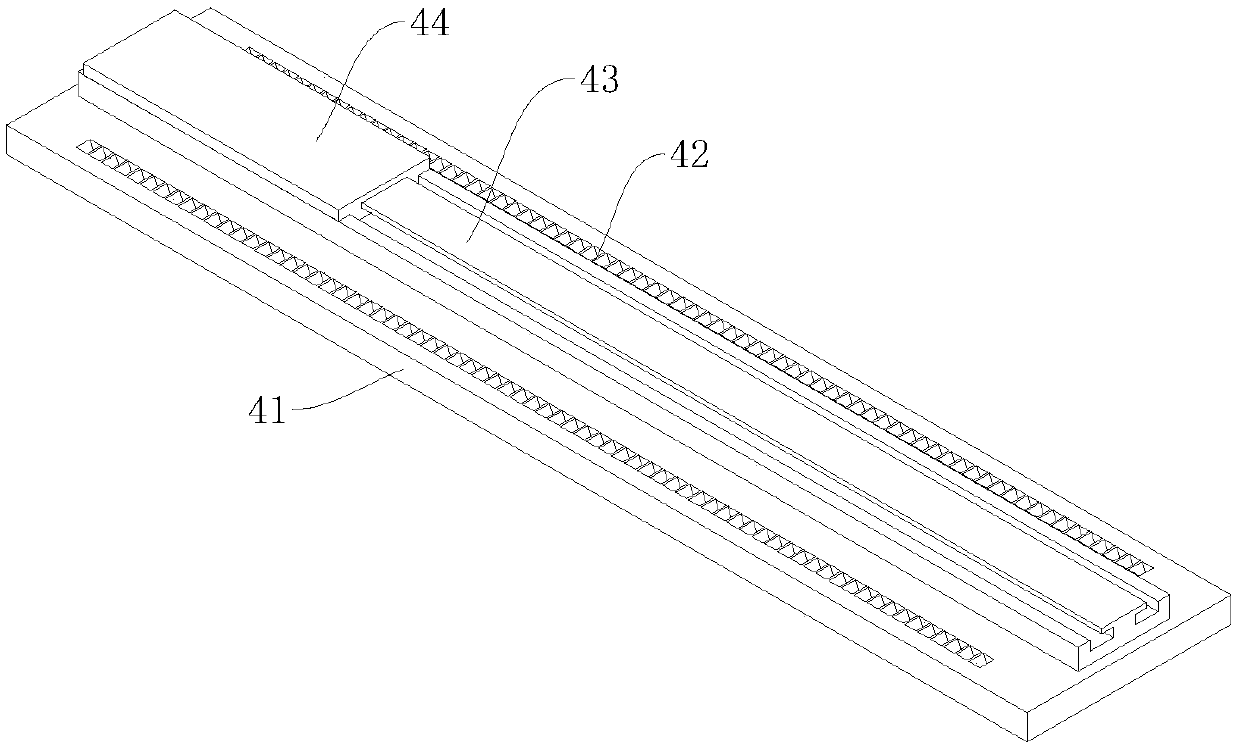

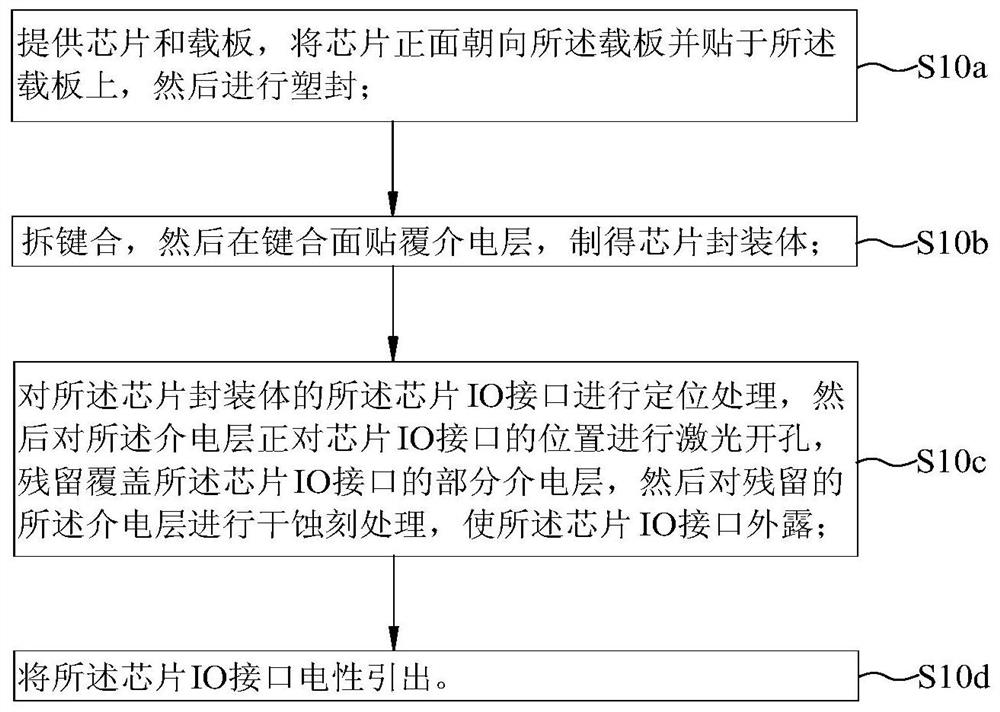

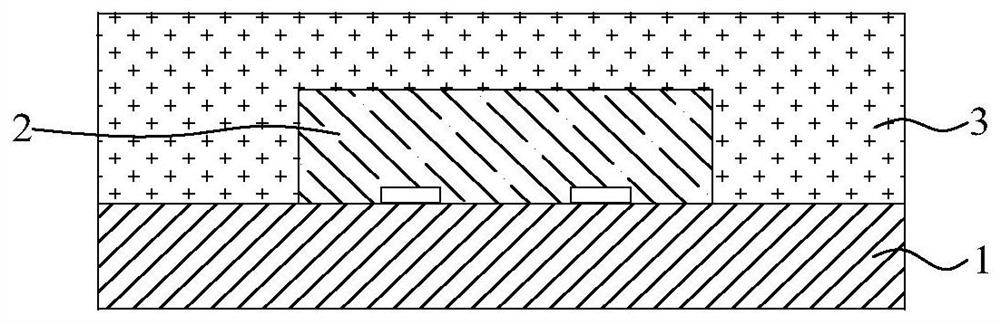

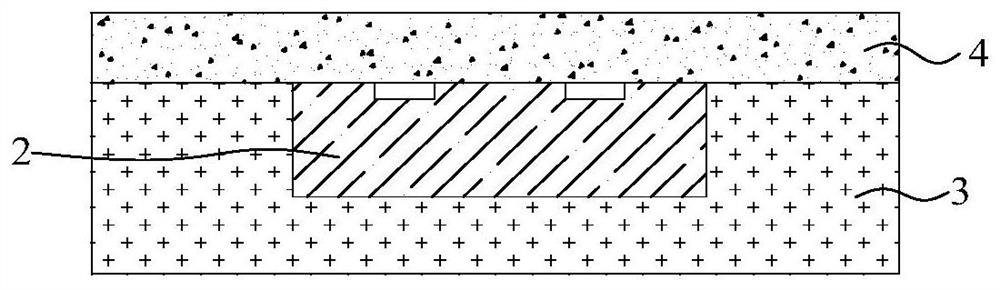

Method for reducing damage to IO interface of packaged chip

PendingCN112309965AAvoid damageImprove hole efficiencySolid-state devicesSemiconductor/solid-state device manufacturingComputer hardwareEmbedded system

The invention discloses a method for reducing damage to an IO interface of a packaged chip. The method comprises the steps: manufacturing a chip packaging body, sequentially carrying out laser hole forming and dry etching on a position, right opposite to the IO interface of a chip, of the chip packaging body, enabling the IO interface of the chip to be exposed, and then enabling the IO interface of the chip to be electrically led out. According to the invention, the position, right opposite to the chip IO interface, of the chip packaging body is firstly subjected to laser hole forming treatment, and then the residual material covering the chip IO interface is subjected to dry etching treatment, so that the chip IO interface is exposed, the production efficiency of the packaged chip is improved, the damage to the chip IO interface is effectively reduced, and the yield of the packaged chip is improved.

Owner:广东佛智芯微电子技术研究有限公司

Opening device for packaging box foam lining plate

ActiveCN110370387AImprove hole efficiencyThe hole size is accurate and consistentMetal working apparatusElectric heatingElectricity

The invention provides an opening device for a packaging box foam lining plate. The opening device comprises an operation platform, wherein a door frame is arranged on the operation platform, a driving mechanism is arranged on the door frame, the two sides of the door frame are provided with a group of electric heating devices, and the operation platform is provided with a supporting device; eachelectric heating device comprises an electric heating wire, and the two ends of the electric heating wire are respectively connected with rotary discs through adjusting screws; and the supporting device comprises a supporting plate, a plurality of air cylinders and a plurality of guide sleeves, wherein the air cylinders and the guide sleeves are arranged on the operation platform, a guide rod is arranged in each of the guide sleeves, and each guide rod and the piston rod of the air cylinder are connected with the supporting plate. The opening device is used for solving the problems that an existing packaging box foam lining plate is not high in hole opening efficiency and large in hole size error.

Owner:宜昌市有为彩印有限公司

Stepped round nose cutter

The invention discloses a stepped round nose cutter. The stepped round nose cutter comprises a cutter handle, a first cutter pole, a second cutter pole, a third cutter pole, a scrap discharging groove, cutting edges, a cutter bit, a cutter blade, a limiting base, a connecting rod, a positioning groove and a clamping rod. The stepped round nose cutter has the advantages that the diameters of pole bodies of the first cutter pole, the second cutter pole and the third cutter pole are reduced gradually to form a stepped cutter pole, and therefore the stepped round nose cutter can adapt to round holes with different machining sizes; the end edge of the cutter bit is in a circular arc shape, the end cutting edge of the cutter bit and the linear cutting edge are connected through a transitional circular arc, and therefore the round nose cutter is not blocked easily during machining. A long and short edge opening cross-over design is adopted for the cutter bit, the blade is in high-low intersecting connection, cutting resistance is reduced, the blade is detachably connected with the cutter bit through a fastening bolt, a new blade is conveniently used for replacement, the blade has a cutterpoint protective angle, the cutter point of the blade is coated with a micro-nano composite coating so that the blade has sufficient strength and anti-impact performance, and meanwhile good resistance to high-temperature oxidation and abrasion resistance are realized.

Owner:赫莱德(常州)精密工具有限公司

Continuous perforating apparatus for medical aluminum-foil bottle caps

The invention discloses a continuous perforating apparatus for medical aluminum-foil bottle caps, comprising a base. A support foot is welded to each of four corners of the outer wall of the bottom of the base, a universal wheel is fixed to the outer wall of the bottom of each support foot through screws, a working box is fixed to the outer wall of the top of the base through screws, two first support rods are welded on one side of the inner wall of the bottom of the working box, a first drum is connected to the outer walls of opposing sides of the two first support rod through bearings, two second support rods are welded to the other side of the outer wall of the bottom of the working box, and a second drum is connected to the outer walls of opposing sides of the two second support rods through bearings. The continuous perforating apparatus for medical aluminum-foil bottle caps is convenient to move, has good mobility, is convenient to fix after being moved, has good stability, and employs a pipeline perforating mode to provide continuous perforating; in addition, an infrared sensor is capable of monitoring the position of an aluminum-foil bottle at any time, perforating is performed automatically via a perforating head of a perforator, and perforating efficiency is significantly improved.

Owner:YANCHENG XINANZHOU PHARMA

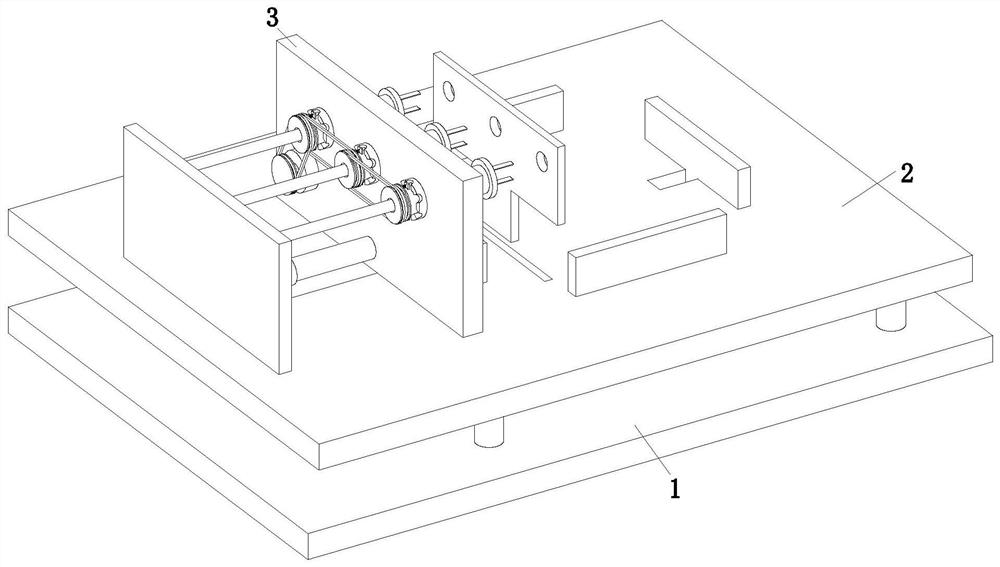

Excavator grab bucket machining device

ActiveCN112589461AImprove hole efficiencyPrevent rotationOther manufacturing equipments/toolsMetal working apparatusExcavatorIndustrial engineering

The invention discloses an excavator grab bucket machining device and belongs to the field of excavator grab buckets. The excavator grab bucket machining device comprises two fixed guide rails; the two fixed guide rails are respectively, independently and fixedly arranged; stepping slide blocks are arranged on the fixed guide rails; the stepping slide blocks are connected with the fixed guide rails in a sliding way; a bearing table is arranged at the top ends of the stepping slide blocks; and a slope table is arranged at the top end of the bearing table. According to the excavator grab bucketmachining device, the tapping efficiency of the grab bucket to be treated is high.

Owner:南通科翰机械工程有限公司

A corrugated box cutting slotting machine

ActiveCN113043657BEasy to openRealize the clamping functionPaper-makingBox making operationsPaper dustCarton

Owner:江西华利包装科技股份有限公司

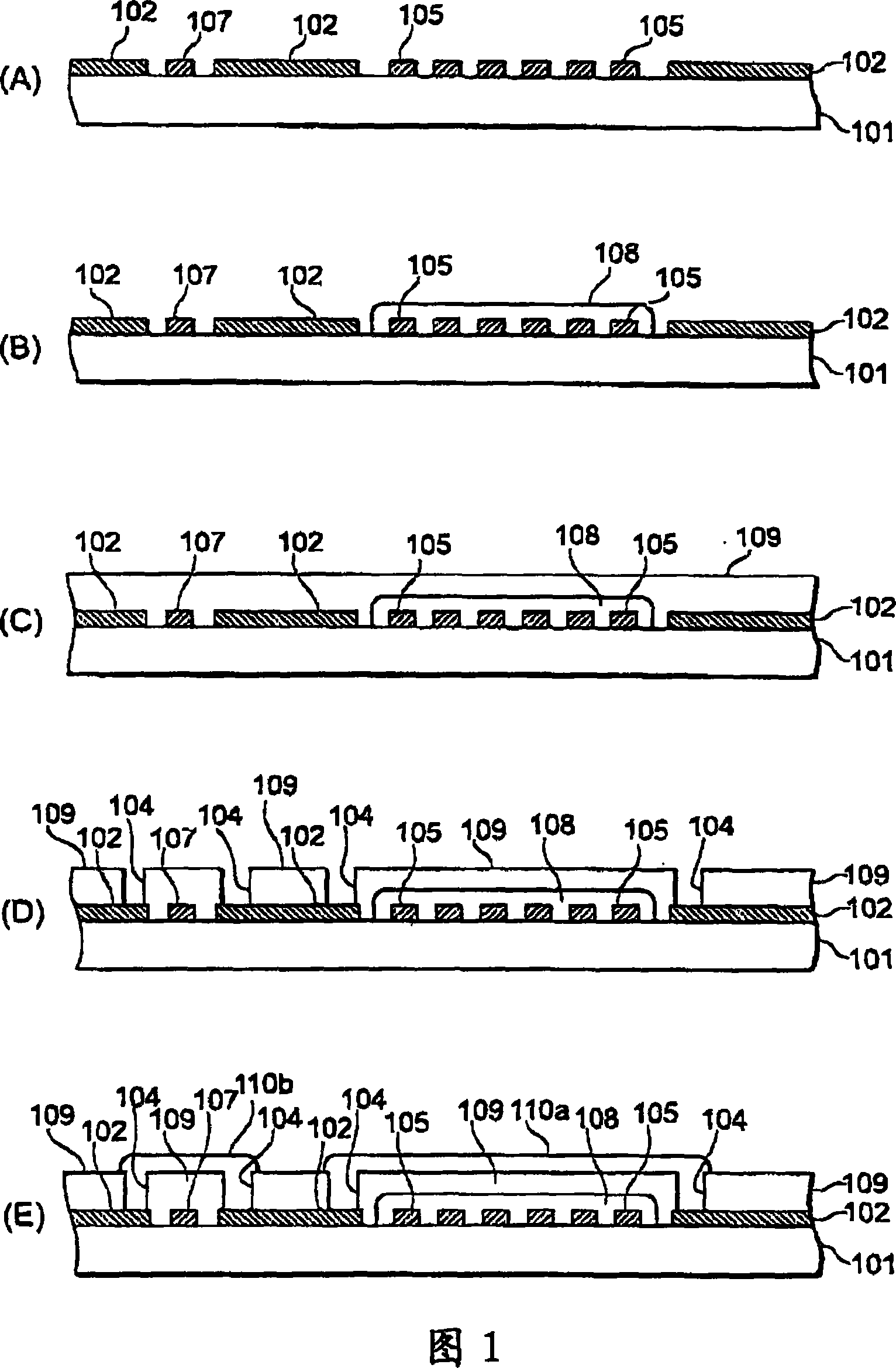

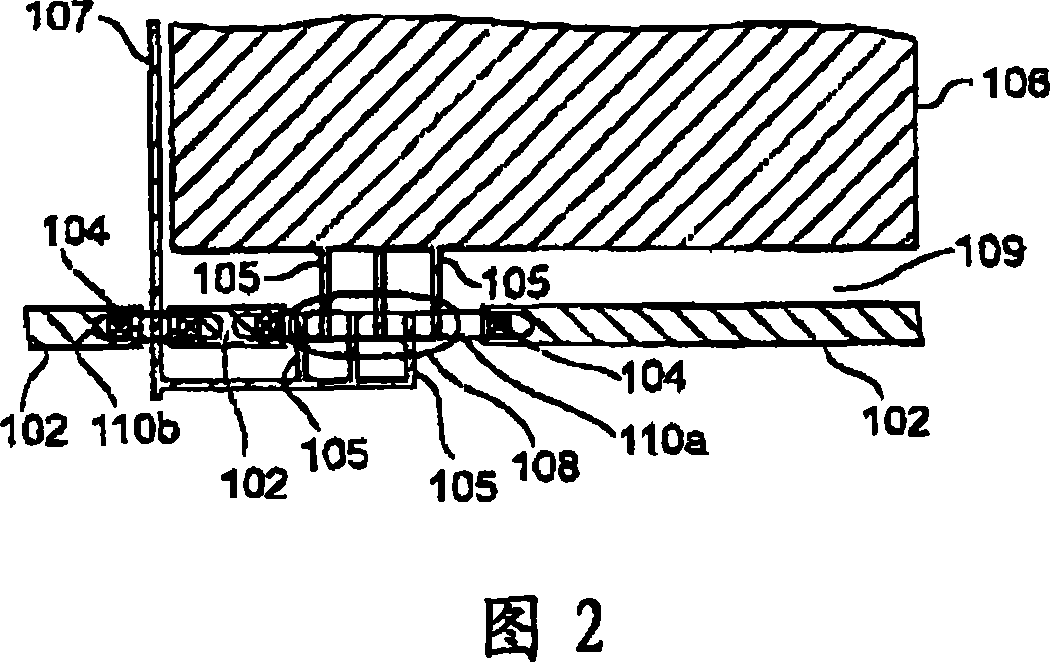

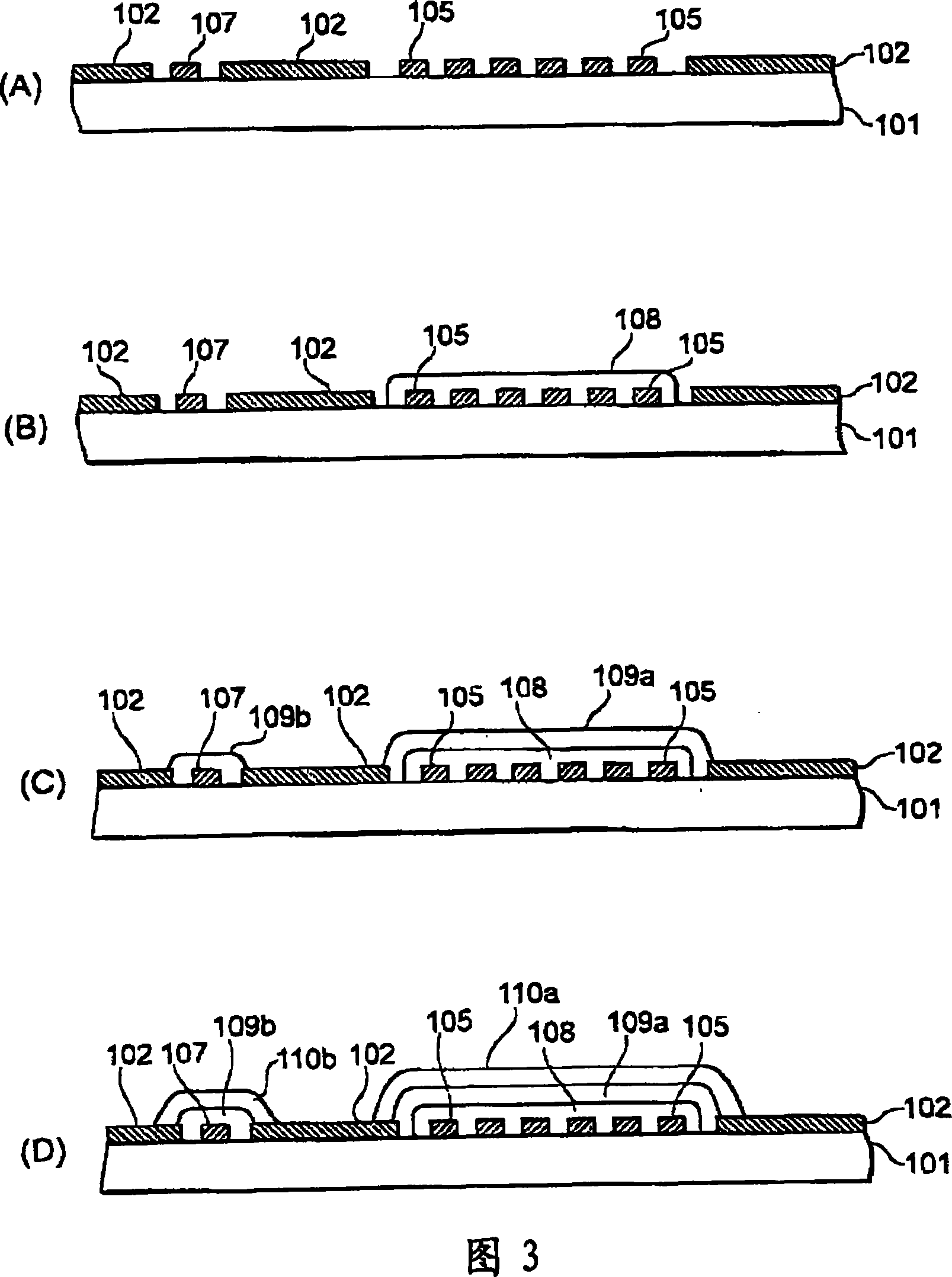

Semiconductor device, manufacturing method thereof, electro-optical device and electric device

InactiveCN101086997AReduce widthReduce areaTransistorSemiconductor/solid-state device detailsInsulation layerActive matrix

The present invention provides a semiconductor device which can reduce resistance value of used grid line (grid signal line), an electro-optical device and a electric device. The grid line transmits grid driven signal with organic semiconductor device in active matrix display. The semiconductor device includes an organic semiconductor transistor provided on a substrate; a data line connected to a source electrode or a drain electrode of the organic semiconductor transistor; and a gate line that is disposed so as to intersect the data line and that is connected to a gate electrode of the organic semiconductor transistor. In the semiconductor device, the gate line includes the gate electrode, a first gate line that transmits signals to the gate electrode, and a second gate line intersecting the data line, with an interlayer insulation layer therebetween; the gate electrode, the first gate line, and the second gate line are connected in series; and the electric conductivity of the first gate line is higher than the electric conductivity of the gate electrode and the electric conductivity of the second gate line.

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com