Semiconductor device, manufacturing method thereof, electro-optical device and electric device

A manufacturing method and semiconductor technology, applied in the fields of semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve problems such as being unsuitable for mass production, requiring labor and time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

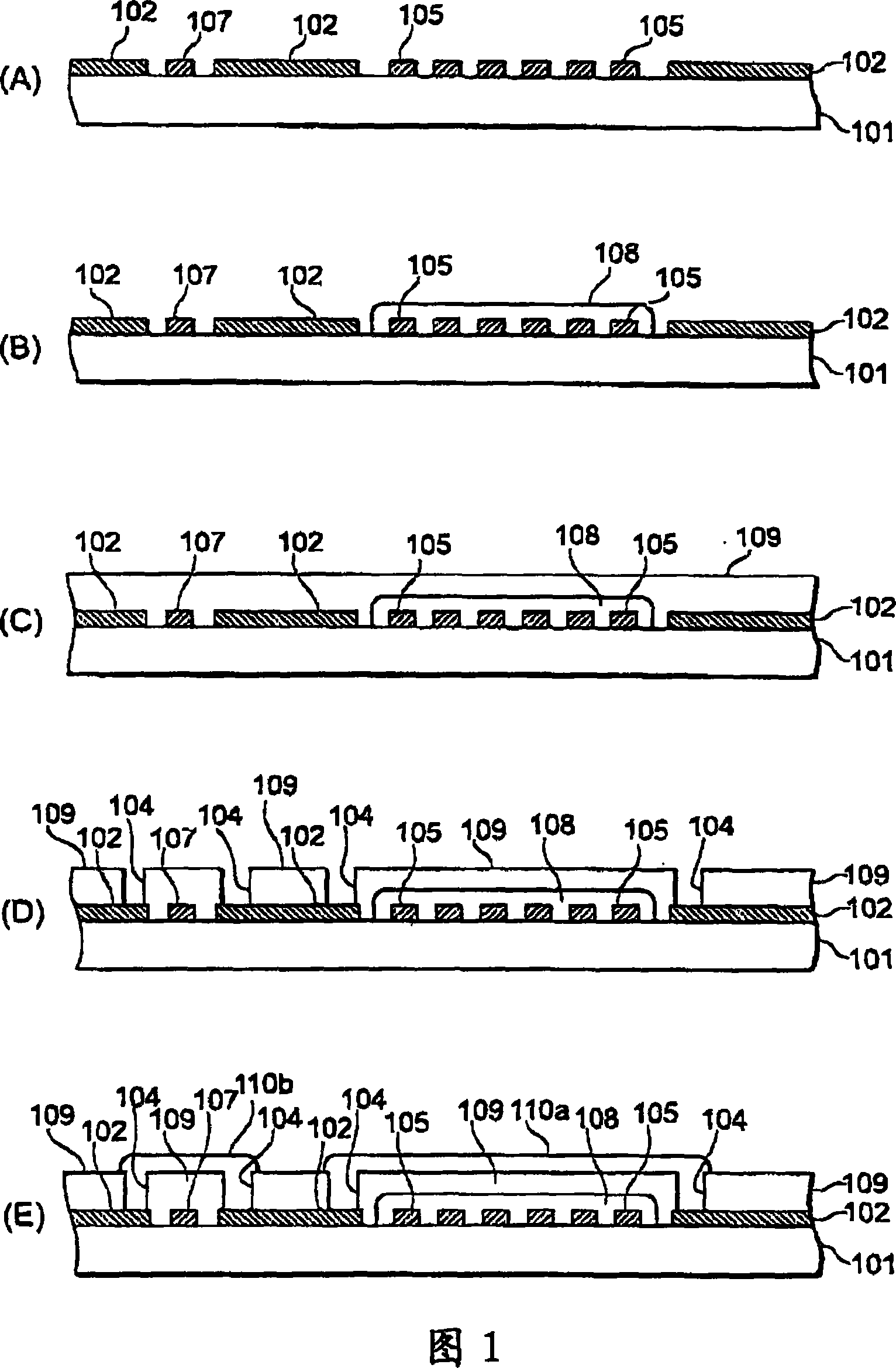

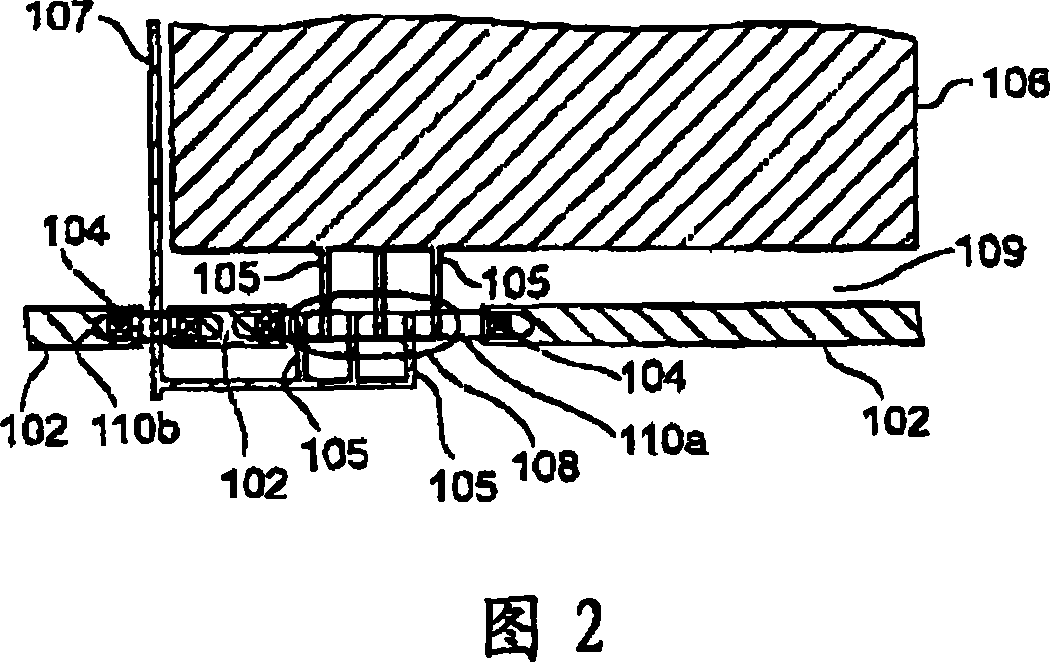

[0039] 1 to 4 show examples in which the organic semiconductor transistor of the present invention is used in a display pixel driving circuit. FIG. 1 is a process diagram illustrating a manufacturing process of an organic semiconductor transistor as a semiconductor device, and FIG. 2 is a plan view of a pixel driving circuit.

[0040] In this embodiment, low-resistance gate lines (wiring) have been formed on the substrate, and the connection between the gate lines and the formation of the gate electrodes are performed in the same process by the printing method.

[0041] First, as shown in FIG. 1(A), a first gate line 102, a data line 107, source and drain electrodes 105, a pixel electrode 106 (see FIG. 2), and an external drive device are formed together on an insulating substrate 101. Terminals for connection, external connection wiring, etc. (not shown).

[0042]As the insulating substrate 101 , for example, a plastic substrate such as PET (polyethylene terephthalate), or a...

no. 2 Embodiment

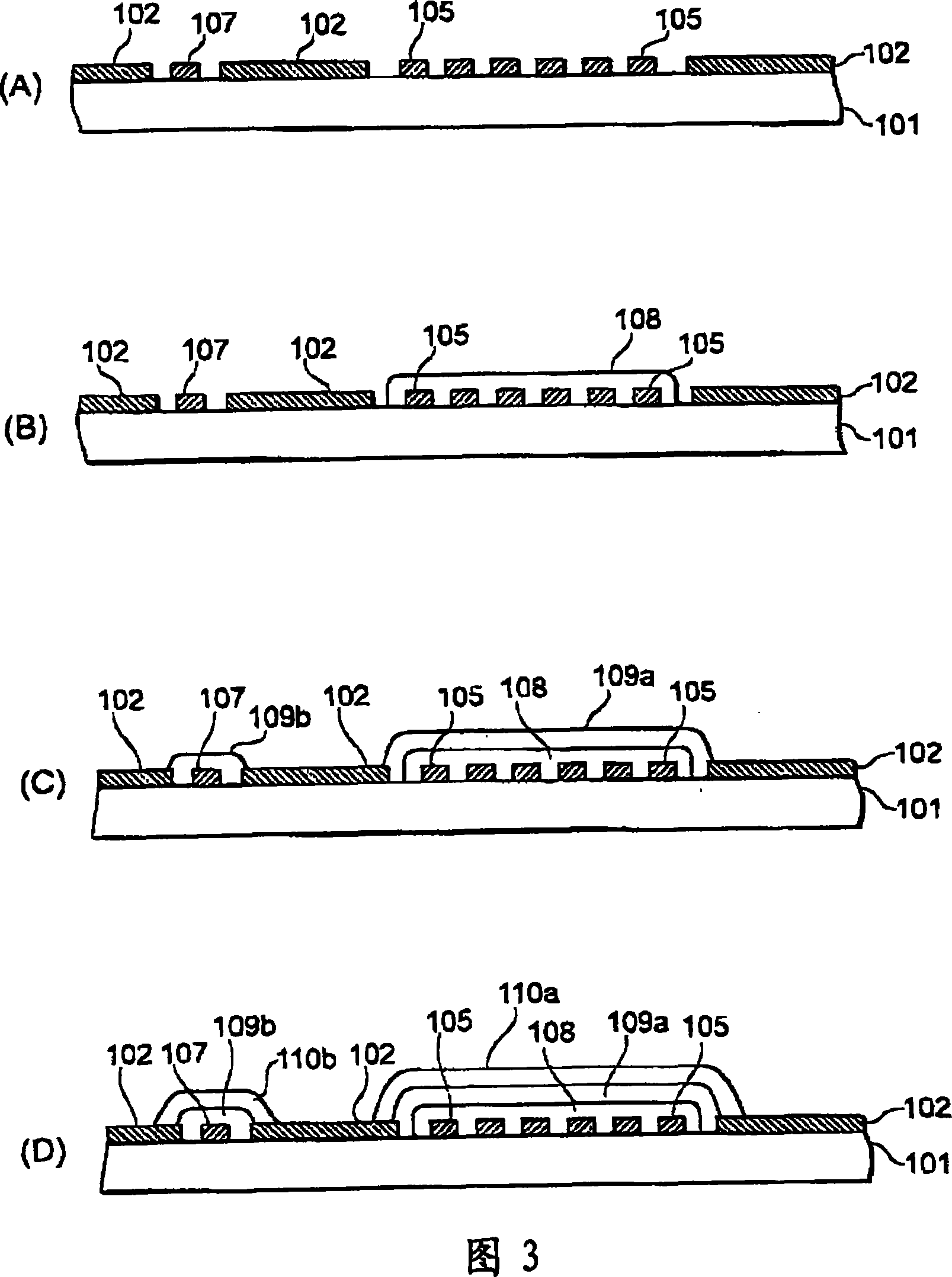

[0062] 3 and 4 show a second embodiment. 3 is a process diagram illustrating a manufacturing process of an organic semiconductor transistor as a semiconductor device, and FIG. 4 is a plan view of a pixel driving circuit. In FIG. 3 and FIG. 4 , the parts corresponding to those in FIG. 1 and FIG. 2 are denoted by the same reference numerals, and descriptions of these parts are omitted.

[0063] First, as shown in FIG. 3(A), a first gate line 102, a data line 107, source and drain electrodes 105, and a pixel electrode 106 (see FIG. 4 ) are formed together on an insulating substrate 101 to communicate with an external driving device. Terminals for connection, external connection wiring, etc. (not shown).

[0064] As shown in Figure (B), the substrate is treated with oxygen plasma and cleaned. Thereafter, F8T2 as an organic semiconductor is dropped and annealed by the inkjet method, and the organic semiconductor layer 108 is formed to have a film thickness of about 50 nm so as to...

no. 3 Embodiment

[0071] 5 and 6 show a third embodiment. 5 is a process diagram illustrating a manufacturing process of an organic semiconductor transistor as a semiconductor device, and FIG. 6 is a plan view of a pixel driving circuit. In FIG. 5 and FIG. 6 , the parts corresponding to those in FIG. 1 and FIG. 2 are given the same reference numerals, and descriptions of these parts are omitted.

[0072] In the third embodiment, the second gate line 110b, the first gate line 102 and the gate electrode 110a shown in the first embodiment (FIG. 1(E)) are composed of one gate electrode as shown in FIG. 5(E). wiring 110c. By constituting as described above, the number of patterns can be reduced, and the number of times of application by the inkjet method can be reduced, which is convenient.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com