Punching device for plastic tanks

A technology of plastic pots and lifting parts, which is applied in metal processing and other directions, can solve the problems that waste materials are easy to fall in the water tank, cannot be taken out, time-consuming and labor-intensive, etc., and achieve the effect of improving hole opening efficiency and reducing scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

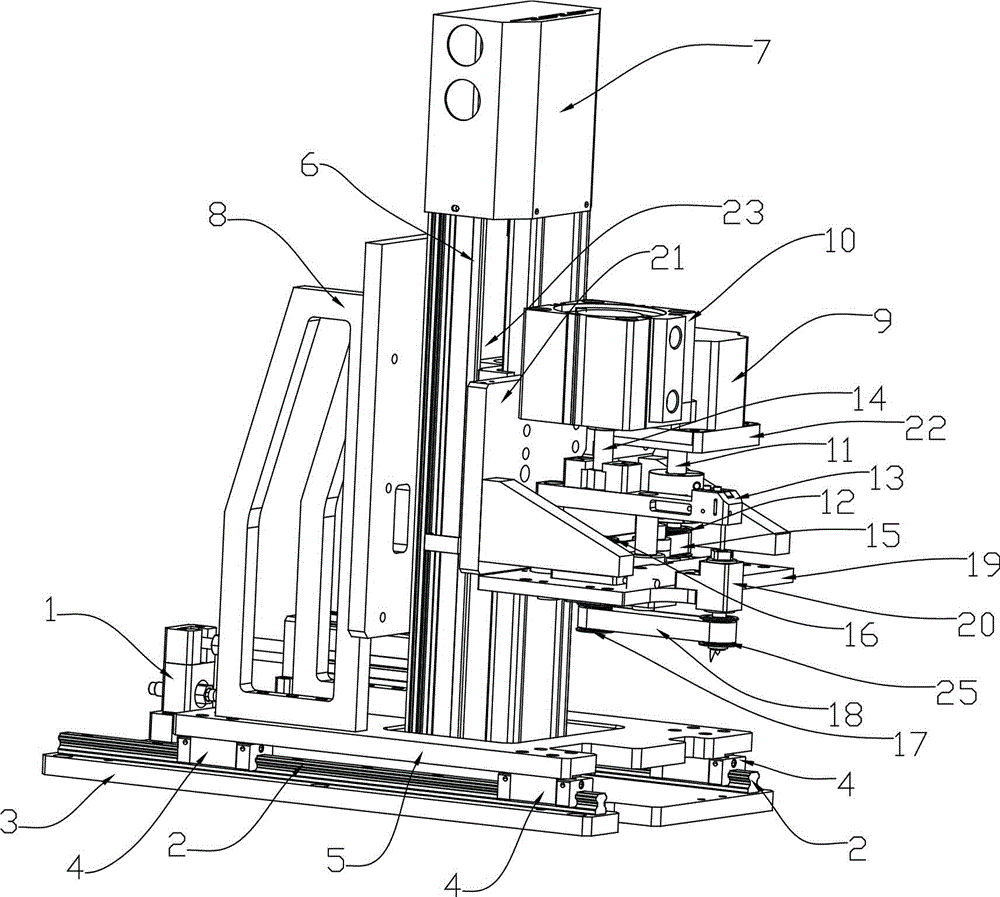

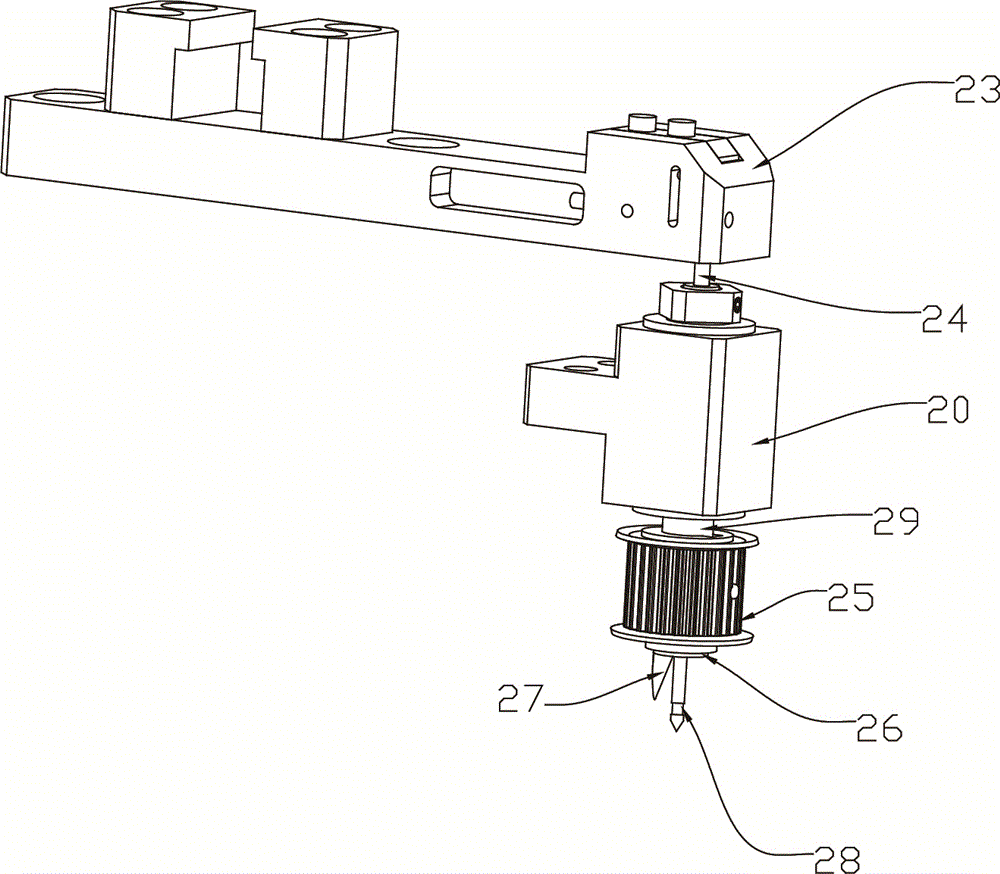

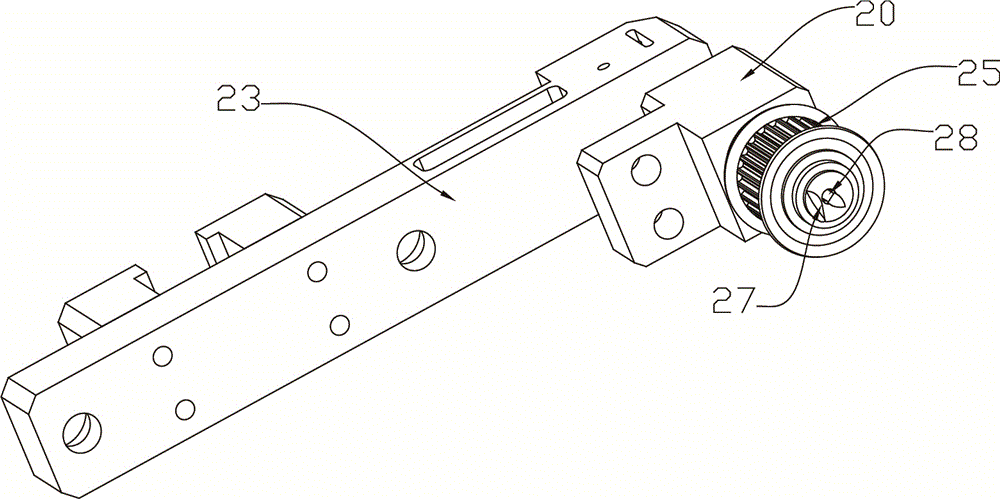

[0014] See Figure 1 to Figure 3 , a device for opening holes in a plastic pot body, comprising a base 3, a supporting part 8, a first lifting part, a moving part, a rotating part, a second lifting part, and a knife head device, the base 3 is provided with a moving part, and the The moving part is provided with a supporting part 8, and the supporting part 8 is provided with a first lifting part, and the first lifting part is provided with a rotating part and a second lifting part, and the rotating part and the second lifting part are connected to the cutter head device, the cutter head device device includes a needle 24, a stabilizer 20, a first runner 25, a rotating disk 26, and a cutter 27, and the needle 24 passes through the stabilizer 20, the first runner 25 and the rotating disk 26 in sequence and is arranged Among them, the turntable 26...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com