Machining method for perforated U-shaped rib

A processing method, U-shaped technology, applied in the field of sheet metal forming, can solve the problems of low processing efficiency, unsuitable for large-scale large-scale production, etc., and achieve the effects of improving hole-out efficiency, reducing processing difficulty, and eliminating internal stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

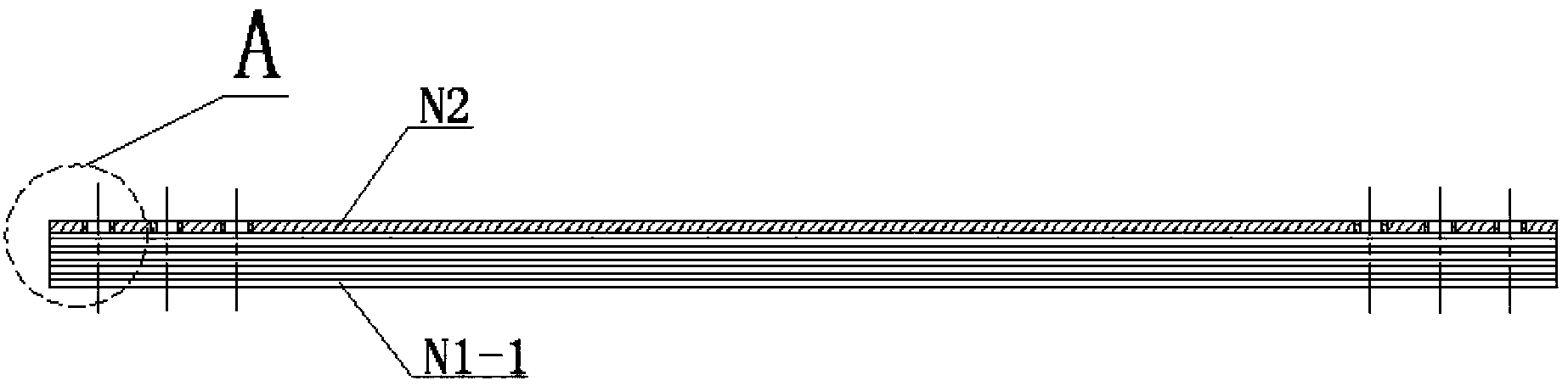

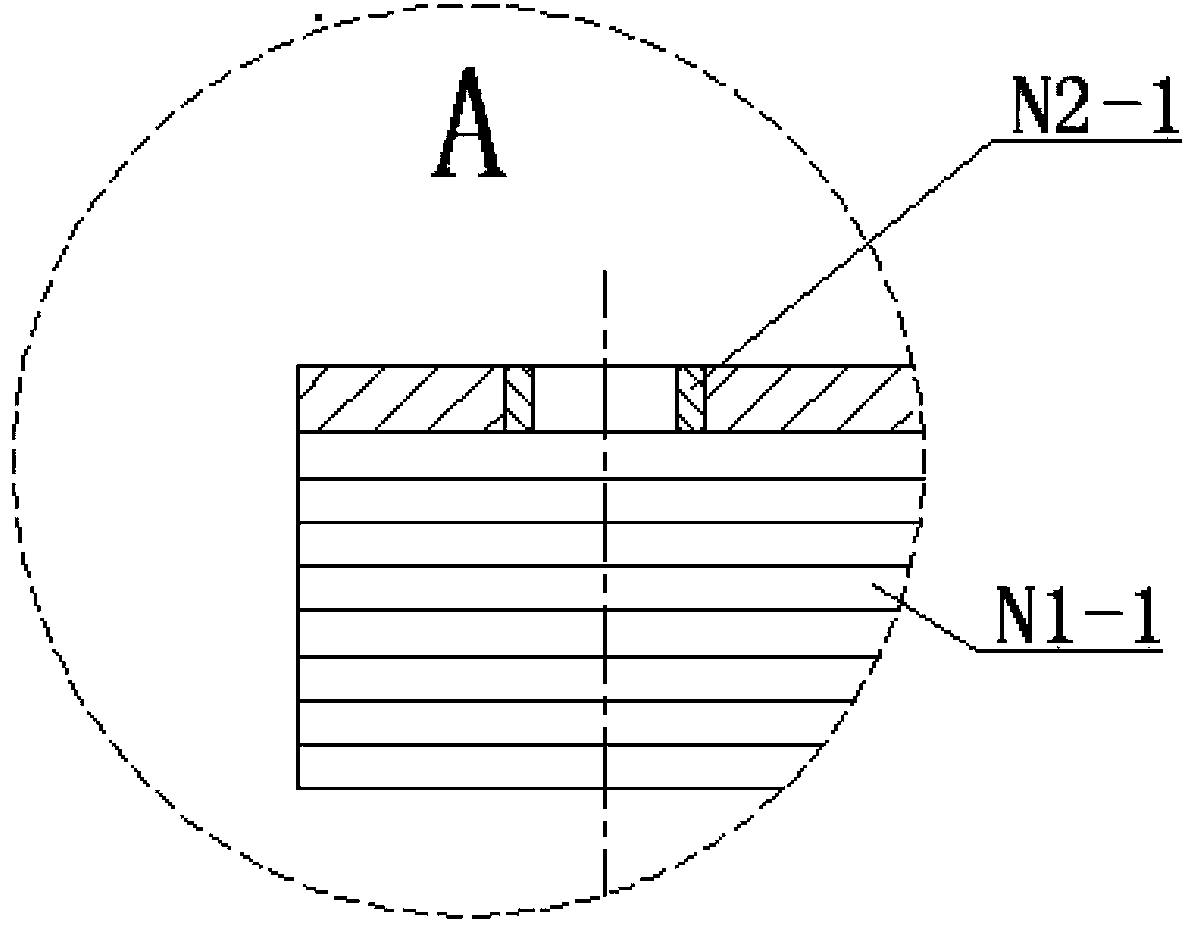

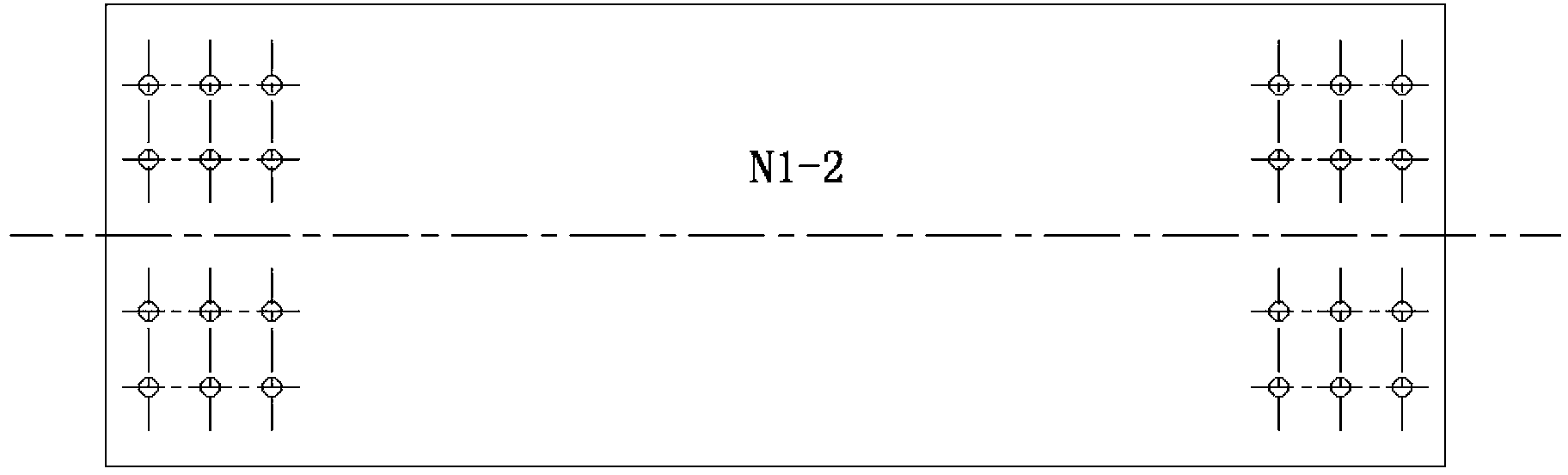

[0031] The process flow of the processing method of the U-shaped rib with holes of the present invention is as follows:

[0032] Steel plate pretreatment - scribing - flame cutting - stacking - milling length side - drilling - milling width side - milling bevel - profiling - inspection.

[0033] Key points of the technological process before U-shaped rib pressing of the present invention:

[0034] 1) Repeat the leveling of the steel plate material 6 to 8 times to eliminate the internal stress of the steel plate, which can greatly reduce the deformation produced in the subsequent processing.

[0035] 2) After the steel plate is pretreated, it is cut and blanked with a flame cutting machine. The width of each plate is the length of the U-shaped rib plus the reserved amount for milling on both sides and the width plus the reserved amount for milling on both sides, and the edge is machined and milled With a margin of 8mm (4mm on each side), hoist the flame-cut plates onto the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com