Tapper used for oscillation tool

An oscillating tool and hole opener technology, applied in the field of power tools, can solve problems such as inability to process, achieve the effect of improving efficiency and expanding application occasions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

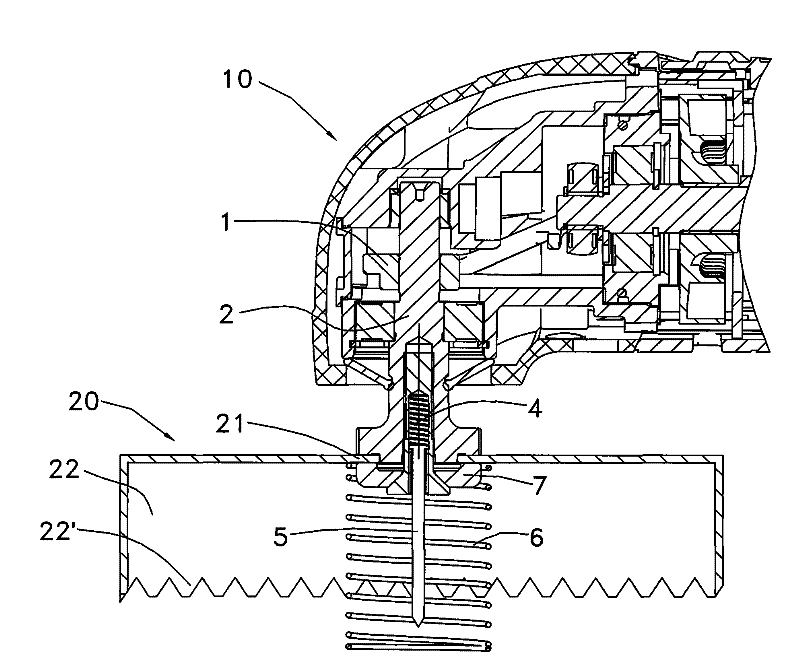

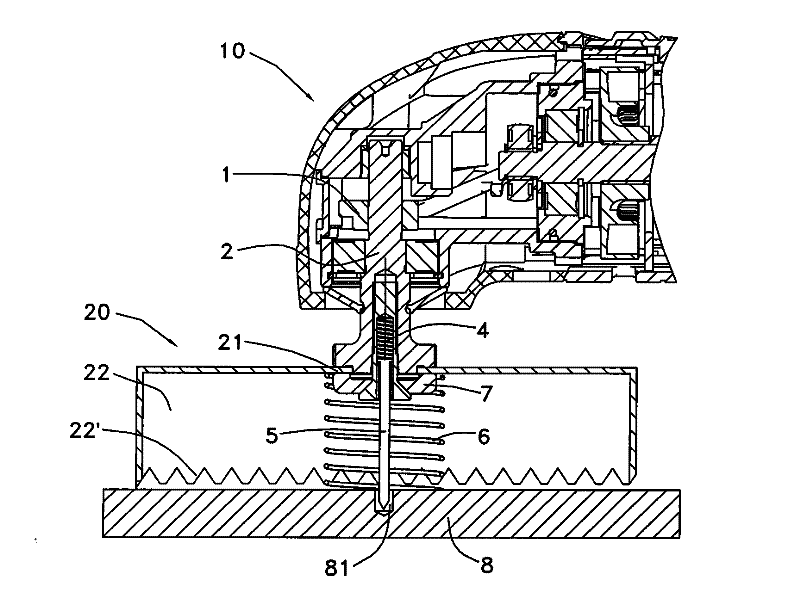

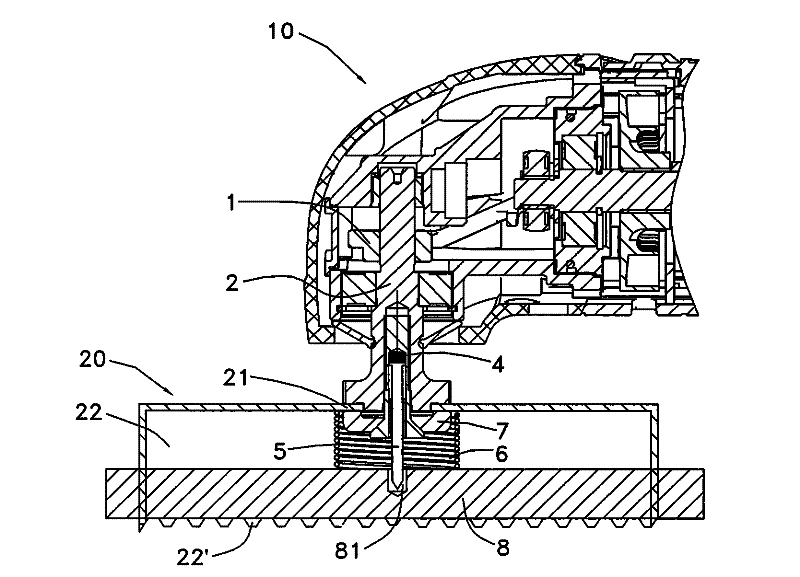

[0027] Such as Figure 1 to Figure 6 As shown, the power tool 10 of the present invention drives the working element in an oscillating manner to process the workpiece 8. The casing of the working head area of the power tool 10 supports an output shaft 2, and the output shaft 2 is driven by the vibrating support 1 around its longitudinal direction. The axis reciprocates with a small yaw angle and high frequency, and the shaft end of the output shaft 2 is equipped with a hole opener 20, combined with Figure 7 to Figure 9 , the hole saw 20 includes a fastening portion 21 having a receptacle 23 for mounting to the vibratory tool 10, the receptacle 23 defining a longitudinal axis Y around which the hole saw 20 can Driven in vibration, the fastening part 21 is connected with a hollow tool 22 having a material processing region 22', the direction of feed of the tool 22 in the workpiece being machined is substantially parallel to the longitudinal axis Y. The cutter 20 can be confi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com