Movable ultra-large-diameter karat pipe wall punching device

A technology of ultra-large diameter and mobile devices, which is applied in metal processing and other directions, can solve the problems of increasing the difficulty of installation and docking between pipes, waste of production costs and human resources, and difficulty in unifying the size of the openings, so as to improve the flexibility of opening holes , improve the efficiency of opening holes, and the effect of rapid collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

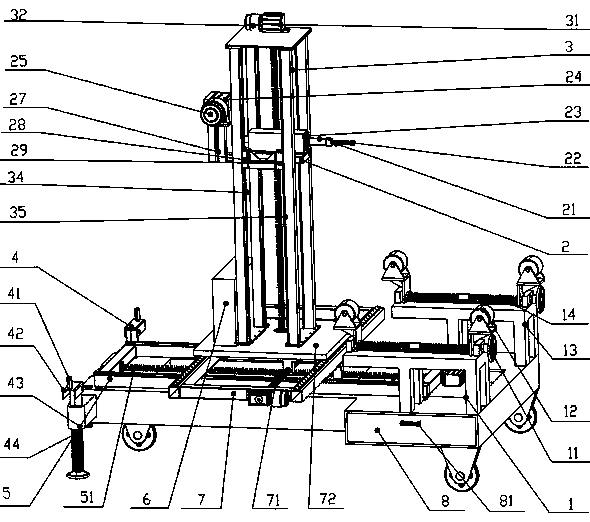

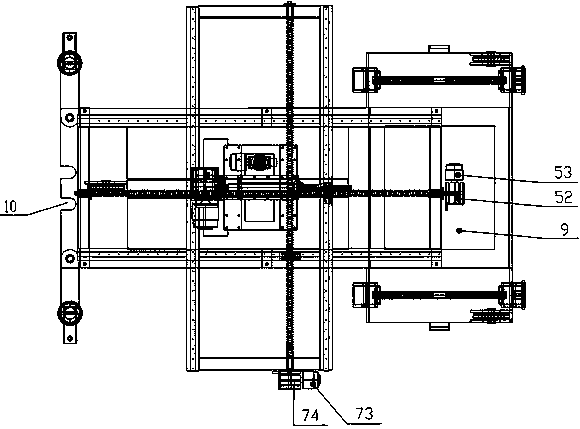

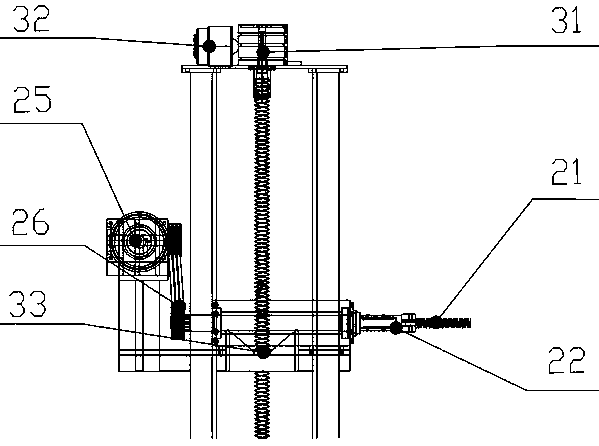

[0023] According to attached figure 1 It can be seen that the present invention is a movable ultra-large-diameter carat pipe wall opening device, which specifically includes a three-dimensional cutting platform, a movable trolley, a cutting tool seat 2 and a tool for controlling the movement of the cutting tool seat on the three-dimensional cutting platform. The X-axis moving device 7, the Y-axis moving device 5, and the Z-axis moving device 3; the cutting tool seat 2 is consolidated with the nut sleeve 33 of the Z-axis moving device 3, and the nut sleeve 33 is sleeved on the driving screw rod, and the driving screw rod The Z-axis reducer 31 and the Z-axis stepping motor 32 are installed in sequence. When the transmission screw is driven by the Z-axis stepping motor 32, the drive nut sleeve 33 drives the cutting tool holder 2 along th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com