Trepanning device used for copper bar insulation sleeve and use method thereof

A technology of hole opener and insulating sleeve, which is used in boring/drilling, drilling/drilling equipment, parts of boring machine/drilling machine, etc. Zinc layer and other problems, to achieve the effect of increasing the scope of application, reliable use, and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

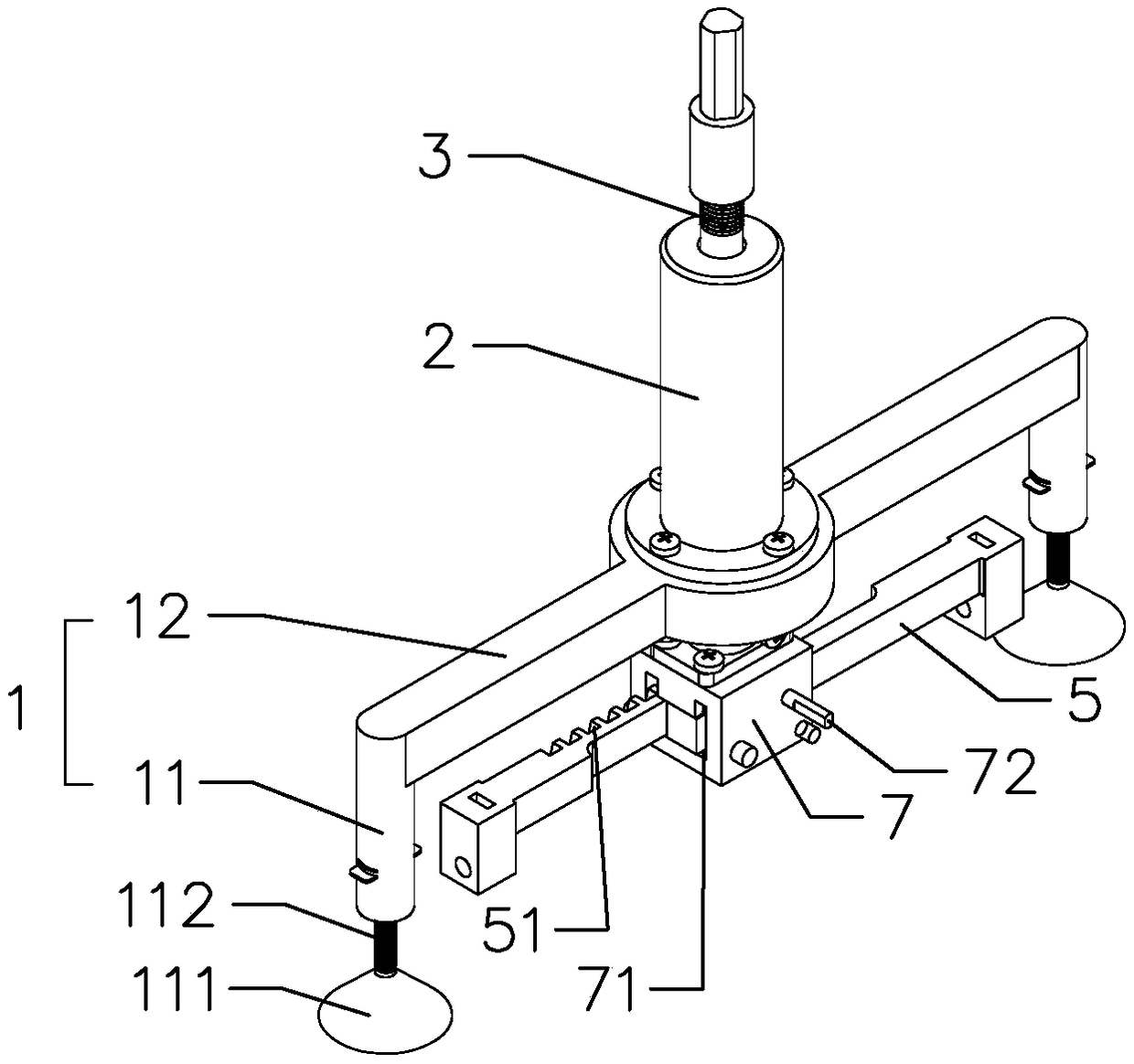

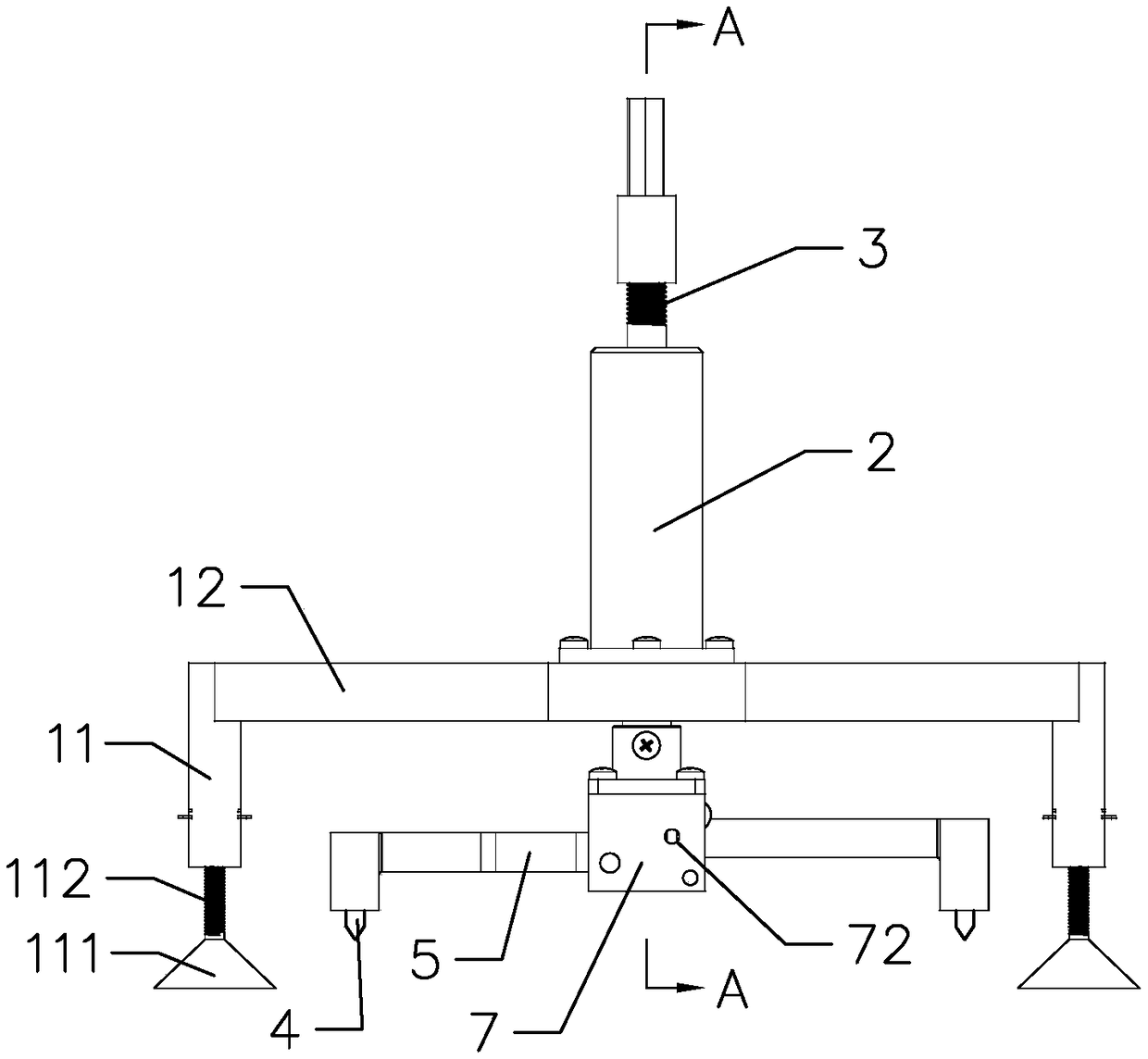

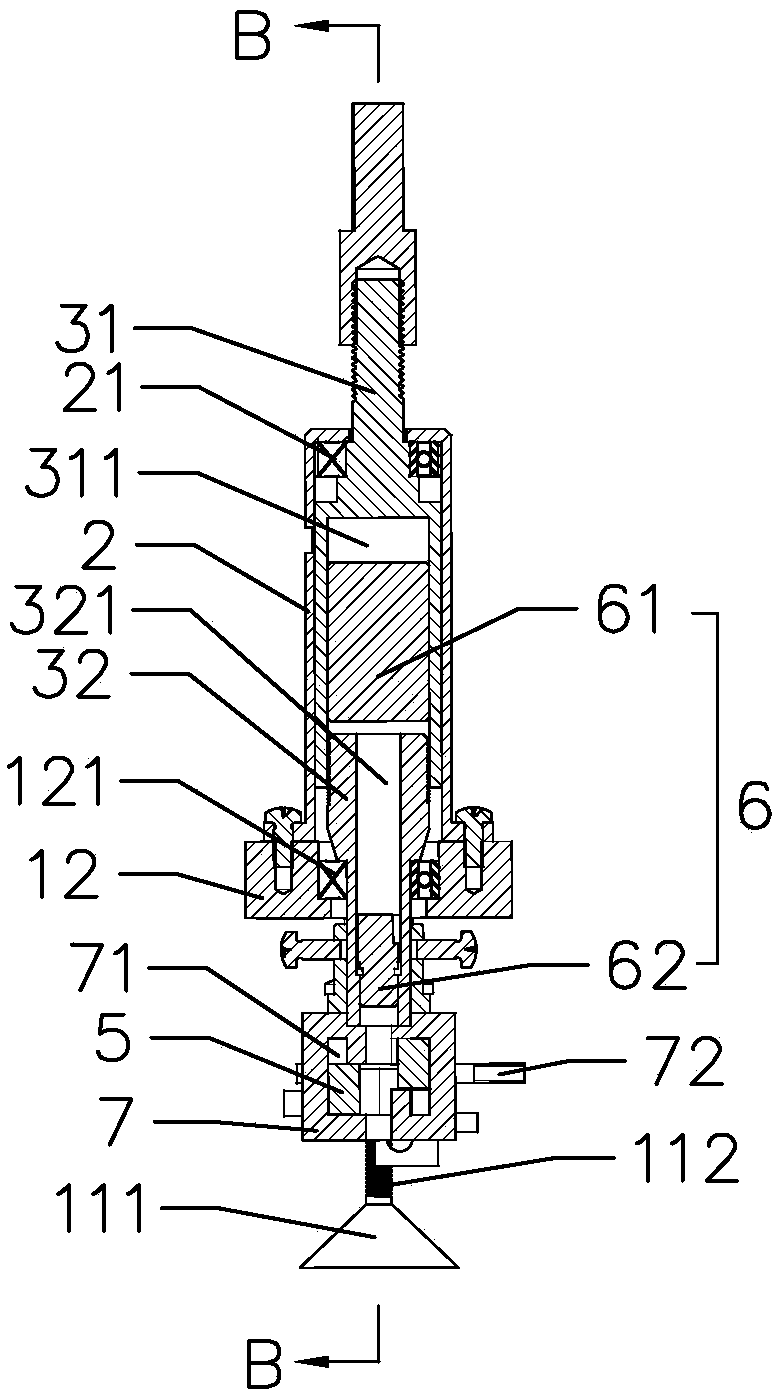

[0037] Such as Figure 1 to 4 As shown, the present invention provides a hole opener for copper bus insulation sleeves, which includes a mounting frame 1 and a hole-opening device. The mounting frame 1 includes two legs 11 and a beam 12 connecting the two legs 11. 1 The fixed hole-opening device makes the hole more stable. The hole-opening device includes a sleeve vertically installed on the beam 12, a connecting screw 3 located in the sleeve 2, and an opening knife 4 located at the lower end of the connecting screw 3. The knives 4 are vertically arranged with the cutting heads facing downwards. Two perforating knives 4 are provided and arranged symmetrically along the connecting screw 3. The lowest points of the cutting heads of the two perforating knives 4 are on the same horizontal plane. It is connected to the connecting screw 3 by two connecting bars 5 respectively. The connecting bars 5 are arranged horizontally and can be moved along its axis, so that the position of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com