Processing mechanism of integrated circuit board

A technology for integrated circuit boards and processing mechanisms, which is applied in the directions of printed circuits, printed circuit manufacturing, electrical components, etc., can solve the problems of insufficient drilling operation accuracy, waste of manpower, etc., and achieve the effect of facilitating the fixed installation of circuit boards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

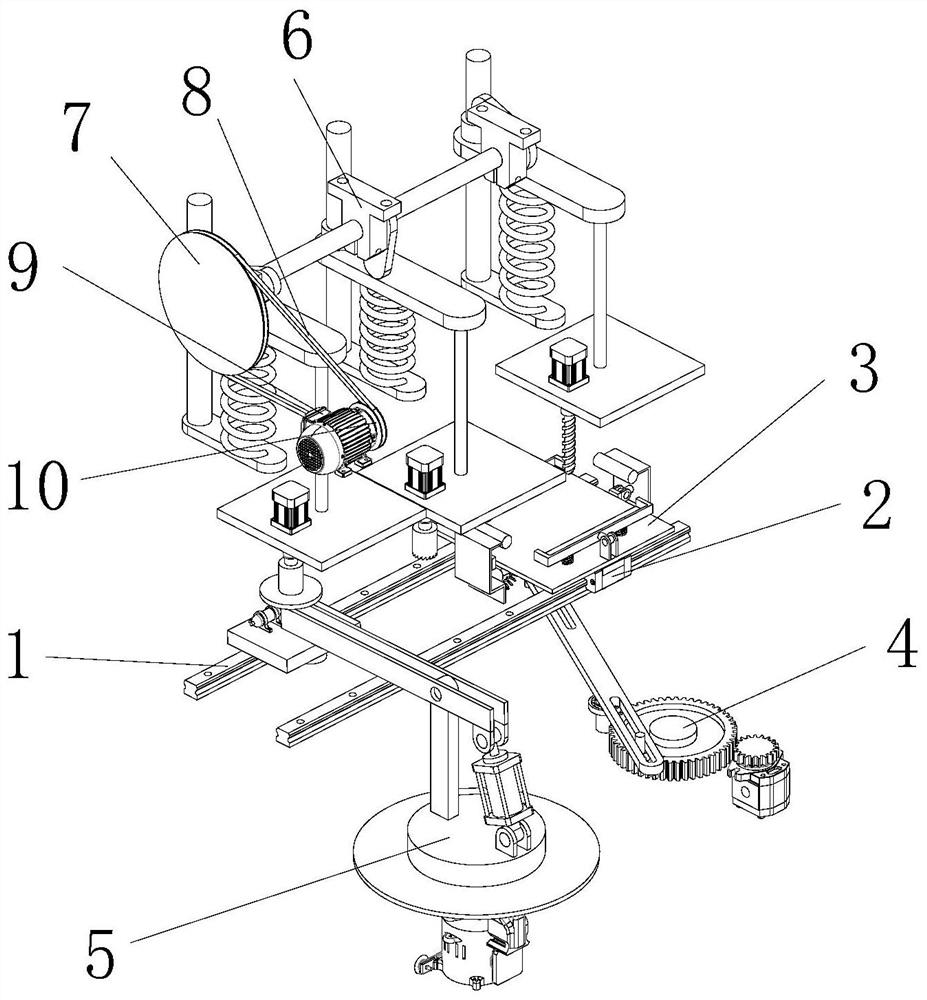

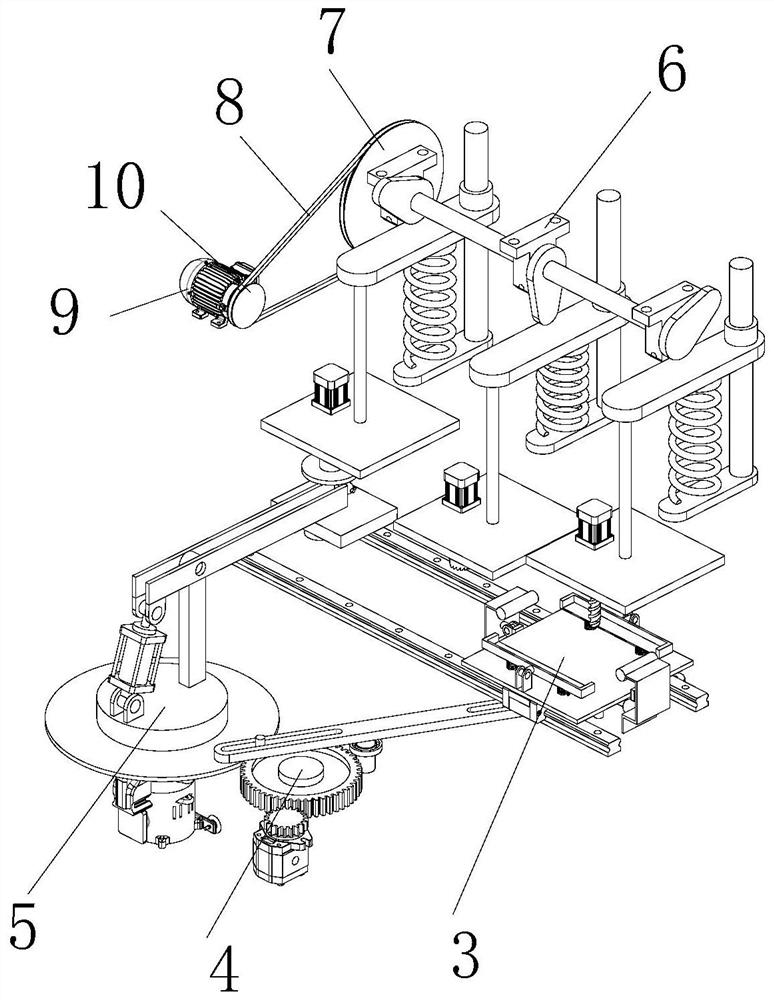

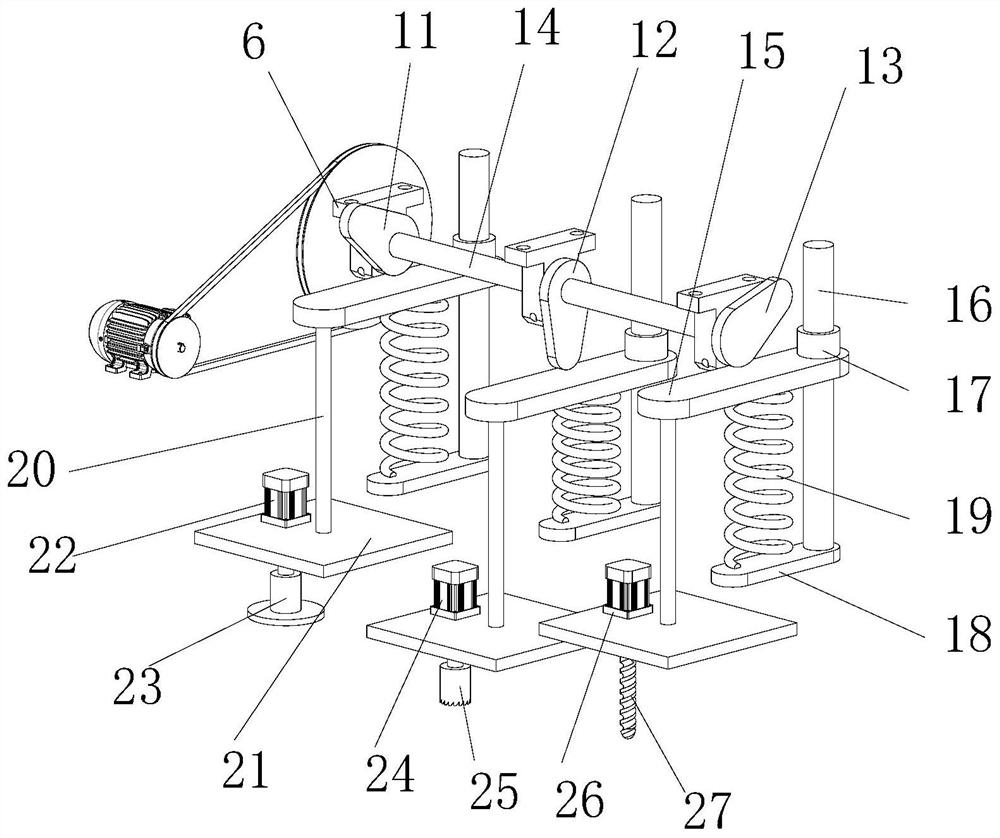

[0025] refer to Figures 1 to 8 The processing mechanism of a kind of integrated circuit board shown, comprises fixed guide rail 1, and described fixed guide rail 1 is provided with two altogether, and fixed guide rail 1 is fixedly installed, and described fixed guide rail 1 is equipped with slider 2, and slider 2 and the fixed guide rail 1 are slidingly connected, and the tops of the two sliders 2 are jointly fixed with a clamping assembly 3. The clamping assembly 3 includes a sliding plate 301, and the opposite sides of the sliding plate 301 are respectively fixed to the tops of the two sliding blocks 2. On the surface, the opposite sides of the upper surface of the sliding board 301 are fixedly equipped with first fixed hinge blocks 302, one side of each first fixed hinge block 302 is equipped with a rotating frame 303, and the middle of the rotating frame 303 is provided with a second A round rod matching the fixed hinge block 302, two pressure springs 304 are arranged on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com