Tapping method for pipeline arc surface and cutting torch support adjusting device for tapping

A technology of adjusting device and curved surface, applied in welding equipment, gas flame welding equipment, metal processing equipment, etc., can solve the problems of irregular opening shape, dense distribution, heavy workload, etc., to improve cutting accuracy and simple operation , The effect of easy disassembly and assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below, combine Figure 1-8 The method for opening holes on the curved surface of pipelines and the cutting torch support adjustment device for opening holes of the present invention will be described in detail.

[0033] The method for opening holes on the curved surface of the pipeline of the present invention comprises the following steps:

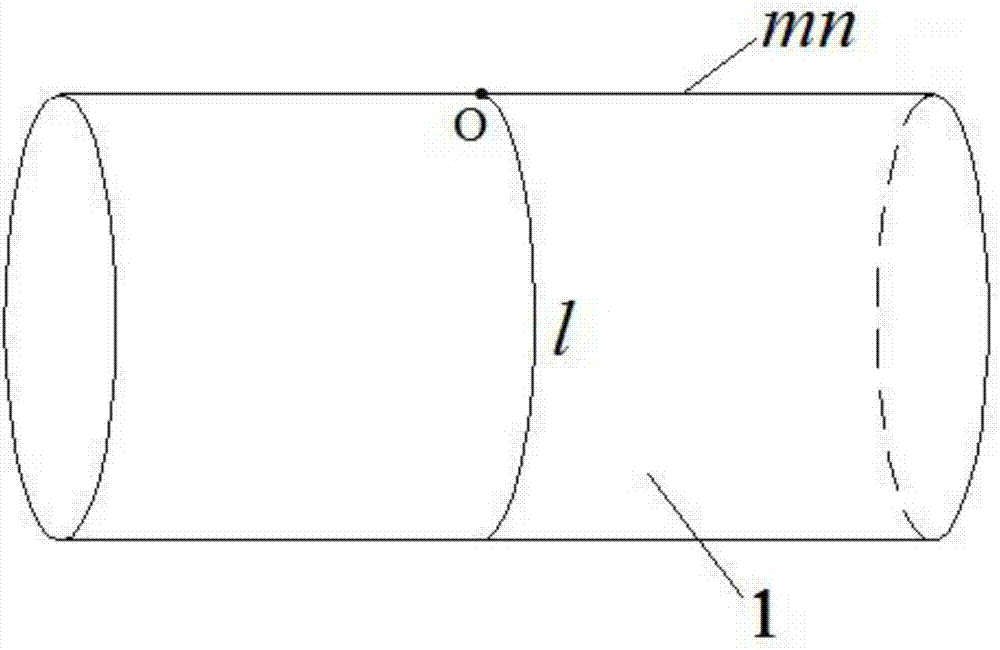

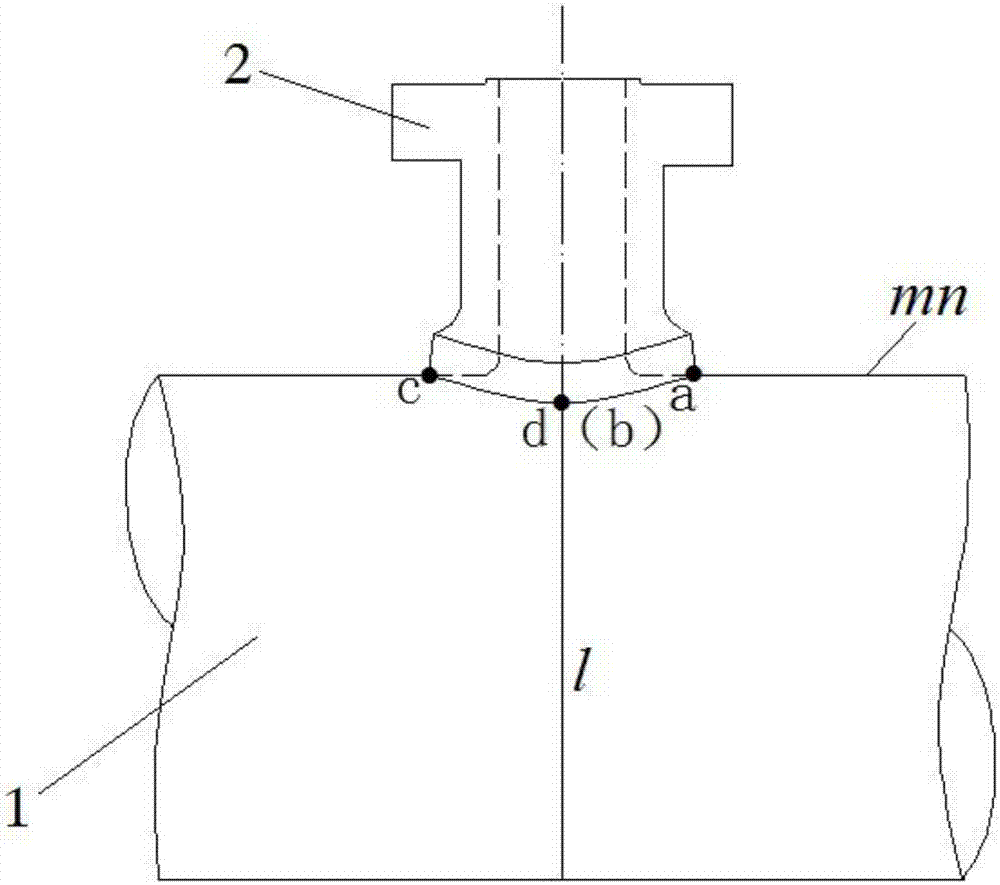

[0034] Step S1, according to the designed opening position, use a measuring ruler to measure the distance between the end surface of the perforated pipeline 1 and the center point O of the perforated pipeline on the outer surface of the perforated pipeline 1, so that Mark the position of the center point O of the opening, such as figure 1 As shown, and on the outer surface of the perforated pipeline 1, the axial positioning line mn and the circumferential positioning line l passing through the center point O of the perforated pipe are drawn.

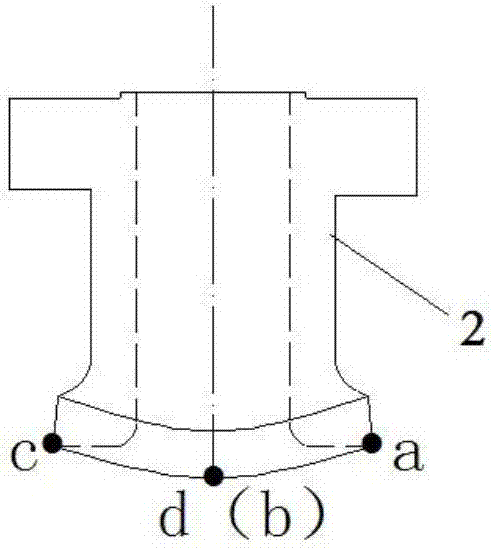

[0035] Step S2, in such as figure 2 Four positioning points a, b, c and d are marked ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com