Personalized mask printing device and mask making and use method

A printing device and facial mask technology, which is applied to the surface coating liquid device, spray device, liquid spray device, etc., can solve the problem of broken or broken masks, achieve small size, strong continuity, and meet the needs of facial care Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

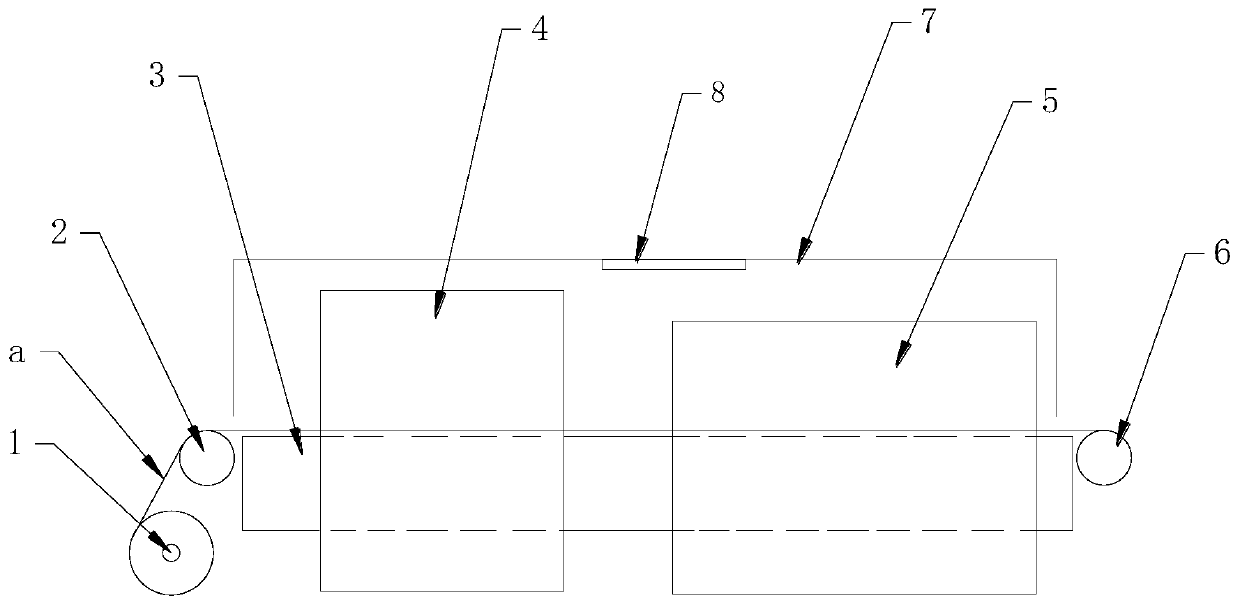

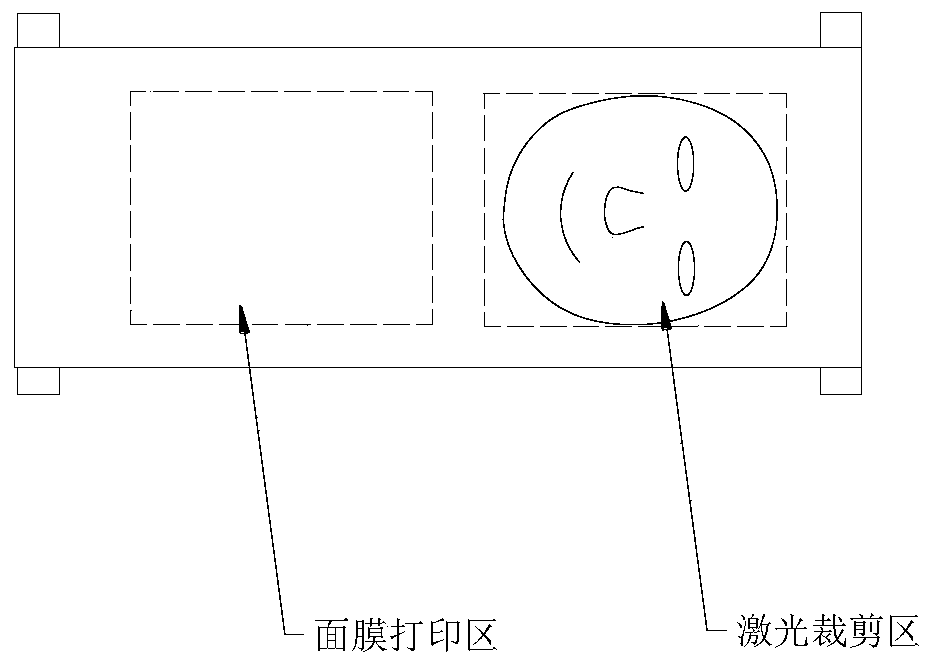

[0043] See attached Figure 1-4 , a personalized facial mask printing device, including a film cloth roll placement part 1, a guide roller 2, a driving roller 6, a support platform 3, a facial mask printing unit 4, a laser cutting unit 5 and a cover body 7.

[0044] The guide roller 2 is arranged on the tail side of the support platform 3, the driving roller 6 is arranged on the tail side of the support platform 3, and the film cloth roll placement part is also located at the tail side of the support platform 3. During work, the film cloth roll is installed on the film cloth roll. The cloth roll is placed on the rack, and then the film cloth a is pulled out, so that the film cloth passes through the guide roller 2 and the support platform 3 in sequence, and is fixed on the driving roller 6, and the film cloth is fed by the driving roller 6.

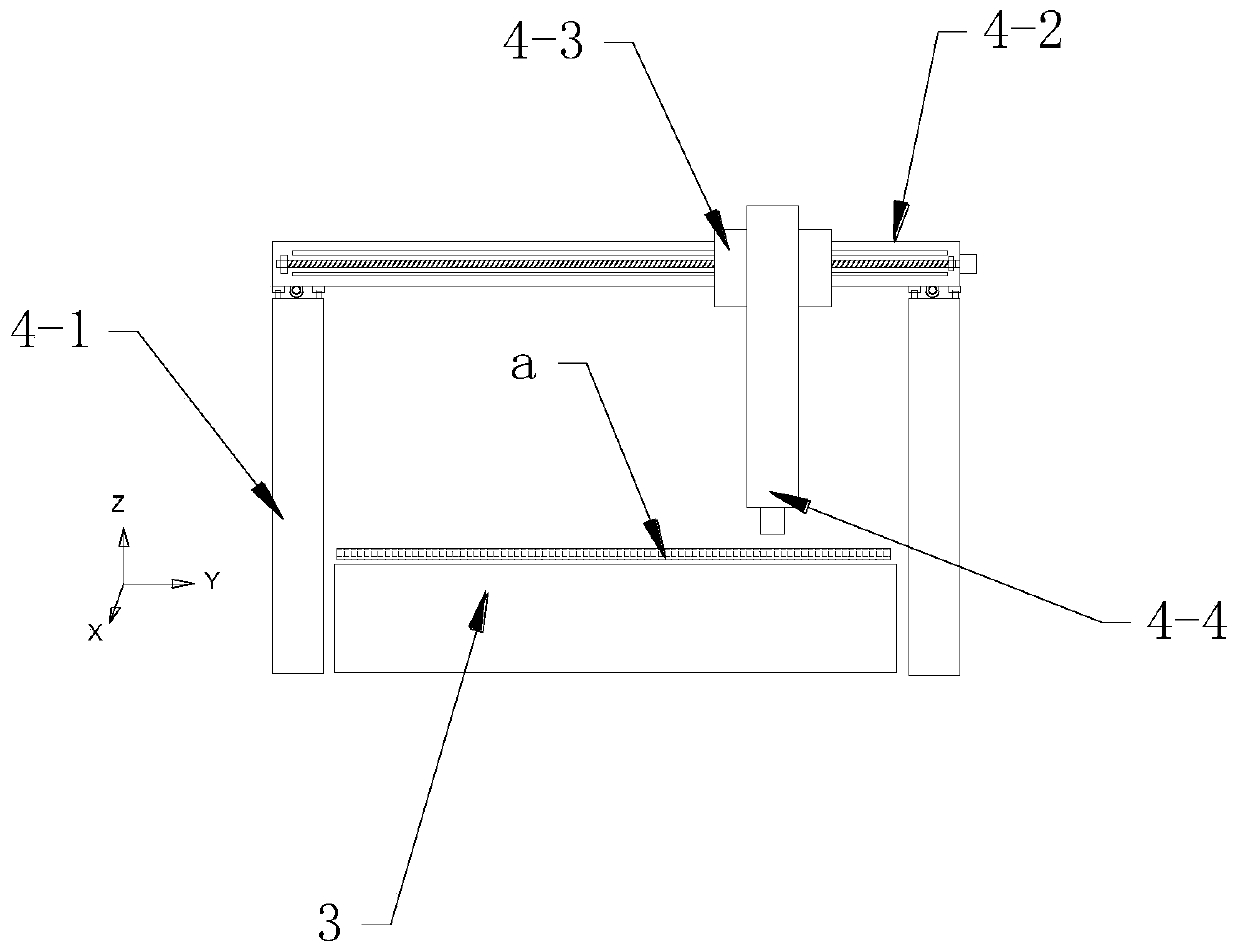

[0045]The mask printing unit 4 is arranged across the support platform 3, and is used to print various skin care essences on the film cl...

Embodiment 2

[0051] On the basis of Embodiment 1, further, refer to the attached Figure 5 , the cover body is also provided with a FUU laminar flow hood 9 (full name is Fan Filter Unit, that is, fan filter unit), its function is to form a uniform flow layer after the air passes through the high-efficiency filter at a certain wind speed, so that the clean air is Vertical one-way flow ensures the cleanliness required by the process in the working area.

Embodiment 3

[0053] On the basis of Embodiment 1, further, the personalized facial mask printing device of the present invention also includes a drying unit, the drying unit includes a heating unit and a fan unit, and the heating unit can be arranged inside the cover body, or can be It is arranged at the lower part of the support platform or other effective heating positions that can act on the membrane cloth. The fan unit is arranged on the cover body, and the air flow around the membrane cloth is strengthened by the fan unit to promote the drying of the membrane cloth. Furthermore, the fan unit is preferably a FUU laminar flow hood with a filtering function (full name is Fan Filter Unit, ie fan filter unit).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com