Industrial robot teaching station

A technology of industrial robots and workstations, applied in teaching models, instruments, educational appliances, etc., can solve problems such as poor structural integrity and compactness, inability to know the correct assembly of materials, and inability to fully meet teaching needs, etc., to achieve high precision in automated assembly , good structural integrity and compactness, and high degree of automation integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

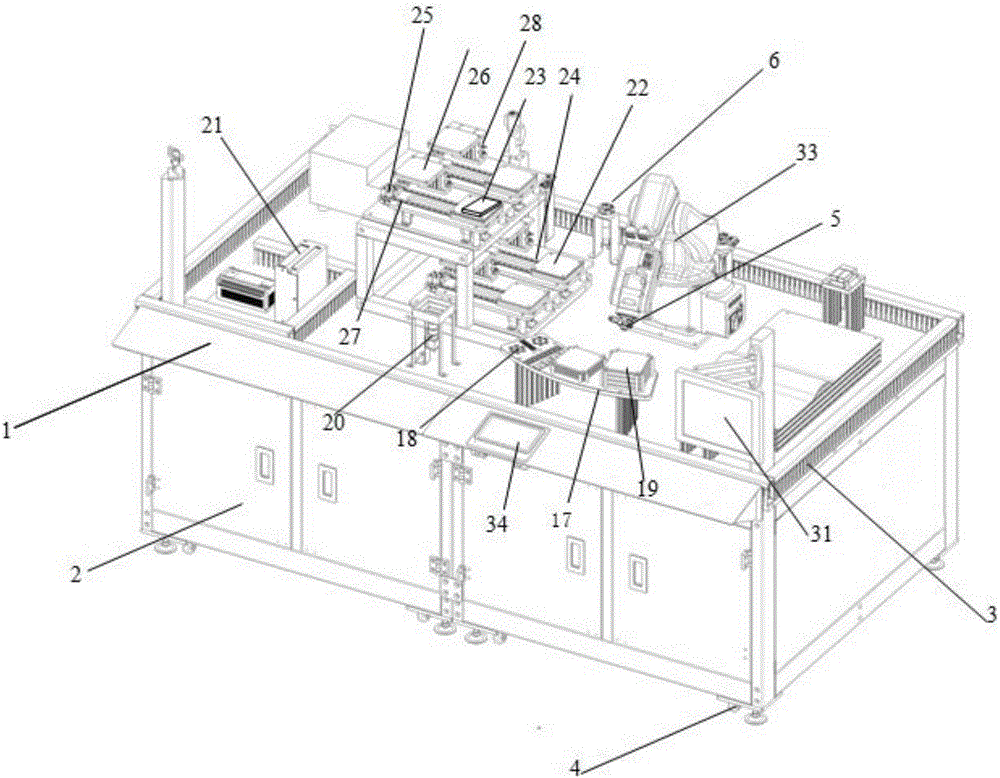

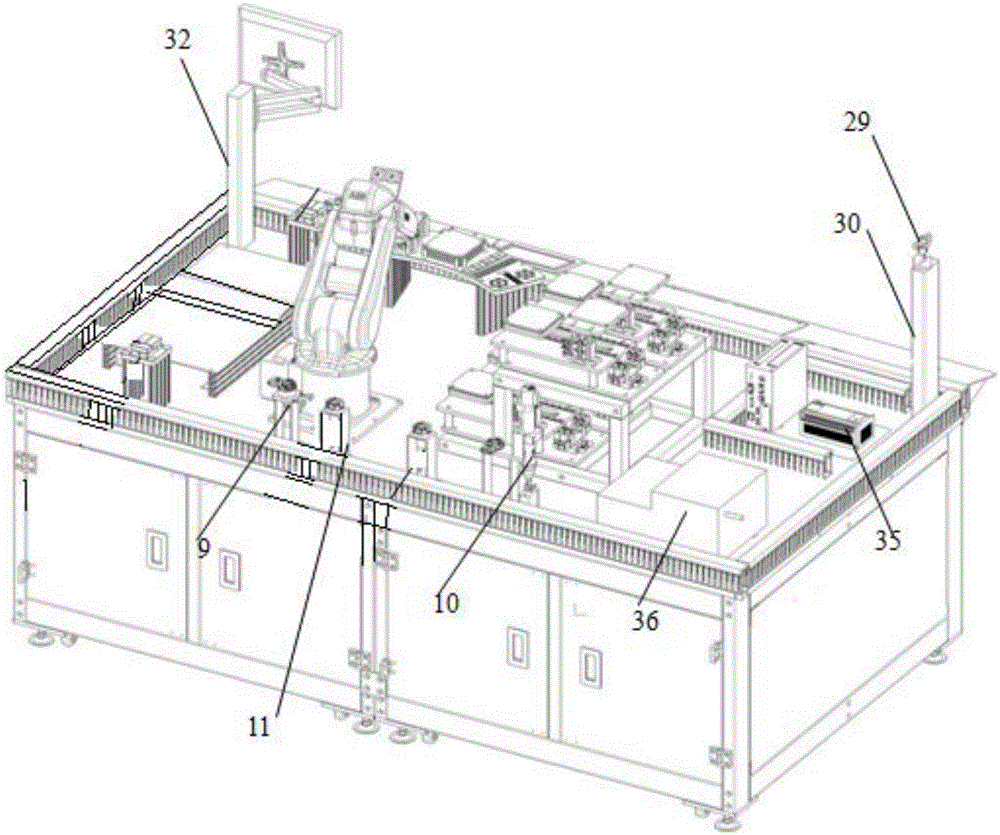

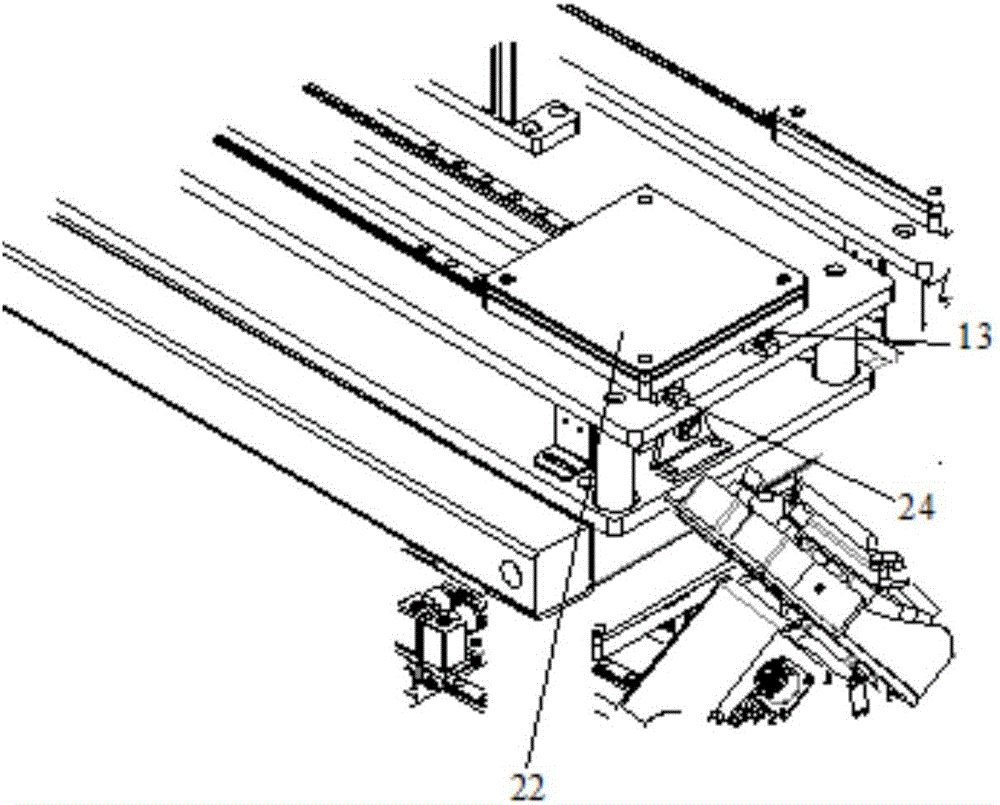

[0036] This embodiment proposes a preferred industrial robot teaching workstation, such as Figure 1 to Figure 6 As shown, the industrial robot teaching workstation includes a workbench cabinet 1 with a work surface, an industrial robot body 33, an industrial robot controller, an industrial robot teaching device, a tool quick change system, a special-shaped chip raw material unit, a visual inspection unit 20, a special-shaped Chip assembly unit, screw feeding unit 36, monitoring system and other components.

[0037] The side of the workbench cabinet 1 of this embodiment is provided with a door 2, and the inside of the workbench cabinet 1 can store objects. The outer periphery of the worktable on the upper surface of the workbench cabinet 1 is provided with wir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com