Tin wire cutting machine controllable in tin amount

A cutting machine and tin wire technology, applied in auxiliary devices, manufacturing tools, metal processing equipment, etc., can solve the problem of inaccurate control of the amount of tin, and achieve the effects of convenient welding process, high automation integration and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

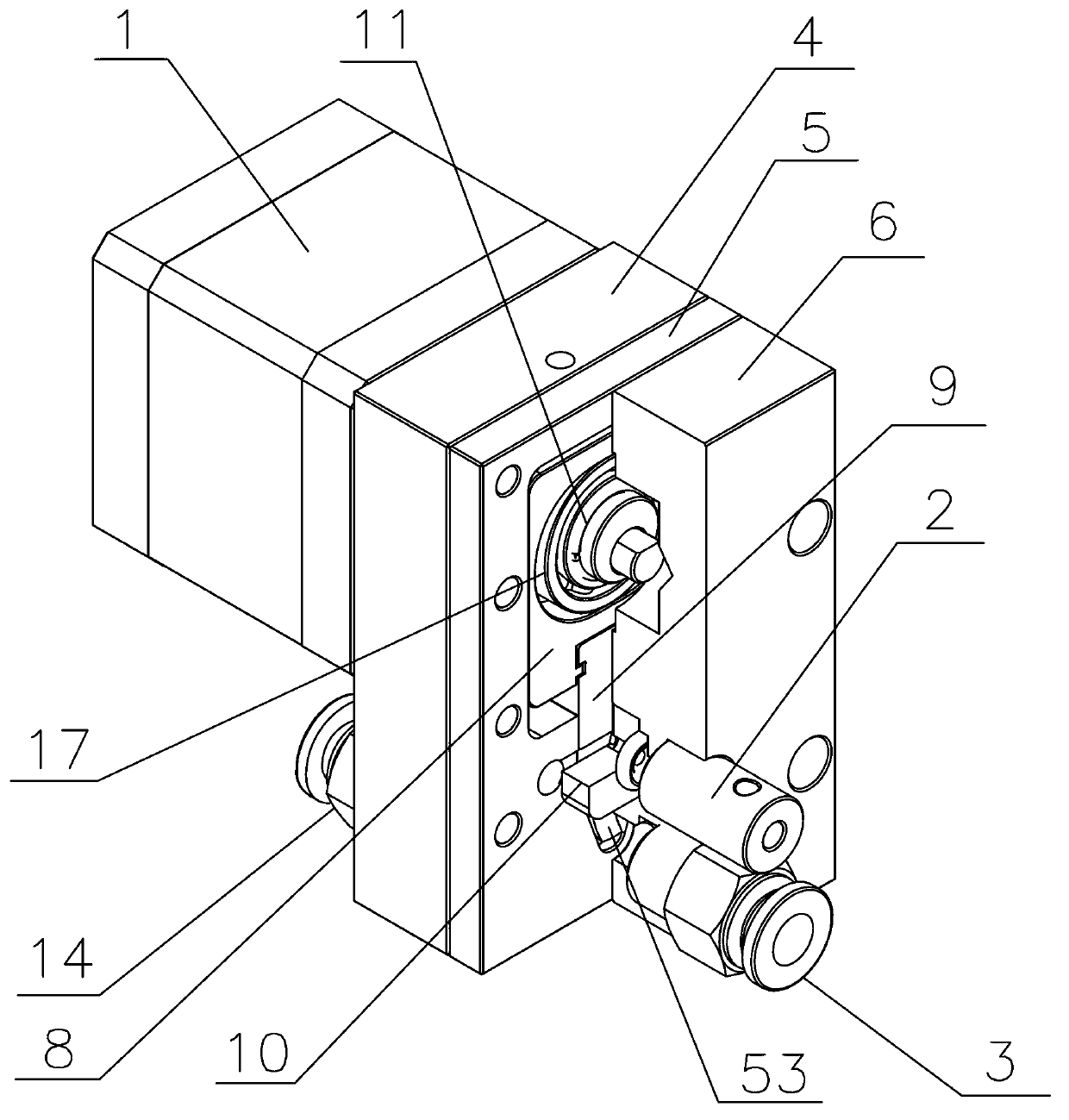

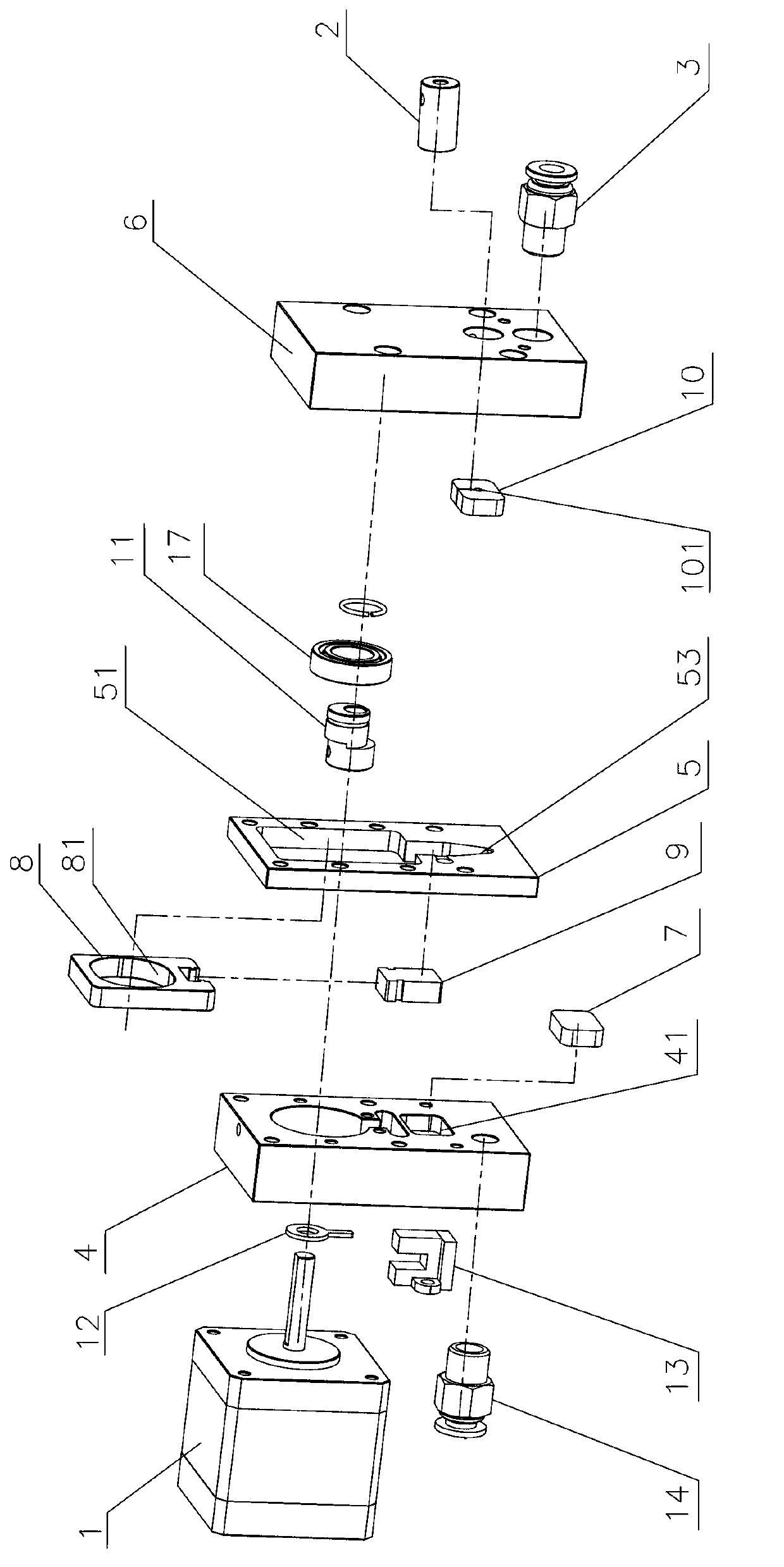

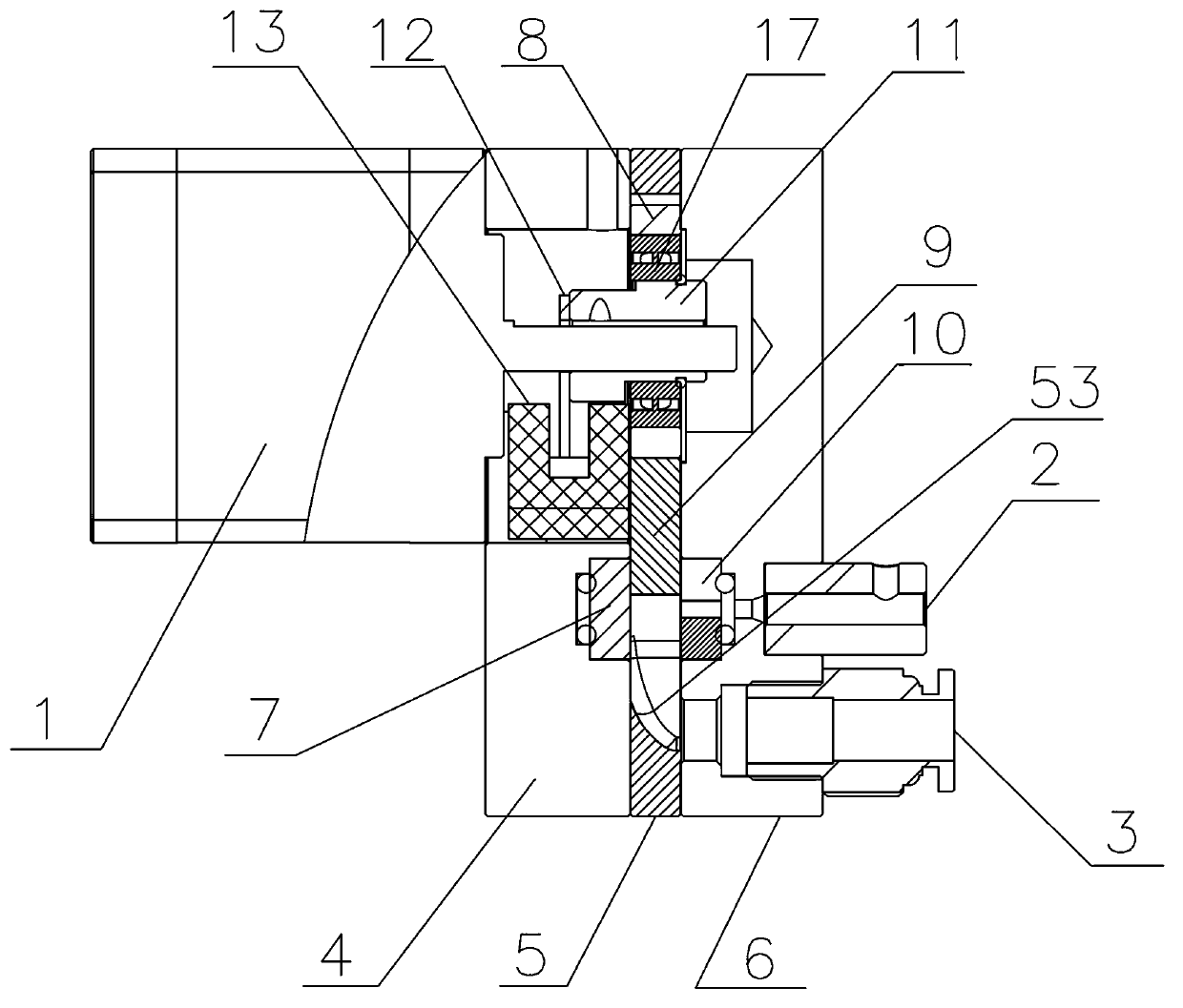

[0028] refer to figure 1 figure 2 image 3 , including a motor 1, the motor shaft of the motor 1 is equipped with a wire cutting device that can perform radial reciprocating movement relative to the motor shaft, and the wire cutting place of the wire cutting device is equipped with a tin wire feeding column 2 for continuous wire feeding, and the wire cutting device The blanking part of the device is equipped with a tin pipe joint 3. The wire cutting device includes a motor fixing plate 4, a blade fixing plate 5 and a front cover 6 which are superimposed and fixed in sequence. The motor 1 is fixedly installed on the end face of the motor fixing plate 4, and the motor is fixed. The end face bottom of plate 4 has first blade groove 41, and first blade groove 41 is embedded with first fixed blade 7, and the end face of blade fixed plate 5 has slider groove 51, and slider groove 51 below has and The slider groove 51 is connected to the second blade groove 52, and the second blad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com