Material taking and feeding device for mechanical automatic part machining

A technology for reclaiming, feeding, and spare parts, applied in conveyor objects, conveyors, transportation and packaging, etc., can solve the problems of low workpiece processing production efficiency, discontinuous feeding, high labor intensity, etc., and achieve a high degree of automation integration. , Improve production efficiency and improve the effect of processing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

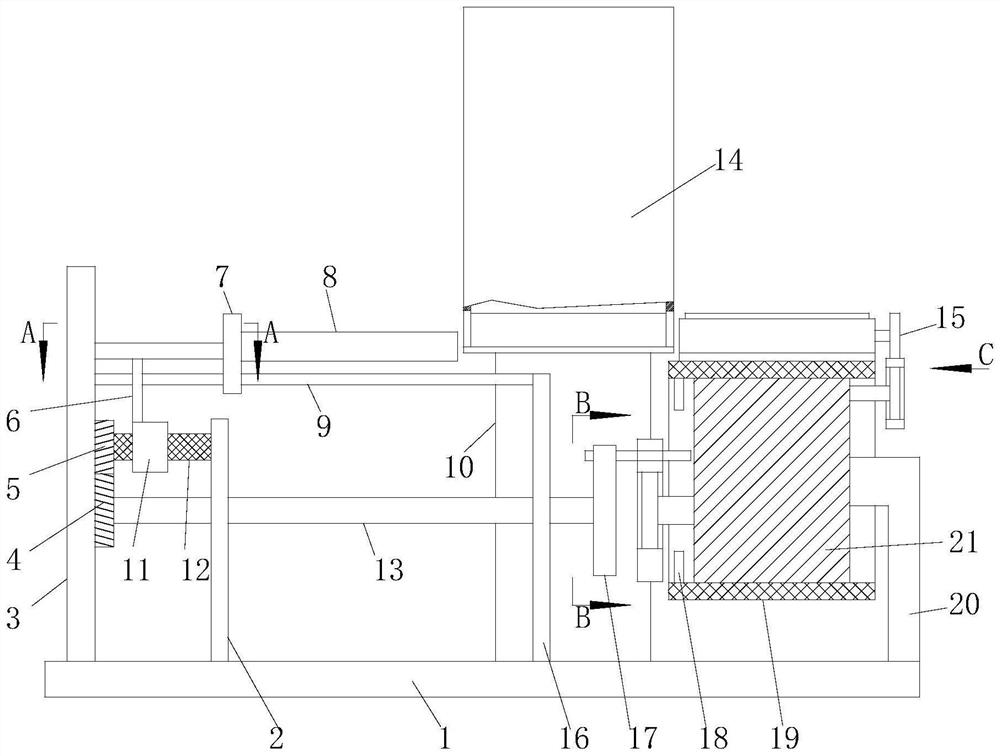

[0029] A feeding and retrieving device for mechanical automation spare parts processing, including a base 1, and also includes:

[0030] A reclaiming mechanism arranged on the base 1;

[0031] The feeding mechanism arranged on the base 1, the feeding mechanism can drive the retrieving mechanism to place the workpiece on the feeding mechanism, and the feeding mechanism adopts an intermittent operation mode to feed the workpiece;

[0032] The cleaning mechanism is arranged on the feeding mechanism, and the feeding mechanism drives the cleaning mechanism to clean the surface of the workpiece on it during the feeding process.

Embodiment 2

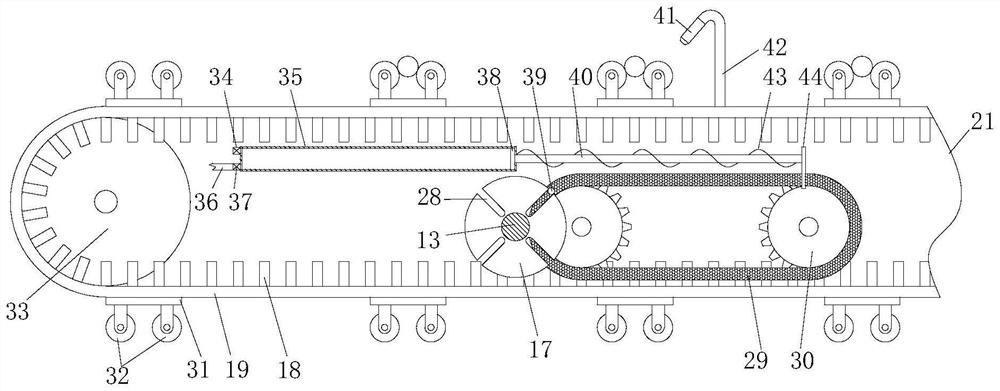

[0034] Embodiment 2 is realized on the basis of Embodiment 1: in this embodiment, the feeding mechanism includes a frame 21, and the frame 21 is fixed on the base 1 by a bracket five 20, and the side wall of the frame 21 rotates on a fixed axis Two sprockets-30 are connected, and the two sprockets-30 are connected through a chain-29 transmission, and one of the sprockets-30 is connected with the motor transmission, and the motor is fixed on the frame 21. The motor is not shown in this application. Out, the shaft 39 is connected with the fixed axis rotation on the chain one 29, and the motor drives the sprocket one 30 to make the sprocket one 30 drive the shaft rod 39 through the chain one 29 to be intermittently connected with the feeding mechanism and the cleaning mechanism respectively. The two ends of the frame 21 are connected with a roller 33 with a fixed shaft rotation, and the two rollers 33 are connected by a transmission belt 19. A plurality of supporting seats 31 are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com