Control valve superior and inferior product checking and sorting mechanism, control valve machining equipment and machining and control method

A kind of processing equipment, high-quality technology, applied in the field of quality inspection and sub-organization of control valve, can solve the problem of low efficiency of manual assembly of control valve, and achieve the effect of eliminating manual operation, improving production efficiency and quality, and accurately placing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

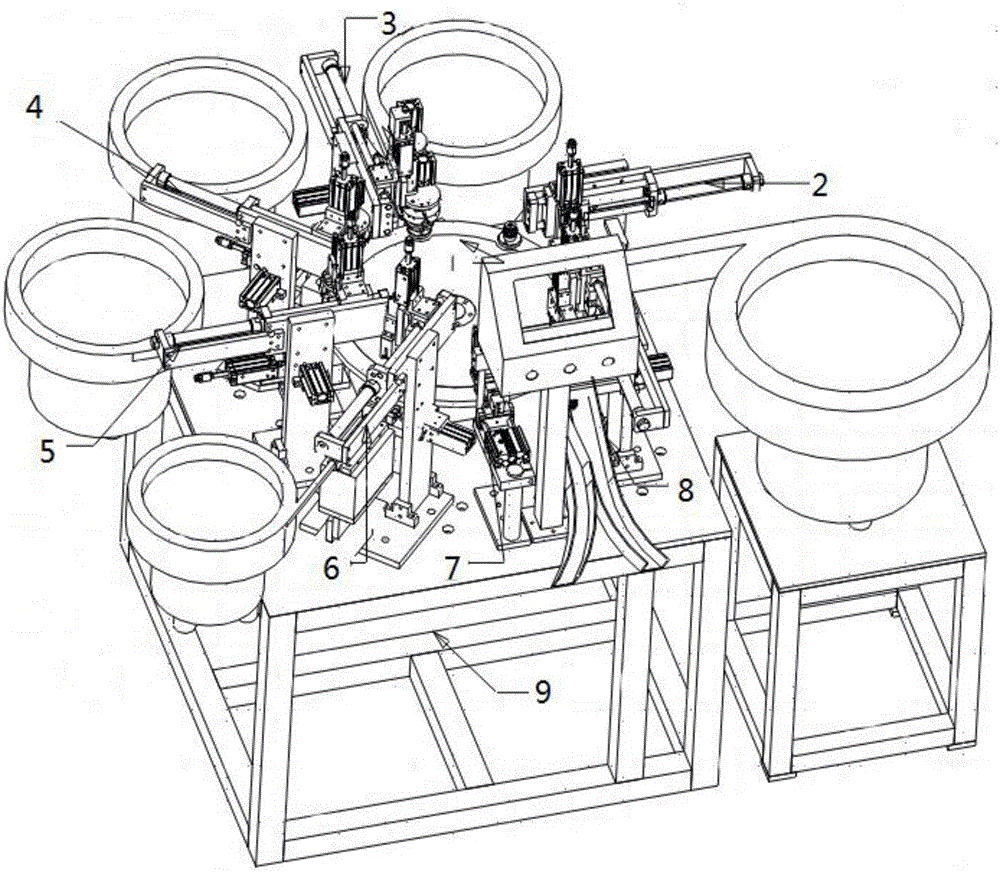

[0056] combine figure 1 , a control valve processing equipment, including a turntable dividing mechanism 1 and an electric control system 9, and also includes an automatic feeding and installation mechanism and a control valve outlet mechanism, wherein the electric control system 9 controls the turntable dividing mechanism 1 and the electric control system 9 respectively During the action execution process, the turntable dividing mechanism 1 receives the control valve to be processed from the automatic feeding equipment of the automatic feeding and installation mechanism, and the installation equipment of the automatic feeding and installation mechanism installs and processes the components on the control valve, and the control valve outlet mechanism is facing With the turntable dividing mechanism 1, the control valve outlet mechanism discharges the processed control valve.

[0057] The turntable dividing mechanism 1 is evenly equipped with control valve fixtures, and the auto...

Embodiment 2

[0068] This embodiment is a good and bad product inspection and classification mechanism applied in embodiment 1, including a good and bad product detection mechanism 7 and a separation mechanism 8, and the signal detected by the good and bad product detection mechanism 7 is transmitted to the electric control system 9, and the electric control system 9 The control system 9 controls the separation mechanism 8 to perform corresponding actions, and collects the good and bad products in the processed control valve separately.

[0069] The good and bad product detection mechanism 7 is located between the valve needle automatic feeding and installation mechanism 5 and the control valve outlet mechanism. Carry out the detection of good and bad products, distinguish good and bad products, improve the quality of control valves, provide users with better quality service and experience, and improve the influence of enterprises.

[0070] There is a separation mechanism 8 at the outlet me...

Embodiment 3

[0075] This embodiment is a valve control processing method applied in Embodiment 1 or Embodiment 2, and its steps are:

[0076] A. According to a control valve processing equipment described above, place the corresponding materials in the vibrating plate of the automatic feeding and installation mechanism, and the valve body of the control valve is along the vibrating plate of the automatic feeding and installation mechanism 2 of the valve body. The slide rails enter the valve body fixture at the end of the slide rails in turn;

[0077] B. The mechanical arm of the valve body automatic feeding and installation mechanism 2 removes the valve body from the valve body fixture and places it above the valve control fixture of the turntable dividing mechanism 1;

[0078] C. The mechanical arm of the valve body automatic feeding and installation mechanism 2 is lowered, and the valve body is placed on the valve control fixture;

[0079] D. The lower apron enters the lower apron fixtu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com