Laser cleaning equipment for tire mold

A technology for cleaning equipment and tire molds, applied in cleaning methods and appliances, chemical instruments and methods, etc., can solve the problems of lack of automatic equipment for cleaning tire molds, reduce maintenance and replacement costs, and achieve high automation integration. The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

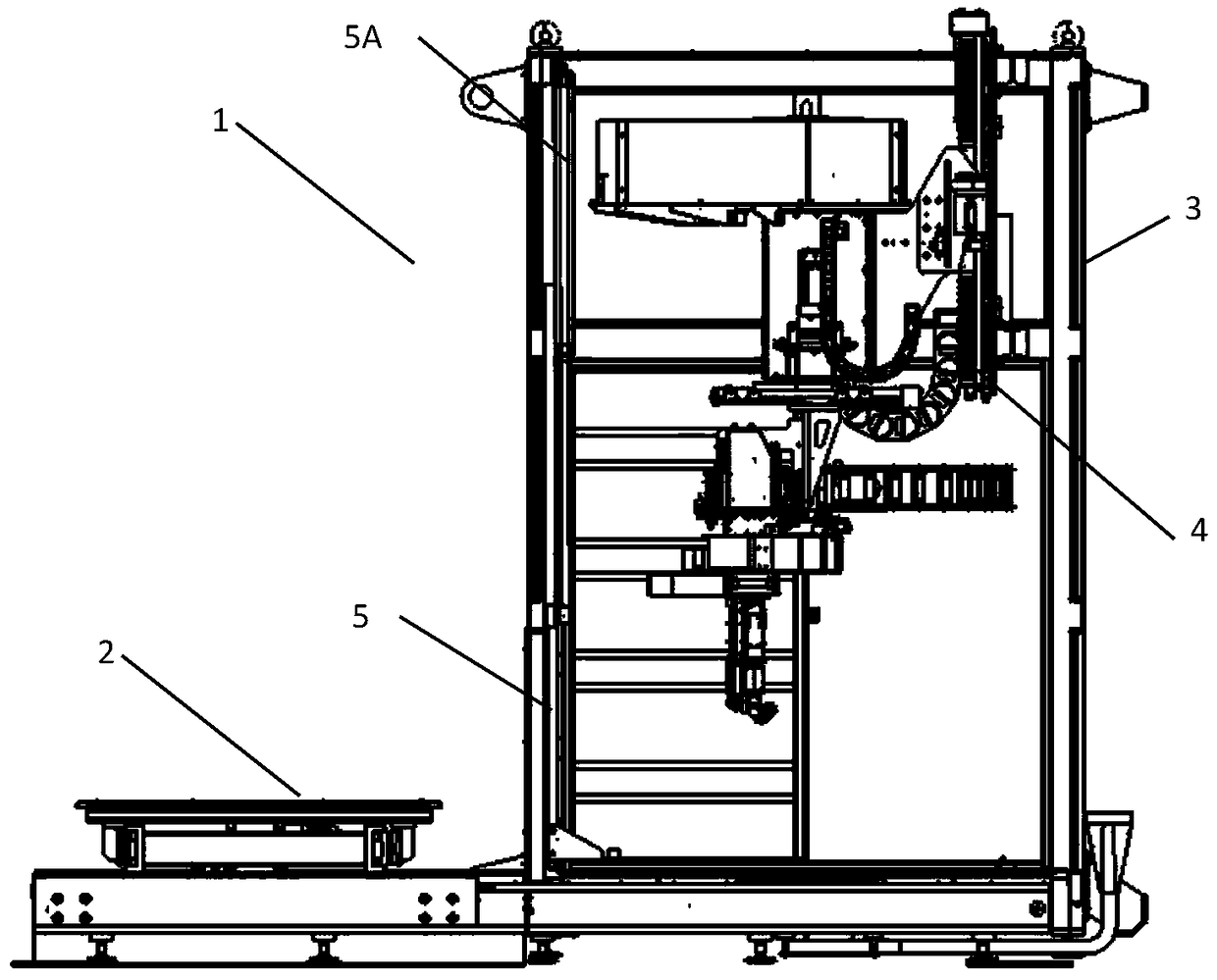

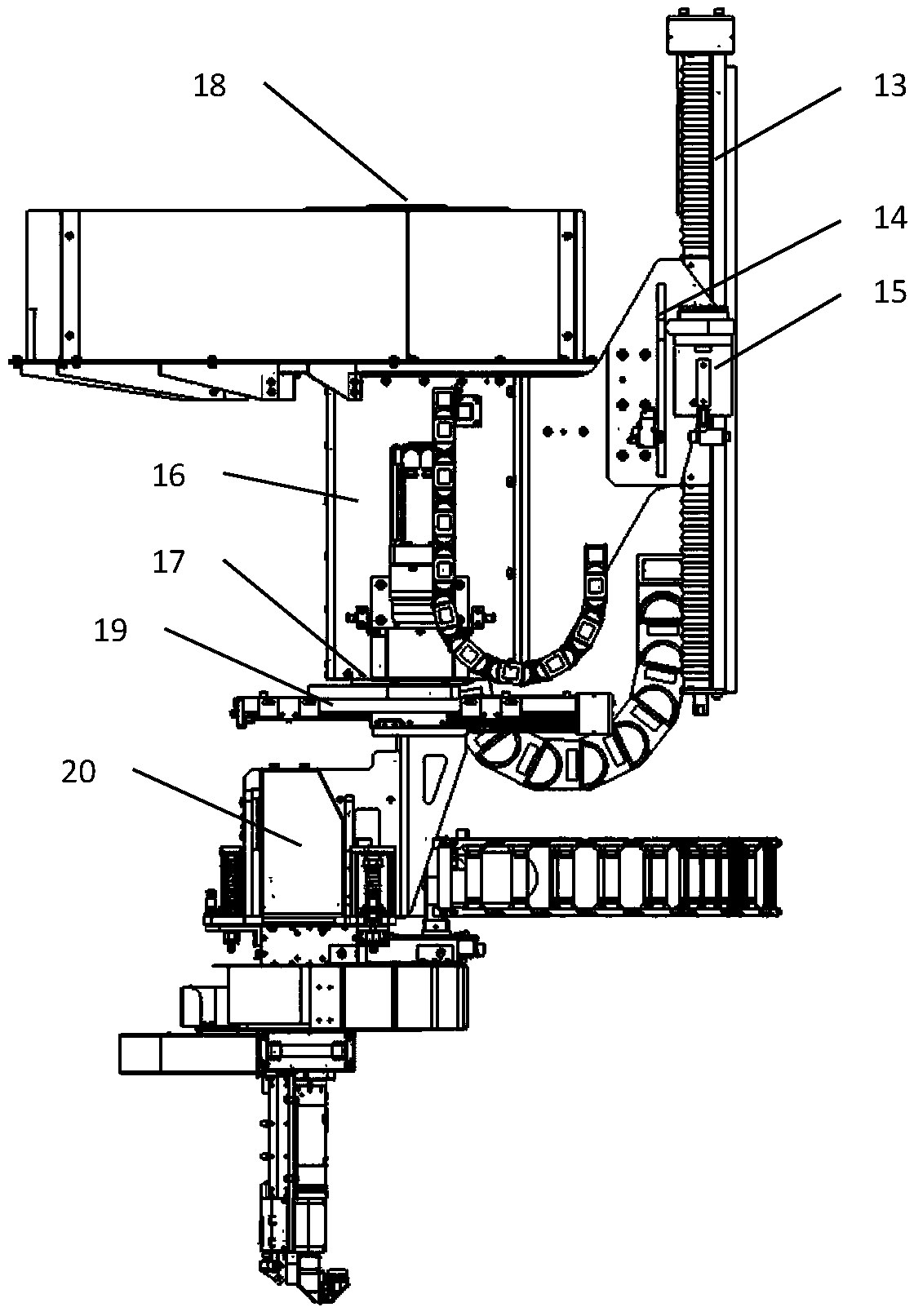

[0055]The tire mold laser cleaning equipment 1 includes the X1 and Y1 working platforms 2 that can carry the mold and move in the direction. Above it is the basically closed whole machine support 3 of the equipment. Inside the whole machine support 3, the equipment processing head part 4 is fixed, and the automatic lifting door 5.

[0056] The main function of the whole machine support 3 is to provide a substantially airtight space during cleaning, so as to facilitate the recovery of the smoke generated by processing. Wherein the processing head part 4 is connected and fixed with the whole machine support 3 by bolts. The automatic lift door 5 uses an actuator 5A to control the opening and closing of the lift door, and the actuator 5A includes, for example, an air cylinder, a hydraulic cylinder, an electric push rod, and the like. The method of spring assist can also be used to reduce the power output of the actuator.

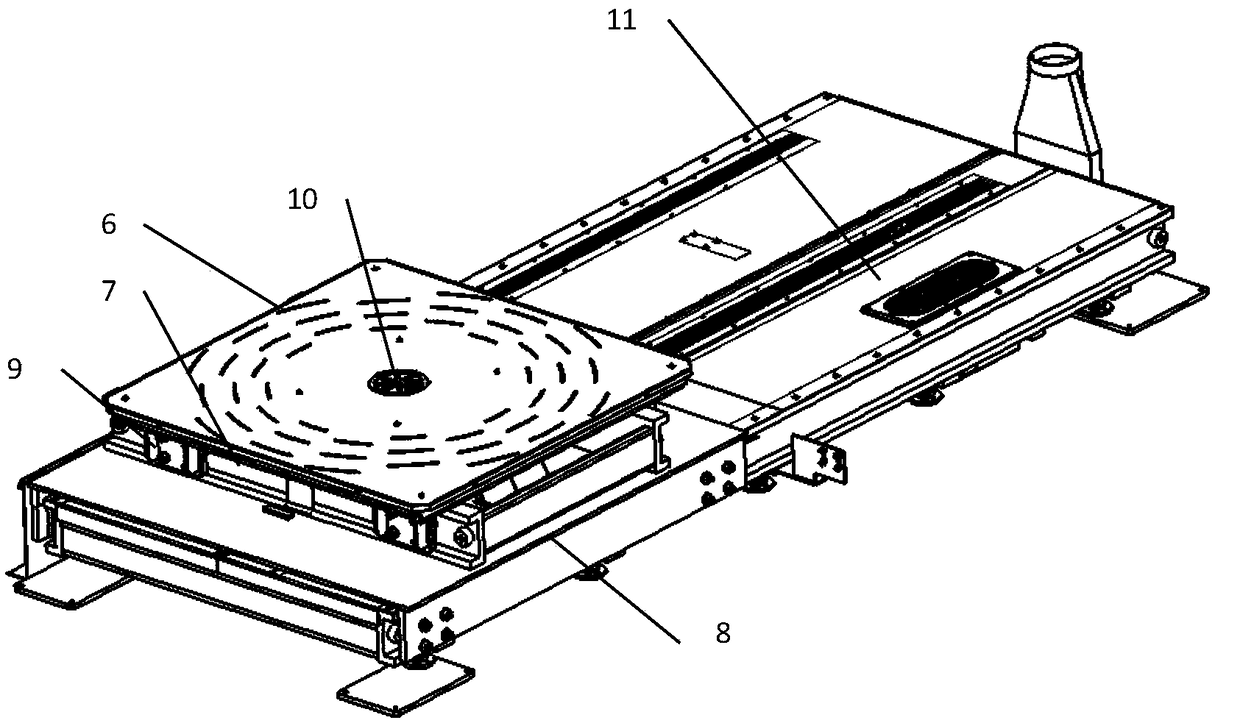

[0057] The X1 and Y1 working platforms 2 generally inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com