Steering elbow for powder-shaped material transportation

A technology for turning elbows and powdery materials. It is applied in the direction of elbows, pipes/pipe joints/fittings, siphons, etc. It can solve problems such as increased maintenance and replacement costs, shortened service life, and wear on the inner wall of arc-shaped elbows. The effect of maintenance and replacement costs, increased service life, and reduced inner wall wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The following is a detailed description in conjunction with the drawings and embodiments:

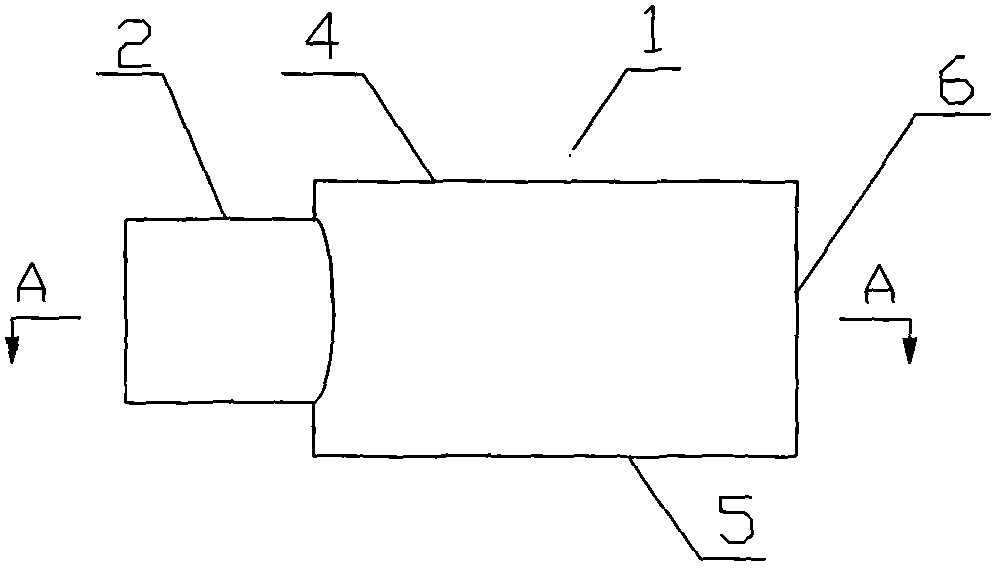

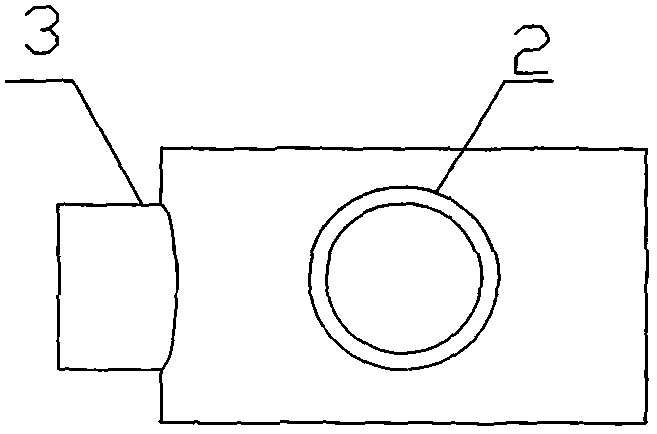

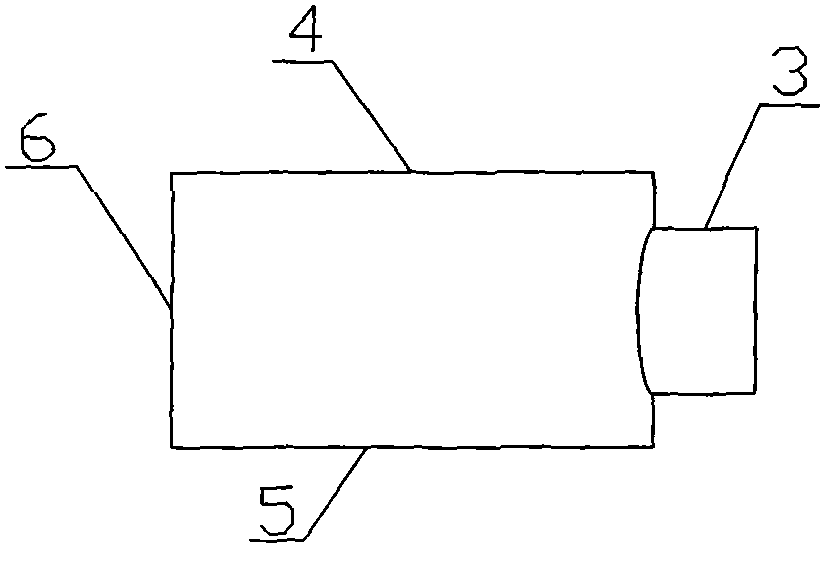

[0020] Such as Figure 1 to Figure 7 As shown, a powder material conveying steering elbow includes an elbow body. The elbow body is a closed shell 1. On the closed shell 1 are fixed an input pipe 2 and an output pipe 3, and an input pipe 2 , The output pipe 3 is communicated with the inner cavity of the casing 1, and the inlet end of the output pipe 3 penetrates into the inner cavity of the casing 1. The distance D9 from the inlet end of the output tube 3 to the inner cavity of the housing 1 is preferably 4 cm.

[0021] The casing 1 described in this embodiment is a closed cylindrical casing, including an upper circular plate 4, a lower circular plate 5 and a cylinder 6. The cylinder 6, the input pipe 2 and the output pipe 3 are all made of Q235 carbon structure. Steel, the upper circular plate 4 and the lower circular plate 5 are respectively welded and fixed on the top surface of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com