Safe tempered glass film hardness detection equipment

A technology of tempered glass film and testing equipment, applied in the direction of testing material hardness, measuring device, strength characteristics, etc., can solve the problems of low degree of automation, reduced production efficiency, manual picking and unloading, etc. The effect of detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

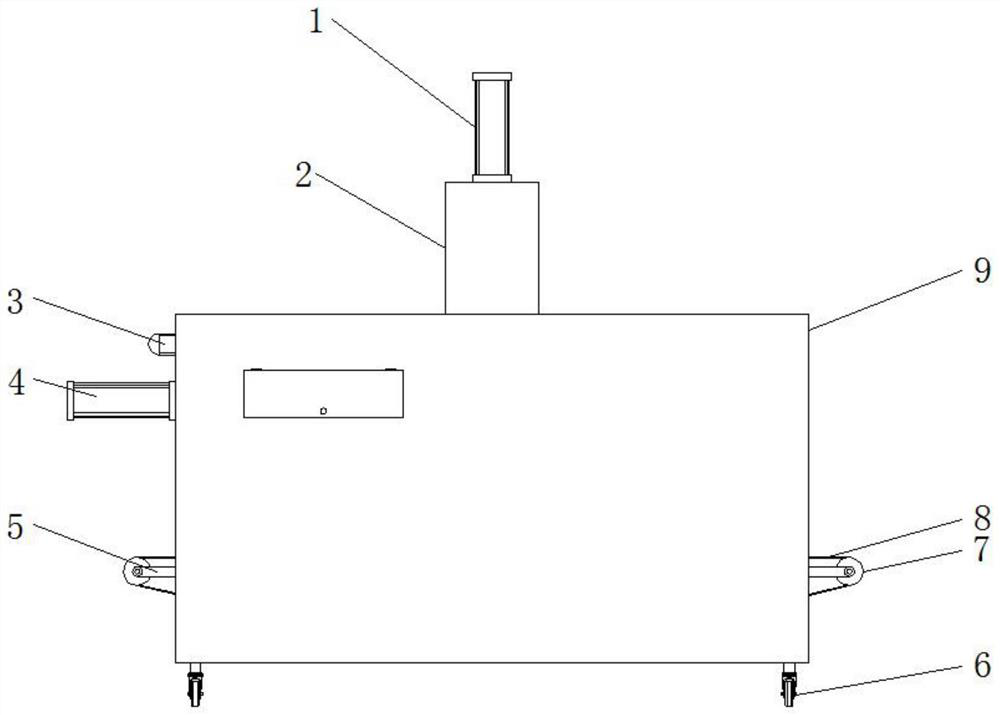

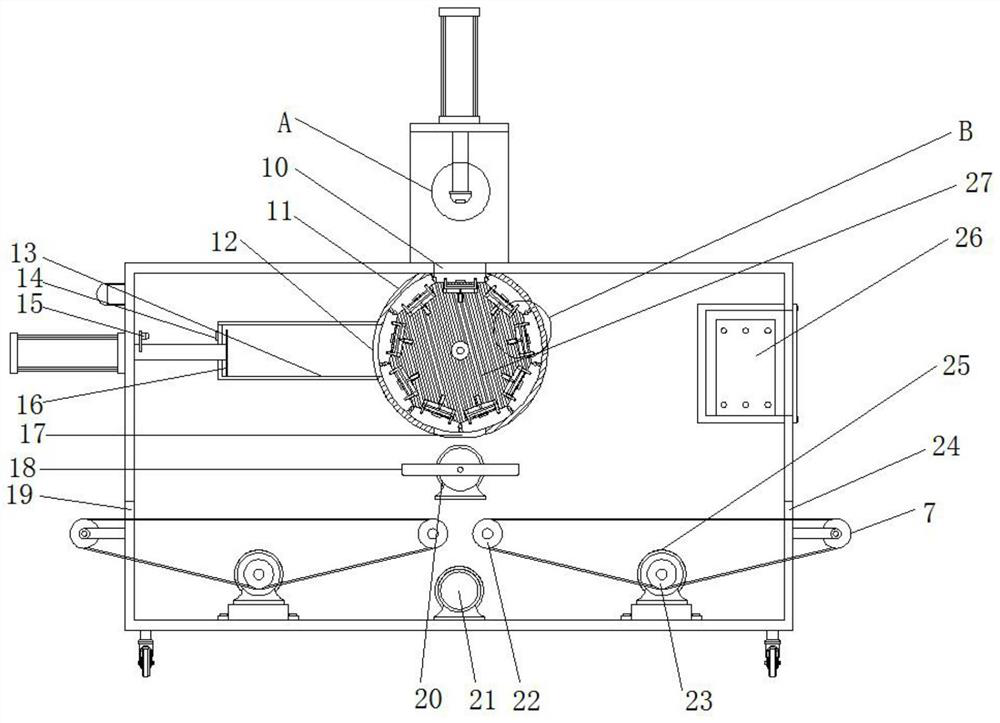

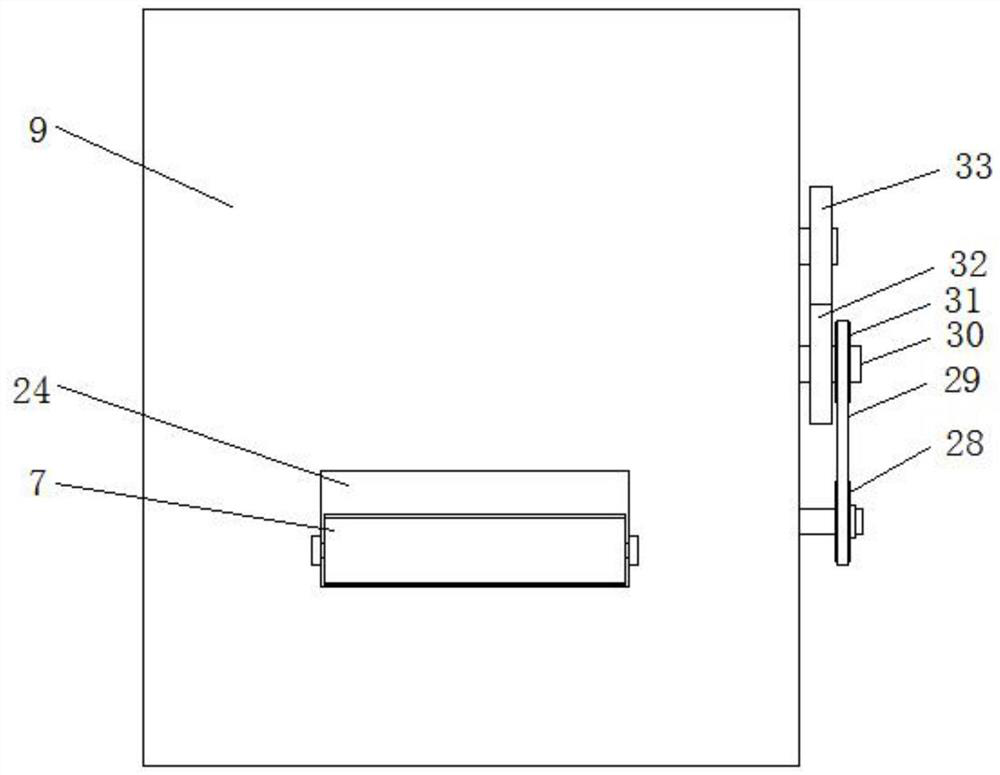

[0030] Such as Figure 1-Figure 8As shown, a safe tempered glass film hardness testing device includes a detection box 9, a fixed frame 2 is fixed in the middle of the upper end of the detection box 9, a first cylinder 1 is fixed on the upper end of the fixed frame 2, and the telescopic part on the lower side of the first cylinder 1 is worn. The fixed frame 2 is fixed with a detection head 39, the lower part of the detection head 39 is inlaid with a pressure sensor 38, the upper part of the detection box 9 is welded and fixed with a limit groove 11, and the detection box 9 inside the limit groove 11 is rotatably connected with a detection seat 27 The side of the det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Vickers hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com