Large bomb production line

A production line and projectile technology, which is applied in the field of automatic appearance spraying and assembly of large projectiles, can solve the problems of dangerous operation and low efficiency of operators, and achieve the effects of avoiding manual operation, stable structure and improving production qualification rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

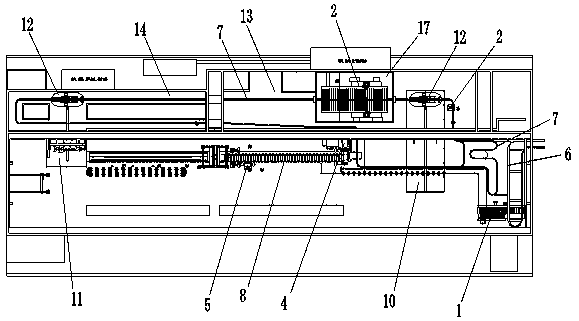

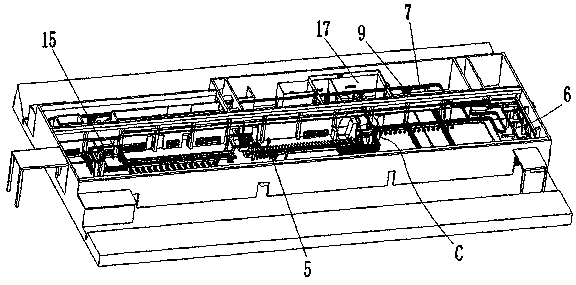

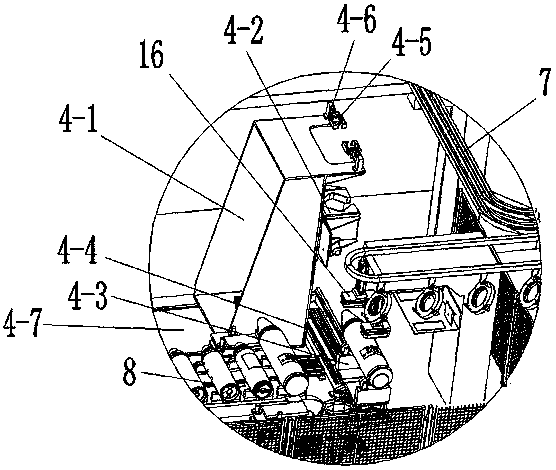

[0079] See Figure 1 to Figure 24 , the large bomb production line of the present embodiment includes a vertical hollow body on-line device 1, a bomb body cleaning device 2, a paint spraying device 3, a vertical blanking device 4, a booster powder column assembly system 5, a drug injection catenary 6, Paint spraying catenary 7 and transmission plate chain machine 8. All are provided with a plurality of traveling carriages 9 that are used to articulate the vertical body on the catenary 6 and the catenary 7 for spraying medicine. The body cleaning device 2, the paint spraying device 3 and the vertical blanking device 4 are arranged below the painting catenary 7 successively along the moving direction of the trolley 9. One end of the painting catenary 7 is connected with the painting catenary 7. The painting catenary 7 transmits the vertical projectile on the line through the vertical hollow body on-line device 1 through the injection workshop for injection. The conveying plat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com