Low-error-feeding method for plate material and apparatus using said method

A feeding method and material technology, which can be used in workpiece feeding devices, feeding devices, wood processing appliances, etc., can solve problems such as large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

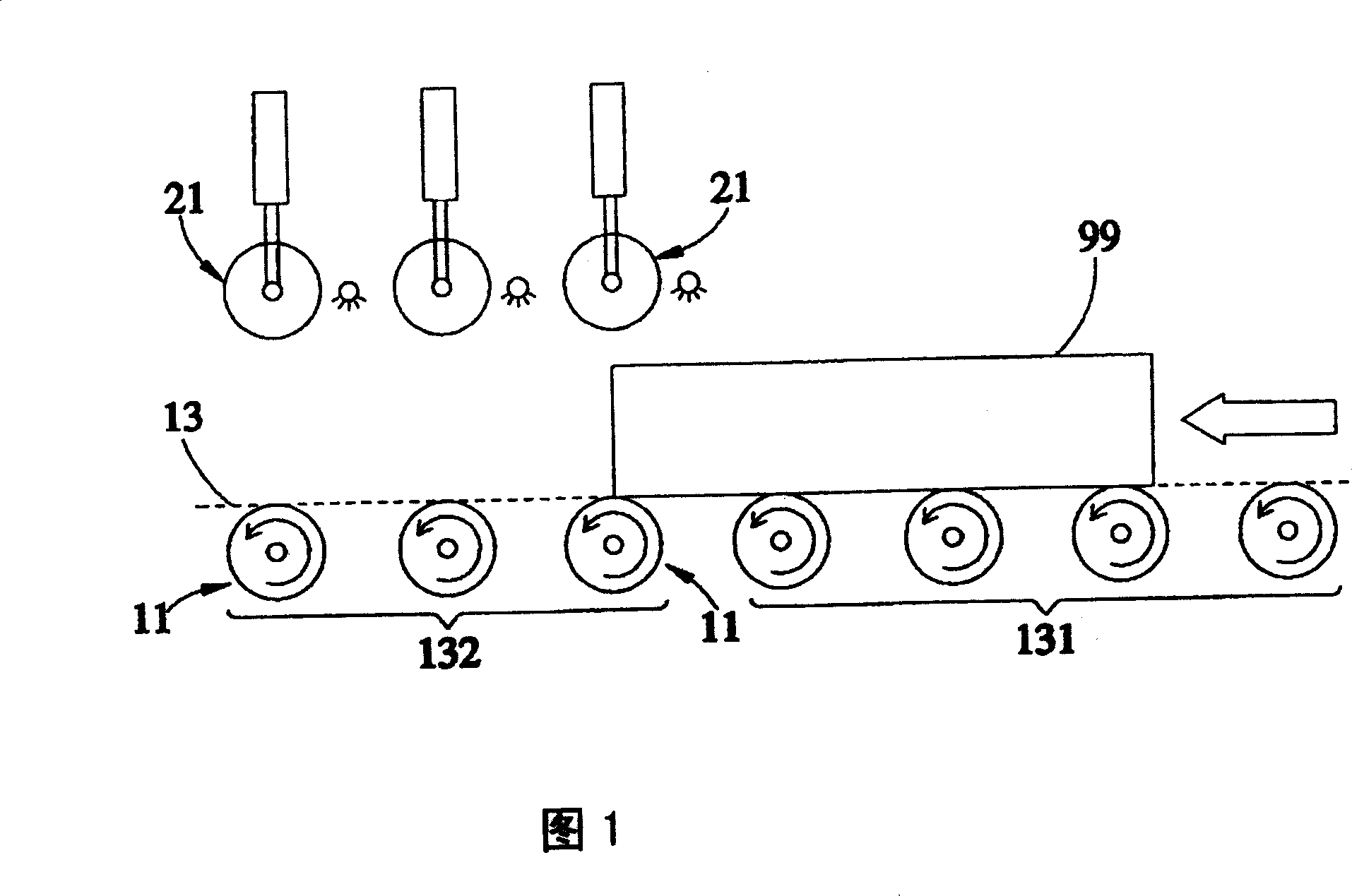

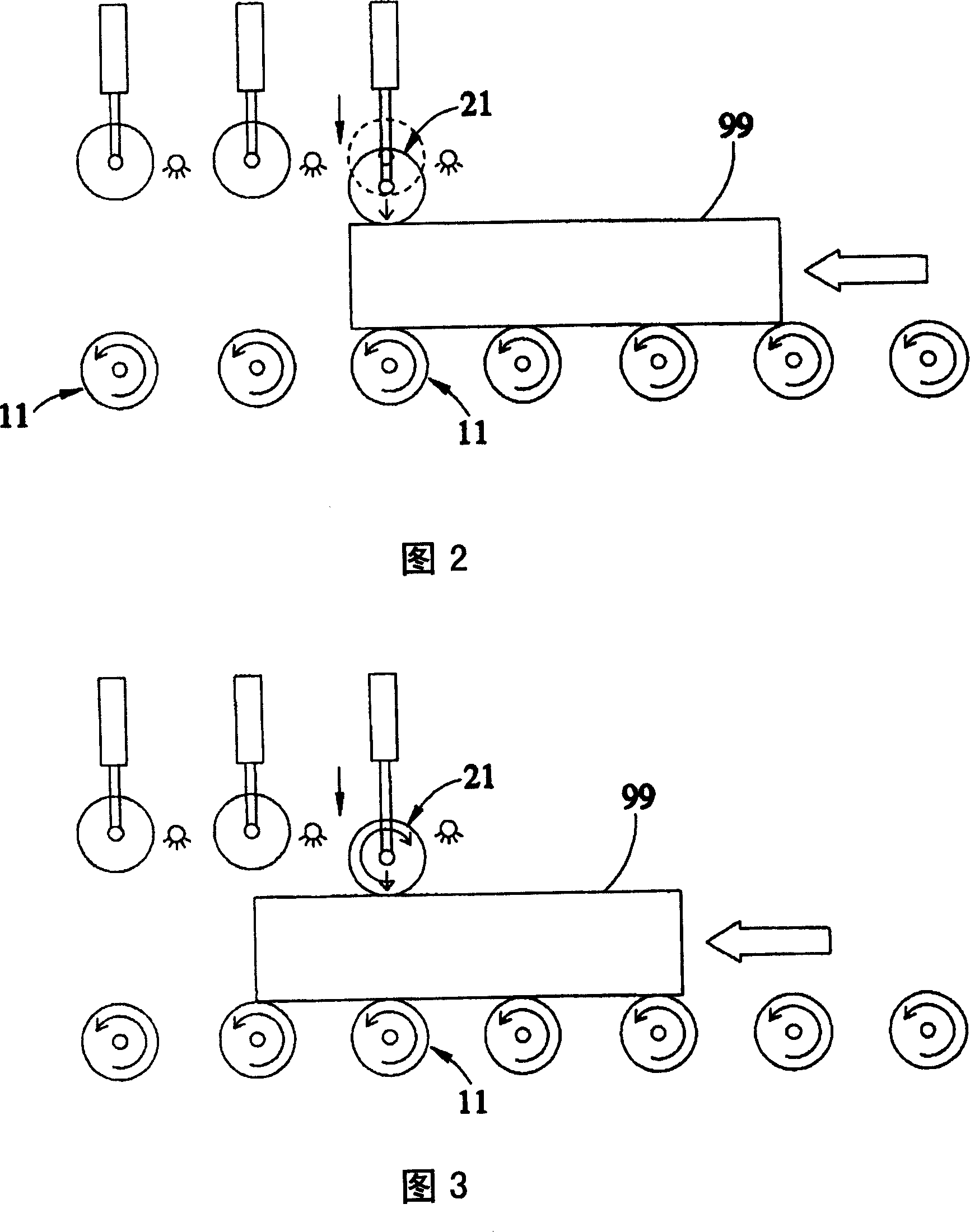

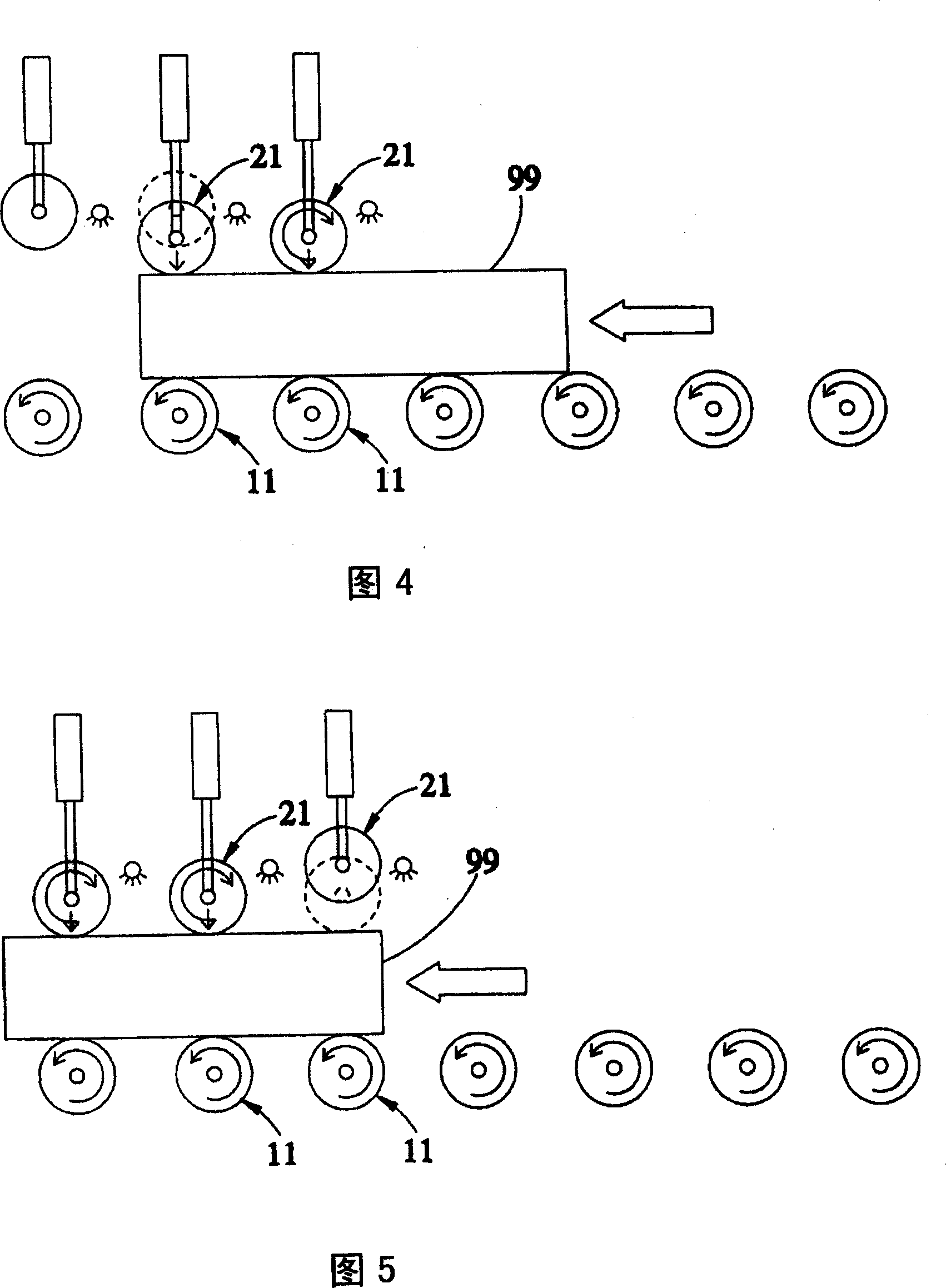

[0030] As shown in Figures 1 to 5, a low-error feeding method for plate-shaped materials provided by the first preferred embodiment of the present invention mainly has the following steps:

[0031] A. Prepare a plurality of driving wheels 11 and a plurality of driven wheels 21: the driving wheels 11 are of the same height and are separated by a predetermined distance, and the driving wheels 11 rotate at the same speed and in the same direction, and define the transport that rotates in a certain direction surface 13, the conveying surface 13 can be divided into a preparatory area 131 at the front and a pressing area 132 at the rear of the preparatory area 131, the driven wheels 21 are respectively located directly above each of the driving wheels 11 in the pressing area 132 and Separated by a predetermined height, and can be controlled to move up and down.

[0032] B. Feeding: Make a plate-shaped material 99 feed between the first driving wheel 11 and the first driven wheel 21 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com