Assembling and positioning jig in blood sampling needle automatic assembling equipment

A technology for positioning jigs and assembling equipment, applied in manufacturing tools, workpiece clamping devices, etc., can solve the problems of the spring 4 failing to correctly launch the needle core 3, the card 10 being stuck, blood sampling failure, etc., and achieving simple structure and assembly position. Correct, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

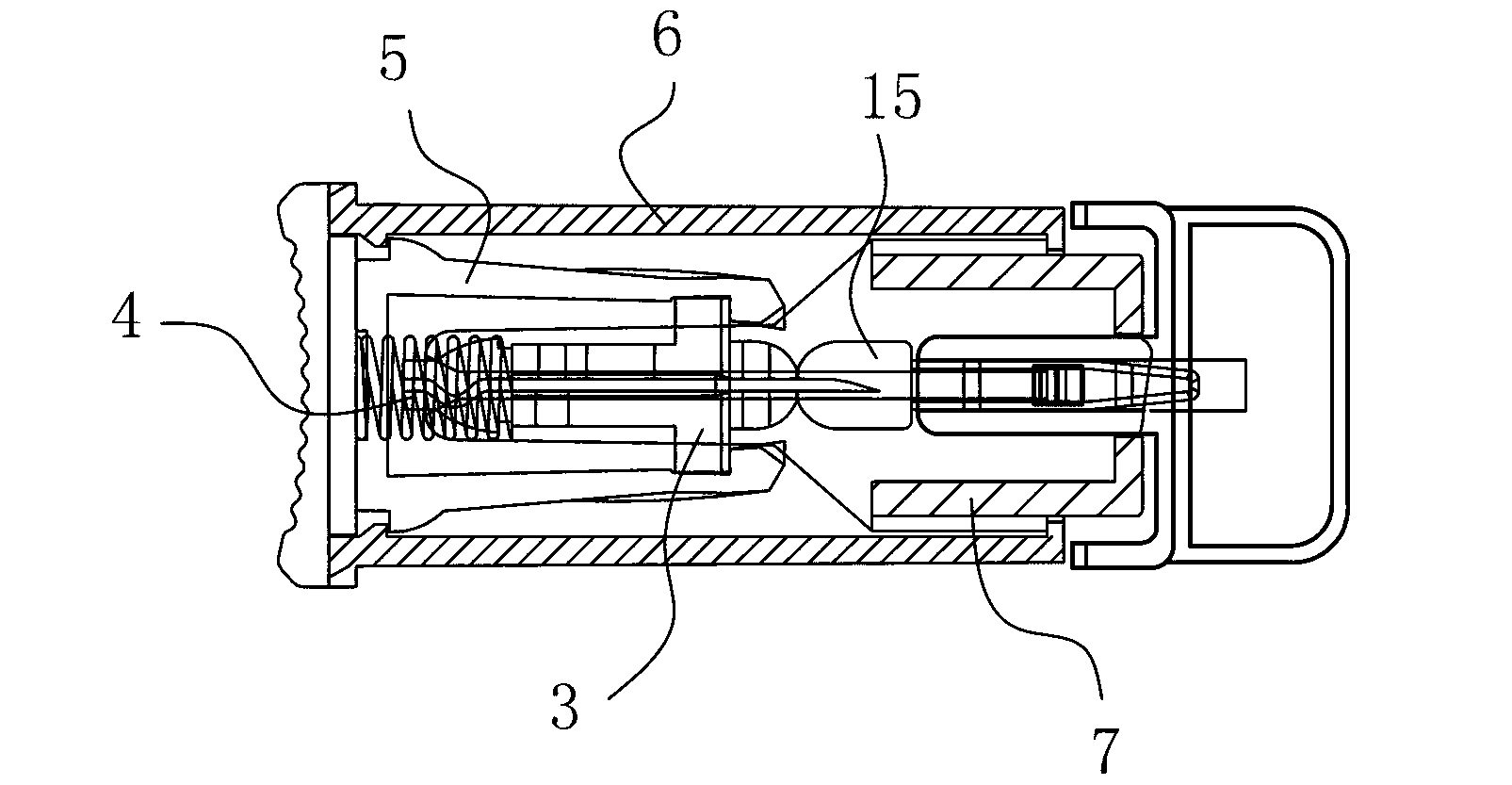

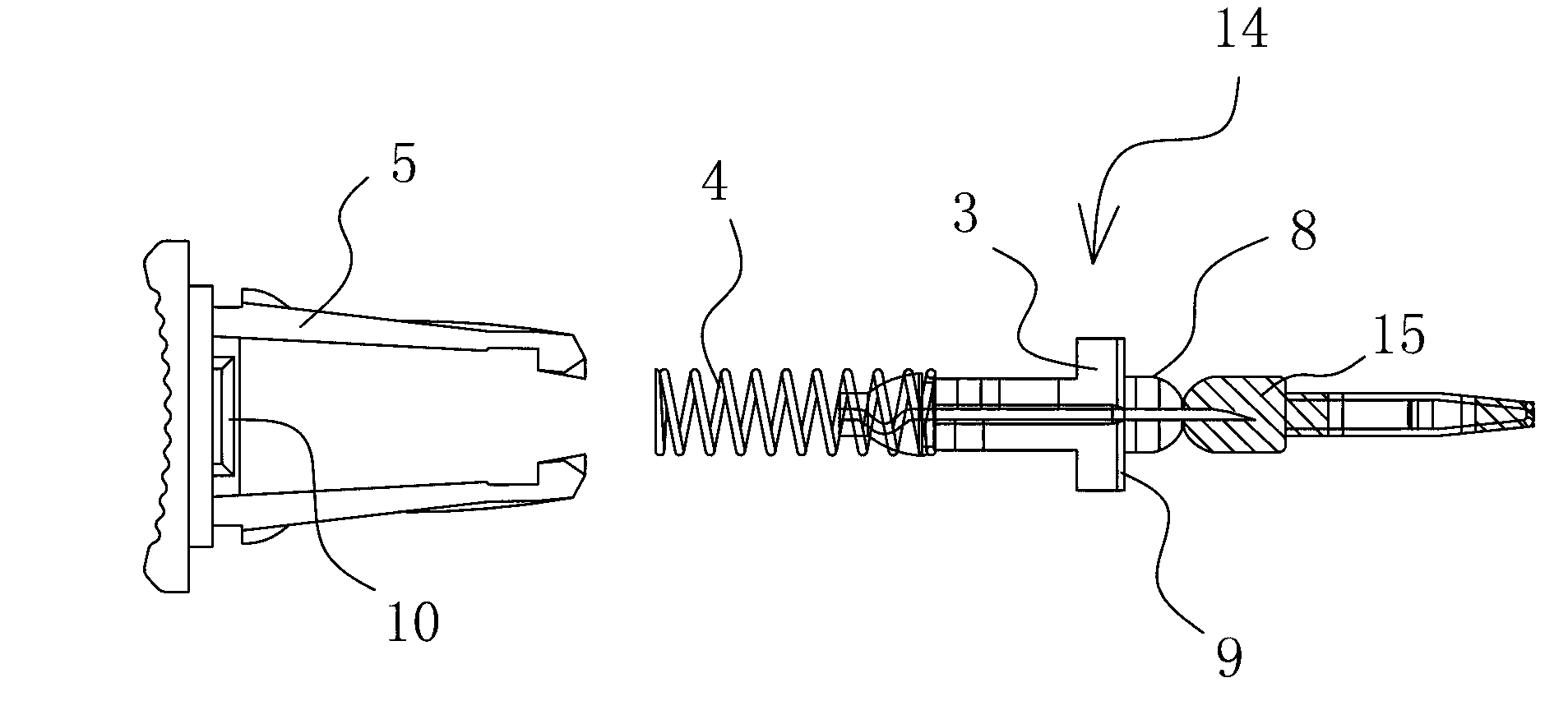

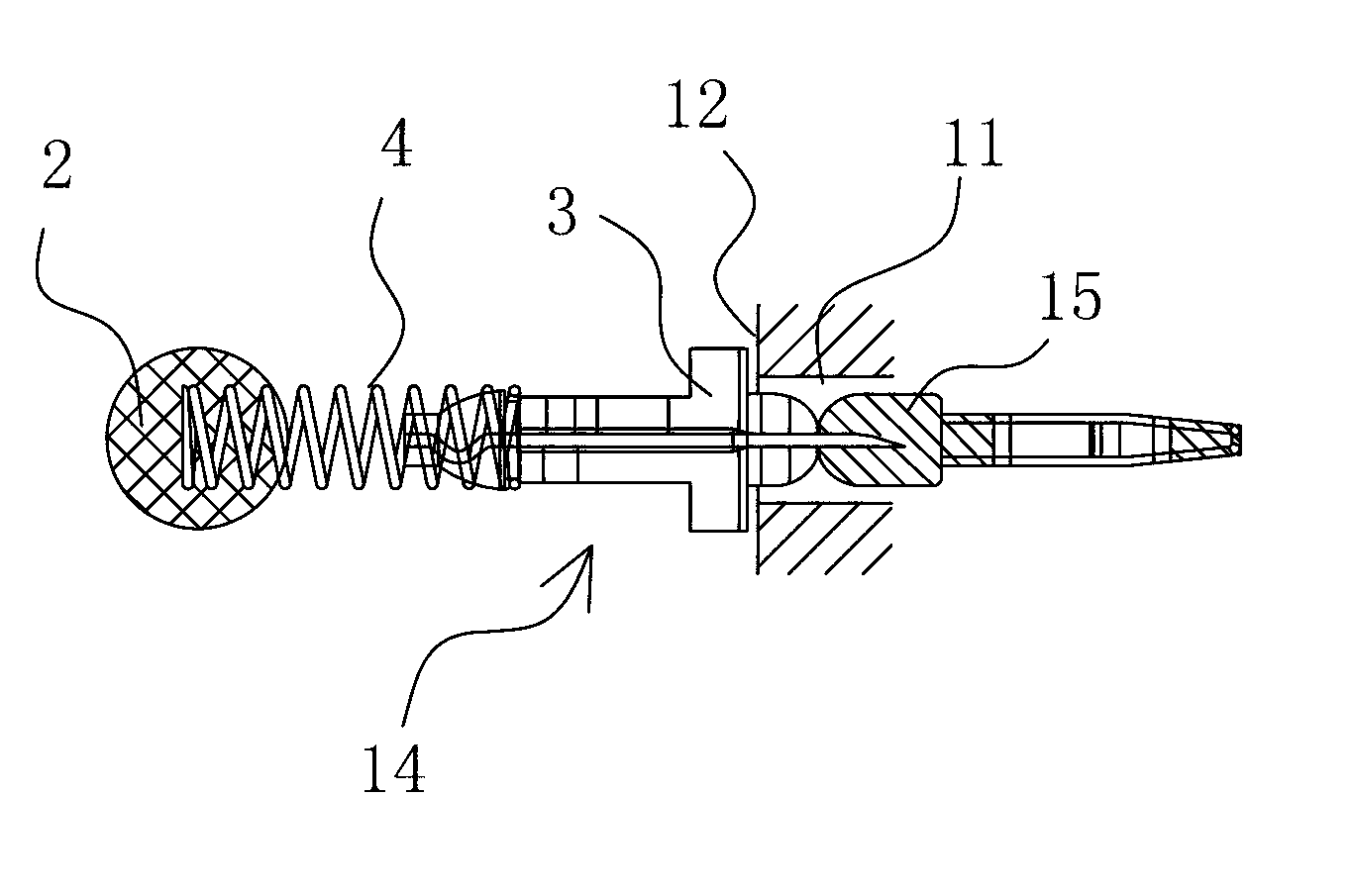

[0021] Example: see attached Figure 3-6 As shown, an assembly and positioning fixture in the automatic assembly equipment of blood collection needles is aimed at the core spring assembly 14 in the blood collection needle. The station 13 of the core spring assembly 14 can balance the force. On the station 13, a U-shaped positioning groove 11 is arranged corresponding to the journal 8 of the needle core 3 in the needle core spring assembly 14, and the U-shaped positioning groove 11 corresponds to the needle. One end of the first end face 9 of the core 3 is provided with a positioning end face 12; on the station 13, a magnetic positioning block 2 is set corresponding to the tail of the spring 4 in the needle core spring assembly 14, so as to form a positioning structure for the needle core spring assembly 14.

[0022] In other examples, the number of stations 13 provided on the base 1 may be one, three, four or other according to the specific usage, as long as it is convenient f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com