Workpiece loading mechanism and workpiece assembling equipment

A technology for assembling equipment and workpieces, applied in metal processing equipment, metal processing, manufacturing tools, etc., can solve problems such as high cost, low efficiency, and high scrap rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

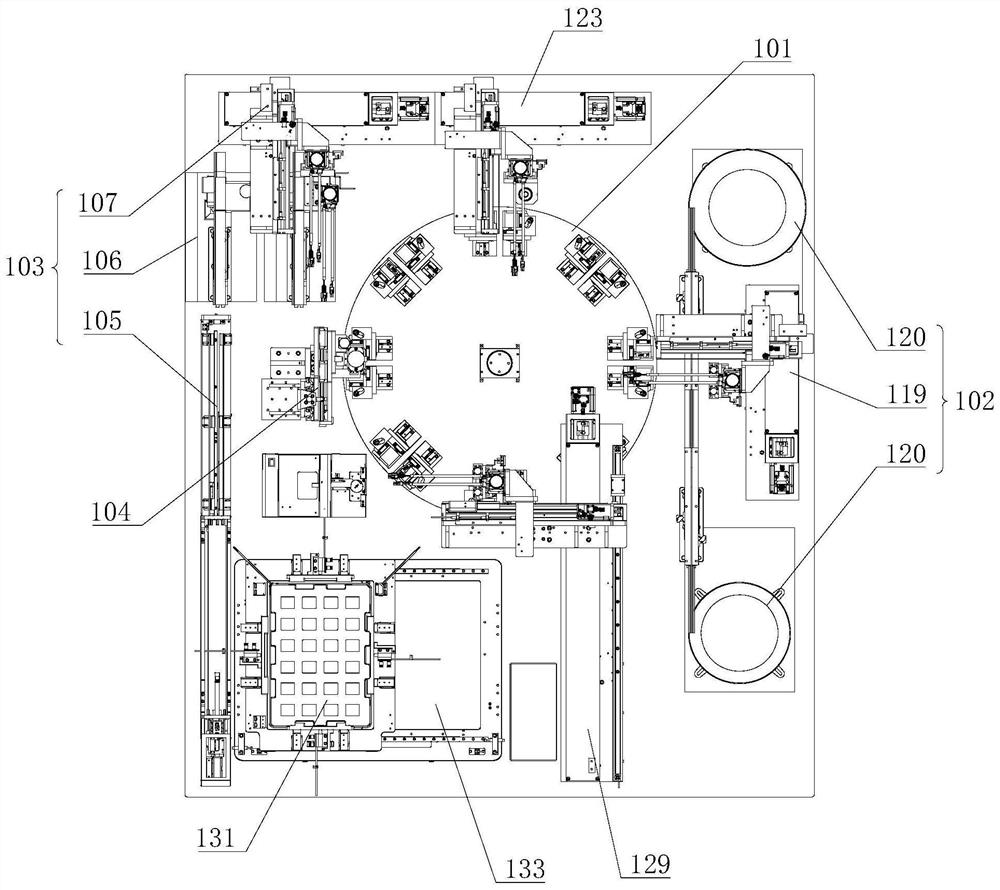

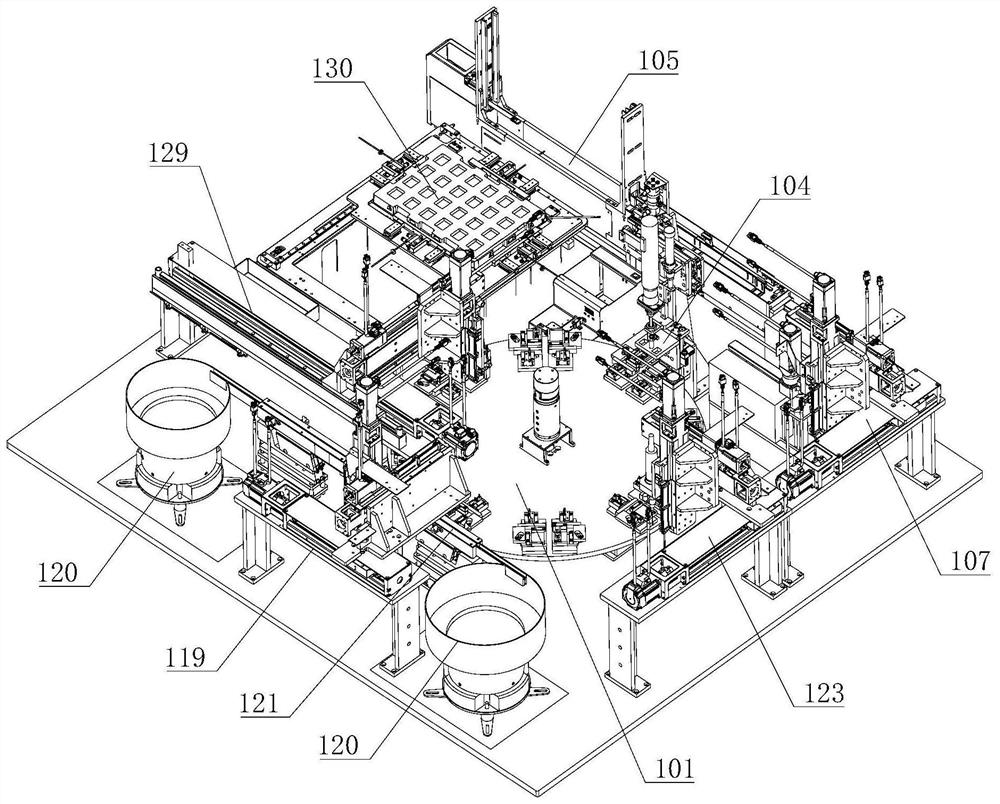

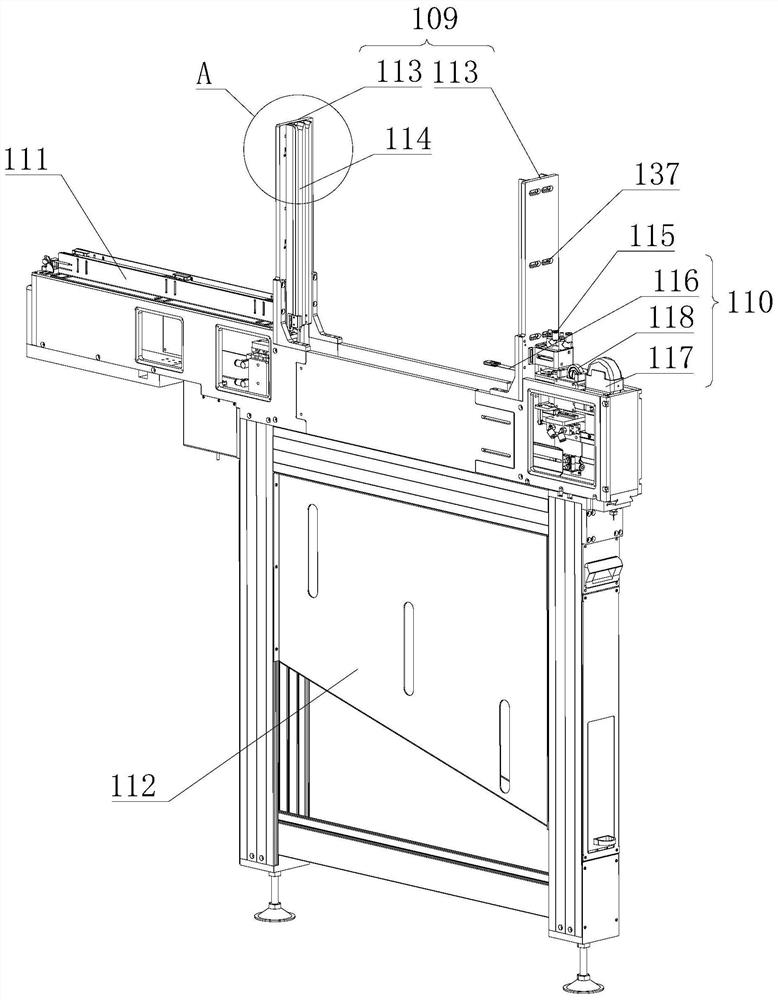

[0056] see Figure 1 to Figure 8 As shown, the workpiece assembly equipment provided by the present application includes a transfer mechanism 101 and a first feeding mechanism 102, a second feeding mechanism 103 (corresponding to the workpiece feeding mechanism) and an assembly mechanism arranged in sequence on the running path of the transfer mechanism 101 104. Such as figure 1 and figure 2 As shown, the transfer mechanism 101 shown in the figure is a circular turntable that rotates counterclockwise, and a plurality of installation positions are formed on the peripheral edge of the circular turntable to install workpieces. The first feeding mechanism 102, the second feeding mechanism 103 and the assembly mechanism 104 are arranged in the circumferential direction of the turntable. Such setting makes the devices more compact and the equipment takes up less space.

[0057] Optionally, the transfer mechanism 101 may also be a transport structure such as a conveyor belt with...

Embodiment 2

[0074] The workpiece assembly equipment in the second embodiment is an improvement on the basis of the above embodiment, and the technical content disclosed in the above embodiment will not be described repeatedly, and the content disclosed in the above embodiment also belongs to the content disclosed in the second embodiment.

[0075] see figure 1 and figure 2 As shown, in an optional solution of this embodiment, the first feeding mechanism 102 includes a first feeding assembly 119 and at least one vibrating plate 120 . Wherein, two vibrating plates 120 are shown in the figure, which can respectively feed radiators of two sizes, large and small.

[0076]The vibration plate 120 includes a fixed seat and a plate body installed on the fixed seat, a quantity detection member and a discharge track 121, so as to transport a preset number of first workpieces to the discharge track 121; the discharge track 121 of a plurality of vibration plates 120 The tail end of is set at the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com