Assembling machining line and assembling process for right gear lever handle for automobile steering wheel

A technology for assembly processing and gear levers, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low assembly accuracy and reduced defective rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

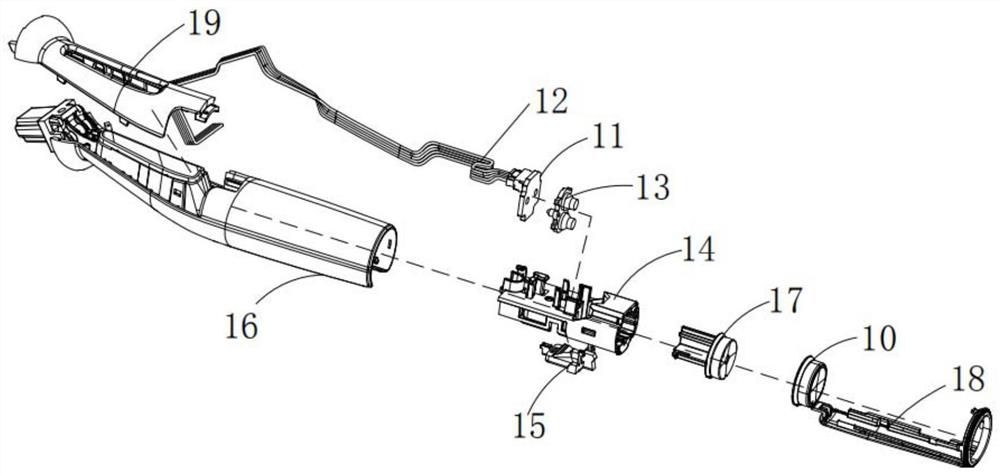

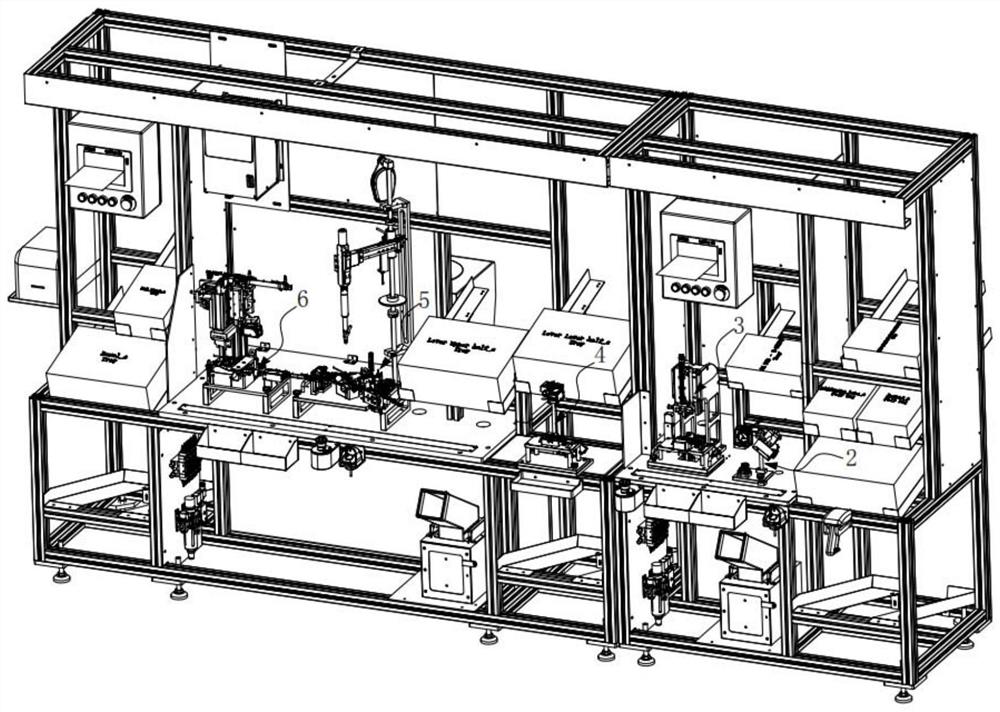

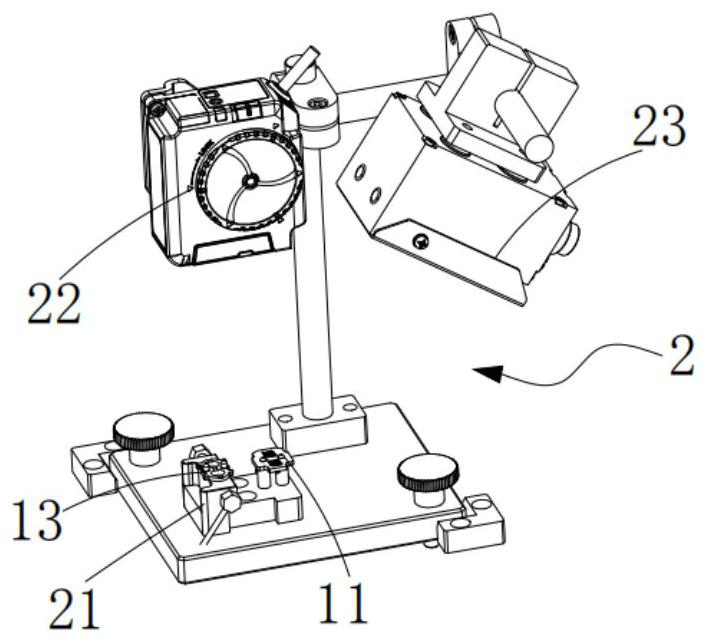

[0097] Such as Figure 1 to Figure 3 As shown, a right gear lever handle assembly and processing line for an automobile steering wheel is used for assembling a right gear lever handle 1. The right gear lever handle 1 is composed of a PCB board 11, a wiring harness 12, a button 13, a mounting seat 14, and a lens sheet 15. , the handle 16, the button 17, the retaining ring 18, the knob 10 and the handle shell 19 are assembled, the PCB board 11 is installed and connected with the wire harness 12 and the button 13, and then snapped on the mounting seat 14, After the mounting base 14 is engaged with the lens sheet 15, it is screwed and fastened with the handle 16. The button 17 and the retaining ring 18 are pressed and engaged with the end of the handle 16. The handle shell 19 is press-fitted and combined with the handle 16, and the assembly processing line for assembling the right gear lever handle 1 includes the electrostatic dust collection assembly 2, the first press-fit assemb...

Embodiment 2

[0160] Such as Figure 24 As shown, a kind of assembly process based on the assembly process line of the right gear lever handle of a kind of automobile steering wheel described in Embodiment 1 comprises the following steps:

[0161] Step 1, electrostatic dust collection cleaning, place the PCB board 11 and the button 13 on the cleaning positioning seat 21 of the electrostatic dust collection assembly 2 for positioning, and perform cleaning treatment by the ion fan 22 located directly above the cleaning positioning seat 21;

[0162] Step 2, PCB board assembly, complete the insertion and assembly of the PCB board 11 after the wiring harness 12 is cleaned, and install the button 13 on the PCB board 11;

[0163] Step 3, one-time installation, after preliminarily installing the PCB board 11 and the lens sheet 15 on the mounting seat 14, the wire harness 12 is wound on the mounting seat 14, and then the mounting seat 14 is placed on the first press Install the positioning jig 31 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com