High temperature superheated steam environment creep fatigue test device

A creep fatigue test, superheated steam technology, applied in measuring devices, using repetitive force/pulse force testing material strength, instruments, etc., can solve the deterioration of equipment material performance, harsh service environment, affecting the safe operation of equipment, etc. problems, to ensure self-isolation, reasonable and reliable structure, and stable cooperation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

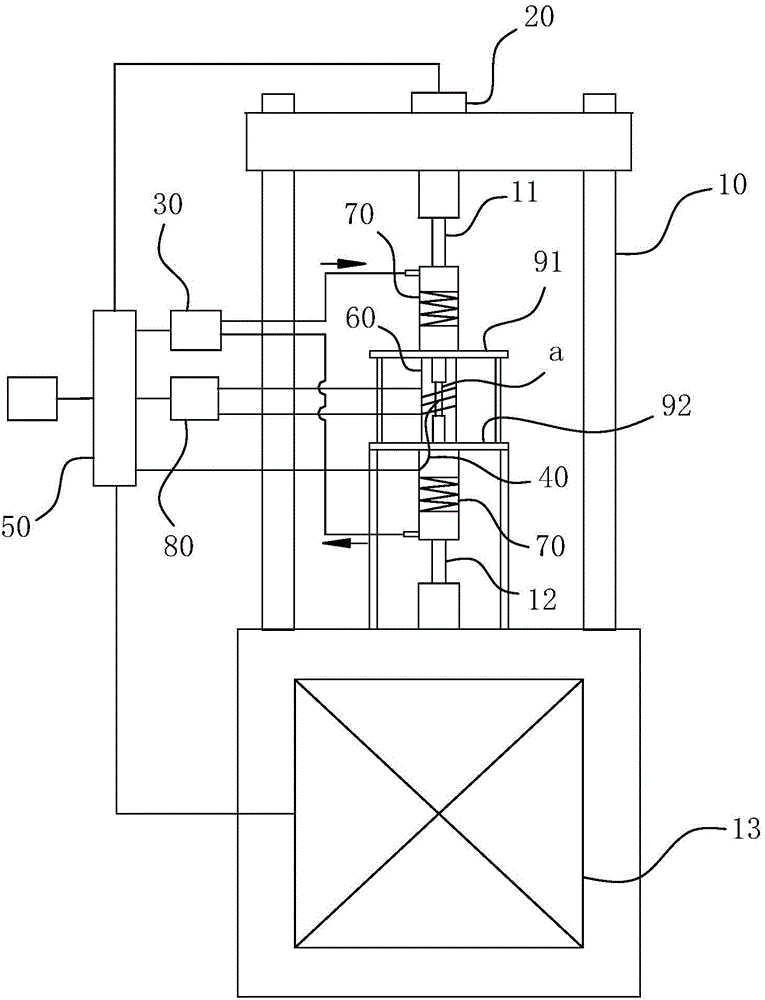

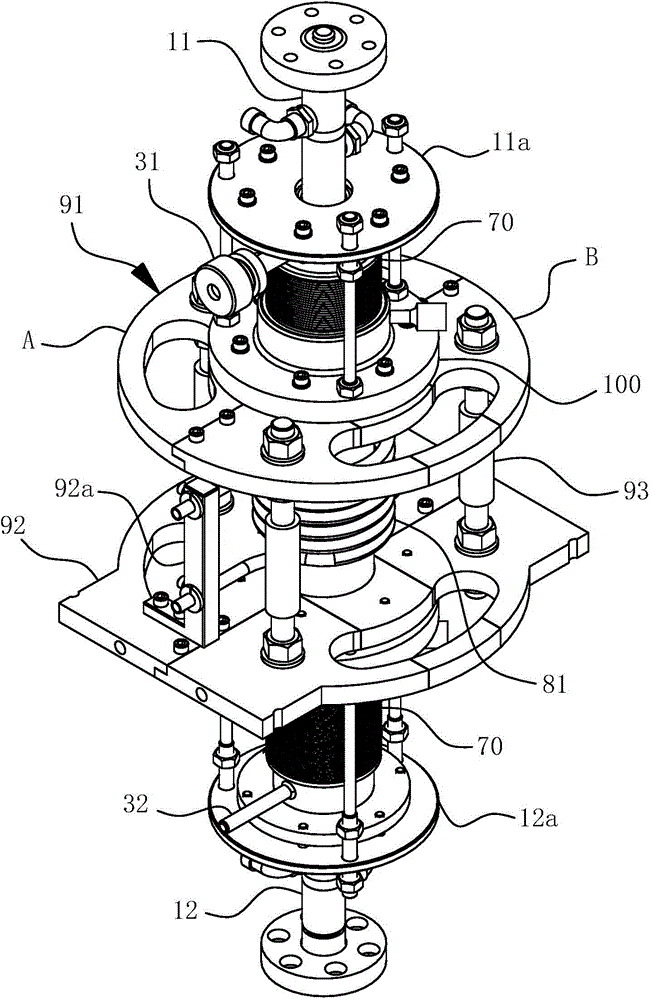

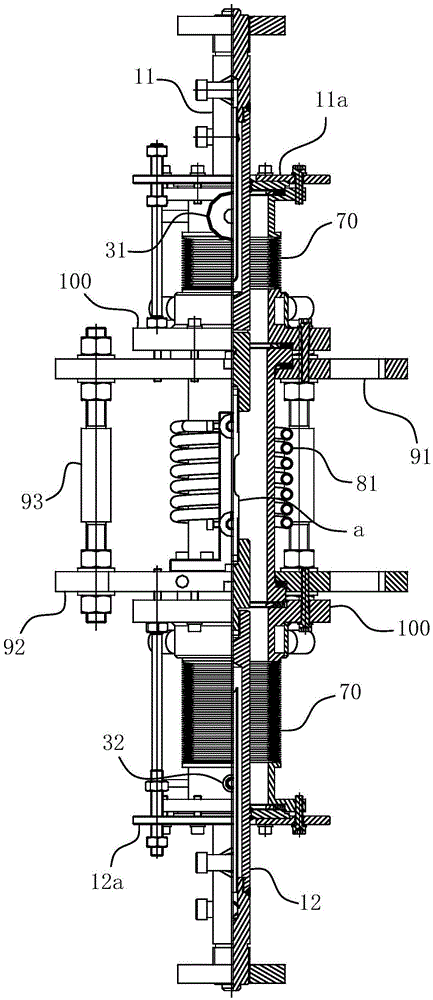

[0035] For ease of understanding, here in conjunction with accompanying drawing, specific testing device of the present invention and its operation process are further described as follows:

[0036] The concrete implementation structure of the present invention, as Figure 1-5 As shown, it includes a creep fatigue testing machine loading frame 10 that provides sample a with creep fatigue loading force, and also includes an upper pull rod 11 and a lower rod 12 for fixing the sample a at both ends, wherein the upper end of the lower rod 12 The fixture passes through the lumen of the bellows 70 located under the heat-resistant transparent tube, that is, the quartz glass tube 60, and finally penetrates into the quartz glass tube 60 to clamp or screw the lower end of the sample a, and the lower end of the pull rod 12 is connected to the The loading transmission assembly 13 is connected. The clamp at the lower end of the pull-up rod 11 passes through the lumen of the bellows 70 abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com