Annular hole sealing device for coal mine gas extraction drill hole

A technology for draining boreholes and coal mine gas. It is applied in earth-moving drilling, sealing/packing, wellbore/well components, etc. It can solve the problems of grouting process influence, low efficiency, and inability to fill, and achieve the effect of on-site use. Obviously, the work efficiency is improved, and the effect of improving the sealing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

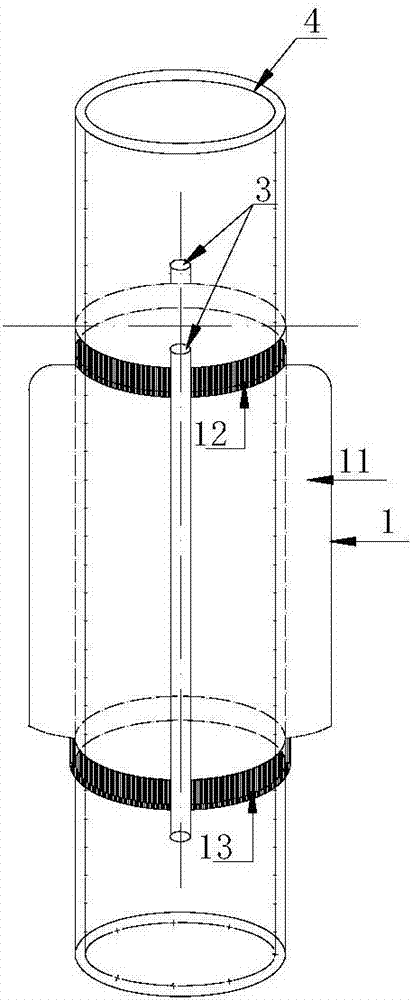

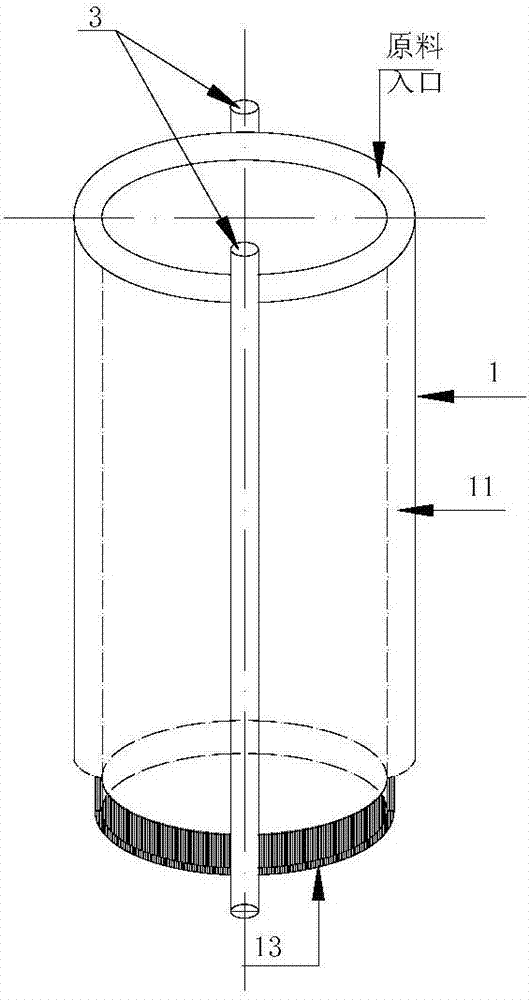

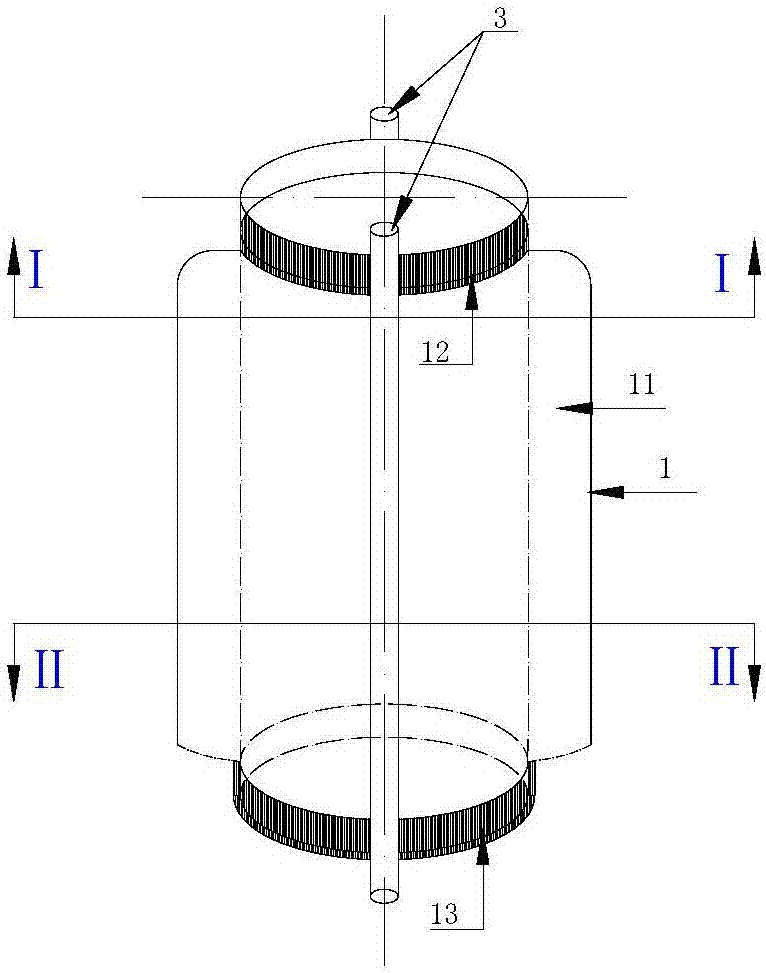

[0020] Embodiment 1: A kind of annular hole sealing device for coal mine gas drainage drilling, it comprises gas drainage pipe 4, and an annular aluminum foil bag 1 is bonded on the outside of gas drainage pipe 4, and annular aluminum foil bag 1 is in the axial direction The top is divided into two left and right chambers by two raw material barrier rods 3, which are filled with expandable polyurethane component A5 and expandable polyurethane component B6 respectively.

[0021] Further, the annular aluminum foil bag 1 is composed of an upper annular sealing edge 12, a middle raw material storage room 11 and a lower annular sealing edge 13. The upper annular sealing edge 12 is the raw material inlet before the two polyurethane components are loaded, and the middle raw material storage room The middle of the chamber 11 is separated by two raw material barrier rods 3, and the lower annular sealing edge 13 is sealed with a sealing machine.

[0022] Further, the inner annular radiu...

Embodiment 2

[0026] Embodiment 2: An annular hole sealing device for coal mine gas drainage drilling, which includes a gas drainage pipe 4, an annular aluminum foil bag 1 is bonded to the outside of the gas drainage pipe 4, and the annular aluminum foil bag 1 is in the axial direction The top is divided into two left and right chambers by two raw material barrier rods 3, which are filled with expandable polyurethane component A5 and expandable polyurethane component B6 respectively.

[0027] Further, the annular aluminum foil bag 1 is composed of an upper annular sealing edge 12, a middle raw material storage room 11 and a lower annular sealing edge 13. The upper annular sealing edge 12 is the raw material inlet before the two polyurethane components are loaded, and the middle raw material storage room The middle of the chamber 11 is separated by two raw material barrier rods 3, and the lower annular sealing edge 13 is sealed with a sealing machine.

[0028] Further, the inner annular radi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com