V-type engines cylinder

A technology for engine cylinder blocks and cylinder blocks, which is applied in the direction of engine components, machines/engines, cylinders, etc., can solve the problems that the strength cannot be guaranteed well, and the main bearing cap is easy to be twisted, so as to improve the strength and avoid loosening or twisting The effect of deformation and precise assembly position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

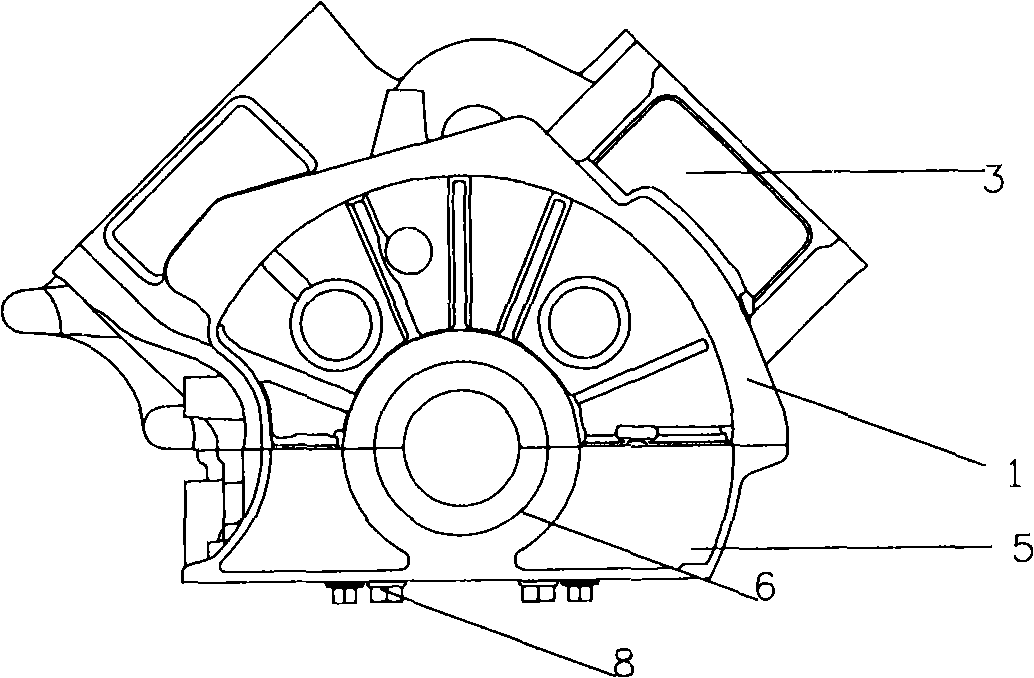

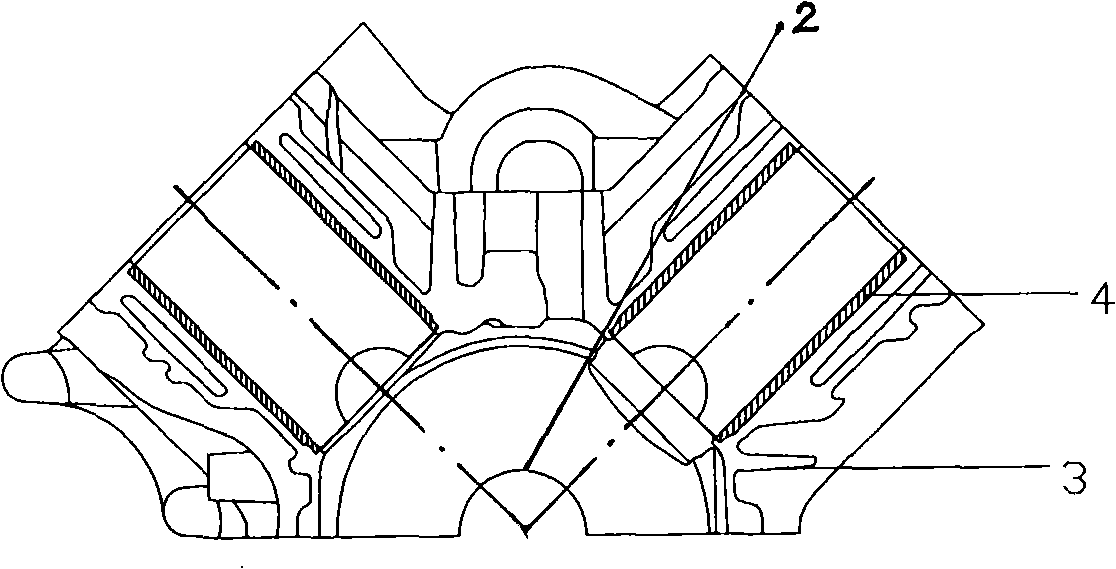

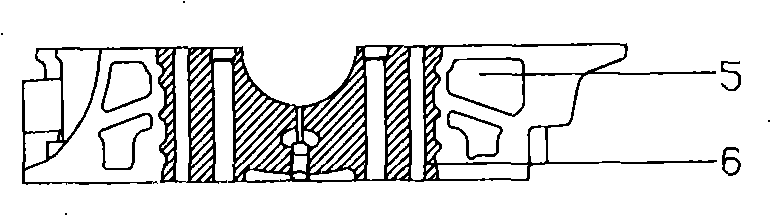

[0013] Examples such as figure 1 , 2 , Shown in 3, 4, and 5, a kind of V-shaped engine cylinder block, cylinder block 1 is made up of upper cylinder block 3 and lower frame 5, and cylinder block V angle 2 is 90 degrees. The upper cylinder body 3 is casted by aluminum alloy, and the cylinder liner 4 is directly cast in. The cylinder liner 4 is made of gray cast iron, which reduces the distortion and wear of the cylinder liner and effectively reduces fuel consumption. The lower frame 5 is casted in aluminum alloy, and the main bearing cap 6 is cast into the aluminum alloy, so that the main bearing cap and the frame fit well, the heat conduction performance is good, and the distortion and deformation of the main bearing cap are reduced. The upper cylinder body and the lower frame are fastened with main bearing cap bolts 8, which are easy to disassemble. This structure makes the cylinder block relatively short, which is convenient for the longitudinal arrangement of the engine i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com