Multi-station permanent magnetic motor assembling device

A permanent magnet motor and assembly equipment technology, which is applied in electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of easily damaged end caps and rotors, increased product scrap rate, low work efficiency, etc., and reduces the number of workers. The effect of reducing the amount of labor, reducing the motor scrap rate and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below.

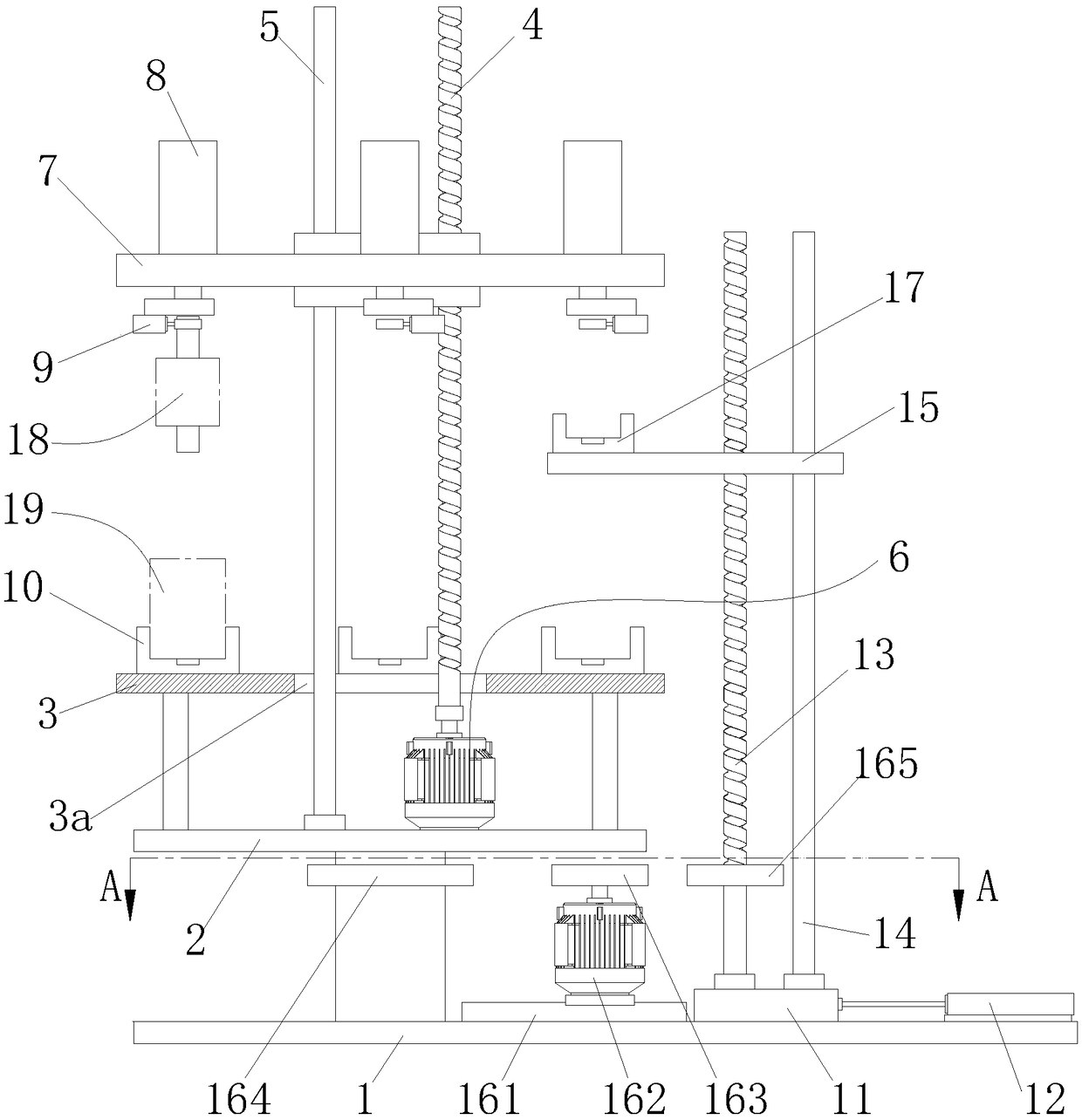

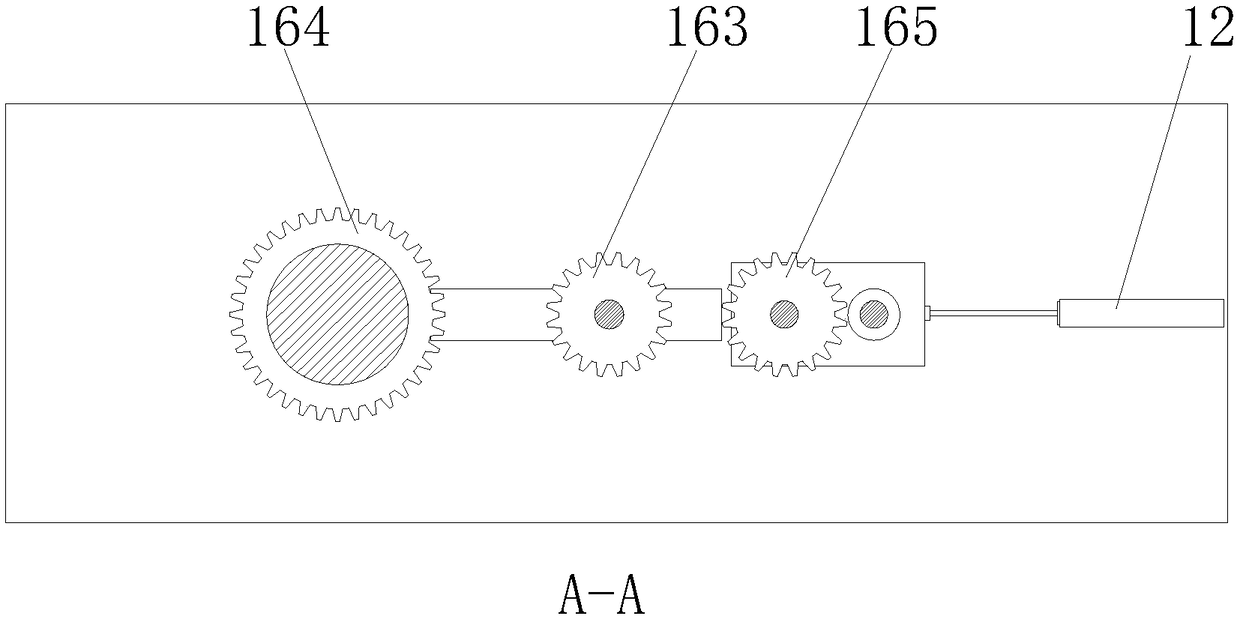

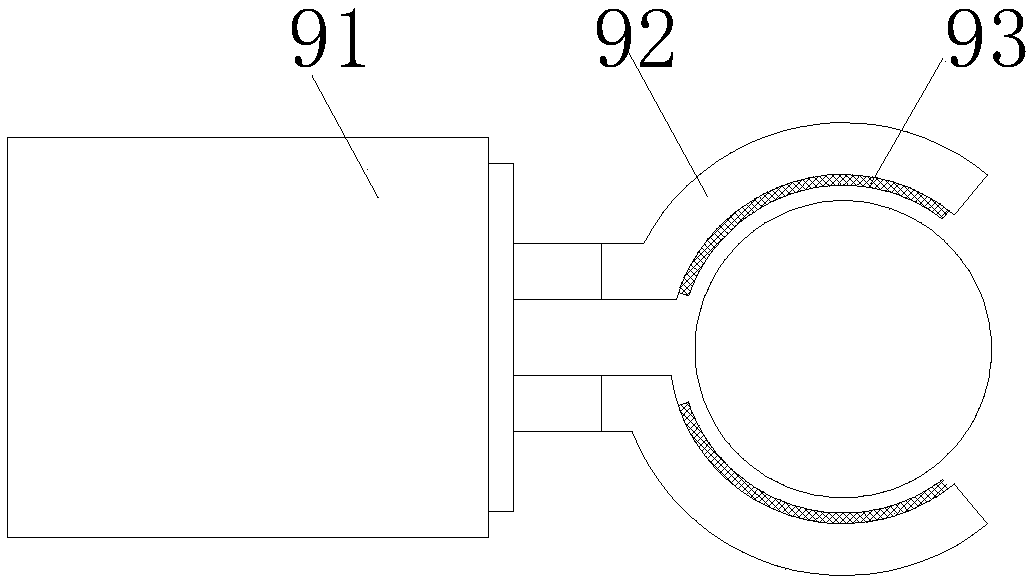

[0022] Such as Figure 1 to Figure 4 As shown, a multi-station permanent magnet motor assembly equipment includes a bottom plate 1, a rotary table 2 is rotatably connected to the bottom plate 1, a stator mounting table 3 is provided on the rotary table 2, and the stator mounting table 3 passes through the The set screw 4 and the guide rod 5 are connected with the motor 6, the screw 4 and the guide rod 5 are jointly connected with a rotor mounting table 7, and the upper ring of the rotor mounting table 7 is provided with several Hydraulic cylinders 8, the output end of any hydraulic cylinder 8 passes through the rotor installation platform 7 and is connected with a jaw mechanism 9 for clamping the rotor 18, and the lower side of any hydraulic cylinder 8 corresponds to a It is used to pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com