Craft manufacturing flow for lost-wax casting value body with more than 8-inch caliber

A wax pattern making and valve body technology, applied in the directions of casting molds, casting mold components, manufacturing tools, etc., can solve the problems of easy cracking and falling off, difficulty in turning over, and bulky wax patterns, and achieve good product quality, beautiful product appearance, and finished products. high rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

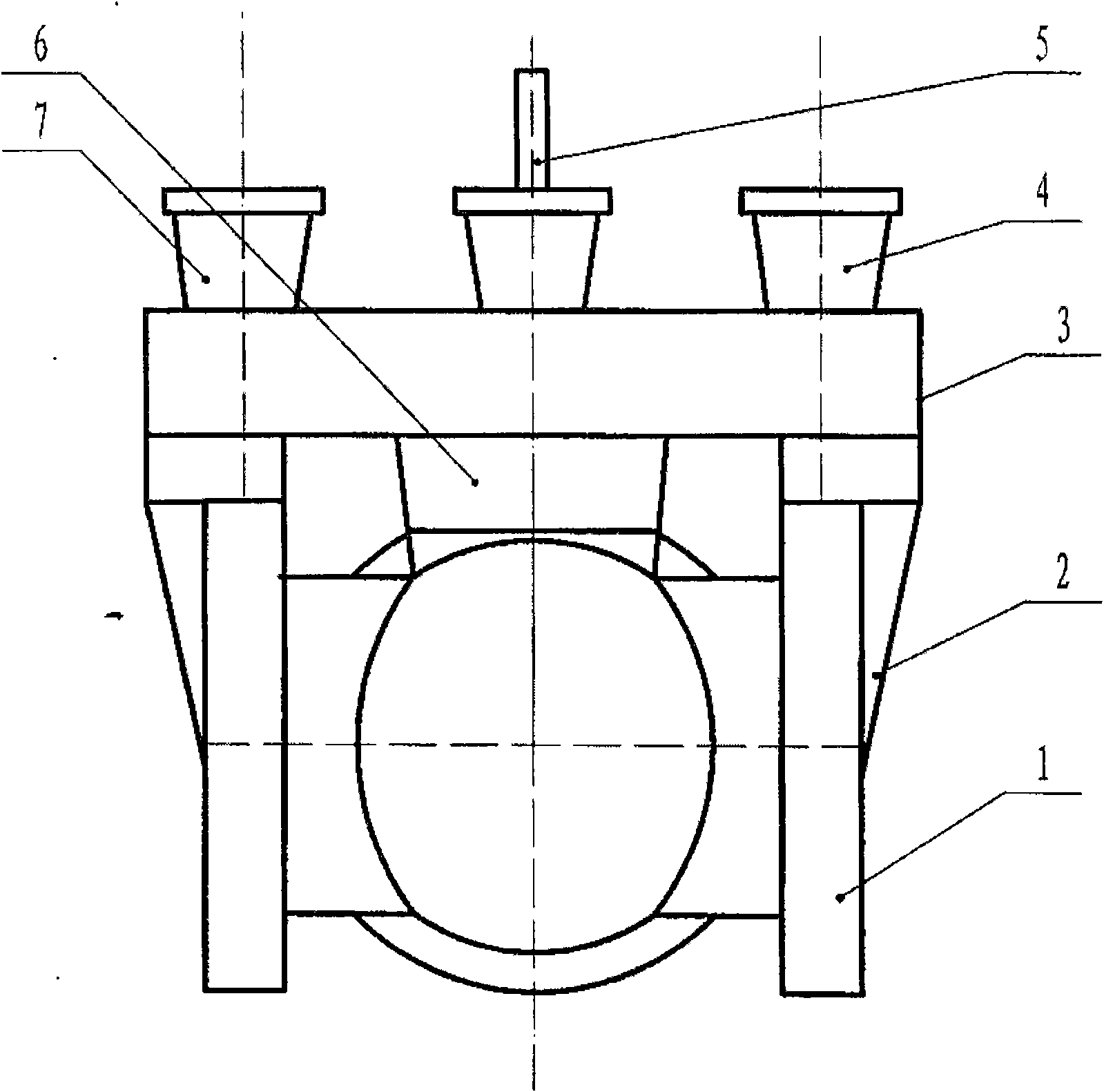

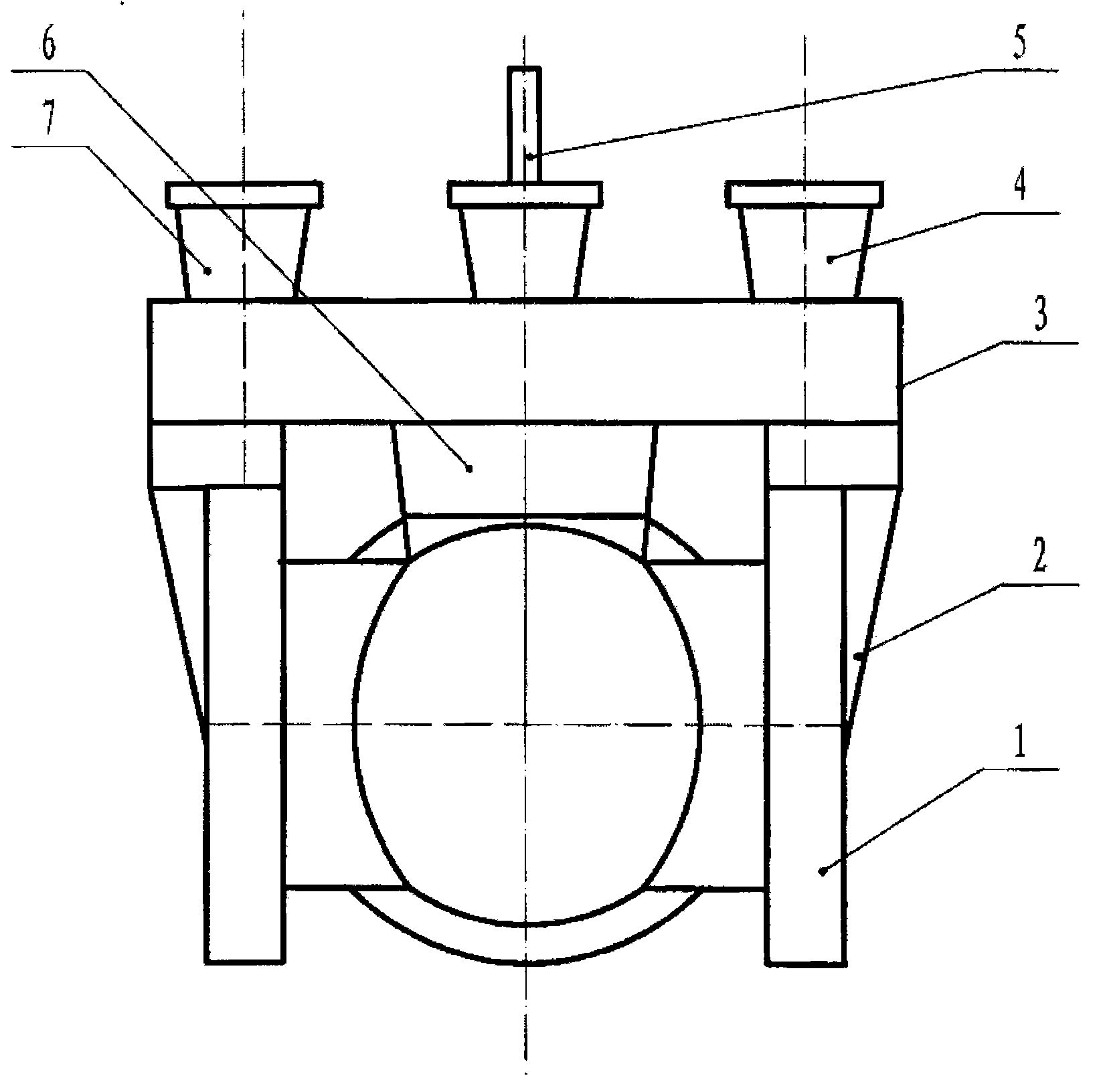

[0011] The manufacturing process of the valve body with a diameter of more than 8 inches in lost wax precision casting of the present invention is as follows:

[0012] 1. Wax pattern production: firstly make a wax pattern of the 8-inch valve body, and increase the strength of the flange side of the wax pattern of the valve body 1. The size of the reinforcing rib 2 is a wedge semicircle, the thickness of the upper opening is equal to the thickness of the flange of the valve 1, the radius of the semicircle is about 75% of the radius of the flange, and the boss of the upper opening is 100×90×100mm. Then make the feeding block 3, the feeding block 3 is 200×200×100mm, and the section of the connecting runner is 100×100mm. Make whole wax pattern again at last, go out feeding block 3, sprue cup 4, wax handle 5, vent hole 7 with integral molding, as a whole. A separate sprue is 150×120×150mm, and the whole valve body and reinforcing rib are integrally molded.

[0013] 2. Coating she...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com