Hand-shaping blank hollow-jun-porcelain grouting manufacturing method and mold used for grouting manufacturing

A production method and hollow technology, applied in the direction of die-casting molds, manufacturing tools, ceramic molding machines, etc., can solve the problems that the overall effect is not as popular as Jun porcelain and the collection value, etc., to shorten the production time, reduce the work intensity and process, The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A realization method of the grouting manufacturing method of a hand-drawn hollow Jun porcelain provided by the present invention includes the following steps:

[0040] 1) Hand-drawing blanks to make hollow Jun porcelain blanks;

[0041] The first is to make a hand-drawn blank that meets the requirements. After the blank is dried to a certain extent, it is then trimmed on the wheel to make it meet the requirements of the fine blank. The standard for the trimmed blank is: accurate shape, smooth lines , smooth surface, moderate thickness. After some blanks are trimmed, it is necessary to carry out the operation of bonding decorative parts, such as bonding spouts and handles of pots, bonding earrings of bottles, pasting flowers, etc., to complete the shape, and then cut the shaped Jun porcelain;

[0042] 2) longitudinally cutting the hollow Jun porcelain body into two sub-bodies;

[0043] In this process, a thin and fast knife is needed to cut the well-shaped hollow Jun p...

Embodiment 2

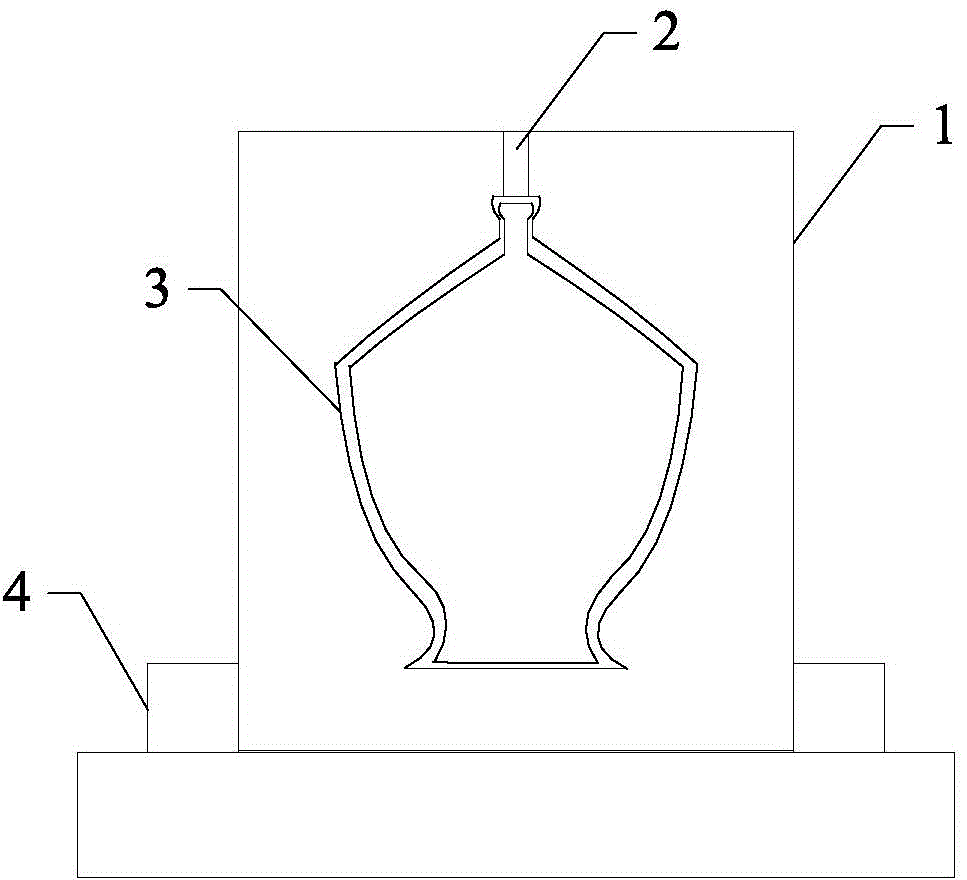

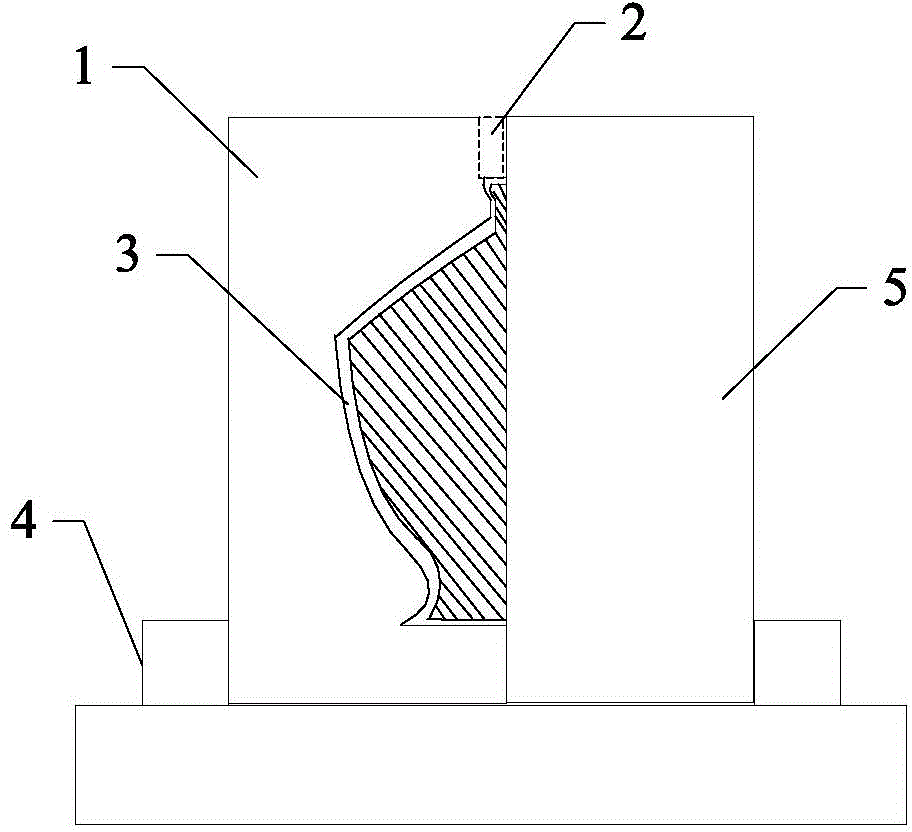

[0060] Such as figure 1 As shown, an implementation of a mold for the grouting manufacturing method provided by the present invention includes:

[0061] The first mold and the second mold are respectively independent grouting molds, which are respectively used for grouting to make the left half or the right half 3 of the hand-drawn hollow Jun porcelain, the first mold or the second mold includes A first sub-mold 1, a second sub-mold 5 and a grouting port 2.

[0062] Preferably, it also includes:

[0063] The upper end of the base 4 is provided with an open slot, and the opening size of the open slot is adapted to the size of the bottom of the first mold or the second mold.

[0064] The grouting manufacturing method provided by the present invention has a simple structure, which can not only realize the mass production of Jun porcelain in the shape of hand-drawn blanks, but also effectively control the thickness and materials of Jun porcelain, saving production costs; and It...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com