Device for preventing repeated machining and omitted machining of crank case of engine

A technology for repeated processing and crankcases, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve problems such as missing processing, confusing crankcase processing status, and repeated processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

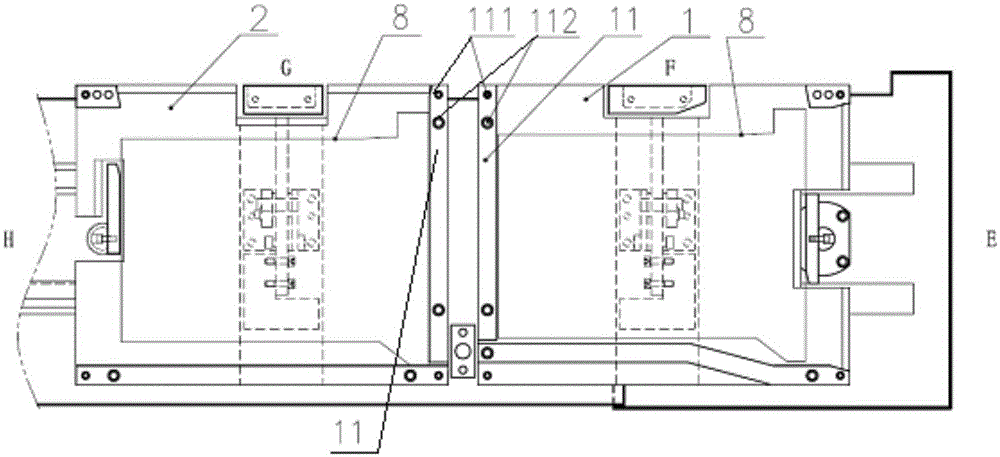

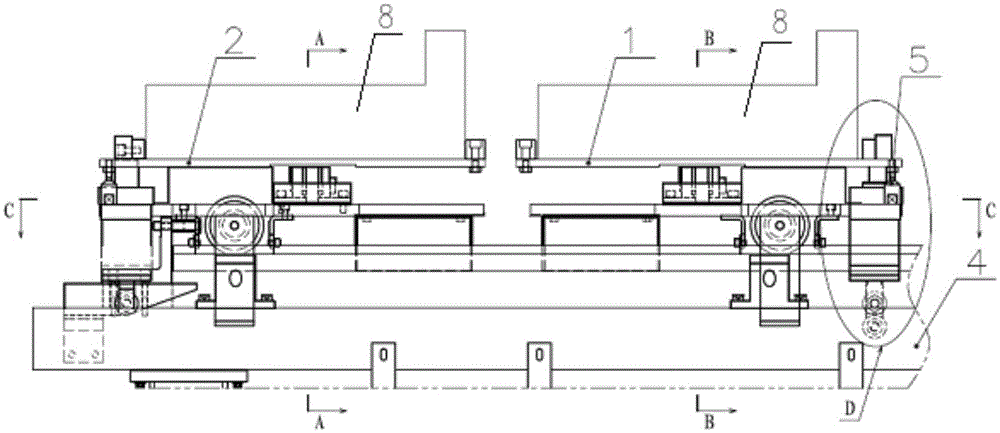

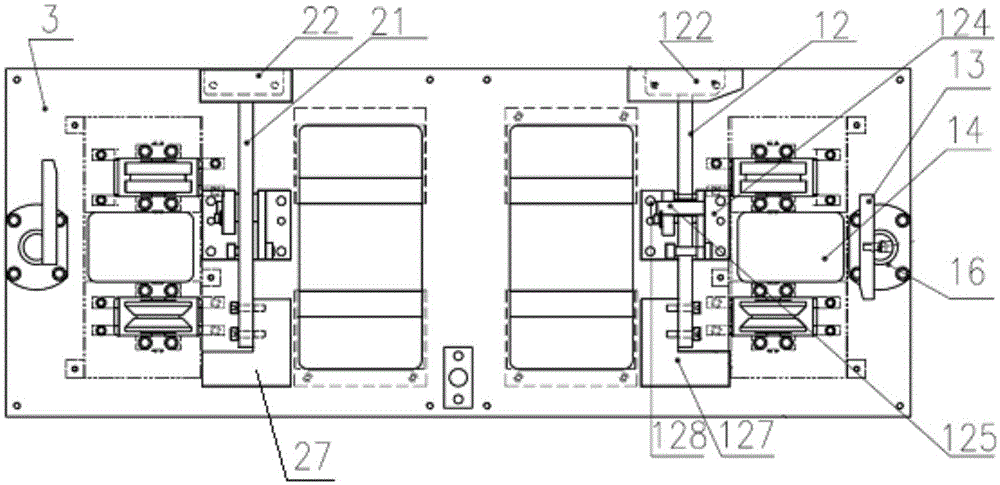

[0021] A device for preventing repeated processing and missing processing of the engine crankcase. The track 4 is located on the left side of the processing equipment. There is a bottom plate 3 on the track 4. The bottom plate 3 slides on the track 4 through the pulley at the bottom, and the bottom plate 3 is fixed by bolts. There are support block 14, support cover 125 and support seat 124, support block 14, support cover 125 and support seat 124 form a support platform and support a loading plate 1 and a blanking plate 2, and the loading plate 1 is positioned at the rear portion of the base plate 3 and The rear end faces the feeding end of the assembly line, the blanking plate 2 is located at the front of the bottom plate 3 and the front end faces the feeding end of the assembly line, the loading plate 1 and the blanking plate 2 are fixed with the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com